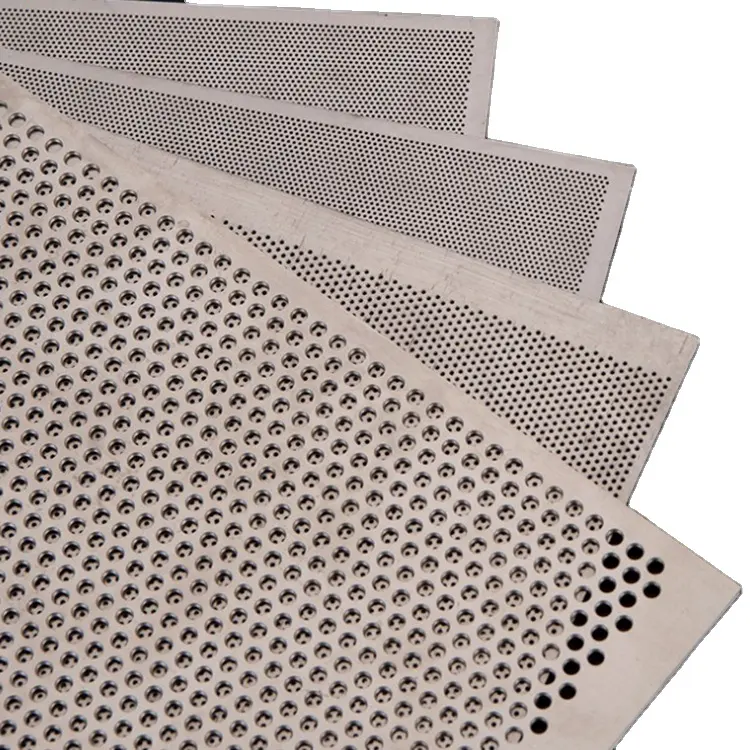

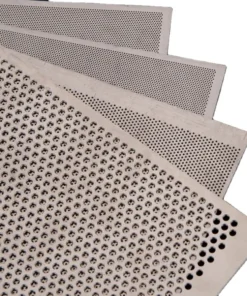

What is a Perforated Metal Sheet?

A perforated metal sheet, commonly referred to as a perforated sheet, is a sheet of metal that has been manually or mechanically stamped or punched to create patterns of holes, slots, or decorative shapes. These sheets are used in various applications, from architectural designs to industrial machinery, offering both aesthetic and functional benefits.

Importance of Quality in Perforated Metal Sheets

The quality of a perforated metal sheet is paramount, especially when used in critical applications. A high-quality sheet ensures durability, longevity, and the desired performance in its application. At Wuxi Lead Precision Machinery, we prioritize quality, ensuring that every sheet we produce meets the highest standards. Our robust QC team conducts thorough inspections to guarantee 100% quality before shipping, making us a trusted partner for top-notch custom metal fabrication services.

The Art of Decorative Perforated Sheet Metal

Aesthetic Appeal and Functional Benefits

Decorative perforated sheet metal is not just about aesthetics; it’s a blend of beauty and functionality. These sheets are often used in architectural applications, such as facades, screens, and partitions, adding a touch of elegance while providing ventilation, light diffusion, and privacy. The unique patterns can transform a simple space into a design masterpiece.

Custom Designs by Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we understand the importance of customization. Our advanced machinery and skilled workforce allow us to produce perforated sheets tailored to your design specifications, ensuring that the final product aligns perfectly with your vision.

