Technical Contents

Engineering Guide: Product Prototype Companies

Engineering Insight for Product Prototype Companies

Precision engineering is not merely a technical specification in prototyping—it is the critical determinant between market success and costly failure. For product prototype companies developing next-generation medical devices, aerospace components, or advanced robotics, dimensional inaccuracies exceeding ±0.01mm can invalidate functional testing, derail certification timelines, and trigger cascading redesign expenses. At Wuxi Lead Precision Machinery, we recognize that your prototype is the foundation of your product’s lifecycle; compromising on manufacturing tolerances during this phase introduces irreversible risks into volume production. Our decades of experience delivering mission-critical components for Olympic timing systems and military-grade avionics underscore a fundamental truth: precision must be engineered from the first prototype, not retrofitted later.

The consequences of inadequate precision manifest early. A medical implant prototype with inconsistent surface finish may fail biocompatibility testing, while an aerospace bracket exceeding geometric tolerances can compromise structural simulations. These errors force iterative redesigns, inflating development costs by 30–50% and delaying time-to-market. At Lead Precision, we implement aerospace-grade process controls during prototyping—such as in-process CMM verification and thermal-stable machining environments—to eliminate guesswork. Our work on satellite deployment mechanisms for the Chinese National Space Administration required tolerances of ±0.002mm under extreme thermal cycling, a discipline we directly apply to client prototypes to ensure test data reflects true product performance.

Material behavior under machining stress further separates high-fidelity prototypes from superficial models. Aluminum alloys used in drone frames, for instance, demand specialized toolpath strategies to prevent micro-deformation. Our engineers analyze material grain structure and residual stress during prototyping to replicate production-intent behavior, avoiding the common pitfall of prototypes that function in lab conditions but fail under real-world loads. This rigor stems from military contracts where component failure is non-negotiable, translating to prototypes that accurately predict mass-production outcomes.

The table below illustrates how our precision standards directly address prototyping vulnerabilities:

| Parameter | Standard Prototyping Tolerance | Lead Precision Standard | Critical Impact |

|---|---|---|---|

| Dimensional Tolerance | ±0.05mm | ±0.005mm | Ensures sensor calibration accuracy in IoT devices |

| Surface Roughness (Ra) | 1.6μm | 0.4μm | Prevents fluid leakage in hydraulic micro-valves |

| Geometric Deviation | 0.1mm | 0.008mm | Guarantees fit for multi-part assemblies |

| Material Stability | Not controlled | Verified pre/post-machining | Eliminates warpage in thin-walled enclosures |

For product prototype companies, selecting a manufacturing partner with proven high-stakes precision experience transforms prototyping from a validation hurdle into a strategic accelerator. At Wuxi Lead Precision Machinery, we embed aerospace and defense-grade discipline into every prototype, ensuring your design intent survives the transition from concept to commercial reality. This commitment prevents the hidden costs of retesting, redesign, and reputational damage—delivering not just parts, but confidence in your product’s future.

