Technical Contents

Engineering Guide: Product Prototype Maker

Engineering Insight: The Non-Negotiable Role of Precision in Product Prototyping

In high-stakes product development, the prototype is far more than a preliminary model; it is the critical validation point determining downstream success or costly failure. Precision engineering at this stage is not merely desirable—it is an absolute requirement. Minute deviations in geometry, surface finish, or material integrity during prototyping cascade into significant functional failures, assembly incompatibilities, and extended time-to-market during full production. A tolerance error of just 0.01mm in a fluid dynamics component can invalidate performance testing. An inconsistent surface finish on a medical implant prototype can mask biocompatibility issues. The financial and reputational risk of overlooking precision in prototyping is measured in millions, not thousands. This is where theoretical design meets physical reality, and only partners with demonstrable mastery of micron-level accuracy can deliver prototypes that truly de-risk your innovation path.

Wuxi Lead Precision Machinery operates at this critical intersection of ambition and execution. Our engineering philosophy treats every prototype as if it were destined for final production—because for many of our clients, it is. We leverage decades of specialized experience in sectors where failure is unacceptable: crafting components for Olympic timing systems demanding sub-micron repeatability and manufacturing mission-critical parts for defense applications requiring extreme environmental resilience. This heritage instills a rigorous, process-driven approach. We deploy advanced multi-axis CNC machining centers with integrated thermal stability compensation, utilize certified metrology labs featuring Zeiss CMMs for in-process and final verification, and enforce material traceability protocols exceeding AS9100 standards. Our engineers don’t just meet drawings; they interrogate them for manufacturability, anticipating how microscopic variances might impact your testing objectives and long-term production scalability.

The following specifications represent the baseline capability we apply to every prototype project, ensuring your design intent is physically realized with uncompromising fidelity:

| Specification Category | Capability | Typical Application Impact |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | Validated performance in精密 mechanisms (e.g., optical mounts, microfluidics) |

| Surface Roughness (Ra) | As low as 0.05 µm | Critical for sealing surfaces, biocompatibility, fatigue resistance |

| Material Range | Titanium Alloys, Inconel, 17-4PH, Aluminum 7075, Tool Steels | Prototyping in final production material for accurate validation |

| Max Work Envelope | 1200 x 800 x 650 mm | Accommodating complex assemblies without compromising precision |

| Machine Platform | 5-Axis Simultaneous Milling/Turning | Complex geometries in single setups, eliminating cumulative error |

Choosing a prototype partner demands scrutiny beyond basic cost quotes. It requires confidence that their precision capability aligns with your product’s functional and regulatory demands. At Lead Precision, our Olympic and military project legacy provides tangible proof of our ability to deliver prototypes that withstand the most stringent validation protocols. We transform your digital design into a physically perfect representation—not a close approximation—enabling accurate testing, informed iteration, and a seamless transition to volume manufacturing. Partner with an engineering team where precision isn’t a claim; it’s the measurable foundation of every component we produce. Your innovation’s integrity depends on it.