Types and Applications of Perforated Sheets

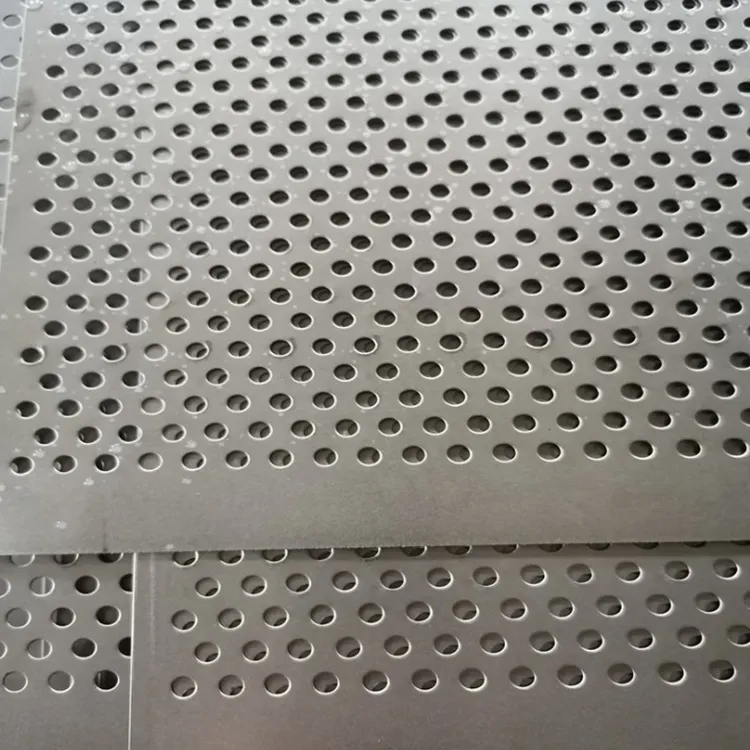

Stainless Steel Perforated Sheets: Strength and Durability

Stainless steel, known for its corrosion resistance and strength, is a popular choice for perforated sheets. These sheets are ideal for outdoor applications or environments where durability is crucial. Common uses include filtration systems, architectural panels, and protective guards.

Aluminum and Brass Perforated Sheets: Lightweight and Versatile

Both aluminum and brass offer a combination of lightness and malleability, making them suitable for decorative purposes. Their resistance to corrosion and aesthetic appeal make them favorites for interior designs, screens, and decorative panels.

Key Industries and Their Uses

From the automotive to the construction industry, perforated sheets have a wide range of applications. They’re used in ventilation systems, sound barriers, filtration systems, and even in electronic devices for heat dissipation.

