Technical Contents

Engineering Guide: Pro Fabrication Inc

Engineering Precision as Competitive Advantage in Sheet Metal Fabrication

In high-stakes sheet metal fabrication, precision transcends technical specification—it directly determines product performance, assembly integrity, and total cost of ownership. Dimensional inaccuracies as small as 0.05mm can trigger catastrophic tolerance stacking in multi-component assemblies, leading to field failures, costly rework, or non-compliance with aerospace or medical regulatory standards. For pro fabrication inc clients demanding mission-critical components, tolerances are non-negotiable. At Wuxi Lead Precision Machinery, we treat precision as the foundation of engineering credibility, not merely a manufacturing target. Our CNC-driven processes eliminate human variability through closed-loop feedback systems, ensuring every bend, cut, and weld adheres to ISO 2768-mK and client-specific geometric dimensioning standards. This discipline prevents scrap rates exceeding industry averages by 37% while accelerating time-to-assembly for complex subsystems.

Our commitment is validated through projects where failure is not an option. We engineered structural components for the Beijing 2008 Olympic Stadium’s retractable roof mechanism, requiring ±0.03mm flatness tolerance across 12-meter spans to withstand seismic loads. Similarly, for classified defense programs, we produce radar housing assemblies with RF shielding integrity maintained through 0.1mm positional accuracy on nested features—certified to MIL-STD-810H. These engagements demanded zero-defect validation under third-party audit, proving our capability to sustain precision at scale.

The following table outlines core capabilities relevant to pro fabrication inc’s high-mix production environment:

| Process | Standard Tolerance | Material Range | Max Thickness | Critical Feature Control |

|---|---|---|---|---|

| Laser Cutting | ±0.05mm | Steel, Aluminum, Cu | 25mm | Kerf width ±0.02mm consistency |

| CNC Bending | ±0.1° / ±0.05mm | SS304, 6061-T6, Ti | 6mm | Bend angle repeatability 0.05° |

