Technical Contents

Engineering Guide: Print Shop Rapid City

Engineering Insight: The Critical Role of Precision in Custom Metal Manufacturing

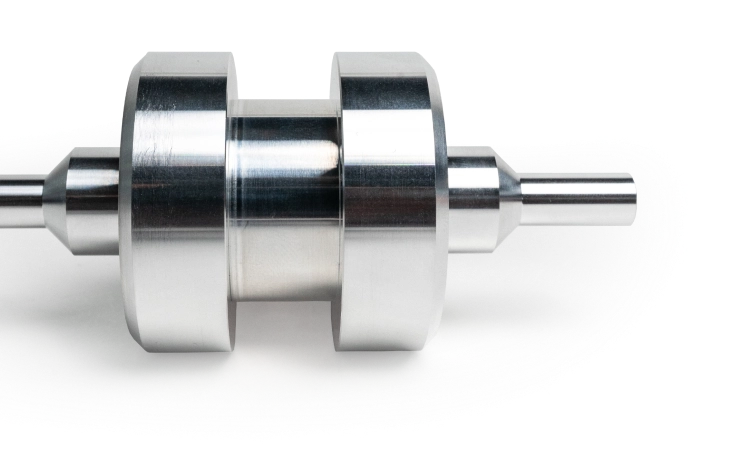

In the world of custom metal manufacturing, precision is not merely a target—it is a standard. For industries ranging from aerospace to defense, and from high-performance automotive to Olympic-grade equipment, the margin for error is effectively zero. At Wuxi Lead Precision Machinery, we understand that the success of a component is determined not just by its design, but by the fidelity with which it is executed. This is where precision engineering becomes the cornerstone of reliability, safety, and performance.

Our work with elite sectors—including the production of components for Olympic athletic equipment and mission-critical military systems—has reinforced a fundamental truth: tolerances measured in microns can define the difference between triumph and failure. In competitive sports, a fraction of a millimeter in a load-bearing joint can affect an athlete’s performance. In defense applications, precision ensures operational integrity under extreme conditions. These high-stakes environments demand more than advanced machinery—they require deep engineering insight, rigorous quality control, and an unwavering commitment to excellence.

At Wuxi Lead, our engineering team leverages over a decade of specialized experience in CNC machining, sheet metal fabrication, and multi-axis milling to deliver parts that meet the most stringent international standards. We utilize state-of-the-art metrology equipment, including coordinate measuring machines (CMM) and laser scanning systems, to validate every dimension. Our ISO 9001-certified processes ensure repeatability and traceability across every production run, no matter the complexity.

We recognize that each client’s needs are unique. Whether supporting rapid prototyping for a new energy system or scaling production for durable chassis components, our approach integrates material science, thermal dynamics, and structural analysis to optimize both form and function. This holistic engineering perspective allows us to anticipate challenges before they arise, reducing lead times and minimizing risk for our partners.

Our collaboration with global innovators has taught us that precision is not a singular achievement, but a continuous discipline. It is reflected in the consistency of surface finishes, the accuracy of thread depths, and the alignment of multi-part assemblies. When performance cannot be compromised, our manufacturing philosophy ensures that every component exceeds expectations.

The following table outlines key specifications that define our precision capabilities:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2 – 3.2 µm (adjustable) |

| Maximum Work Envelope | 2000 x 1200 x 800 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| CNC Machining Centers | 3-axis, 4-axis, 5-axis simultaneous |

| Quality Standards | ISO 9001:2015, MIL-STD-810G (military-grade testing) |

| Lead Times (Prototype) | 7–15 days, depending on complexity |

Precision is not just what we deliver—it is how we think, design, and manufacture. For partners like print shop rapid city seeking excellence in custom metal fabrication, Wuxi Lead Precision Machinery stands as a proven leader in engineering integrity and manufacturing excellence.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising accuracy for mission-critical metal components through integrated advanced manufacturing and metrology systems. Our core strength lies in multi-axis CNC machining, specifically leveraging DMG MORI and Hermle 5-axis vertical machining centers. These platforms enable simultaneous five-axis contouring of complex geometries—including organic aerospace brackets, fluidic manifolds, and medical implant interfaces—with sub-micron repeatability. The elimination of secondary setups reduces cumulative error while accelerating throughput for intricate parts that demand ±0.005 mm positional tolerances across all features. Material versatility spans aerospace-grade titanium (Ti-6Al-4V), Inconel 718, hardened tool steels (up to 60 HRC), and aluminum alloys, processed with optimized toolpaths to minimize thermal distortion and maximize surface integrity.