Production Process at Wuxi Lead Precision Machinery

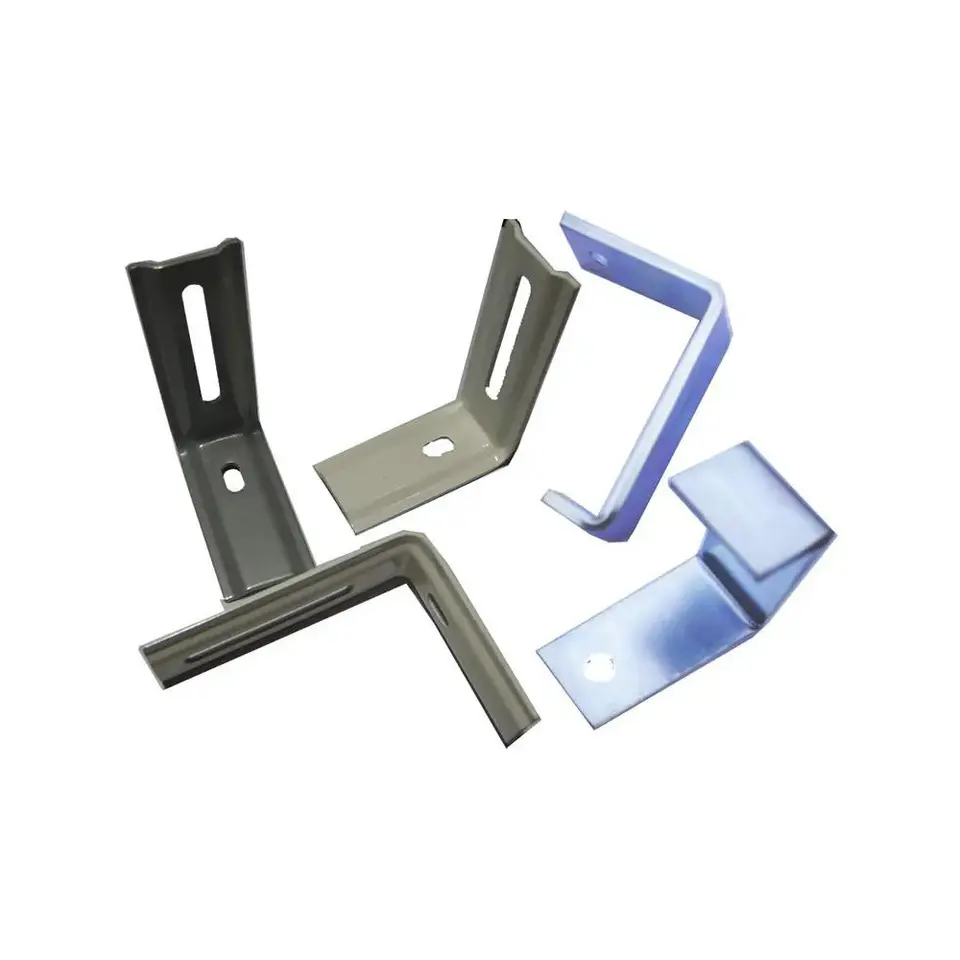

Advanced CNC Machining Techniques

Utilizing state-of-the-art CNC machines, Wuxi Lead Precision Machinery ensures precision in every perforated sheet. Our machines can handle complex patterns, ensuring consistency across large batches.

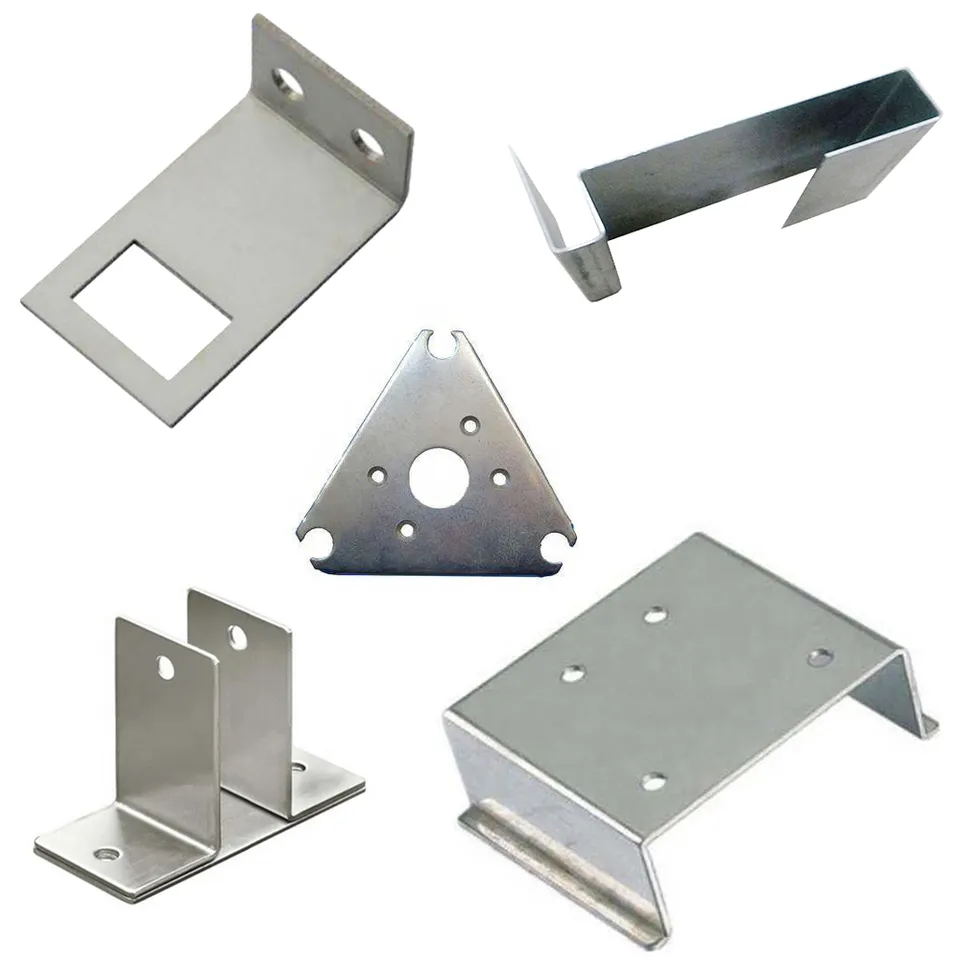

Metal Stamping and Sheet Metal Fabrication

Our expertise extends beyond CNC machining. With advanced metal stamping and sheet metal fabrication capabilities, we can produce perforated sheets with intricate designs and high repeatability.

