Overview of Sheet Metal Services.

Sheet metal services have been an integral part of manufacturing and construction for centuries. The ability to shape, mold, and create structures using metal sheets has led to innovations in various industries. With the advent of CNC technology, the precision and capabilities of sheet metal fabrication have reached new heights.

The importance of precision in sheet metal fabrication cannot be overstated. Whether it’s for aerospace components, automotive parts, or architectural structures, the accuracy of cuts, bends, and shapes determines the functionality and safety of the final product. Inaccuracies can lead to product failures, increased costs, and potential safety hazards.

The evolution of sheet metal services with CNC technology has transformed the industry. Computer Numerical Control (CNC) allows for computerized instructions to guide machinery in precise movements. This ensures that every cut, bend, and shape is exact to the specified dimensions. The result is a product that meets the highest standards of quality and precision.

Wuxi Lead Precision Machinery, with its state-of-the-art machinery and expert teams, stands at the forefront of this evolution. Offering top-notch custom metal fabrication services, they cater to clients of all sizes, ensuring a smooth process from design to delivery. Whether it’s a short run or a large contract, Wuxi Lead’s commitment to excellence is evident in every product they deliver.

In the next section, we’ll explore why Wuxi Lead Precision Machinery is the preferred choice for custom sheet metal fabrication and delve deeper into their offerings and capabilities.