Precision Specs & Tolerances

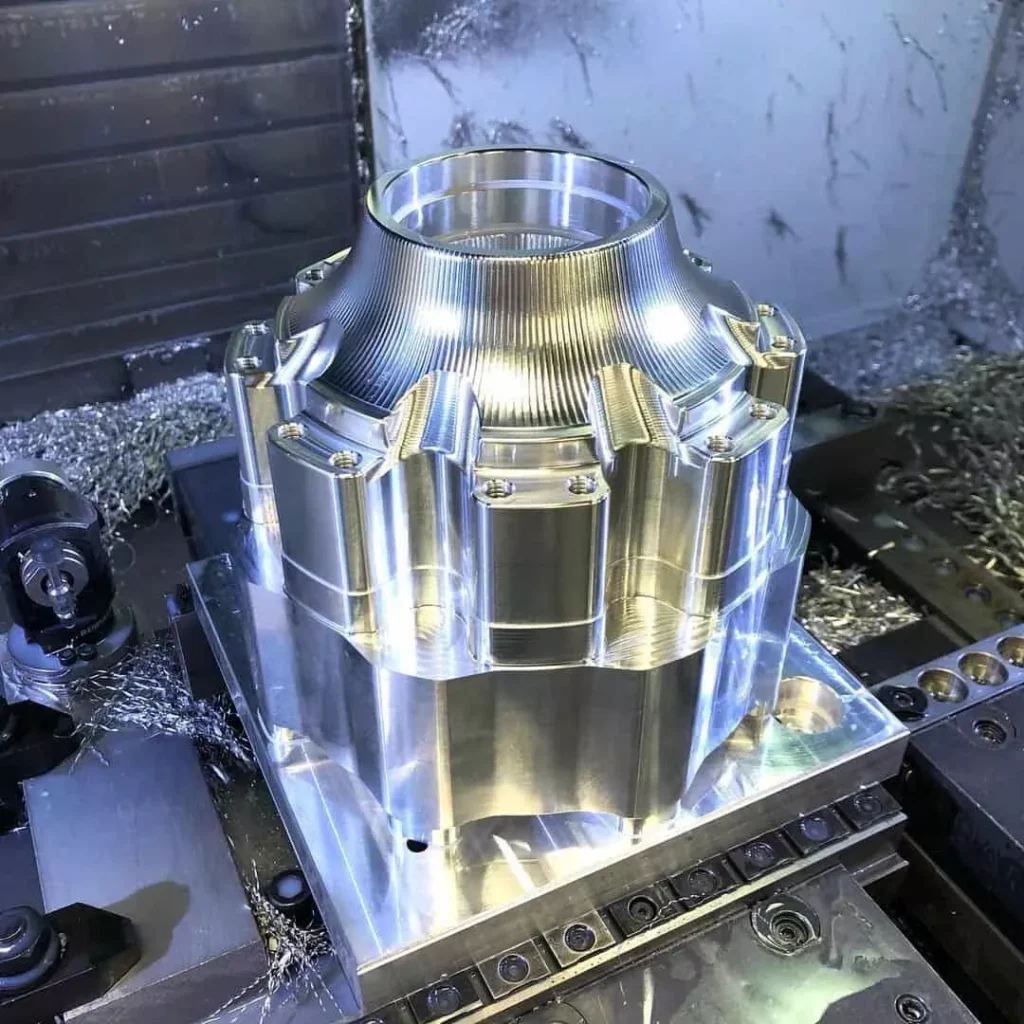

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored specifically for product prototype companies requiring high-precision components at rapid turnaround. Our technical capabilities are built around a foundation of 5-axis CNC machining, enabling us to produce complex geometries with exceptional accuracy and surface finish—critical for engineering validation, functional testing, and pre-production prototyping. With full 5-axis simultaneous machining, we eliminate the need for multiple setups, reducing lead times and minimizing cumulative error, while maintaining tight tolerances across intricate features.

Our facility is equipped with a fleet of state-of-the-art 5-axis CNC machining centers, capable of handling a wide range of engineering metals including aluminum alloys, stainless steel, titanium, brass, and high-performance engineering plastics. These machines integrate high-speed spindles, automated tool changers, and real-time tool monitoring systems to ensure consistent part quality and process reliability. Whether producing single prototype units or low-volume batches, our machining centers provide the flexibility and precision required for iterative design development and rapid validation cycles.

Quality assurance is integral to our manufacturing process. Every component undergoes comprehensive inspection using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), ensuring full dimensional compliance with customer specifications. Our CMM system provides high-accuracy 3D metrology with sub-micron repeatability, enabling detailed analysis of critical features such as hole positions, profile deviations, flatness, and geometric dimensioning and tolerancing (GD&T). Inspection reports are generated for every job, providing full traceability and documentation for engineering review and regulatory compliance.

We understand that prototype development demands not only precision but also consistency across iterations. Our in-house quality lab supports first-article inspection (FAI), process validation, and ongoing quality checks throughout production. All inspection data is stored digitally, allowing for trend analysis and continuous process improvement across design revisions.

