Technical Contents

Engineering Guide: Printing On Aluminum Sheet

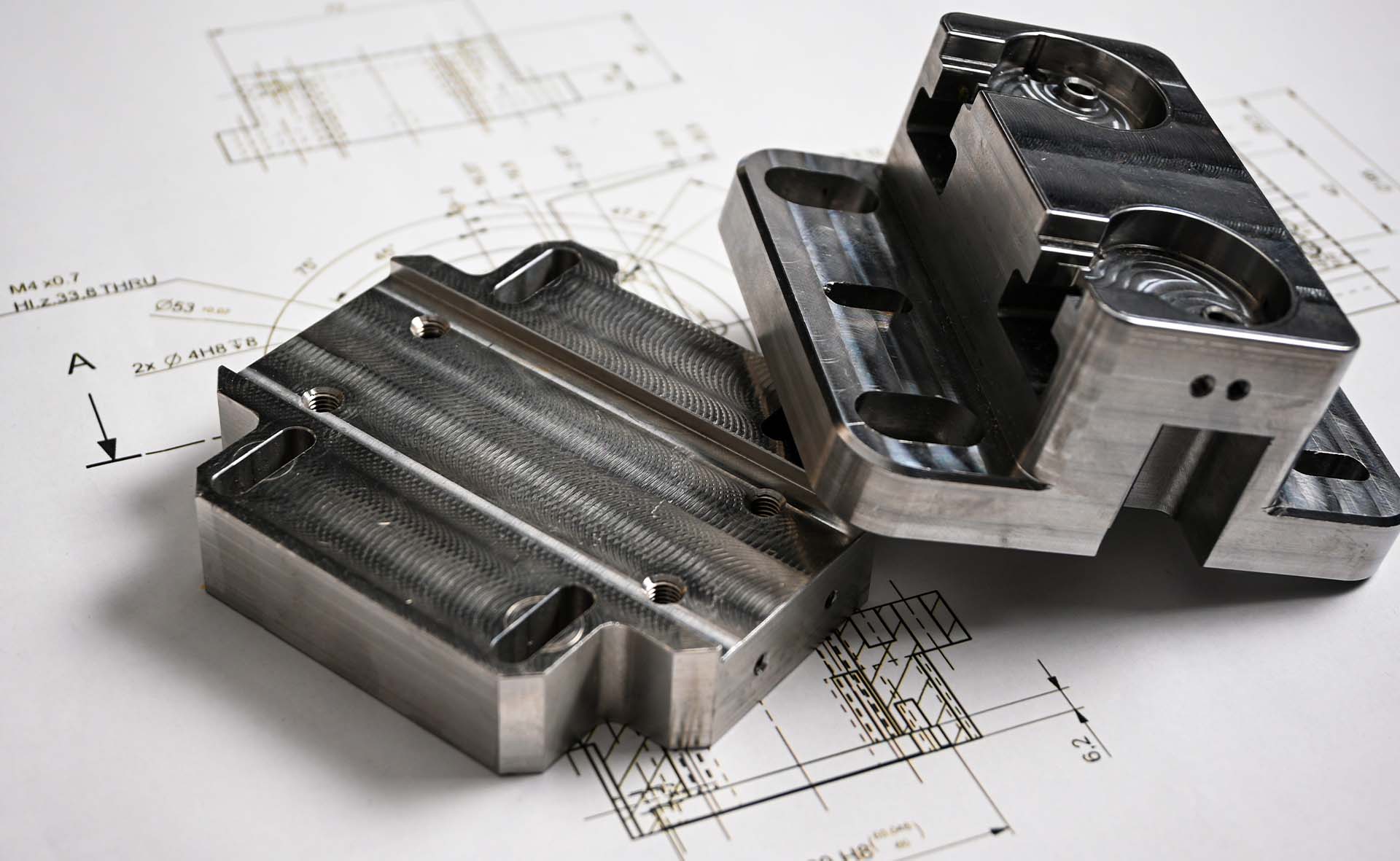

Engineering Insight Precision in Aluminum Sheet Printing

Achieving flawless printing on aluminum sheets demands far more than standard industrial processes. At the micron level, surface topography, thermal stability, and chemical adhesion determine whether a printed component meets aerospace tolerances or fails prematurely in corrosive environments. Aluminum’s inherent reactivity and thermal expansion characteristics introduce critical variables: inconsistent surface preparation causes ink delamination, while uncontrolled thermal cycles during curing induce micro-warping. These deviations—often invisible to the naked eye—compromise part functionality in high-stakes applications like avionics housings or precision instrumentation panels.