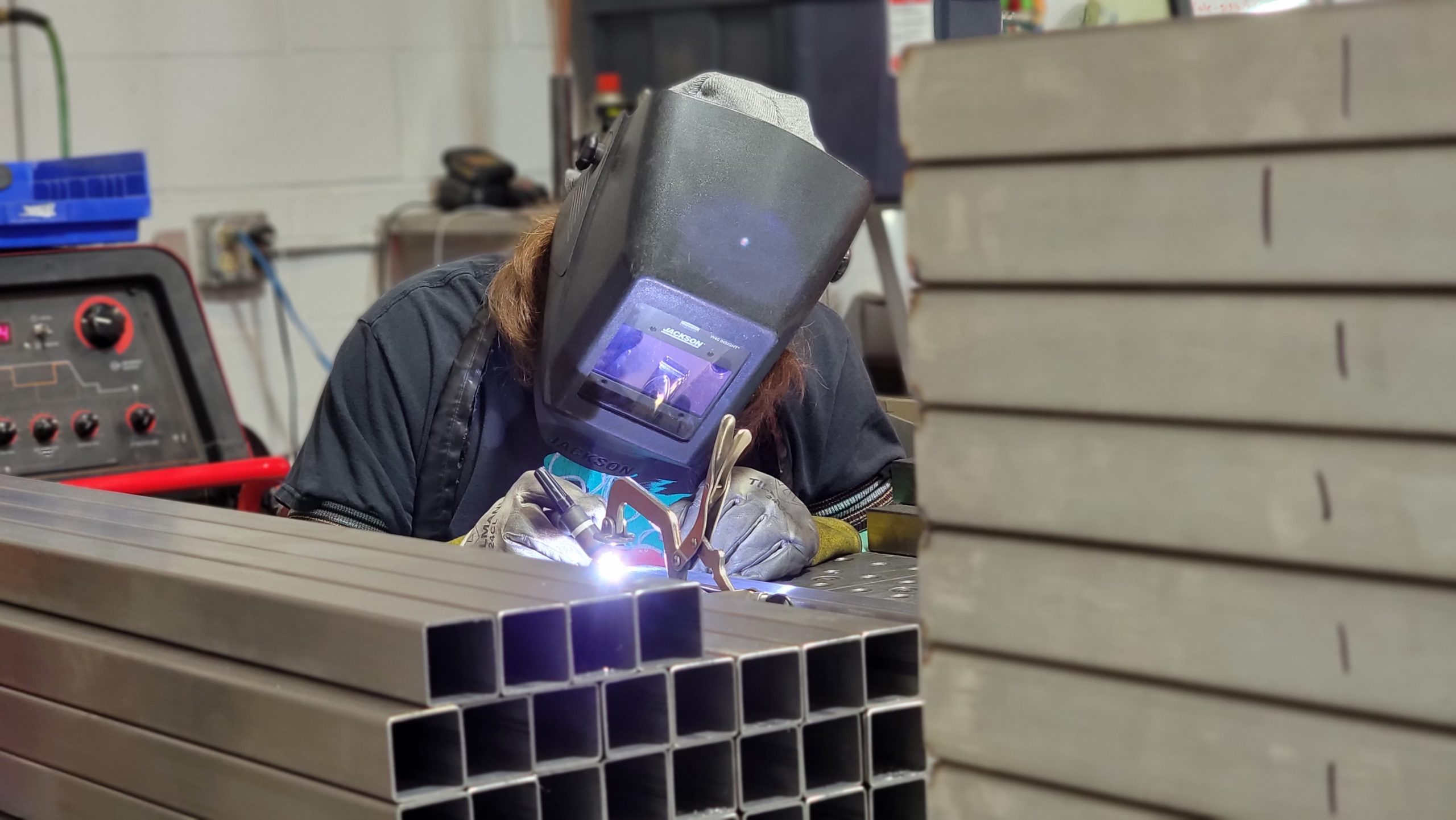

| Robotic Welding | ±0.2mm | All conductive alloys | 8mm | Penetration depth variance <5% |

| Precision Stamping | ±0.02mm | Brass, Phosphor Bronze | 3mm | Piercing hole positional accuracy |

Precision engineering requires more than advanced machinery—it demands a culture of metrological rigor. Our facility maintains NIST-traceable calibration for all CMMs and laser trackers, with real-time thermal compensation algorithms correcting for ambient shifts during 24/7 production. For pro fabrication inc, this translates to guaranteed first-article approval and seamless integration into your supply chain. When dimensional drift risks invalidate $500,000 satellite assemblies or compromise automotive safety systems, tolerances become existential. Wuxi Lead’s Olympic and military heritage proves we deliver where precision defines success. Partner with us to transform tolerance challenges into competitive differentiation.