The following table outlines our standard machining capabilities and achievable tolerances:

| Feature | Specification |

|---|---|

| Maximum Work Envelope (XYZ) | 1200 mm × 600 mm × 500 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Linear Tolerance (Standard) | ±0.025 mm |

| Linear Tolerance (Precision) | ±0.005 mm |

| Geometric Tolerance (Flatness, Perpendicularity, etc.) | ±0.01 mm per 100 mm |

| Surface Finish (Typical) | Ra 0.8 µm (as machined), down to Ra 0.2 µm with polishing |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass, PEEK, Delrin |

By combining advanced 5-axis CNC technology with rigorous CMM-based quality control, Wuxi Lead Precision Machinery ensures that every prototype meets the highest standards of dimensional accuracy and functional performance—accelerating your path from concept to validation.

Material & Finish Options

Material Selection for High-Fidelity Prototypes

Selecting the optimal material is critical for product prototype performance, manufacturability, and validation accuracy. At Wuxi Lead Precision Machinery, we guide engineering teams through data-driven choices that balance functional requirements with CNC machining efficiency. Aluminum alloys dominate prototyping for their lightweight strength and exceptional machinability. 6061-T6 offers weldability and corrosion resistance for structural components, while 7075-T6 delivers aerospace-grade strength for high-stress applications. Both alloys accept precise tolerances down to ±0.005mm and enable rapid iteration cycles.

Stainless steel variants serve prototypes demanding extreme durability or medical compliance. 303 stainless provides superior machinability for complex geometries with minimal tool wear, ideal for intricate mechanisms. 304 stainless prioritizes corrosion resistance in fluid-handling or outdoor-exposed prototypes, though it requires optimized cutting parameters to prevent work hardening. Both steels achieve mirror finishes via CNC milling but add 15-20% machining time versus aluminum.

Titanium Ti-6Al-4V remains reserved for mission-critical prototypes where strength-to-weight ratio and temperature resistance outweigh cost considerations. Its low thermal conductivity demands specialized tooling and reduced feed rates to avoid galling, extending lead times by 30%. We recommend titanium only when aluminum or steel cannot meet thermal or fatigue requirements in validation testing.

Surface finishes significantly impact prototype functionality and user experience. Anodizing is the industry standard for aluminum, enhancing wear resistance and enabling color-coding for assembly validation. Type II (sulfuric acid) anodizing provides economical corrosion protection with dye options for branding. Type III (hardcoat) anodizing delivers 50-70μm thickness for abrasion resistance in high-contact prototypes, though it requires tighter dimensional allowances. Note that anodizing adds 3-5 days to lead time and necessitates non-critical dimension masking.

Material properties directly influence CNC process planning. Below is a comparative reference for common prototyping metals:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Corrosion Resistance | Typical Prototype Use Cases |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 95 | Good | Enclosures, brackets, heat sinks |

| Aluminum 7075-T6 | 2.8 | 572 | 70 | Moderate | Aerospace fittings, drone arms |

| Stainless 303 | 8.0 | 620 | 85 | Excellent | Valves, shafts, medical instruments |

| Stainless 304 | 8.0 | 505 | 70 | Excellent | Marine hardware, chemical housings |

| Titanium Ti-6Al-4V | 4.4 | 900 | 35 | Excellent | Implants, racing components |

Wuxi Lead engineers collaborate with your team during the design phase to mitigate material-related risks. We analyze thermal loads, stress points, and finish requirements to prevent costly rework. Our CNC facilities maintain dedicated parameters for each alloy, ensuring prototype fidelity matches production intent. Contact us early in your selection process to leverage material science expertise that accelerates time-to-validation.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, we specialize in delivering precision metal components to product prototype companies that demand reliability, repeatability, and uncompromising quality. Our end-to-end manufacturing process is engineered to transition seamlessly from initial concept to full-scale production, ensuring zero defects at every stage. This integrated approach minimizes risk, accelerates time-to-market, and guarantees consistency across low-volume prototypes and high-volume manufacturing runs.

The process begins with collaborative design evaluation. Our engineering team works directly with clients to review CAD models, perform DFM (Design for Manufacturability) analysis, and recommend optimizations for material selection, tolerances, and feature geometry. This early engagement ensures that every component is not only functional but also optimized for precision machining, reducing waste and improving yield before any metal is cut.