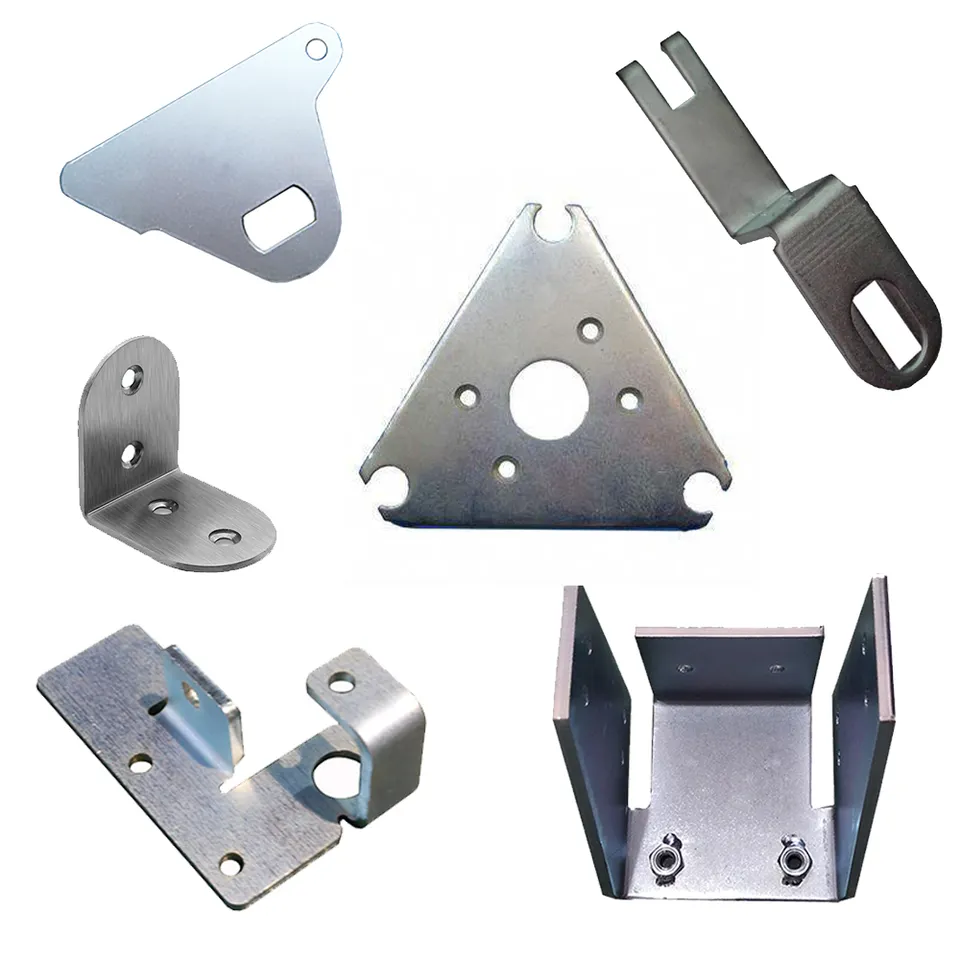

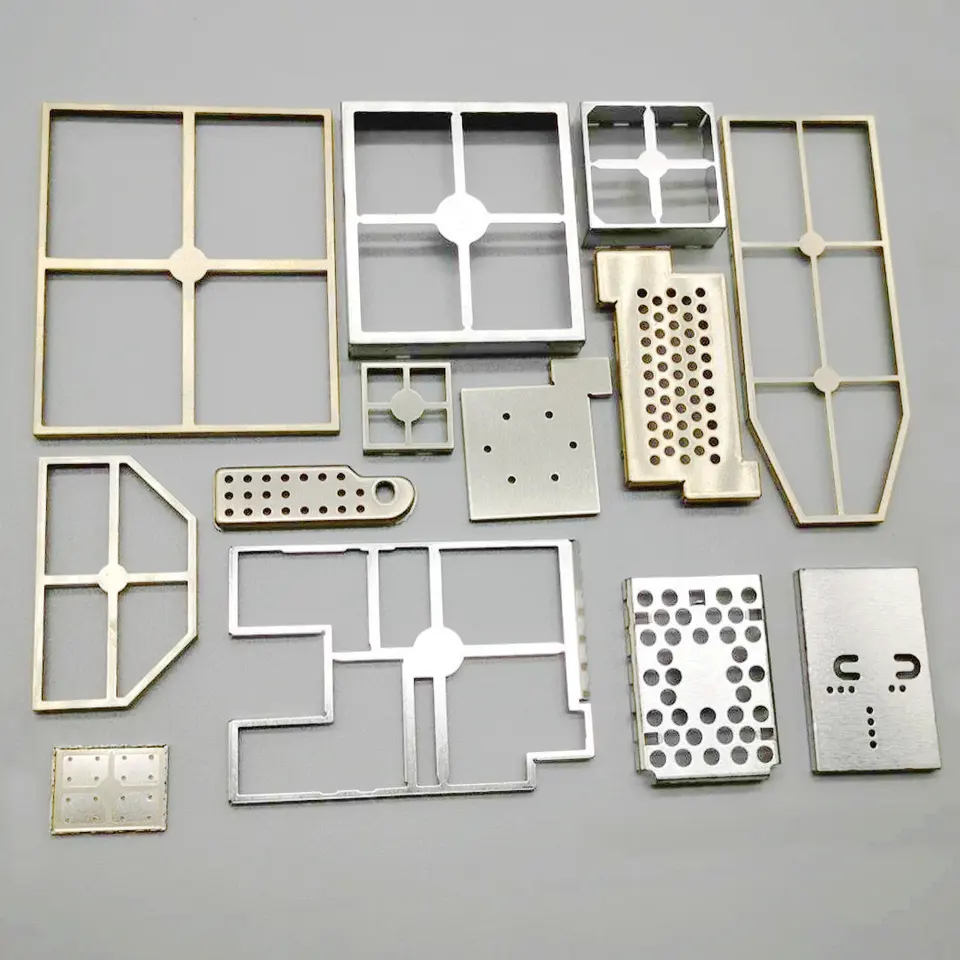

Types and Applications of Custom Steel Sheet Services

Sheet metal fabrication is a versatile process, catering to various industries. Let’s delve into the different types of custom steel sheet services and our applications:

- CNC Machining in Sheet Metal: CNC technology has revolutionized sheet metal fabrication. With computerized control guiding the machinery, every cut and bend is precise, ensuring products that are consistent in quality and design. This precision is especially crucial in industries like aerospace and automotive, where even the slightest deviation can have significant repercussions.

- Applications Across Industries: The versatility of sheet metal fabrication means it finds applications in a myriad of industries. Aerospace components, automotive parts, construction materials, and even intricate designs for art installations – the possibilities are endless. Wuxi Lead, with its expertise and advanced machinery, caters to all these industries and more, ensuring products that are not just functional but also aesthetically pleasing.

The Production Process at Wuxi Lead Precision Machinery

1. Design & Prototyping: Before diving into full-scale production, the design team at Wuxi Lead collaborates with clients to understand their requirements. Using advanced CAD software, they draft detailed designs, ensuring that every aspect aligns with the client’s vision. Once the design is finalized, a prototype is created, offering a tangible representation of the final product.