Ensuring Precision and Quality in Every Sheet

Every sheet undergoes rigorous quality checks. Our commitment to excellence ensures that each perforated sheet meets the desired specifications and stands up to real-world applications.

Questions International Buyers Should Ask Their Chinese Suppliers

Understanding the Cost and Price Dynamics

When sourcing perforated metal sheets, it’s essential to understand the factors influencing the cost. Questions about raw material sourcing, production overheads, and any additional costs can provide clarity on the pricing structure.

Customization Options and Minimum Order Quantities

Before placing an order, it’s crucial to understand the supplier’s capabilities. Inquiring about customization options, design flexibility, and minimum order quantities can help buyers tailor their orders to their specific needs.

Shipping, Packaging, and After-Sales Support

Logistics play a vital role in international trade. Questions about shipping methods, packaging standards, and after-sales support can ensure a smooth transaction and long-term partnership.

FAQs and Tips

What are the primary applications of perforated metal sheets in architecture? In architecture, perforated metal sheets are often used for facades, sunscreens, decorative partitions, and acoustic panels. Their ability to control light and airflow while adding aesthetic appeal makes them a popular choice for modern building designs.

How does the hole pattern impact the functionality of the perforated sheet? The hole pattern, including its size, shape, and arrangement, can influence various properties of the sheet, such as airflow, light penetration, and sound absorption. For instance, larger holes allow more air and light to pass through, while smaller holes offer more privacy.

Are there specific materials recommended for outdoor applications? For outdoor applications, it’s essential to choose materials that can withstand environmental factors like rain, sun, and temperature fluctuations. Stainless steel and aluminum are commonly used due to their corrosion resistance and durability.

How do perforated metal sheets contribute to sustainable building designs? Perforated sheets can help in energy conservation by controlling sunlight, leading to reduced cooling costs. They also contribute to green building certifications by using recycled materials and aiding in passive solar heating.

Can I request custom hole patterns and designs with Wuxi Lead Precision Machinery? Absolutely! Wuxi Lead Precision Machinery specializes in custom solutions. Whether you have a unique hole pattern in mind or a specific design requirement, our team can bring your vision to life.

How do perforated sheets compare to solid sheets in terms of strength and durability? While perforations introduce voids in the material, if designed correctly, perforated sheets can retain a significant portion of their strength. The durability largely depends on the material used and the environmental conditions they’re exposed to.

What factors should I consider when choosing the thickness of the perforated metal sheet? The sheet’s thickness should be determined based on its intended application, expected load, and desired aesthetics. For structural applications, thicker sheets might be required, while decorative uses might allow for thinner sheets.

How does Wuxi Lead Precision Machinery ensure the quality of its perforated metal sheets? Quality is a cornerstone of our operations. From sourcing high-grade raw materials to employing advanced manufacturing processes and conducting rigorous quality checks, we ensure that every sheet meets international standards.

Is there a difference in the perforation process for different metals? While the basic perforation process remains consistent, different metals might require adjustments in terms of force, tooling, and lubrication due to their varying properties.

How do I handle and store perforated metal sheets to ensure their longevity? It’s essential to handle the sheets with care to avoid scratches or dents. When storing, place them in a dry environment, preferably stacked horizontally with separators to prevent scratching.

Perforated metal sheets, with their blend of functionality and aesthetics, play a pivotal role in various industries. Whether it’s for architectural designs, industrial applications, or decorative purposes, the importance of quality cannot be overstated. Wuxi Lead Precision Machinery, with its expertise and commitment to excellence, stands as a beacon for those seeking the best in perforated metal sheets. Partnering with us ensures not just a product but a promise of quality, precision, and dedication.