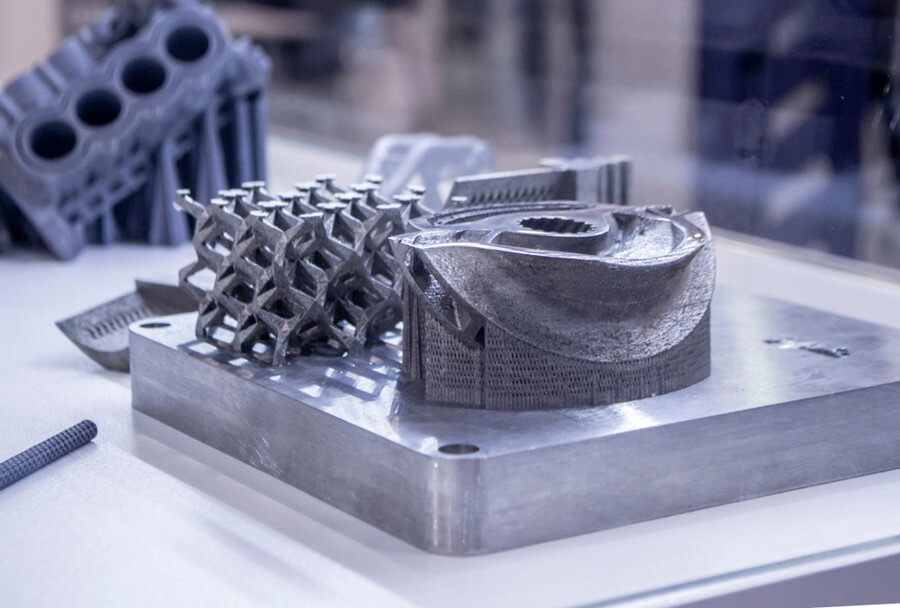

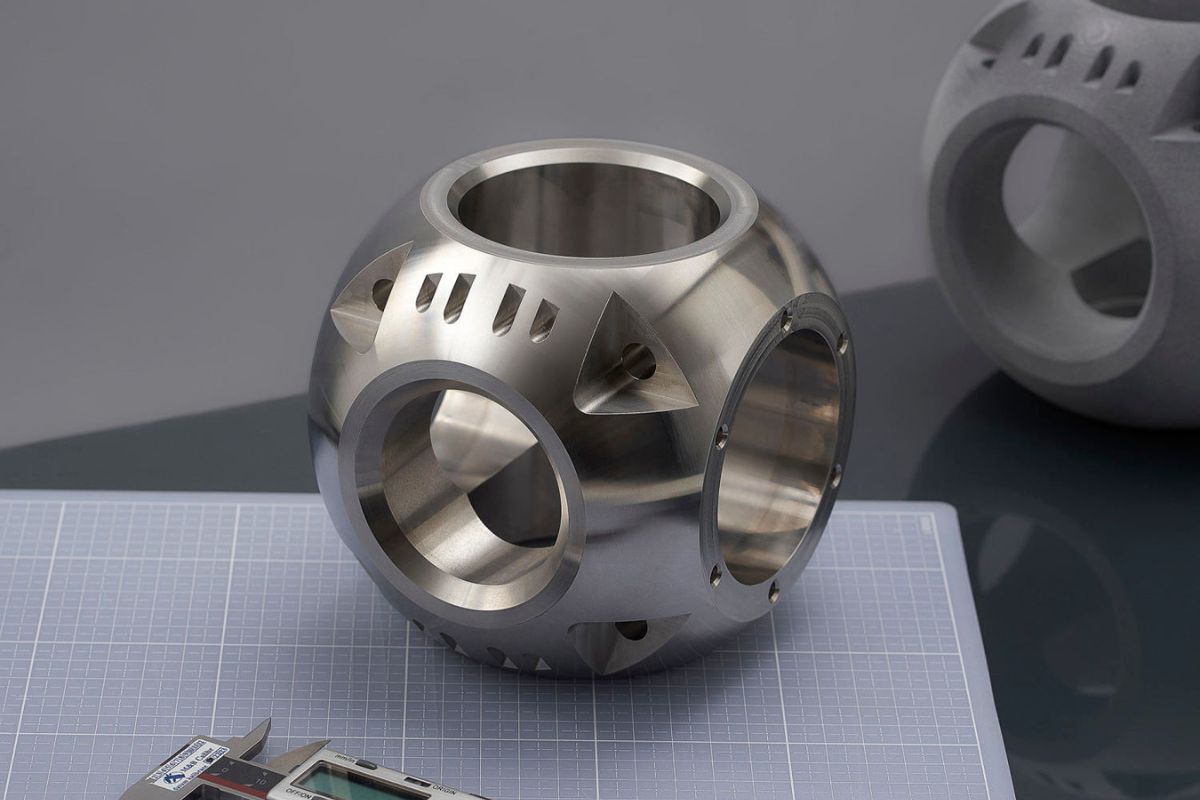

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the rigorous demands of high-performance industries such as aerospace, medical devices, automotive, and industrial automation. At the core of our production infrastructure is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to produce complex, high-precision components with exceptional repeatability and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring and feature orientation. This capability is essential for manufacturing intricate geometries that cannot be achieved with conventional 3-axis equipment, including organic forms, undercuts, and deep cavities—all within a single setup, minimizing human intervention and part handling errors.

Our machining processes support a wide range of engineering-grade metals, including aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium (Grade 5), brass, and specialty materials such as Inconel and tool steels. We apply optimized cutting strategies, high-speed machining techniques, and adaptive toolpathing to maximize material removal rates while preserving dimensional accuracy and tool life. Each program is verified using advanced simulation software to prevent collisions and ensure process reliability before any metal is cut.

