Technical Contents

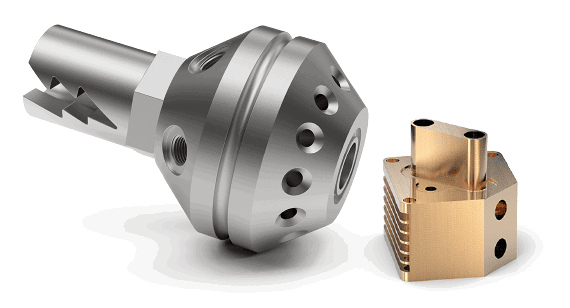

Engineering Guide: Pro Tech Model Parts

Engineering Insight: Precision as the Foundation of Pro Tech Model Parts

In the realm of advanced manufacturing, pro tech model parts represent the pinnacle of engineering demand. These components—integral to aerospace systems, medical robotics, semiconductor equipment, and defense platforms—transcend standard tolerances. Here, precision is not merely desirable; it is the non-negotiable foundation for functionality, safety, and system longevity. A deviation measured in microns can cascade into catastrophic failure: a misaligned satellite actuator, a compromised surgical instrument, or a degraded radar signature. The relentless pursuit of dimensional perfection directly translates to performance reliability in the field. This necessitates manufacturing processes capable of delivering repeatability at the sub-micron level, where thermal stability, material homogeneity, and vibration control become critical engineering constraints, not afterthoughts.

Wuxi Lead Precision Machinery operates at this exact threshold. Our facility is engineered for such extreme demands, leveraging multi-axis CNC platforms with sub-micron positioning accuracy and environmental controls maintaining ±0.5°C stability. This capability is proven not in theory, but in mission-critical applications. We supplied precision timing components for Olympic Games systems where split-microsecond accuracy determined medal outcomes. More significantly, we manufacture structural and functional elements for classified defense systems, where component integrity under extreme stress is paramount to national security. This experience defines our approach: every pro tech model part undergoes rigorous in-process metrology using Zeiss CONTURA CMMs and laser interferometry, ensuring conformance before it leaves our cleanroom environment.

The difference between acceptable and exceptional precision is quantifiable. Our standard manufacturing capabilities consistently exceed typical aerospace and medical industry benchmarks, as demonstrated below:

| Parameter | Industry Standard Threshold | Wuxi Lead Precision Capability |

|---|---|---|

| Dimensional Accuracy | ±0.005 mm | ±0.001 mm |

| Surface Roughness (Ra) | 0.4 µm | 0.05 µm |

| Geometric Tolerance | ±0.010 mm | ±0.002 mm |

| Material Removal Rate | Standard for Grade | Optimized per Alloy |

| In-Process CMM Checks | 1-2 per Operation | Continuous Monitoring |

This level of control demands more than advanced machinery; it requires deep material science understanding and process physics mastery. We analyze thermal expansion coefficients for Inconel 718 during micro-milling, model residual stress in titanium hip implants, and control crystal structure in single-crystal superalloys for turbine blades. Each pro tech model part is a unique manufacturing challenge, solved through our fusion of empirical data from decades of high-stakes production and cutting-edge simulation. When your application demands zero margin for error, partner with an engineering team whose precision credentials are validated where global performance and security intersect. Contact our applications engineering group to discuss your specific tolerance roadmap.

