Introduction to CNC Bending Parts

CNC bending, a pivotal process in modern manufacturing, involves the precise bending of materials, primarily metals, using computer-controlled machines. This method ensures high accuracy, repeatability, and efficiency, making it a preferred choice for industries worldwide. From intricate designs in the electronics sector to robust components in the automotive industry, CNC bending caters to a plethora of applications.

The CNC Bending Process: From Design to Production

The journey of creating a CNC bent part starts long before the actual bending occurs. It begins with a meticulously crafted design, often developed using advanced software, ensuring every bend, angle, and dimension is accounted for. Once the design is finalized, it’s fed into the CNC machine, which interprets these designs as a set of instructions. The machine then uses its tools to bend the material precisely as per the design. But the process doesn’t end here. Every bent part undergoes rigorous quality checks to ensure it meets the set standards, ensuring that what was envisioned in the design phase is accurately realized in the final product.

Materials play a crucial role in the bending process. The choice of material, be it cold-rolled steel, 304 SS, galvanneal, or aluminum, depends on the application and the desired properties of the final product. For instance, aluminum, known for its lightweight and resistance to corrosion, might be preferred for aerospace applications, while cold-rolled steel, known for its strength, might be chosen for automotive components.

Types and Applications of CNC Bending Parts

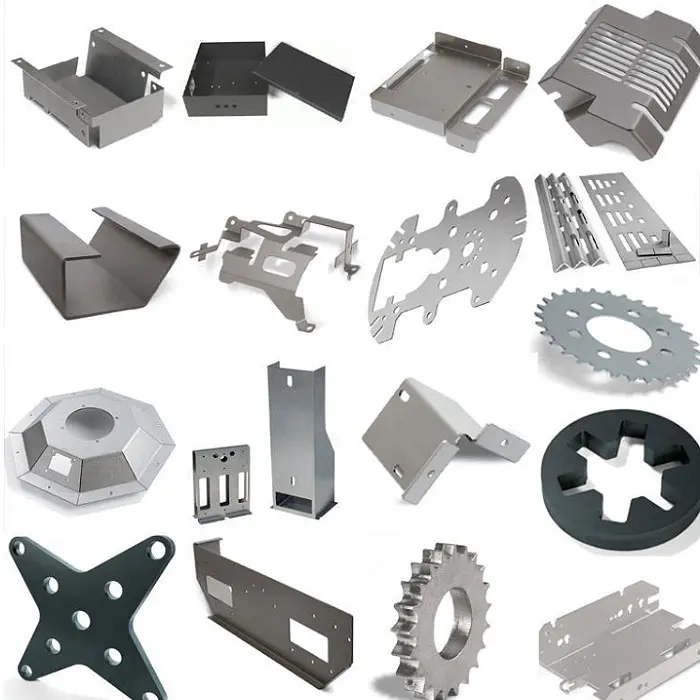

CNC bending is versatile, catering to a wide range of industries and applications. Some common parts produced using this method include:

- Brackets: These are often used in construction, machinery, and electronics to provide support or for attachment purposes.

- Enclosures: Used in electronics and machinery to protect internal components.

- Frames and Chassis: Found in automotive and machinery, these provide structural support.

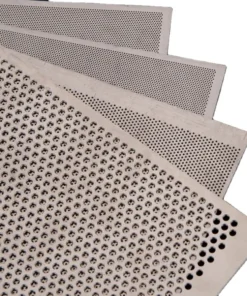

- Panels and Covers: Used in various industries to provide a protective or aesthetic outer layer.

Different sectors have unique requirements. For instance, the aerospace industry might require lightweight yet durable parts, while the automotive sector might prioritize strength and durability.

Key Considerations in CNC Bending Design

Designing for CNC bending requires a deep understanding of both the process and the material being used. Some key considerations include:

- Bend Radius: This determines how sharp or smooth a bend will be. A smaller radius results in a sharper bend, while a larger one gives a more gradual curve.

- Material Thickness: This impacts the bend radius and the overall strength of the part.

- Tooling: Different tools can produce different results, and it’s essential to choose the right one for the job.

Questions International Buyers Should Ask Their Chinese Suppliers

Engaging with suppliers, especially from a different country, requires due diligence. Here are some questions buyers should consider:

- What certifications do you hold? This gives an insight into the quality standards the supplier adheres to.

- Can you provide references or showcase previous projects? A proven track record can instill confidence.

- How do you handle custom requests? Understanding the supplier’s flexibility can be crucial for unique projects.

FAQ Tips

- 1. What are the advantages of CNC bending over traditional bending methods? CNC bending offers unparalleled precision, repeatability, and efficiency. With computer-controlled operations, the chances of human error are minimized, ensuring consistent quality across large production runs.

2. How does material selection impact the CNC bending process? Different materials have varying properties, like tensile strength and elasticity. Choosing the right material is crucial to ensure the desired bend without compromising the material’s integrity.

3. Can CNC bending handle complex designs? Absolutely! With advanced software and state-of-the-art machinery, CNC bending can handle intricate designs that might be challenging for manual processes.

4. What’s the typical lead time for CNC bending projects at Wuxi Lead Precision Machinery? Lead times can vary based on the project’s complexity and volume. However, Wuxi Lead Precision Machinery is known for its swift turnarounds, ensuring projects stay on schedule.

5. Are there any limitations to CNC bending? While CNC bending is incredibly versatile, there are limitations based on machine capabilities, tooling, and material properties. It’s always best to consult with experts, like those at Wuxi Lead Precision Machinery, to understand any project-specific constraints.

6. How does Wuxi Lead Precision Machinery ensure the quality of CNC bent parts? Quality is paramount at Wuxi Lead Precision Machinery. Every part undergoes rigorous quality checks, from the raw material stage to the final product, ensuring adherence to international standards.

7. Is there a minimum order quantity for CNC bending projects? Order requirements can vary. It’s best to reach out to Wuxi Lead Precision Machinery directly to discuss specific project needs and any minimum order considerations.

8. How does CNC bending impact the overall cost of a project? While CNC bending might have higher initial setup costs compared to manual methods, the efficiency, precision, and reduced waste often result in cost savings in large production runs.

9. Can I get a prototype or sample before committing to a large order? Yes, Wuxi Lead Precision Machinery often provides samples or prototypes to ensure client satisfaction and alignment with project specifications before mass production.

10. How do I ensure my design is optimized for CNC bending? Engaging with the design and engineering team at Wuxi Lead Precision Machinery can help optimize designs for the CNC bending process, ensuring efficiency and quality.

CNC bending has revolutionized the manufacturing sector, offering unparalleled precision and efficiency. For businesses looking to leverage this technology, partnering with experts like Wuxi Lead Precision Machinery ensures top-notch results every time.