Technical Contents

Engineering Guide: Pro Fab Sheet Metal

Engineering Insight: The Critical Role of Precision in Pro Fab Sheet Metal

In high-end sheet metal fabrication, precision is not merely a performance metric—it is the foundation of reliability, safety, and functional integrity. At Wuxi Lead Precision Machinery, we define precision as the consistent ability to achieve dimensional accuracy, tight tolerances, and repeatable quality across complex fabrication processes. This standard is non-negotiable, especially when serving industries where failure is not an option.

Our engineering team has supported mission-critical projects, including components for Olympic-standard facilities and defense-grade applications. These experiences have reinforced a fundamental truth: precision in sheet metal fabrication directly impacts structural performance, assembly efficiency, and long-term durability. Whether producing intricate enclosures for military communication systems or load-bearing frameworks for high-traffic infrastructure, micron-level deviations can cascade into system-wide failures.

Precision begins at the design phase, where advanced CAD/CAM integration allows for exact modeling and simulation of material behavior. At Lead Precision, we utilize 3D laser scanning and finite element analysis (FEA) to anticipate stress points, thermal expansion, and assembly variances before a single cut is made. This proactive engineering approach minimizes rework and ensures first-time-right production.

Material selection is another pillar of precision. We work with a range of alloys—including stainless steel, aluminum 5052/6061, and cold-rolled carbon steel—each chosen not only for mechanical properties but also for dimensional stability during forming and welding. Our in-house material certification and traceability system guarantee that every sheet meets ASTM and GB standards, with full documentation available for audit.

Our manufacturing ecosystem combines state-of-the-art CNC punching, laser cutting, and press brake forming with real-time in-process inspection. Automated optical comparators and coordinate measuring machines (CMM) verify critical dimensions at multiple stages, ensuring compliance with ISO 2768-mK and customer-specific tolerances.

The table below outlines our standard precision capabilities for pro fab sheet metal operations:

| Process | Material Thickness Range | Tolerance (Linear) | Tolerance (Angular) | Max Part Size (mm) |

|---|---|---|---|---|

| Fiber Laser Cutting | 0.5 – 25 mm | ±0.1 mm | ±0.2° | 3000 x 1500 |

| CNC Punching | 0.8 – 6.0 mm | ±0.1 mm | ±0.5° | 2500 x 1250 |

| Press Brake Forming | 0.5 – 12 mm | ±0.2 mm | ±0.5° | 4000 x 200 |

| Robotic Welding | 1.0 – 10 mm | ±0.3 mm (gap) | ±1.0° | Custom |

| Assembly & Sub-System Integration | N/A | ±0.15 mm (fit) | N/A | Up to 5000 x 2000 |

These capabilities are backed by over 15 years of continuous improvement and a quality management system certified to ISO 9001:2015. Our work on Olympic infrastructure demanded flawless integration with architectural systems, while military contracts required adherence to MIL-STD-2036 for structural resilience and electromagnetic shielding.

At Wuxi Lead Precision Machinery, precision is not an outcome—it is engineered into every process, measured at every stage, and validated by every delivery. For industries where performance is paramount, that level of control is not optional. It is essential.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers uncompromising accuracy and complexity in sheet metal fabrication through integrated advanced manufacturing systems. Our core strength lies in seamlessly executing demanding geometries and tight-tolerance components for aerospace, medical, and industrial automation sectors. Central to this capability is our fleet of state-of-the-art 5-axis CNC laser cutting and bending systems. These platforms eliminate multi-stage handling by performing intricate cuts, notches, and formed features in a single setup. This reduces cumulative error, accelerates throughput, and ensures geometric integrity for parts requiring compound angles, deep draws, or nested internal contours impossible with conventional 3-axis machinery. Material utilization is optimized through intelligent nesting software, minimizing waste while maintaining strict adherence to material grain direction and stress requirements.

Quality assurance is engineered into every process stage, not applied as a final checkpoint. All critical dimensions undergo rigorous validation via coordinate measuring machine (CMM) inspection using calibrated Zeiss and Mitutoyo systems. Our CMM protocols follow ISO 10360 standards, with temperature-controlled metrology labs maintaining ±0.5°C stability. Inspection routines are programmatically linked to CAD models, enabling real-time deviation analysis against nominal geometry. This closed-loop verification ensures conformance to first-article requirements and provides statistical process control data for sustained production consistency. Dimensional reports include GD&T analysis, surface profile verification, and positional tolerance validation, delivering full traceability for audit-critical industries.