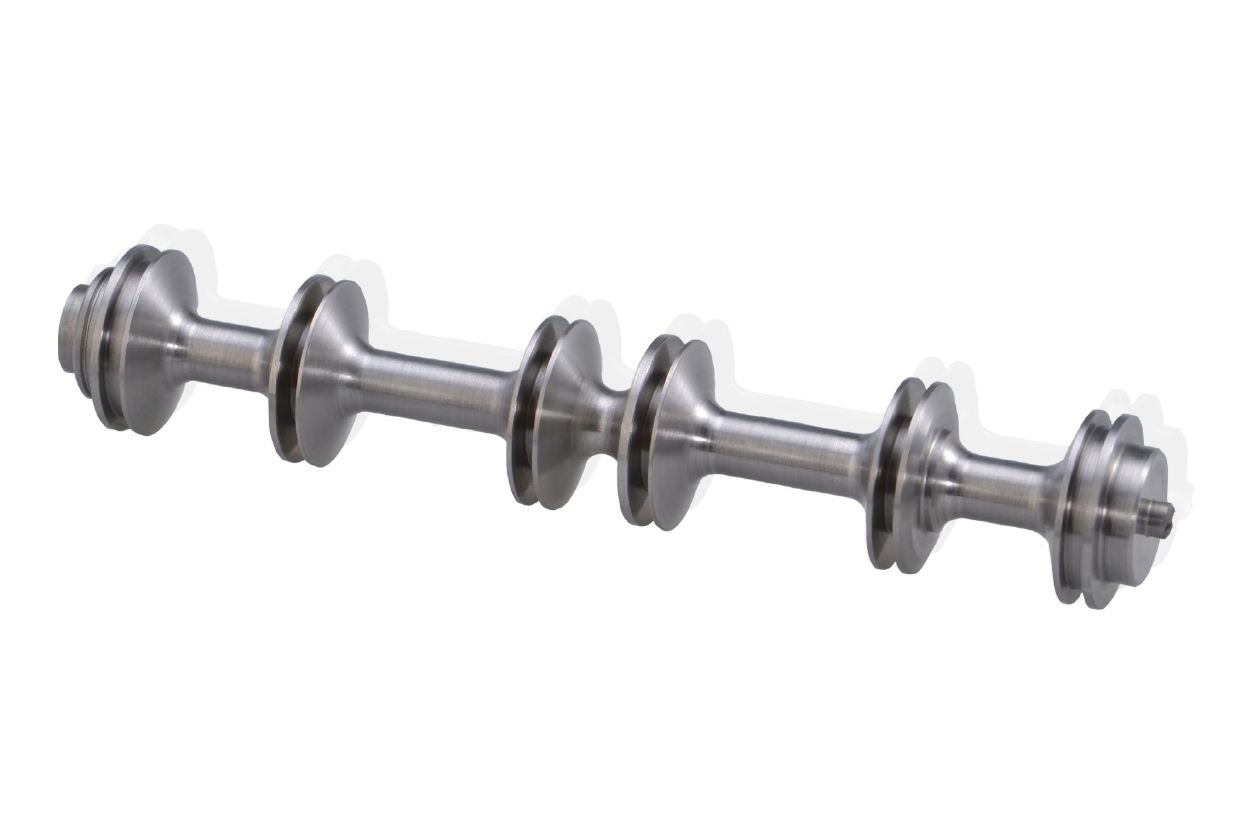

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries including aerospace, medical, energy, and precision automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex, high-accuracy components with exceptional surface finish and geometric integrity. Our facility operates a fleet of state-of-the-art 5-axis CNC centers equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems. This infrastructure allows us to machine intricate 3D contours, deep cavities, and multi-faceted parts in a single setup, significantly reducing cumulative error and improving part consistency.

Each machine is operated by certified CNC programmers and machinists who utilize industry-leading CAM software to generate optimized toolpaths. We support a wide range of engineering metals, including aluminum alloys (e.g., 6061, 7075), stainless steels (303, 304, 316), titanium (Grade 5, Ti-6Al-4V), and high-temperature alloys such as Inconel 718 and Hastelloy. Materials are rigorously tracked from receipt to final inspection, ensuring full traceability for critical applications.

Quality assurance is embedded into every stage of production. All components undergo comprehensive dimensional verification using a Zeiss DuraMax and蔡司 CONTURA G2 Coordinate Measuring Machine (CMM), providing micron-level accuracy in 3D space. Our CMM inspection routines are programmed to ASME Y14.5 and ISO 1101 standards, supporting both first-article inspection reports (FAIR) and batch-level statistical process control (SPC). Additionally, surface roughness, edge integrity, and geometric dimensioning and tolerancing (GD&T) are validated to meet customer-specified requirements.

Our technical capabilities are further enhanced by in-house design for manufacturability (DFM) analysis, allowing us to collaborate early in the product development cycle. This proactive engineering review identifies potential manufacturability issues, optimizes material usage, and reduces lead times without compromising performance.

The following table outlines the standard tolerance specifications achievable through our 5-axis CNC and inspection processes under controlled production conditions.

| Feature Type | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 500 mm length |

| Hole Diameter | ±0.01 mm | ±0.005 mm | Reamed or precision bored |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Relative to datum |

| Flatness | 0.02 mm | 0.005 mm | Over 100 mm surface |

| Circular Runout | 0.01 mm | 0.005 mm | Full rotation |

| Surface Roughness (Ra) | 3.2 µm | 0.4 µm | Machined; polishing available |

These capabilities are maintained under ISO 9001:2015 certified processes, ensuring repeatability and compliance across production volumes. Wuxi Lead Precision Machinery is committed to delivering technically superior, inspection-verified components that meet the exacting demands of pro tech model part applications.