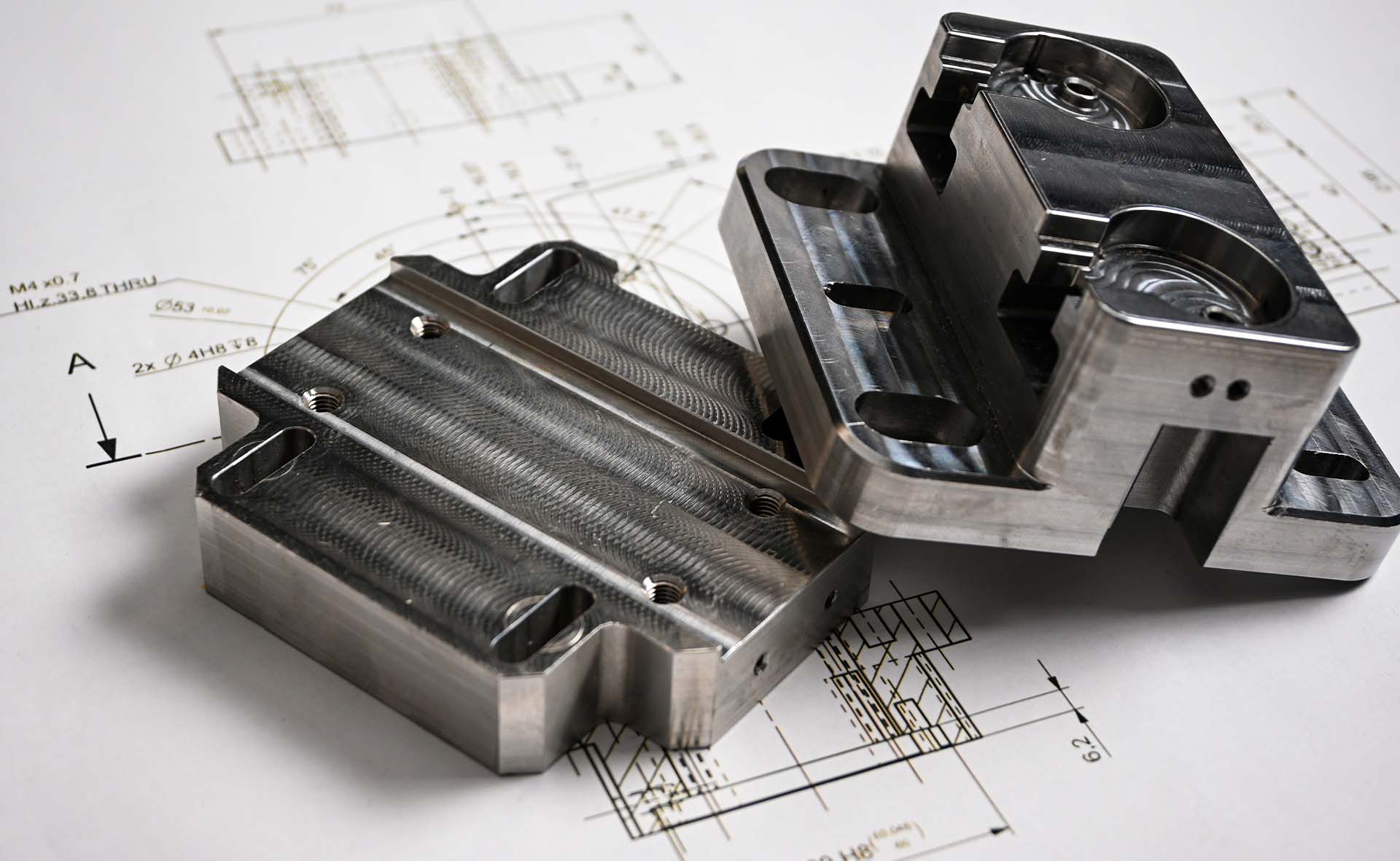

To maintain the highest standard of quality, Wuxi Lead implements a comprehensive quality control system anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems perform full geometric dimensioning and tolerance (GD&T) analysis, ensuring that every prototype meets the exact specifications defined in the engineering drawings. All inspections are documented with detailed first-article inspection (FAI) reports, including measurement traceability and compliance certifications upon request. This metrology-backed validation process is critical for clients requiring design verification, regulatory compliance, or production ramp-up validation.