Wuxi Lead Precision Machinery addresses these challenges through metrology-driven workflows. Our CNC-integrated printing systems maintain ±0.005mm flatness tolerance across 2m x 1m sheets, validated by Zeiss coordinate measuring machines at every production stage. This precision stems from empirical evidence gathered through mission-critical projects: producing 12,000+ Olympic medal blanks requiring absolute surface uniformity for laser engraving, and fabricating military-grade control panels where printed circuit markers must withstand -55°C to +125°C thermal cycling without dimensional shift. Such projects demand adherence to MIL-STD-810H and ISO 2768-mK standards—benchmarks that expose the limitations of conventional printing lines.

The table below contrasts industry-standard practices with Wuxi Lead’s engineered approach:

| Specification Parameter | Standard Industry Practice | Wuxi Lead Precision Standard |

|---|---|---|

| Surface Roughness (Ra) | 0.8–1.2 μm | 0.2–0.4 μm (optically polished) |

| Dimensional Stability (ΔL/L) | ±0.05% after curing | ±0.008% (verified at 80°C) |

| Coating Adhesion (ASTM D3359) | 3B–4B | 5B (zero flaking) |

| Thermal Expansion Control | Unmonitored | Real-time IR compensation (±2°C) |

| In-Process Metrology | Spot-checking | 100% automated CMM validation |

This rigor eliminates post-print rework—a hidden cost eroding 15–20% of project margins in typical operations. Our closed-loop systems dynamically adjust ink viscosity and curing profiles based on real-time humidity and substrate temperature data, ensuring repeatability across batches of 5 to 5,000 units. For clients in defense or medical manufacturing, where traceability is non-negotiable, each sheet’s digital twin records 200+ process parameters from raw material certification to final inspection.

Precision printing on aluminum transcends aesthetics; it is a structural and functional imperative. At Wuxi Lead, we engineer print processes as critical path operations—not finishing steps—because when a satellite’s thermal control panel or a fighter jet’s cockpit display fails, the root cause is rarely the ink. It begins with micron-level control of the substrate. This philosophy, forged through Olympic and military-grade deliverables, defines our commitment to manufacturing integrity. For applications where failure is not an option, precision is the only specification that matters.