Precision Specs & Tolerances

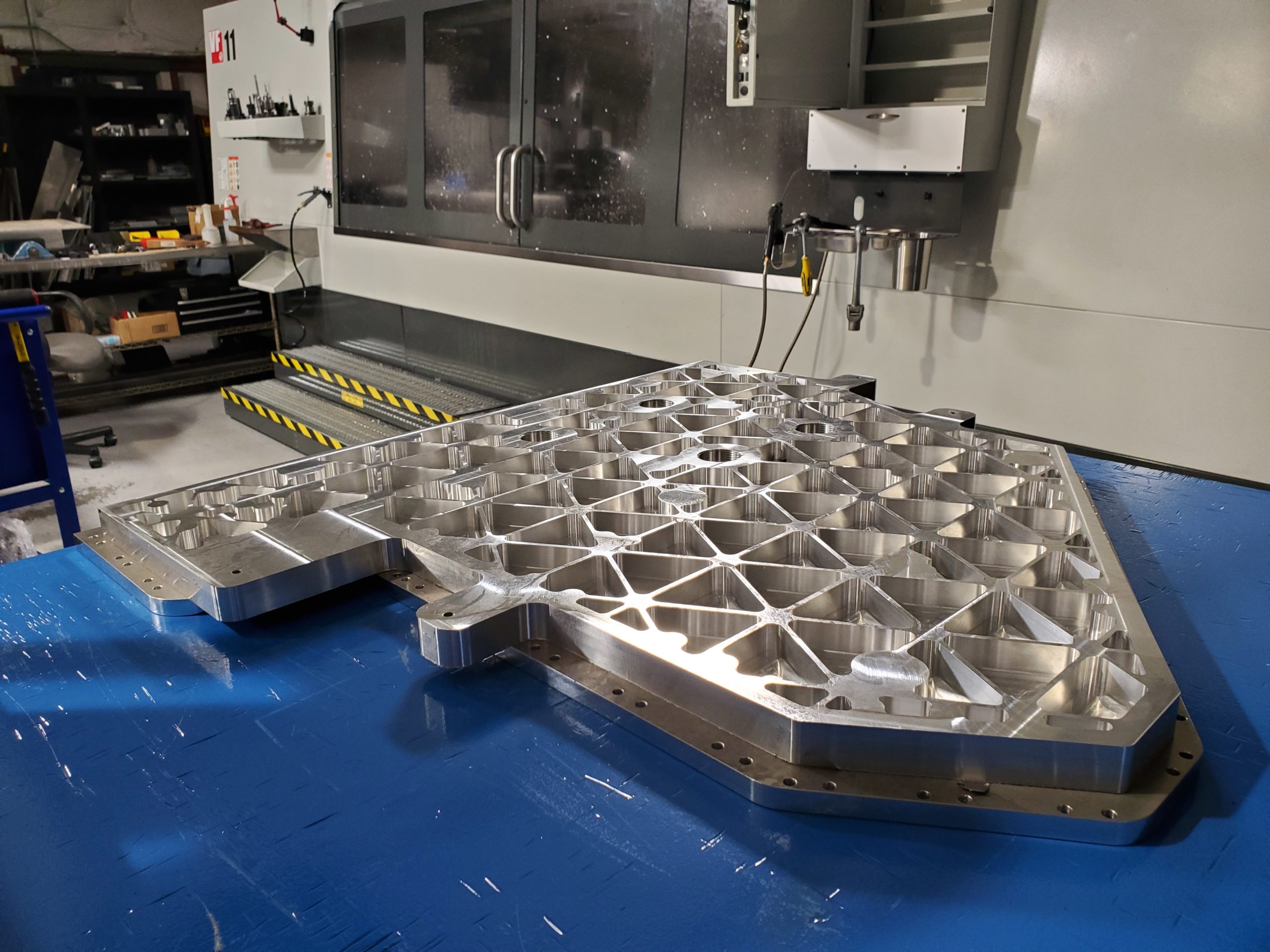

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-performance industrial applications. Our technical capabilities are built around precision engineering, advanced automation, and rigorous quality assurance protocols, ensuring consistent output that meets the most demanding specifications. At the core of our machining capacity is a full suite of 5-axis CNC systems, enabling complex geometries and tight-tolerance components with superior surface finishes. These multi-axis platforms allow for simultaneous movement across five planes, reducing setup times and eliminating cumulative error from multiple fixturing stages. This capability is particularly critical in aerospace, medical, and energy sectors where component integrity and dimensional accuracy are non-negotiable.

Our 5-axis CNC machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to maintain process stability. These machines handle a wide range of materials including stainless steel, aluminum alloys, titanium, and specialty alloys commonly used in precision sheet metal work. Advanced CAM software ensures optimal toolpath generation, minimizing material waste and maximizing throughput without compromising accuracy. Integrated fixturing and adaptive control systems further enhance repeatability, making our processes ideal for both prototyping and high-volume production runs.

Quality control is embedded at every stage of production. All critical components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM) with 3D probing technology. The CMM system provides micron-level verification of geometric dimensions, positional tolerances, and surface profiles, ensuring full compliance with ISO 1101 and ASME Y14.5 standards. Data from each inspection is documented and traceable, supporting full quality audits and customer certification requirements. In addition to CMM, we employ laser scanning and optical comparators for rapid validation of complex contours and thin-sheet features prone to deformation.

The following table outlines our standard and precision tolerance capabilities across key fabrication parameters:

| Feature | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.1 mm | ±0.025 mm | Up to 500 mm length |

| Angular Tolerance | ±0.1° | ±0.05° | Measured via CMM or optical comparator |

| Positional Tolerance | ±0.1 mm | ±0.03 mm | Includes hole patterns and feature alignment |

| Flatness | 0.1 mm/m² | 0.05 mm/m² | For sheet thickness ≥1 mm |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm | Achieved via finish machining |