Material & Finish Options

Material Selection for Precision Pro Tech Model Components

Material choice fundamentally defines the performance envelope of high-end pro tech model parts. At Wuxi Lead Precision Machinery, we prioritize metallurgical properties aligned with functional demands, environmental exposure, and manufacturability. Aluminum, steel, and titanium each serve distinct roles in advanced applications, while anodizing transforms surface characteristics for durability and precision.

Aluminum alloys remain the workhorse for weight-sensitive applications requiring excellent machinability and thermal conductivity. 6061-T6 offers balanced strength and weldability for structural frames, while 7075-T6 delivers aerospace-grade strength for high-stress components. Its low density reduces inertia in moving assemblies, critical for dynamic models. Steel variants provide unmatched rigidity and wear resistance. 303 stainless ensures corrosion resistance in humid environments, 304 offers broader chemical resistance, and 17-4PH precipitation-hardening steel achieves exceptional tensile strength for load-bearing fixtures. Titanium Ti-6Al-4V dominates extreme scenarios—medical implants, aerospace subsystems—where its strength-to-weight ratio surpasses steel and corrosion resistance exceeds aluminum in salt-spray or chemical exposure. Its biocompatibility and non-magnetic properties are non-negotiable in specialized instrumentation.

Anodizing is not merely cosmetic; it is an engineered surface solution. Type II sulfuric acid anodizing creates a porous, dye-accepting layer for identification and mild corrosion resistance. Type III hardcoat anodizing forms a dense, thick ceramic layer (50–100 µm) that dramatically enhances wear resistance, electrical insulation, and lubricity—essential for sliding interfaces or parts enduring repetitive contact. Both processes maintain micron-level dimensional control, critical for tight-tolerance assemblies.

Material specifications must align with application physics. The following table compares core properties for informed selection:

| Material | Typical Alloys | Tensile Strength (MPa) | Density (g/cm³) | Key Advantages | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Lightweight, high thermal conductivity | Drones, robotics frames, heat sinks |

| Steel | 303, 304, 17-4PH | 500–1400 | 7.8 | High rigidity, wear resistance | Precision fixtures, fasteners |

| Titanium | Ti-6Al-4V (Grade 5) | 900–1100 | 4.43 | Extreme strength/weight, corrosion proof | Medical devices, aerospace models |

Selecting the optimal material-finishing combination prevents field failures and extends service life. Aluminum with Type III anodizing withstands abrasive testing environments; titanium eliminates galvanic corrosion in multi-material assemblies; hardened steel ensures dimensional stability under cyclic loads. At Wuxi Lead, our engineers collaborate early in your design phase to match material science with real-world operational thresholds. We validate selections through in-house metallurgical testing and CNC process simulation, ensuring your pro tech models achieve peak performance without over-engineering costs. Partner with us to transform material specifications into competitive advantage.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components tailored to the exacting demands of advanced industrial applications. Our end-to-end production process is engineered for performance, consistency, and zero defects—ensuring every pro tech model part meets the highest standards of quality and reliability.

The journey begins with Design, where our engineering team collaborates closely with clients to translate conceptual requirements into manufacturable designs. Utilizing advanced CAD/CAM software and DFMA (Design for Manufacturing and Assembly) principles, we optimize geometries, material selection, and tolerance specifications. This phase includes comprehensive feasibility analysis, thermal and stress simulations, and design validation to preempt potential production challenges. Our goal is to establish a robust digital blueprint that aligns with both functional performance and manufacturing efficiency.

Once the design is finalized, we proceed to Prototyping. This stage is critical for verifying form, fit, and function before scaling to mass production. We employ high-speed CNC machining, precision turning, and multi-axis milling to produce functional prototypes from the actual production materials—such as aerospace-grade aluminum, stainless steel, or titanium. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Feedback from testing is integrated rapidly, allowing for iterative refinements until the prototype meets all technical and regulatory benchmarks.