Our technical team combines decades of machining expertise with engineering insight to support clients from design for manufacturability (DFM) through final inspection. We specialize in low-to-medium volume prototype and bridge production runs, ensuring rapid turnaround without compromising precision. With in-house tooling, fixturing, and CAM programming, Wuxi Lead maintains full control over the manufacturing workflow, enabling fast iterations and responsive adjustments.

The following table outlines the standard technical specifications and achievable tolerances across our 5-axis CNC operations:

| Feature | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Geometric Tolerance (Flatness, Perpendicularity, etc.) | ±0.01 mm (per GD&T) |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finish), typical 1.6–3.2 µm |

| Maximum Work Envelope | 1200 × 800 × 600 mm (X-Y-Z) |

| Minimum Feature Size | 0.5 mm (drilled holes, slots) |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Brass, Inconel, Tool Steel |

| Inspection Method | CMM, Optical Comparator, Calipers, Micrometers |

Wuxi Lead Precision Machinery is committed to precision, consistency, and technical excellence in every prototype produced. Our capabilities are designed to bridge the gap between concept and production, ensuring clients receive functional, high-fidelity parts that accelerate development timelines and reduce time-to-market.

Material & Finish Options

Material Selection for Precision Metal Prototyping

Material choice fundamentally impacts prototype performance, manufacturability, and cost. At Wuxi Lead Precision Machinery, our CNC workshops consistently achieve tight tolerances across aluminum, steel, and titanium alloys. Selecting the optimal base material requires balancing mechanical properties, environmental exposure, and finishing requirements. This guide outlines critical considerations for high-integrity prototypes.

Aluminum alloys dominate rapid prototyping due to their favorable strength-to-weight ratio and machinability. 6061-T6 offers excellent weldability and moderate strength for structural components, while 7075-T6 delivers superior hardness for aerospace or high-stress applications. Both grades accept anodizing readily, enhancing surface durability without dimensional compromise. Aluminum’s thermal conductivity also benefits heat-sensitive prototypes.

Carbon and stainless steels provide unmatched rigidity for load-bearing prototypes. 304 stainless steel excels in corrosive environments like medical or marine applications, whereas 4140 alloy steel delivers exceptional wear resistance for tooling or mechanical parts. Steel prototypes often require post-machining heat treatment to achieve target hardness. Machinability varies significantly—free-machining grades like 12L14 improve CNC throughput but may sacrifice corrosion resistance.

Titanium Ti-6Al-4V is reserved for extreme-performance prototypes demanding aerospace-grade strength at half steel’s weight. Its exceptional fatigue resistance and biocompatibility justify higher costs for medical implants or critical flight components. Titanium’s low thermal conductivity necessitates specialized CNC parameters to prevent work hardening, a capability our 5-axis mills excel at managing.

Anodizing remains the premier finish for aluminum prototypes, creating a wear-resistant ceramic layer integrated with the substrate. Type II (sulfuric acid) anodizing provides standard corrosion protection and dye acceptance for visual prototypes. Type III (hardcoat) anodizing achieves 50-70 μm thickness with Rockwell C60+ hardness for functional testing in abrasive conditions. All anodizing processes at Wuxi Lead undergo salt spray testing per ASTM B117 to validate performance.

Key material properties for prototyping are summarized below:

| Material | Key Grades | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Best Prototype Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310, 570 | Moderate to High | Excellent | Enclosures, brackets, heat sinks |

| Stainless Steel | 304, 17-4PH | 505, 1000 | Very High | Fair to Good | Medical devices, marine fixtures |

| Titanium | Ti-6Al-4V | 900 | Exceptional | Poor | Aerospace components, implants |

Material selection directly influences CNC programming strategy, tooling choices, and lead time. Wuxi Lead’s engineering team collaborates with clients during the design phase to recommend optimal alloys and finishes based on functional requirements and volume intent. We validate material certifications to ISO 9001 standards and provide mechanical test reports upon request. For prototypes demanding extreme precision, consult our specialists to align material properties with your performance targets—ensuring your design transitions seamlessly from concept to production.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal manufacturing solutions tailored to the exacting demands of global industries. Our end-to-end production process is engineered for performance, consistency, and zero-defect outcomes, ensuring your product transitions seamlessly from concept to commercialization.