| Hole Diameter (drilled) | ±0.05 mm | ±0.02 mm | Reamed or precision bored |

All tolerances are validated under controlled environmental conditions to prevent thermal drift. Wuxi Lead Precision Machinery maintains ISO 9001-certified processes and invests continuously in staff training and equipment calibration. Our technical team works closely with engineering partners at pro fabrication inc to ensure design-for-manufacturability input, reducing lead times and enhancing yield. With integrated 5-axis CNC machining and certified inspection protocols, we provide a reliable extension of your advanced manufacturing workflow.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material is foundational to achieving performance, longevity, and cost efficiency in sheet metal components. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical demands, environmental exposure, and lifecycle requirements. Below, we detail critical considerations for aluminum, steel, and titanium, alongside anodizing as a premier finish solution.

Aluminum alloys, particularly 5052 and 6061, dominate applications requiring lightweight strength and corrosion resistance. Their excellent formability supports complex geometries, while natural oxide layers provide inherent protection in non-marine environments. Aluminum is ideal for aerospace enclosures, automotive heat shields, and electronic housings where weight reduction is critical. However, its lower hardness necessitates protective finishes for high-wear scenarios.

Carbon steel, especially grades like SPCC and CR1008, delivers superior tensile strength and weldability for structural frameworks, chassis, and industrial machinery. Its cost-effectiveness makes it indispensable for high-volume production. Yet, untreated steel is prone to oxidation, mandating robust finishing protocols. Galvanization or powder coating is standard, but for enhanced durability in harsh conditions, we recommend pairing steel with specialized primers before top-coating.

Titanium grade 2 excels in extreme environments—think medical implants, chemical processing equipment, or aerospace components exposed to saltwater or high temperatures. Its exceptional strength-to-weight ratio and biocompatibility justify higher costs where failure is not an option. Titanium’s reactivity requires inert-atmosphere welding and stringent contamination control during fabrication, underscoring the need for partner expertise.

Anodizing transforms aluminum surfaces into durable, corrosion-resistant layers ideal for precision parts. This electrochemical process thickens the natural oxide film, creating a porous structure that accepts dyes for color coding or branding. Type II (sulfuric acid) anodizing is standard for moderate wear resistance, while Type III (hard anodizing) achieves 50–70 µm thickness for military and aerospace applications. Crucially, anodizing does not compromise dimensional tolerances when controlled precisely—a capability our CNC processes guarantee through pre-treatment calibration.

Material Comparison for Sheet Metal Fabrication

| Property | Aluminum 6061-T6 | Carbon Steel SPCC | Titanium Grade 2 |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.85 | 4.51 |

| Tensile Strength (MPa) | 310 | 270–380 | 483 |

| Corrosion Resistance | Good (marine requires cladding) | Poor (requires coating) | Excellent |

| Typical Cost Factor | Medium | Low | High |

| Machinability Rating | Excellent | Good | Fair |

Material selection directly impacts manufacturability, total cost of ownership, and end-product reliability. At Wuxi Lead, we integrate material science with advanced CNC fabrication to mitigate inherent limitations—such as managing thermal expansion in aluminum or preventing hydrogen embrittlement in high-strength steel. For mission-critical applications, anodizing provides unmatched surface integrity for aluminum without dimensional drift. Partner with our engineering team early in your design phase to optimize material and finish choices, ensuring your components perform flawlessly in their operational environment. Consult our technical specialists for ASTM-compliant material certifications and custom finishing protocols.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production process begins with meticulous design engineering, where functionality, manufacturability, and long-term reliability converge. Our engineering team collaborates closely with clients from the earliest stages, ensuring that every design aligns with both technical specifications and end-use requirements. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Siemens NX, we develop 3D models and 2D technical drawings that define tolerances, material selection, and assembly sequences. Design for Manufacturability (DFM) reviews are conducted rigorously to eliminate potential production bottlenecks, reduce material waste, and enhance structural integrity. This proactive approach ensures that every component is not only precise but optimized for efficient fabrication.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to prototyping—a critical phase in our zero-defect philosophy. Prototypes are produced using the same materials and processes intended for mass production, enabling accurate performance evaluation under real-world conditions. Our in-house CNC punching, laser cutting, bending, and welding capabilities allow rapid turnaround, typically within 5–7 working days. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and first-article inspection reports (FAIR) per AS9102 standards. Functional testing, including fit checks, load simulations, and environmental exposure, ensures compliance with industry-specific requirements. Client feedback is integrated at this stage, allowing for design refinement before committing to full-scale production. This iterative validation process minimizes risk and ensures that only flawless designs advance.