Prototyping follows immediately after design validation. Using state-of-the-art CNC machining centers, we produce functional prototypes in the actual production materials—such as aluminum 6061, stainless steel 304/316, or titanium—enabling accurate performance testing and design verification. Our rapid prototyping cycle typically delivers parts within 5–7 business days, with full inspection reports and first-article certifications available upon request. This phase is critical for product prototype companies iterating toward final design freeze.

Once the prototype meets all functional and dimensional requirements, we transition to mass production. Our facility operates under strict ISO 9001-certified quality protocols, with real-time process monitoring, automated in-line inspection, and SPC (Statistical Process Control) to maintain consistency across thousands of parts. Each production run undergoes comprehensive final inspection, including CMM (Coordinate Measuring Machine) verification, surface roughness testing, and visual examination under magnification. Our zero-defect philosophy is enforced through traceability systems that log every operation, tool life, and inspection result per batch.

All components are manufactured in-house, eliminating supply chain variability and ensuring full control over quality and delivery timelines. Our equipment includes multi-axis CNC mills, turning centers, and automated pallet systems that support lights-out manufacturing, enabling cost-effective scaling without sacrificing precision.

Below are key technical specifications reflecting our production capabilities:

| Parameter | Specification |

|---|---|

| Machining Tolerances | ±0.005 mm (±0.0002 in) |

| Surface Roughness | Ra 0.8 μm (32 μin) standard, down to Ra 0.2 μm (8 μin) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, Copper Alloys, Engineering Plastics |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), RoHS compliant |

From design through mass production, Wuxi Lead Precision Machinery ensures that every metal component meets the highest standards of precision and reliability. For product prototype companies, this means confidence in every part—whether it’s one prototype or one hundred thousand.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Prototype Excellence

Product development hinges on precision manufacturing partners who transform concepts into functional realities without delay or compromise. At Wuxi Lead Precision Machinery, we specialize in accelerating your prototyping phase through advanced metal fabrication engineered for zero-defect outcomes. Our ISO 9001-certified facility in Wuxi integrates 5-axis CNC milling, turning, and multi-tasking systems to deliver complex geometries with micron-level accuracy. Unlike generic suppliers, we prioritize your timeline and technical integrity from the first sketch to final validation.

Prototype failures incur cascading costs: delayed market entry, redesign loops, and eroded stakeholder confidence. Lead Precision mitigates these risks through proactive engineering collaboration. Our technical team engages early to review DFM feasibility, material selection, and tolerance stack-ups—ensuring your design is optimized for manufacturability before metal is cut. We maintain rigorous in-process inspections using Zeiss CMMs and optical comparators, guaranteeing conformance to AS9100 and ISO 2768-mK standards. This structured approach reduces iteration cycles by up to 40% while elevating first-article success rates.

Our capabilities are engineered for the unique demands of prototype development:

| Specification | Capability Detail | Material Compatibility |

|---|---|---|

| Tolerance Range | ±0.005 mm (standard); ±0.001 mm (tight-tolerance) | Aluminum, Stainless Steel, Titanium, Brass |

| Max Work Envelope | 1200 x 800 x 650 mm | Magnesium, Inconel, Plastics |

| Surface Finish | Ra 0.8 μm (standard); Ra 0.4 μm (precision) | |

| Lead Time | 15 days (typical prototype batch) | |

| Certifications | ISO 9001, ISO 14001, NADCAP Heat Treat |

This technical foundation is paired with transparent project management. You receive real-time updates via our client portal, including inspection reports, process videos, and milestone confirmations. No black-box manufacturing—only verifiable progress aligned with your R&D milestones.

Initiate your prototype project with engineering certainty. Contact our technical sales team at [email protected] to schedule an engineer-to-engineer consultation. Share your CAD files and requirements for a tailored feasibility assessment within 24 hours. We operate under strict NDAs and welcome urgent RFQs for medical, aerospace, and industrial automation prototypes.

Wuxi Lead Precision Machinery is your committed partner in de-risking innovation. Let us convert your vision into a validated, production-ready prototype—on time, to spec, and without compromise. Reach out today to secure your development timeline.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.