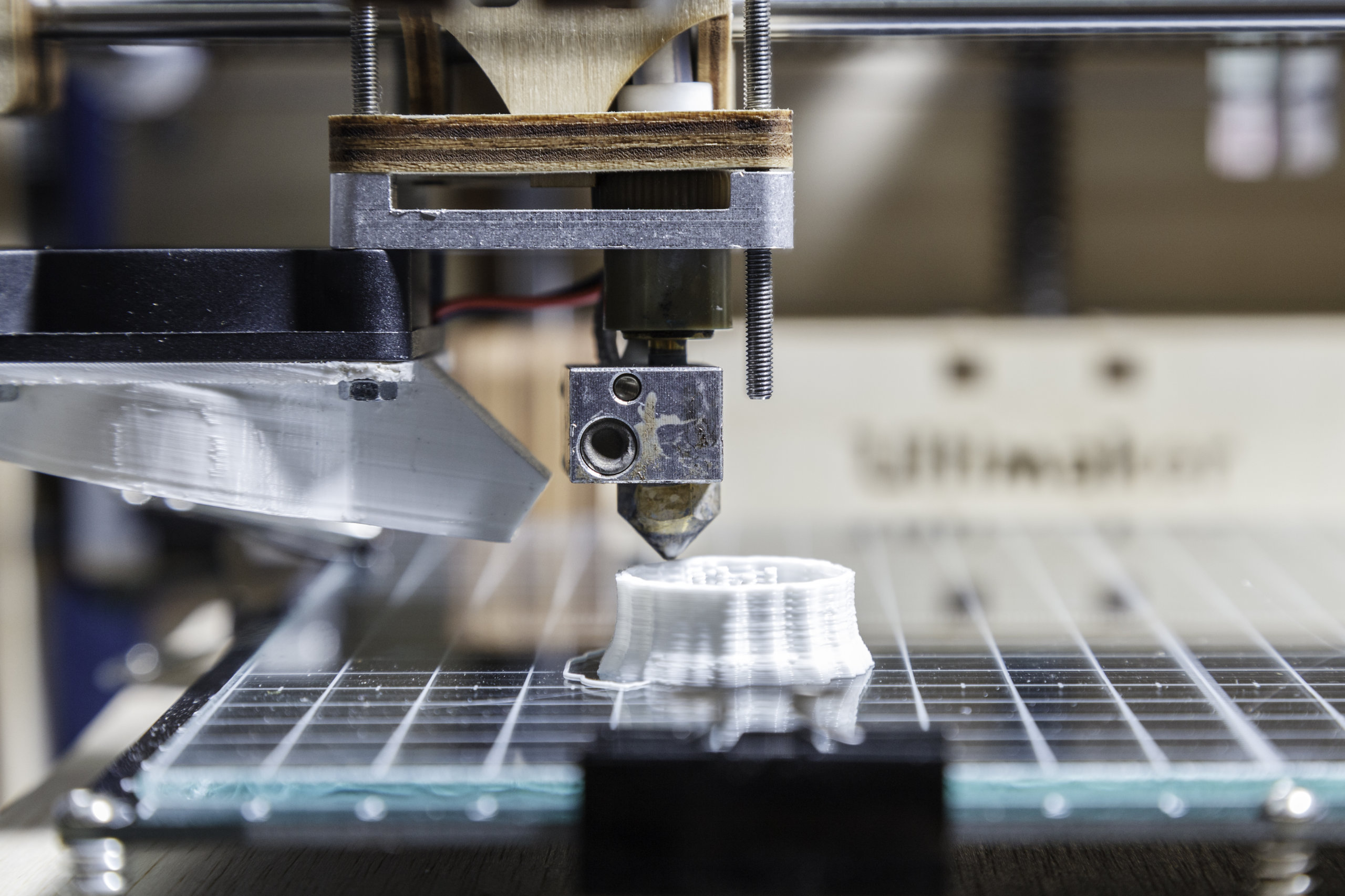

The journey begins with Design Engineering, where our team collaborates closely with clients to translate ideas into manufacturable designs. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry, material selection, and tolerances early in the cycle. This phase includes Design for Manufacturability (DFM) reviews, which identify potential production challenges before any metal is cut, reducing risk and accelerating time-to-market.