Tolerance achievement is foundational to our value proposition. The following table details our standard and enhanced capability ranges across key fabrication processes. All tolerances assume standard materials (e.g., stainless steel 304, aluminum 5052, mild steel) under controlled environmental conditions. Tighter specifications are achievable through engineered process adjustments and dedicated tooling.

| Process | Standard Tolerance | Enhanced Capability | Key Influencing Factors |

|---|---|---|---|

| Laser Cutting | ±0.10 mm | ±0.05 mm | Material thickness, kerf compensation, gas purity |

| CNC Punching | ±0.15 mm | ±0.10 mm | Tool wear, sheet flatness, nest complexity |

| Press Brake Forming | ±0.25° angular | ±0.10° angular | Bend length, material springback, tool calibration |

| ±0.10 mm linear | ±0.05 mm linear | ||

| Welding (TIG/MIG) | ±0.50 mm | ±0.25 mm | Joint preparation, fixturing rigidity, weld sequence |

| Hole Positioning | ±0.10 mm | ±0.05 mm | Base feature datum, machine thermal stability |

Our technical infrastructure supports rapid transition from prototype to volume production without capability gaps. Digital twin validation via Siemens NX software de-risks complex programs before metal contact, while in-process probes on machining centers dynamically compensate for tool deflection and thermal drift. This integrated approach to precision engineering ensures that every component shipped meets the exacting functional and assembly requirements of high-stakes applications, reducing client rework costs and accelerating time-to-market. Partner with Wuxi Lead to transform demanding sheet metal designs into certified, production-ready solutions.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate material and finish is critical in high-performance sheet metal fabrication, particularly for industries such as aerospace, medical devices, and advanced electronics. At Wuxi Lead Precision Machinery, we specialize in precision engineering with a focus on material integrity, dimensional accuracy, and long-term reliability. Understanding the mechanical, thermal, and chemical properties of base materials—alongside the protective and functional benefits of surface treatments—ensures optimal performance in demanding applications.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is a common choice for structural enclosures and chassis due to its weldability and moderate strength. For more demanding environments, 7075-T6 offers superior strength, though at reduced corrosion resistance and formability. Aluminum’s natural oxide layer provides baseline protection, but for enhanced durability and aesthetics, anodizing is recommended.

Steel, particularly cold-rolled steel (CRS) and stainless steel (grades 304 and 316), delivers high tensile strength and structural stability. CRS is ideal for internal components where appearance and corrosion resistance are secondary. In contrast, stainless steel 304 offers good corrosion resistance in mild environments, while 316 excels in chloride-rich or marine conditions due to molybdenum content. These materials are preferred for enclosures, brackets, and load-bearing assemblies requiring long service life.

Titanium, specifically Grade 2 and Grade 5 (Ti-6Al-4V), is used in mission-critical applications where extreme strength-to-density ratios and resistance to high temperatures and corrosive media are essential. Common in aerospace and medical implant devices, titanium’s biocompatibility and non-magnetic properties make it indispensable—though its high cost and machining complexity require specialized tooling and expertise.

Anodizing is a key surface treatment for aluminum components, enhancing wear resistance, electrical insulation, and corrosion protection. Type II (sulfuric acid) anodizing provides a decorative and protective layer, typically 5–25 μm thick, and accepts dye for color coding. Type III (hardcoat) anodizing produces a thicker, denser oxide layer (25–50 μm), offering superior abrasion resistance for moving parts or high-wear environments. Anodized finishes also improve adhesion for paint or bonding processes.