Precision Specs & Tolerances

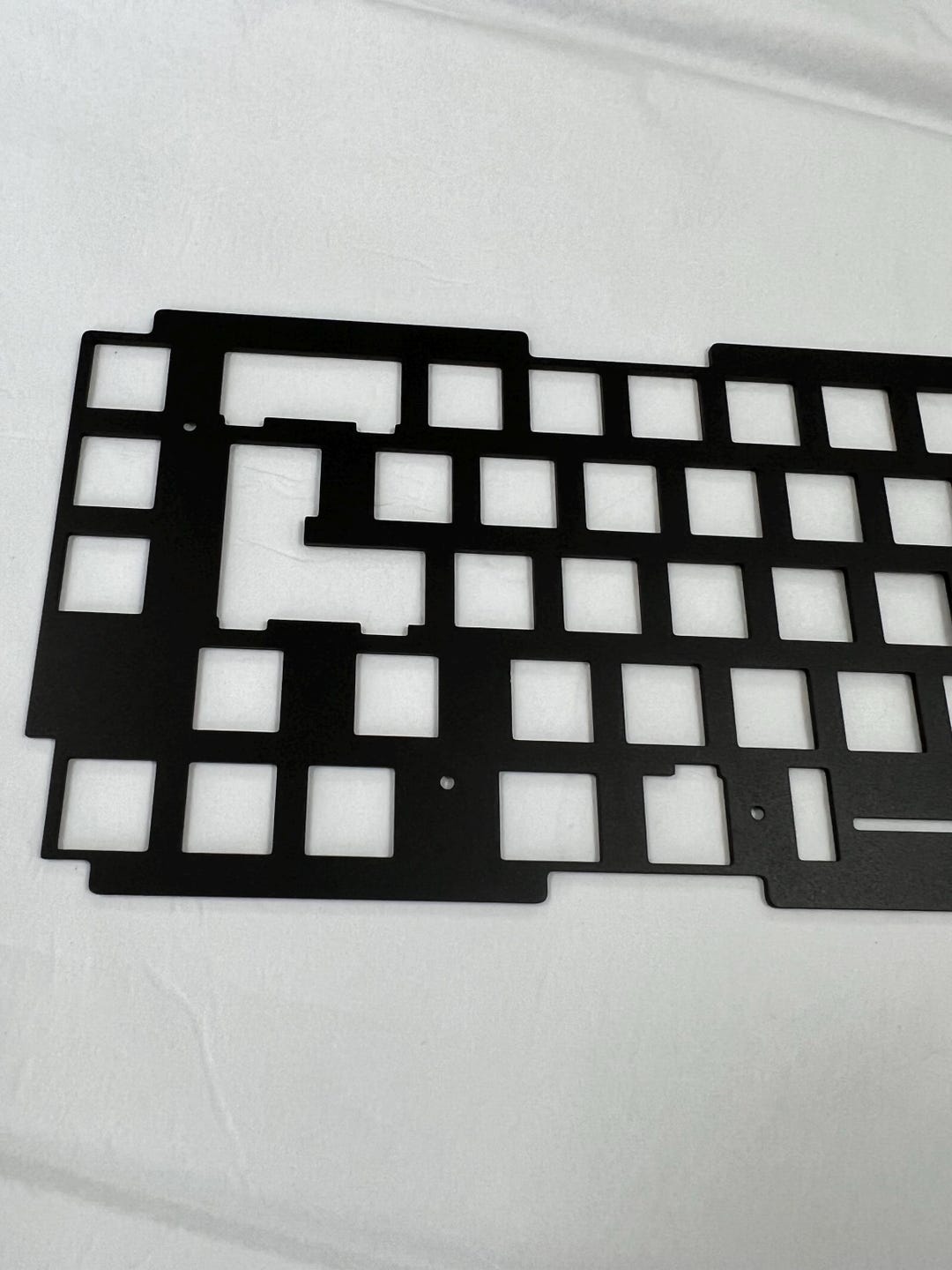

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-intensity industrial applications, specializing in precision processing of aluminum sheets for sectors including aerospace, automotive, electronics, and medical devices. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, which enable complex, multi-faceted operations with exceptional accuracy and repeatability. These machines allow for simultaneous movement across five axes, facilitating intricate geometries, undercuts, and compound angles that are unattainable with conventional 3-axis equipment. This level of precision is critical when integrating printed or engraved identification, logos, serial numbers, or functional textures directly onto aluminum substrates.

Our 5-axis CNC platforms are equipped with high-speed spindles, automated tool changers, and real-time adaptive control systems that maintain dimensional stability across variable aluminum alloys, including 5052, 6061, and 7075. The integration of advanced CAM software ensures optimized toolpaths, minimizing cycle times while maximizing surface finish quality—essential for post-processing steps such as anodizing, powder coating, or direct digital printing. We support both subtractive engraving and additive-assisted marking techniques, enabling high-contrast, durable print replication on aluminum surfaces with minimal material deformation.

Quality assurance is embedded throughout our production workflow. Every machined aluminum sheet undergoes comprehensive inspection via Coordinate Measuring Machine (CMM) technology, ensuring compliance with stringent geometric dimensioning and tolerancing (GD&T) requirements. Our metrology lab operates under ISO 17025 standards, with temperature-controlled environments to eliminate thermal drift during measurement. CMM validation covers critical features such as positional accuracy of printed elements, depth consistency of engraved text, flatness of reference surfaces, and alignment of multi-feature arrays.

We maintain strict process control from raw material intake to final packaging, supported by digital traceability systems that log machine parameters, inspection data, and operator records for full batch accountability. This ensures consistent output across prototyping and high-volume production runs. Our engineering team collaborates directly with clients to evaluate design intent, recommend optimal aluminum grades, and validate print placement for maximum legibility and durability under operational conditions.

The following table outlines our standard technical specifications and achievable tolerances for machining and surface printing on aluminum sheets:

| Feature | Specification |

|---|---|

| Material Types | Aluminum 5052, 6061, 7075, and custom alloys |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positional Tolerance | ±0.005 mm |

| Depth Control (Engraving) | ±0.01 mm |

| Surface Finish (Ra) | As low as 0.4 µm (polished), typical 1.6–3.2 µm |

| Feature Repeatability | ±0.003 mm (over 100-part batch) |

| CMM Measurement Uncertainty | < 0.002 mm (k=2) |

| Lead Time (Prototype) | 5–7 working days |

| Production Capacity | Up to 10,000 units/month |

Wuxi Lead Precision Machinery combines engineering expertise with industrial-grade technology to deliver reliable, high-precision aluminum sheet processing tailored to the exacting demands of global OEMs and Tier-1 suppliers.