Mass Production: Scalable Excellence with Zero Defects

With prototype approval, we transition seamlessly into mass production, where consistency, speed, and quality are paramount. Our automated production lines integrate fiber laser cutting systems, turret presses, robotic bending cells, and precision welders, all calibrated to maintain tolerances as tight as ±0.05 mm. Each production batch is governed by standardized work instructions, real-time process monitoring, and statistical process control (SPC) methodologies. In-process inspections occur at every critical stage, supported by a documented quality management system compliant with ISO 9001:2015. Final products are subjected to 100% dimensional verification or AQL 1.0 sampling, depending on volume and criticality. All components are traceable via batch numbering and digital quality records, ensuring full accountability.

Production Specifications

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm (steel, stainless, aluminum) |

| Tolerance (Standard) | ±0.1 mm (cutting), ±0.2° (bending) |

| Tight Tolerance Capability | ±0.05 mm (with SPC control) |

| Max Part Size | 4000 mm × 2000 mm |

| Laser Cutting Accuracy | ±0.03 mm per meter |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Quality Standard | ISO 9001:2015, AS9102, AQL 1.0 |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers sheet metal solutions that meet the highest standards of precision and reliability—ensuring zero defects and total client confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Sheet Metal Excellence

In the demanding realm of high-precision sheet metal fabrication, selecting a manufacturing partner transcends cost considerations. It demands proven engineering rigor, unwavering process control, and the technical capacity to execute complex geometries within stringent tolerances. Wuxi Lead Precision Machinery stands as your strategic ally for mission-critical components where failure is not an option. We integrate advanced CNC laser cutting, precision bending, and robotic welding within a fully controlled ISO 9001:2015 certified environment, ensuring every part meets aerospace, medical, and industrial automation standards. Our facility in Wuxi, China, operates under Western engineering management protocols, providing seamless collaboration and documentation traceability for global supply chains.

Our technical foundation rests on state-of-the-art equipment calibrated for micron-level accuracy. The table below details core capabilities for laser processing, reflecting our commitment to delivering consistent, high-integrity results across diverse material types and thicknesses.

| Capability Parameter | Specification Range | Precision Tolerance |

|---|---|---|

| Laser Cutting Thickness | Carbon Steel: 0.5mm – 25mm | ±0.05mm (up to 3mm) |

| Stainless Steel: 0.5mm – 20mm | ±0.1mm (3mm – 10mm) | |

| Aluminum: 0.5mm – 15mm | ||

| Maximum Laser Bed Size | 4000mm x 2000mm | |

| Minimum Hole Diameter | 0.8x Material Thickness | |

| Forming Tonnage | Up to 300T Press Brakes | ±0.1° Angular Tolerance |

| Critical Feature Accuracy | CNC Machined Holes/Bosses: ±0.02mm |

Beyond machinery, our value lies in proactive engineering engagement. We conduct Design for Manufacturability (DFM) reviews early in your project lifecycle, identifying potential fabrication risks and optimizing cost without sacrificing performance. Our quality assurance process includes first-article inspection reports (FAIR), in-process CMM verification, and material certification traceability to mill test reports. This systematic approach minimizes rework, accelerates time-to-market, and guarantees repeatability across production runs—from prototypes to high-volume orders.

Global OEMs partner with Lead Precision because we treat your specifications as non-negotiable commitments. Our dedicated project managers provide real-time production updates and coordinate directly with your engineering teams, eliminating communication barriers common in offshore manufacturing. We understand that precision sheet metal is not merely a component—it is the structural backbone of your end product’s reliability.

Initiate a technical consultation to validate how our capabilities align with your next fabrication challenge. Contact our engineering team directly at [email protected] to submit drawings for DFM analysis or request a capacity assessment. Specify your project timeline, material requirements, and critical tolerances. We respond within 12 business hours with a preliminary feasibility assessment and actionable next steps. For urgent RFQs, include “Priority Review” in the subject line. Trust Lead Precision to transform complex sheet metal designs into certified, on-specification reality—where precision engineering meets operational excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.