Custom Fabrication Metal

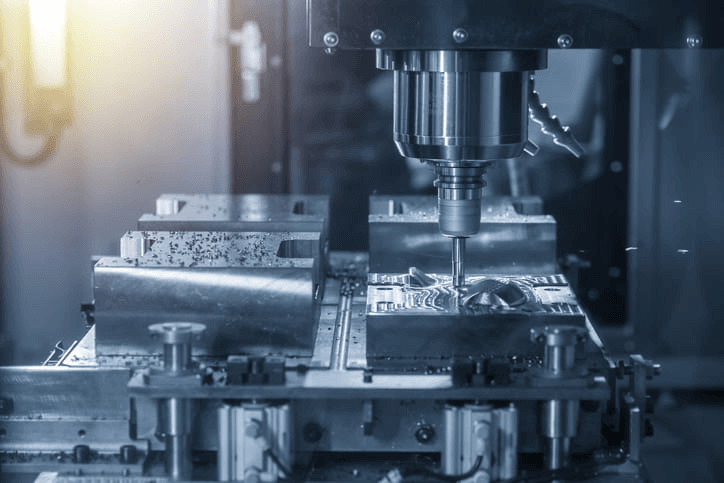

In the world of advance technologies and modern fabrication and manufacturing techniques like Additive manufacturing or 3d Printing, Subtractive Manufacturing way of fabricating industrial or commercial parts especially with metals is still a common practice. Apart from Computerized Numeric Control (CNC) Milling or CNC Turning Machines which are most common of them all we also have metal stamping, Sheet metal working and other machining facilities as well and by the use of processes like Rolling, Bending, Cutting, Surface Treatment and Joining metal we provide our customer with final fabricated metal product that is with extremely low tolerance in meeting the specification from the design and accuracy in microns so that the custom fabricated metal product serves the best use for our client.

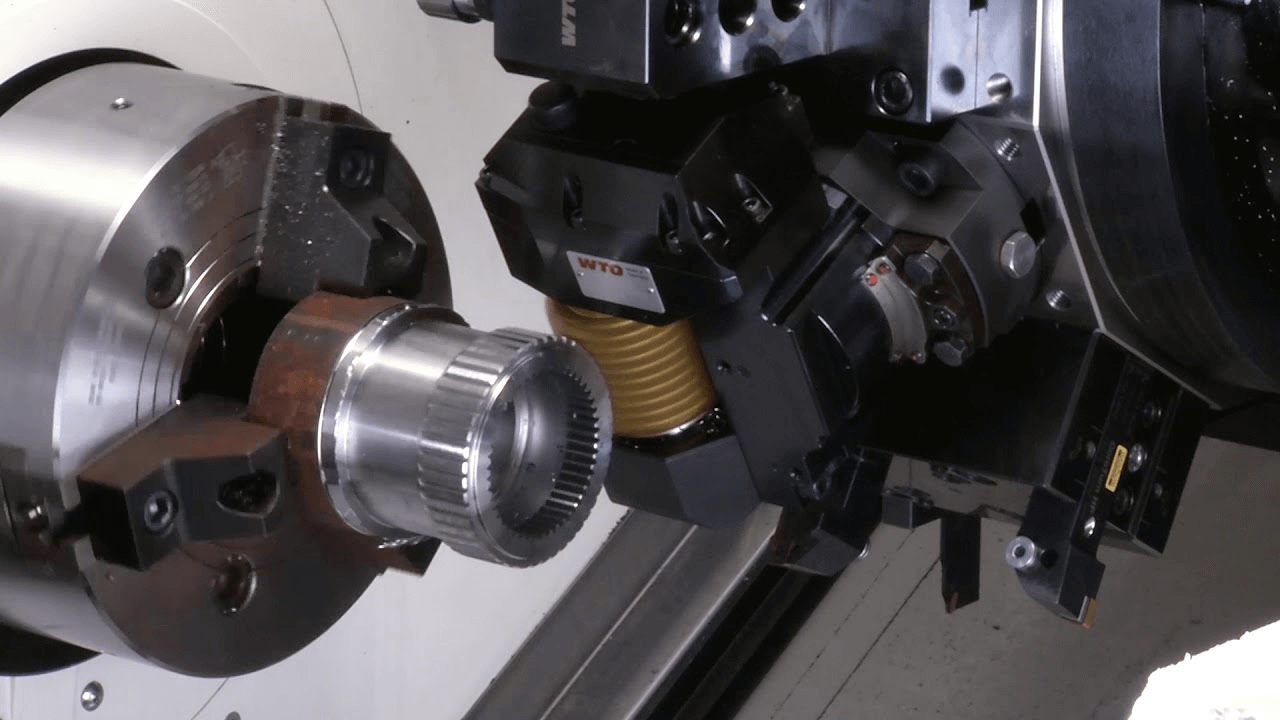

Our CNCs aren’t limited to tradition 3 axis but 4th axis allows making of complex part with ease and dismantling of the part for changing the plane isn’t required anymore as comprehensive jigging system around the 4th axis allows for the machining of multiple parts along several planes in one setting.