2. Material Selection: The choice of material plays a pivotal role in determining the product’s durability, finish, and overall performance. Wuxi Lead sources high-quality steel sheets, ensuring they meet the industry’s stringent standards. Depending on the product’s application, the team selects the most suitable material, be it stainless steel, aluminum, or any other metal alloy.

3. Cutting & Forming: With the design and material in place, the production process kicks off. Advanced CNC machines, guided by the design’s digital blueprint, cut the metal sheet with pinpoint accuracy. Following this, the sheet undergoes various forming processes, such as bending, punching, and stamping, transforming it into the desired shape.

4. Welding & Assembly: For products that comprise multiple components, welding is an essential step. Wuxi Lead’s skilled welders ensure that every joint is robust, guaranteeing the product’s longevity. Once all components are ready, they’re assembled, bringing the product to life.

5. Finishing Touches: A product isn’t complete without the finishing touches. Depending on the client’s requirements, the product might undergo painting, powder coating, or any other finishing process, enhancing its aesthetics and adding an extra layer of protection.

6. Quality Control & Dispatch: Before the product is dispatched, it undergoes a thorough quality check. Wuxi Lead’s QC team inspects every nook and cranny, ensuring it aligns with the company’s high standards. Once it gets the green light, the product is packed with care and dispatched, ready to serve its purpose.

Questions International Buyers Should Ask Their Chinese Suppliers

- Certifications & Compliance: Does the supplier have the necessary certifications, ensuring their products meet international standards?

- Lead Time: How long does it take for the order to be ready for dispatch?

- Customization Capabilities: Can the supplier accommodate specific design requirements?

- Volume Discounts: Are there any discounts available for bulk orders?

- Shipping & Logistics: Does the supplier offer assistance with shipping and logistics?

- After-Sales Support: In case of any issues, what kind of after-sales support does the supplier offer?

- Material Source: Where does the supplier source their materials from?

- Previous Collaborations: Can the supplier provide references or case studies of previous collaborations?

- Payment Terms: What are the payment terms, and are they negotiable?

- Sample Policy: Does the supplier offer samples before diving into full-scale production?

FAQ Tips

- What materials does Wuxi Lead work with?

- Wuxi Lead works with a variety of metals, including stainless steel, aluminum, brass, and more.

- Can I get a prototype before placing a bulk order?

- Yes, Wuxi Lead offers prototyping services, allowing clients to assess the product before committing to a large order.

- How does Wuxi Lead ensure the quality of its products?

- Quality is paramount at Wuxi Lead. Every product undergoes rigorous inspections, ensuring it meets the highest standards.

- Do you offer design services?

- Yes, Wuxi Lead has a dedicated design team that collaborates with clients, bringing their vision to life.

- What’s the minimum order quantity (MOQ)?

- The MOQ varies depending on the product. Please get in touch with our sales team for more information.

Global Reach of Wuxi Lead Precision Machinery

1. International Collaborations: Wuxi Lead Precision Machinery isn’t just a renowned name in China; its reputation transcends borders. The company has established collaborations with businesses across North America, Europe, and Asia-Pacific. These partnerships are a testament to Wuxi Lead’s commitment to quality and its capability to cater to diverse market needs.

2. Export Excellence: A significant portion of Wuxi Lead’s production caters to international clients. The company’s export portfolio is diverse, ranging from automotive components for German car manufacturers to aerospace parts for American defense contractors. Each product, irrespective of its destination, adheres to international quality standards.

3. Participations in Global Trade Fairs: To showcase its prowess and innovations, Wuxi Lead regularly participates in global trade fairs and exhibitions. These events offer a platform to interact with potential clients, understand market trends, and stay ahead of the competition.

4. Client Testimonials: The satisfaction of clients is the best indicator of a company’s competence. Wuxi Lead boasts a plethora of positive testimonials from international clients, lauding the company’s professionalism, product quality, and commitment to deadlines.

5. Custom Solutions for Global Markets: Understanding that every market has its unique requirements, Wuxi Lead offers custom solutions tailored to regional needs. Be it specific design alterations or adherence to regional standards, Wuxi Lead ensures its products seamlessly fit into any market.