Material & Finish Options

Material Selection for Precision Printed Aluminum Components

Selecting the optimal base material and surface finish is critical for achieving durable, high-fidelity printed results on aluminum sheets in demanding industrial applications. While steel and titanium serve specific high-strength or extreme-environment roles, aluminum remains the dominant substrate for printed components due to its exceptional balance of machinability, weight, corrosion resistance, and surface receptivity. Wuxi Lead Precision Machinery leverages extensive production data to guide clients toward the most reliable material-finish-print process combination for longevity and visual integrity.

Aluminum alloys, particularly the 1000, 3000, 5000, and 6000 series, offer the ideal foundation for printing. Their naturally reactive surface readily accepts chemical pre-treatments essential for ink adhesion, while their lower hardness compared to steel minimizes tool wear during precision cutting or bending prior to printing. Steel substrates require significantly more aggressive surface profiling and priming, often compromising fine print detail, and are generally cost-prohibitive for non-structural printed elements. Titanium, while offering superior strength-to-weight and extreme corrosion resistance, presents substantial challenges; its inert surface demands specialized, expensive pre-treatments and printing processes, making it impractical for most standard printed signage or decorative panels. Aluminum’s thermal conductivity also ensures minimal distortion during curing processes common in industrial printing.

Anodizing is the paramount surface finish for printed aluminum, transforming the surface into a durable, porous aluminum oxide layer that permanently bonds with dyes and inks. This process is non-negotiable for outdoor or high-wear applications. Standard sulfuric acid anodizing (Type II) provides the essential porous structure for dye absorption. Critical parameters include controlled anodizing thickness and effective hot water or nickel acetate sealing. Inadequate sealing leads to dye bleed and premature fading, while excessive thickness can cause micro-cracking under thermal cycling. Our production standards strictly adhere to ASTM B580 and ISO 7599 specifications to ensure consistent pore structure and sealing integrity.

The following specifications outline key material and finish parameters for successful printing:

| Material / Finish | Key Properties for Printing | Recommended Thickness / Grade | Critical Process Control Points |

|---|---|---|---|

| Aluminum 5052 H32 | Excellent corrosion resistance, moderate strength, superior formability | 0.8mm – 6.0mm | Consistent surface etch, tight alloy Fe/Si control |

| Aluminum 6061 T6 | High strength, good machinability | 1.5mm – 12.0mm | Avoid over-machining before anodizing |

| Type II Anodizing | Porous layer for dye/ink integration | 8μm – 15μm (Standard) | Electrolyte temp ±1°C, voltage stability |

| Sealed Anodized Surface | Sealed pores lock in color, prevent corrosion | Post-anodize sealing required | Sealing temp 95-100°C, time >20 minutes |

For the highest print durability and color fidelity, we mandate anodizing immediately followed by the printing process. Post-print baking must align precisely with the ink manufacturer’s specifications to avoid compromising the anodized layer’s integrity. Wuxi Lead Precision Machinery integrates material science with precision engineering to ensure your printed aluminum components meet the most stringent industrial requirements for appearance and service life. Consult our engineering team to validate the optimal alloy, anodizing parameters, and printing methodology for your specific environmental and aesthetic demands.

Manufacturing Process & QC

The production process for high-precision printing on aluminum sheets at Wuxi Lead Precision Machinery follows a disciplined, end-to-end workflow designed to ensure zero defects and consistent quality across all manufacturing stages. This process begins with detailed design engineering and culminates in scalable mass production, with prototyping serving as the critical validation phase.

Design is the foundational step, where engineering teams collaborate with clients to translate conceptual requirements into technical specifications. Utilizing advanced CAD/CAM software, we define critical parameters such as sheet dimensions, alloy type, surface finish, and ink compatibility. Thermal expansion coefficients, reflectivity, and adhesion characteristics are analyzed to ensure print durability under operational conditions. Every design undergoes finite element analysis (FEA) to predict performance under mechanical and environmental stress, minimizing rework and ensuring manufacturability.

Once the design is finalized, the prototyping phase commences. A limited batch of aluminum sheets is produced using the same equipment and materials intended for mass production. This ensures process fidelity and enables real-world validation. Printing is executed via industrial-grade digital or screen printing systems, calibrated for precise ink deposition. Curing is performed under controlled temperature and humidity to achieve optimal bond strength. Each prototype undergoes rigorous inspection, including optical scanning for print alignment, adhesion testing per ASTM D3359, and accelerated aging cycles. Feedback from this stage is integrated into final process adjustments, ensuring full compliance with client specifications.