From tip of Pen to the nozzle of the space rocket almost every consumer good and industrial sector relies on Custom fabrication of metals using CNC Machines at some point of their production. Therefore, We “Wuxi Lead Precision Machinery” with our vast experience and wide variety of our production services targeting mainly custom Fabrication of metals offer our services at reasonable cost without compromising on quality. Target industry for our products and services mainly includes, Electronics, Medical, Optics, Automation, Military and Automotive industry.

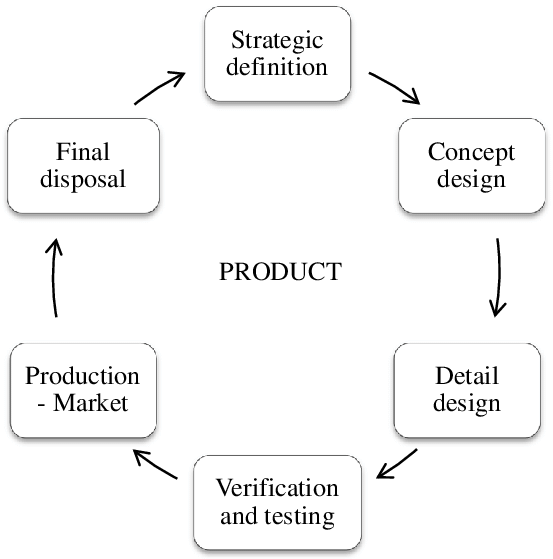

Making a Design from a scratch using Computer Aided Design (CAD) Techniques to modelling it on most advance solid modelling software’s and then using Computer Aided Manufacturing software’s to set the parameters of CNC machines and beginning the production with complete efficiency also by reducing the waste of material to avoid in contributing to the pollution.

During the Design process the choice of metal material and optimum process for Metal Fabrication is critical and depends on factors such as the intended use, environmental conditions, and budget. Therefore we expertly use common materials such as steel, aluminum, stainless steel, and more. CNC machining of Titanium which is of high strength and is corrosion resistance is the unique service that we offer with effectiveness and efficiency as produced parts are being used in sports, automotive and aerospace industry.

Wuxi Lead Precision Machinery offers her services without any delay in completion time as Diverse and State of the art CNC machines are capable of Low volume, Small batch CNC custom metal fabrication to large scale production without defected parts as our Quality Control team passes the part only with 100% compliance. Coordinate Measuring Machine Thread and Ring Gages, Vertical Measuring System Micro-Hardness Tester and Transfer Gage are some state of the art equipment that help us to maintain Zero Defect part Policy by complete check and balance of the work.

Precision and Accuracy is very important in Designing and Manufacturing as it helps the fabricated part to function as intended by its designer. Therefore Wuxi Lead Precision Machinery caters for this important notion and provides not only precision in Custom Fabrication of Metals but also accuracy.

Problem Solving

Relationship of customers with Wuxi Lead Precision Machinery is not just like supplier and buyer but like a friend who solves the problem of another friend. Therefore we help our customers with following problems faced by them while dealing with Custom Fabrication Metal Industries:

- Inflation: Managing the cost of Metal fabrication operations while maintaining quality is one of the biggest challenges faced by the customer therefore we help our client to tackle this problem by offering them affordable prices.

- Supply: Raw materials and most machines that come from overseas have encountered bottlenecks and delays so despite of the uncertainties about supply we with our reliable Raw material vendors always have full inventories so that our customers can get the fabricated metal product at any desired time.

- Skilled Staff Shortage: Due to shortage of skilled staff many customers around the world get delays in receiving their final products but that’s not the case with Wuxi Lead Precision Machinery as we have abundant skilled staff and operators.

- Delivery Time: Delivery Time at steady speed is the biggest relief for our client which is a challenge they face while dealing with the metal fabrication industry. Customers mostly are so accustomed to timely manufacturing want their parts without delay. As we meet ambitious delivery times which help us thrive.