Sustainability and Environmental Responsibility

In today’s age, businesses bear the responsibility of environmental stewardship. Wuxi Lead Precision Machinery is at the forefront of sustainable manufacturing.

1. Eco-friendly Processes: Wuxi Lead employs processes that minimize waste and reduce carbon emissions. From recycling metal scraps to using energy-efficient machinery, every step is taken with environmental conservation in mind.

2. Renewable Energy: A significant portion of the energy requirements at the Wuxi Lead facility is met through renewable sources. Solar panels and wind turbines dot the facility, reducing reliance on non-renewable energy.

3. Green Packaging: Wuxi Lead uses sustainable materials for packaging, ensuring minimal environmental impact. The packaging is not only eco-friendly but also robust, ensuring products reach clients in pristine condition.

4. Employee Training: Employees at Wuxi Lead undergo regular training on sustainable practices. This ensures that every individual, from the shop floor worker to the top executive, is aligned with the company’s environmental goals.

Conclusion

Wuxi Lead Precision Machinery stands as a beacon of excellence in the realm of CNC sheet metal services. With a commitment to quality, innovation, and sustainability, the company is not just meeting market demands but setting industry standards. Whether you’re a business seeking a reliable partner or an individual curious about CNC processes, Wuxi Lead is the name to trust.

In the next segment, we’ll delve deeper into the intricacies of sheet metal fabrication, offering insights into the technological marvels that power this industry.

Technological Marvels in Sheet Metal Fabrication

1. Advanced Laser Cutting Technology: Laser cutting is a revolutionary technique in sheet metal fabrication. Wuxi Lead employs the latest laser cutting machines, ensuring precision cuts with minimal wastage. The technology allows for intricate designs, tight tolerances, and high repeatability, making it ideal for complex projects.

2. 3D CAD Modeling: Before any fabrication begins, Wuxi Lead’s design team uses advanced 3D CAD (Computer-Aided Design) software to create detailed models of the products. This not only helps in visualizing the final product but also identifies potential issues, ensuring a smooth fabrication process.

3. Robotic Automation: To enhance efficiency and precision, Wuxi Lead has integrated robotic automation into its production line. These robots handle repetitive tasks, ensuring consistent quality and faster production times.

4. Turret Punching Systems: For projects that require multiple holes or specific patterns, turret punching systems are invaluable. These machines can punch a variety of shapes and sizes with impeccable accuracy, making them a staple in Wuxi Lead’s facility.

5. Precision Press Brakes: Bending sheet metal to exact specifications requires advanced machinery. Wuxi Lead’s precision press brakes ensure that every bend, irrespective of its angle or radius, is perfect.

6. Welding Innovations: Welding is a critical aspect of sheet metal fabrication. Wuxi Lead employs both traditional welding techniques and the latest innovations, like spot welding and TIG (Tungsten Inert Gas) welding, to ensure strong and durable joints.

Quality Control and Assurance

Ensuring that every product meets the highest quality standards is a priority for Wuxi Lead.

1. In-house Testing Labs: Every batch of products undergoes rigorous testing in Wuxi Lead’s in-house labs. From tensile strength tests to corrosion resistance evaluations, each product is scrutinized to ensure it meets the set standards.

2. Advanced Inspection Equipment: To guarantee precision, Wuxi Lead uses advanced inspection equipment like CMM (Coordinate Measuring Machines) and digital calipers. These tools ensure that every dimension is accurate to the micron.

3. Continuous Improvement: Quality control isn’t just about identifying and rectifying issues. At Wuxi Lead, it’s also about continuous improvement. Feedback from quality checks is integrated into the production process, ensuring that the same issue doesn’t recur.

4. Client Feedback: Wuxi Lead values feedback from its clients. Every product delivery is followed by a feedback session, ensuring that client expectations are not just met, but exceeded.

Conclusion

Sheet metal fabrication is an art and a science, and Wuxi Lead Precision Machinery has mastered both. With a blend of advanced technology, skilled craftsmanship, and an unwavering commitment to quality, Wuxi Lead stands as a testament to what’s possible in the realm of CNC sheet metal services. Whether you’re in the automotive sector, aerospace, or any industry in between, Wuxi Lead is the partner you can trust for all your sheet metal needs.