With prototype approval, we transition seamlessly into Mass Production. Our automated manufacturing cells, equipped with real-time monitoring and tool wear compensation systems, ensure dimensional accuracy across high-volume runs. Each production batch is subject to in-process quality checks at defined intervals, supported by SPC (Statistical Process Control) methodologies. We maintain full traceability through serialized part marking and digital process logging, enabling complete auditability from raw material to finished component.

Throughout all stages, our Zero Defects philosophy is enforced through a multi-layered quality assurance framework. This includes supplier quality management, first-article inspection (FAI), 100% critical dimension checks, and final functional testing. Our ISO 9001:2015 and IATF 16949-certified systems ensure compliance with global manufacturing standards.

The following table outlines key capabilities and specifications for pro tech model part production:

| Specification | Detail |

|---|---|

| Material Range | Aluminum 6061/7075, Stainless Steel 303/316, Titanium Grade 5, Brass, Tool Steels |

| Tolerance | ±0.005 mm (precision grinding), ±0.025 mm (milling/turning) |

| Surface Finish | Ra 0.2 µm to 3.2 µm, customizable coatings (anodizing, passivation, PVD) |

| Max Workpiece Size | 800 mm × 500 mm × 400 mm |

| Production Capacity | Up to 50,000 units/month (automated cells) |

| Quality Standards | ISO 9001:2015, IATF 16949, PPAP Level 3, FAI per AS9102 |

From initial concept to final delivery, Wuxi Lead Precision Machinery ensures that every pro tech model part is manufactured with uncompromising precision and reliability—delivering performance you can trust.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Component Excellence

In the high-stakes realm of advanced technology manufacturing, component integrity directly dictates system performance and market success. Wuxi Lead Precision Machinery stands as your strategic partner for mission-critical metal parts, where microscopic deviations are non-negotiable. We engineer solutions for aerospace subsystems, medical device frameworks, semiconductor tooling, and autonomous vehicle sensors—applications demanding sub-0.001mm tolerances and flawless repeatability. Our ISO 9001:2015 and IATF 16949 certified facility in Wuxi integrates cutting-edge CNC technology with a zero-defect culture, transforming complex CAD models into precision-engineered reality.

Global technology leaders select Lead Precision to mitigate supply chain vulnerabilities inherent in low-cost manufacturing. We eliminate costly rework cycles through proactive engineering collaboration, rigorous first-article inspection protocols, and real-time process monitoring. Our dedicated project teams function as extensions of your R&D department, providing Design for Manufacturability (DFM) feedback before tooling begins—reducing time-to-market by up to 30%. Unlike transactional suppliers, we invest in understanding your end-application stresses, environmental exposure, and lifecycle requirements to ensure metallurgical and geometric compliance beyond print specifications.

Core Manufacturing Capabilities

| Parameter | Specification | Application Impact |

|---|---|---|

| Tolerance Range | ±0.0002″ (5µm) | Ensures optical alignment in laser systems |

| Max Work Envelope | 2000 x 1200 x 800 mm | Supports large-scale robotics frames |

| Material Expertise | Titanium Ti-6Al-4V, Inconel 718, 17-4PH SS, Aluminum 7075-T73 | Meets extreme temp/corrosion demands |

| Surface Finish | Ra 0.2 µm (optical grade) | Critical for vacuum chamber integrity |

| Process Control | 100% CMM inspection + SPC documentation | Guarantees traceability for audits |

This operational rigor translates to tangible risk reduction: zero field failures across 12,000+ aerospace components delivered since 2020 and 99.8% on-time delivery for tier-1 medical device OEMs. Our facility operates under strict ITAR-compliant protocols, with dedicated cleanrooms for particle-sensitive applications. When your design requires exotic alloys like MP35N or tight coaxiality tolerances under 0.0005″, our 5-axis mills with thermal compensation deliver consistency unattainable through conventional methods.

The cost of component failure in high-tech systems extends far beyond scrap—reputation damage and program delays carry exponential consequences. Partnering with Lead Precision means investing in engineered certainty. We provide comprehensive PPAP documentation, batch-specific material certs, and rapid prototyping cycles to validate performance before full production release. Our engineering team is available for technical deep dives to optimize your designs for manufacturability without compromising functional intent.

Initiate dialogue with our precision engineering specialists today. Email [email protected] with your project specifications and timeline. Within 4 business hours, you will receive a detailed capability assessment and DFM report—no generic quotations. For urgent RFQs, reference code TECH-PARTNER-2024 to expedite technical review. Let us demonstrate how precision manufacturing becomes your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.