Once the design is finalized, we move into the Prototyping phase. Precision is non-negotiable. Using CNC milling, turning, and multi-axis machining centers, we produce functional prototypes that mirror final production quality. These prototypes undergo rigorous in-house testing, including dimensional inspection via coordinate measuring machines (CMM), material verification, and fit/function validation. This iterative process allows for rapid design refinement and client approval under real-world conditions. Our prototyping turnaround is typically 7–14 days, depending on complexity, ensuring speed without compromise.

Upon prototype approval, we transition to Mass Production using a scalable, fully documented manufacturing system built on lean principles and Six Sigma methodologies. Every production run is governed by standardized work instructions, first-article inspections, and real-time process monitoring. Our facility runs certified CNC equipment from brands such as DMG MORI and Haas, maintained to ISO 9001 standards. In-process inspections and final QA audits ensure every component meets the specified tolerances and surface finish requirements.

Our zero-defect philosophy is enforced through a closed-loop quality management system. Any deviation triggers immediate root cause analysis and corrective action, preventing recurrence. Traceability is maintained at the batch and serial level, with full documentation provided upon request. This disciplined approach has earned us long-term partnerships with leaders in medical, aerospace, automation, and high-end industrial equipment sectors.

The following table outlines key specifications supported across our production workflow:

| Parameter | Capability Range |

|---|---|

| Tolerance | ±0.005 mm (precision grade) |

| Surface Finish | Ra 0.2 – 3.2 μm (adjustable per request) |

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Inconel, Tool Steels |

| Max Part Size | 1200 × 800 × 600 mm |

| Prototyping Lead Time | 7–14 working days |

| Production Lead Time | 15–30 working days (volume-dependent) |

| Quality Standards | ISO 9001:2015, PPAP, FAI, CMM Reports |

From initial design to full-scale production, Wuxi Lead Precision Machinery ensures every component meets the highest standards of precision, reliability, and repeatability—delivering not just parts, but engineered confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Prototype Integrity

Selecting a prototype manufacturing partner demands more than technical capability; it requires engineering foresight to prevent costly iteration cycles and market delays. At Wuxi Lead Precision Machinery, we specialize in transforming complex metal prototypes from concept to validation-ready hardware with zero compromise on dimensional accuracy or material integrity. Our ISO 9001:2015-certified facility in Wuxi integrates Western engineering standards with advanced CNC infrastructure, ensuring your prototype performs identically to final production units. This eliminates the hidden costs of redesigns caused by manufacturing variances—critical when validating functionality for investors or regulatory bodies.

Our process begins with a dedicated engineering review to identify potential manufacturability risks before metal is cut. We deploy 5-axis milling, precision turning, and multi-tasking centers capable of holding tolerances unattainable through conventional prototyping. The table below outlines our core capabilities for mission-critical prototypes:

| Specification | Capability | Impact on Prototype Development |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | Eliminates fit/alignment failures in assemblies |

| Material Compatibility | Aluminum 7075-T6, Titanium Ti-6Al-4V, Inconel 718, Stainless 17-4PH | Validates performance under operational stress |

| Surface Finish | Ra 0.4 µm (16 µin) achievable | Ensures accurate functional testing for seals/bearings |

| Lead Time | 7–12 days for complex geometries | Accelerates design validation cycles |

| Max Work Envelope | 1,200 x 800 x 750 mm (47″ x 31.5″ x 29.5″) | Supports full-scale functional prototypes |

Unlike volume-focused shops, we treat every prototype as a standalone engineering challenge. Our NDA-protected workflow includes real-time machining data logs and in-process CMM verification, providing traceable evidence of conformance for your technical documentation. You receive not just a part, but a validated manufacturing baseline—complete with material certifications, first-article inspection reports, and actionable feedback for production scalability.

Commercial flexibility further de-risks your development phase. We require no minimum order quantities and offer scalable pricing from single prototypes to pilot batches of 50 units. Our engineering team collaborates directly with your designers to suggest cost-saving geometry adjustments without sacrificing performance—turning potential roadblocks into optimization opportunities.

Do not let substandard prototyping undermine your innovation. Contact our engineering team at [email protected] to schedule a confidential technical consultation. Include your CAD file and target specifications; we will respond within 4 business hours with a feasibility assessment and timeline. When precision defines your product’s success, partner with the manufacturer that treats your prototype as the foundation of your market entry—not just another job. Wuxi Lead Precision Machinery: Where Engineering Ambition Meets Manufacturing Certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.