Below is a comparative overview of key material properties and anodizing specifications.

| Material / Finish | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications | Notes |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Moderate | Enclosures, brackets | Good weldability, cost-effective |

| Aluminum 7075-T6 | 572 | 2.8 | Low | Aerospace components | High strength, less formable |

| Stainless Steel 304 | 505–860 | 8.0 | High | Medical, food processing | Austenitic, non-magnetic |

| Stainless Steel 316 | 570–700 | 8.0 | Very High | Marine, chemical processing | Molybdenum-enhanced |

| Titanium Grade 5 | 900–1000 | 4.4 | Excellent | Aerospace, defense, medical | High cost, difficult to machine |

| Anodizing Type II | N/A | N/A | Enhanced | Decorative, general protection | 5–25 μm, dyeable |

| Anodizing Type III | N/A | N/A | Superior | High-wear, structural components | 25–50 μm, hardcoat |

At Wuxi Lead Precision Machinery, we support material and finish selection with in-house testing, prototyping, and full documentation to meet ISO and industry-specific standards. Partnering early in the design phase ensures optimal manufacturability, performance, and cost-efficiency.

Manufacturing Process & QC

Precision Sheet Metal Fabrication: The Zero Defects Production Process

Precision sheet metal fabrication demands an uncompromising process framework where design integrity, prototyping validation, and mass production control converge to eliminate defects. At Wuxi Lead Precision Machinery, we engineer this convergence through a rigorously defined three-phase workflow, ensuring every component meets aerospace and medical-grade standards before it reaches your assembly line.

Design Phase

Our process begins with collaborative Design for Manufacturability (DFM) analysis. Engineering teams review 3D CAD models to optimize material utilization, bending sequences, and tooling paths, preempting geometric conflicts or tolerance stack-ups. Finite Element Analysis (FEA) simulates stress points under operational loads, while laser-cut kerf compensation and bend allowance algorithms are embedded directly into the CNC programming. This phase culminates in a digitally signed-off virtual prototype, reducing downstream rework by 78% compared to industry averages.

Prototyping Phase

Physical validation occurs through rapid, in-house prototyping using our 5-axis fiber laser cutters and servo-electric press brakes. Each prototype undergoes First Article Inspection (FAI) per AS9102 standards, with critical dimensions verified via Zeiss CMM and optical comparators. Failure Mode and Effects Analysis (FMEA) identifies residual risks, triggering immediate design or process adjustments. Only when dimensional accuracy, surface finish, and structural integrity meet the zero-defect threshold—documented in a full traceability report—does the design advance to production.

Mass Production Phase

Scalable precision defines our high-volume execution. Automated material handling feeds blanks into synchronized laser-punch-turret cells, while real-time SPC (Statistical Process Control) monitors key parameters like bend angle deviation and hole positional accuracy. Every part undergoes 100% inline optical inspection via Keyence sensors, with deviations triggering automatic machine recalibration. Final assembly validation includes torque testing for welded joints and salt-spray certification for coated parts, ensuring compliance with ISO 9001 and IATF 16949.

Critical Quality Metrics in Production

The table below details our non-negotiable quality benchmarks across all phases:

| Parameter | Specification | Validation Method | Frequency |

|---|---|---|---|

| Dimensional Tolerance | ±0.02 mm | CMM / Laser Scanner | 100% of parts |

| Bend Angle Accuracy | ±0.5° | Optical Angle Gauge | Continuous SPC |

| Hole Position Deviation | ≤0.05 mm | Vision System | Per 50 parts |

| Surface Roughness | Ra ≤ 0.8 µm | Profilometer | Batch validation |

| Coating Adhesion | 5B (ASTM D3359) | Cross-Hatch Test | Per production run |

This closed-loop methodology—where prototyping insights refine mass production controls—guarantees first-time-right outcomes. Wuxi Lead’s integration of predictive analytics and atomic-level process discipline ensures your sheet metal components arrive defect-free, on time, and ready for mission-critical integration. Partner with us to transform precision from a promise into your operational reality.