Mass production leverages fully automated CNC-controlled printing lines integrated with inline quality monitoring. Sheets are fed through precision alignment systems to maintain positional accuracy within ±0.05 mm. The printing environment is maintained under ISO Class 8 cleanroom conditions to prevent particulate contamination. Real-time vision systems inspect every sheet for defects such as smudging, misregistration, or incomplete curing, automatically rejecting non-conforming units. Production data is logged for full traceability, supporting root cause analysis and continuous improvement.

Wuxi Lead Precision Machinery enforces a zero-defect philosophy through statistical process control (SPC), with process capability (Cp/Cpk) monitored continuously. All operators are certified under internal quality protocols, and third-party audits are conducted quarterly to validate compliance with ISO 9001 and IATF 16949 standards.

Below are key production specifications maintained throughout the process:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.2 mm – 6.0 mm |

| Tolerance (Dimensional) | ±0.05 mm |

| Print Resolution | Up to 1200 dpi |

| Color Accuracy (ΔE) | < 1.5 |

| Adhesion Rating | 5B (ASTM D3359) |

| Curing Temperature | 180°C – 220°C (adjustable by ink type) |

| Production Speed | Up to 30 sheets per minute (varies by size) |

| Surface Roughness (Ra) | 0.4 – 1.6 µm (controlled finish) |

| Environmental Control | ISO Class 8 Cleanroom, RH 45–55% |

This structured approach ensures that every aluminum sheet produced meets the highest standards of precision, durability, and aesthetic quality required in aerospace, automotive, and high-end electronics applications.

Why Choose Wuxi Lead Precision

Elevate Your Aluminum Printing Capabilities with Lead Precision Engineering

Achieving flawless, durable, and dimensionally precise printing on aluminum sheets presents significant technical hurdles for demanding industrial applications. Standard printing processes often fail to deliver the required adhesion, color fidelity, or surface integrity essential for aerospace components, high-end architectural panels, or sophisticated electronic enclosures. At Wuxi Lead Precision Machinery, we transcend these limitations through integrated engineering expertise and cutting-edge manufacturing technology. We don’t merely apply ink; we engineer the entire surface treatment and printing process to meet the exacting tolerances and performance criteria of your most critical projects. Our vertically integrated facility in Wuxi, China, combines advanced CNC machining, precision surface preparation, and industrial-grade digital printing under one roof, ensuring absolute control over every micron of your component.

Partnering with Lead Precision means accessing a dedicated engineering team that treats your specifications as the foundational blueprint. We begin with rigorous material analysis and surface profiling to optimize adhesion and eliminate defects like cracking or peeling under thermal cycling or mechanical stress. Our proprietary pre-treatment protocols, developed through years of metallurgical research, create the ideal substrate for ink bonding without compromising the aluminum’s structural properties. This engineering-first approach guarantees results that off-the-shelf printing services cannot replicate, especially for complex geometries or mission-critical parts requiring aerospace or medical-grade validation.

Our technical capabilities are built for industrial scale and precision. The table below outlines the core specifications achievable through our integrated process:

| Specification Category | Lead Precision Capability | Industry Standard Comparison |

|---|---|---|

| Material Thickness Range | 0.5 mm – 12.0 mm | Typically limited to 1.0 mm – 6.0 mm |

| Print Resolution | Up to 1200 dpi (true optical) | Often 600 dpi or interpolated |

| Color Accuracy (Delta E) | < 1.5 (under controlled lighting) | Typically > 3.0 |

| Adhesion Strength | Passes ASTM D3359 Class 5 (Cross-Hatch) | Frequently Class 3-4 |

| Dimensional Tolerance (Post-Print) | ±0.025 mm | Often ±0.1 mm or worse |

| Environmental Testing | Customizable (Salt Spray, UV, Temp Cycling) | Rarely offered comprehensively |

This level of control translates directly to reduced scrap rates, accelerated time-to-market, and components that perform reliably in the field. We specialize in low-volume, high-mix production where precision outweighs sheer quantity, serving global leaders in transportation, renewable energy, and precision instrumentation. Our engineers collaborate with you from CAD file review through final inspection, providing material certifications, process validation data, and actionable feedback loops to refine your design for manufacturability.

The complexity of high-performance aluminum printing demands a partner with deep metallurgical knowledge and process ownership, not just a service provider. Wuxi Lead Precision Machinery delivers engineered surface solutions that become a seamless extension of your quality system. Contact our technical sales team immediately to discuss your specific application requirements and receive a detailed capability assessment. Email [email protected] with your project specifications and material drawings. Our engineers will respond within 24 business hours with a preliminary feasibility analysis and scheduling options for a dedicated consultation. Transform your aluminum component performance through precision engineering partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.