Products & Services

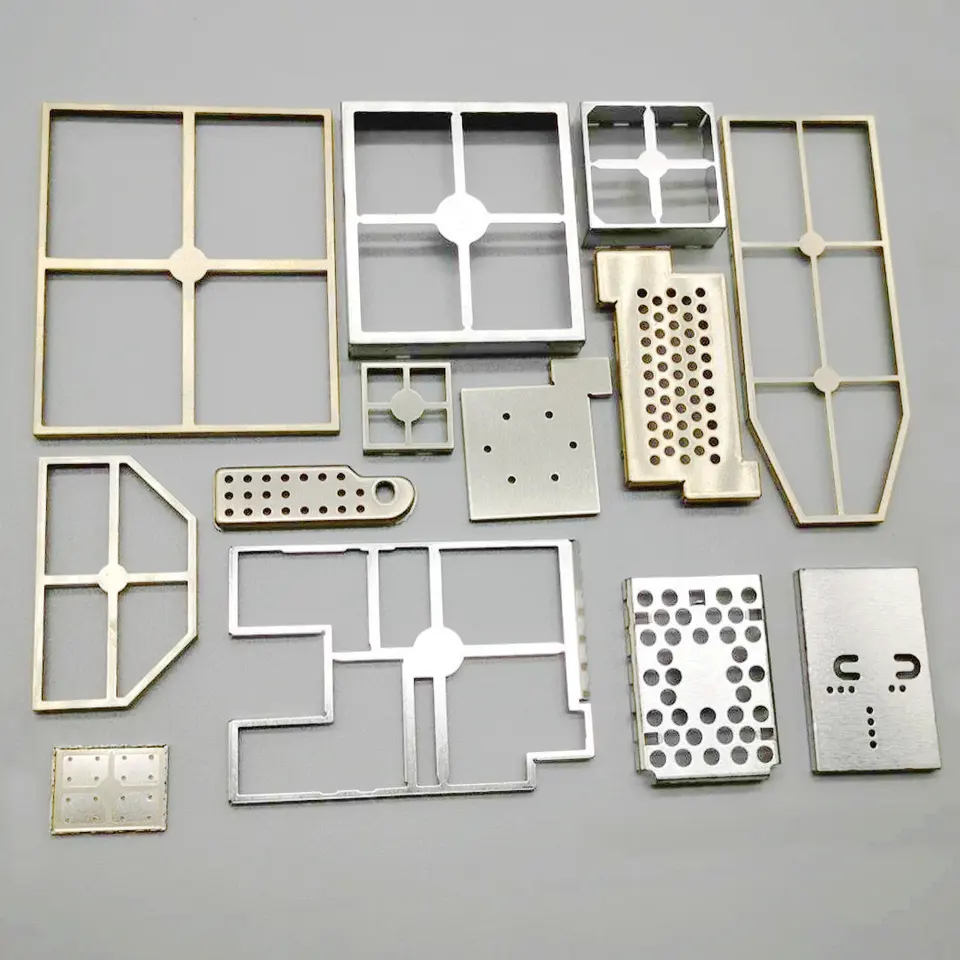

Our wide variety of products include:

- CNC bending commonly fabricated metal parts like Brackets: used in construction Industry and machinery, Enclosures, Frames and Chassis mainly used in automotive industry as a component of structural support.

- CNC Laser Engraving machine to draw pattern on acrylic plastic sheets.

- CNC Laser or Plasma cutting helps to be precise in cutting operation as compared to traditional gas cutting techniques where there is more room for error.

- CNC Drilling process is commonly used rotary equipment like spindles, Coolant systems, Tool Changers so parts made like through holes, blind and tapered holes are done.

- CNC Grinding is very common post processing work done in Custom Fabrication of metals.

- CNC Turning centers used to make metal parts like Pistons, Shafts, Axles, Bushings, Rods, etc. by using common methods like Lathe Machines.

- CNC Milling with Tolerance: +/-0.005mm is used to make mechanical wonders and is not limited to make molds and dies for further use in injection molding but also finished products like gears, etc.

- Drawing of Components by metal forming to make fuel tanks , Cooking Pots and Tin Cans, etc.

- Fabrication of Perforated metal sheets used in ventilation systems and as a component of HVAC systems and Heat Exchangers.

- Sheet Metal fabrication via Cutting & Forming, Assembly & Welding and finishing all in a single house facility of Wuxi Lead Precision Machinery provides our customers ease to get what they want under a single roof.

- CNC Punching stamping parts are metal parts that have been shaped, cut, or formed using a press machine and a stamping die Gears, Panels, Brackets are made using this technique.

- Sand Blasting, Polishing, Electro Plating and Powder coating are some finishing process available at our place that allows the final product aesthetically pleasing to the eye of the client as well as surface treatment increases the product life and avoid rust and corrosion to save not only the part but also client’s hard earned money.

- Last but not the least CNC Electric Discharge Machining EDM a non-traditional Sheet metal fabrication facility is also available at our company.

If you have any questions,please contact us via the following inquiry form.