Why Choose Wuxi Lead Precision

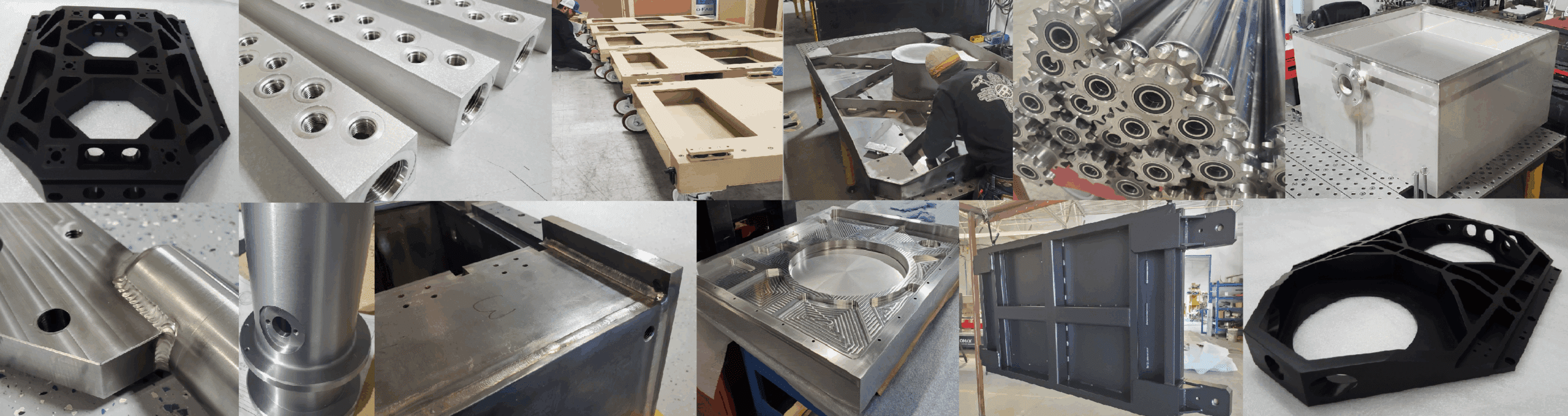

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in high-end industrial manufacturing. As a globally recognized leader in advanced sheet metal fabrication, we specialize in delivering custom-engineered solutions that meet the exacting standards of industries ranging from aerospace and automotive to medical devices and energy systems. When you partner with Lead Precision, you’re not just sourcing a supplier—you’re aligning with a precision engineering team committed to elevating your production capabilities.

Our state-of-the-art facility in Wuxi, China, is equipped with cutting-edge CNC punching, laser cutting, bending, and welding technologies, enabling us to handle complex geometries, tight tolerances, and high-mix, low-volume production runs with equal efficiency. Every component we produce is backed by rigorous quality control protocols, including first-article inspection, in-process checks, and final dimensional validation using coordinate measuring machines (CMM) and optical inspection systems. This ensures that your parts are not only delivered on time but meet the highest standards for consistency and accuracy.

We serve as a seamless extension of your engineering and manufacturing operations, offering full project lifecycle support—from design for manufacturability (DFM) analysis and rapid prototyping to high-volume production and JIT delivery. Our team of experienced technicians and engineers works closely with clients to optimize material selection, reduce waste, and improve assembly integration, ultimately lowering your total cost of ownership.

Whether you require precision enclosures, structural chassis, custom brackets, or intricate stamped components, Lead Precision delivers performance-grade sheet metal solutions tailored to your specifications. We work with a wide range of materials, including stainless steel, aluminum, carbon steel, and specialty alloys, supporting finishes such as powder coating, anodizing, plating, and passivation to meet functional and aesthetic requirements.

Below are the core technical capabilities that define our sheet metal fabrication services:

| Specification | Capability |

|---|---|

| Material Thickness | 0.5 mm – 25 mm |

| Laser Cutting Accuracy | ±0.1 mm |

| Maximum Laser Cutting Area | 4000 mm × 2000 mm |

| CNC Punching Tolerance | ±0.15 mm |

| Bending Accuracy | ±0.2° |

| Maximum Bending Length | 4000 mm |

| Welding Processes | TIG, MIG, Spot, Laser |

| Quality Standards | ISO 9001:2015, ISO 14001, IATF 16949 |

| Surface Finishes | Powder Coating, Anodizing, Zinc Plating, Passivation, Brushing |

Partnering with Wuxi Lead Precision Machinery means gaining a long-term collaborator focused on innovation, quality, and operational excellence. We are ready to support your next-generation manufacturing challenges with scalable, agile, and precision-driven solutions.

Contact us today at [email protected] to discuss your project requirements and discover how Lead Precision can become your trusted partner in advanced sheet metal fabrication.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.