Quality assurance is engineered into every workflow stage, anchored by Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMMs). Each component undergoes full-spectrum dimensional validation against CAD nominal data, with automated reporting of GD&T callouts, form deviations, and critical feature alignments. Our ISO 17025-accredited lab performs 100% first-article inspection for new programs and statistical process control (SPC) sampling on production runs, ensuring batch-to-batch consistency. Real-time thermal compensation systems on all CNC assets counteract ambient fluctuations, while in-process probing verifies workholding accuracy prior to cutting—preventing scrap from fixturing drift. This closed-loop methodology guarantees that surface finishes consistently achieve Ra 0.4 µm on critical interfaces and Ra 1.6 µm on secondary surfaces, meeting stringent aerospace and medical device requirements.

Noting your reference to ‘print shop rapid city’, we emphasize that Wuxi Lead specializes exclusively in high-precision metal manufacturing. Our capabilities target industries requiring certified metal components—not print media or paper-based production. Should your application involve metal parts for machinery, instrumentation, or industrial equipment, our technical infrastructure delivers the rigor your specifications demand.

Precision Performance Specifications

| Parameter | Standard Capability | Enhanced Capability (Optimized Programs) |

|---|---|---|

| Linear Tolerance | ±0.010 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Max. Part Dimension | 1200 x 800 x 650 mm | 800 x 500 x 400 mm |

| Material Hardness Limit | 55 HRC | 60 HRC (via slow-speed machining) |

| CMM Measurement Uncertainty | ±1.9 µm + L/300 µm | ±1.3 µm + L/400 µm |

This technical foundation—combining 5-axis agility, metrology-grade validation, and material science expertise—ensures your components perform reliably in extreme operational environments. We partner with clients to refine manufacturability during DFx reviews, translating ambitious designs into flawless physical assets with documented traceability from raw material to final shipment.

Material & Finish Options

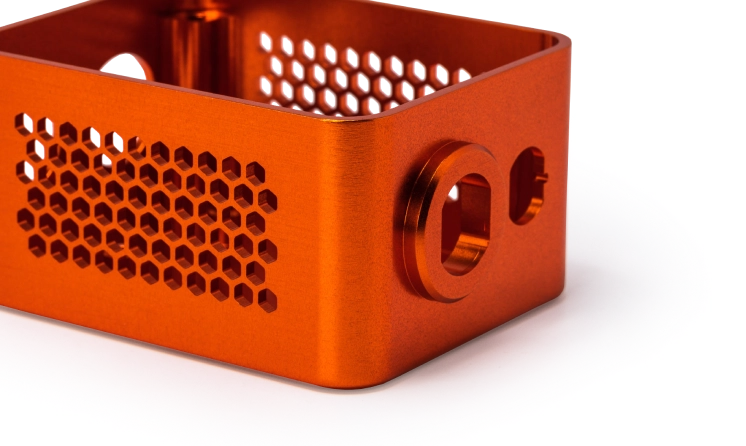

Material selection is a critical step in custom metal manufacturing, directly influencing performance, durability, and cost-effectiveness. At Wuxi Lead Precision Machinery, we specialize in precision-engineered components using high-grade aluminum, steel, and titanium—each offering distinct advantages depending on application requirements. Understanding the mechanical properties and compatibility with finishing processes such as anodizing ensures optimal part functionality and longevity.

Aluminum is widely favored in industries ranging from aerospace to consumer electronics due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications where weight reduction is essential without compromising structural integrity. Our standard use of 6061-T6 and 7075-T6 aluminum alloys provides high tensile strength and thermal conductivity, making them ideal for heat sinks, enclosures, and structural frames. When paired with anodizing, aluminum gains enhanced surface hardness and wear resistance. Type II and Type III (hard coat) anodizing are commonly applied, with thicknesses ranging from 15 to 50 µm, depending on operational demands.

Steel remains the backbone of heavy-duty applications. We utilize both carbon steel (e.g., 1045) and stainless steel (e.g., 304, 316) to meet diverse industrial needs. Carbon steel offers high strength and weldability, often used in machinery frames and tooling. Stainless steel, particularly grades 304 and 316, provides superior corrosion resistance due to chromium and nickel content, making it ideal for medical devices, food processing equipment, and marine environments. While steel cannot be anodized, we offer alternative surface treatments such as passivation, electropolishing, and powder coating to enhance durability and appearance.

Titanium, though more costly, delivers unmatched performance in extreme conditions. Grade 5 (Ti-6Al-4V) is our most commonly processed titanium alloy, known for its exceptional strength-to-density ratio, biocompatibility, and resistance to high temperatures and corrosive environments. It is extensively used in aerospace, defense, and medical implant applications. While titanium does not anodize in the traditional sense, it undergoes a similar electrochemical process that produces decorative and functional oxide layers, improving surface hardness and corrosion resistance.

The following table summarizes key mechanical and finishing properties of the primary materials we work with:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Compatible Finishes |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Good | Anodizing (Type II/III), Powder Coat |

| Steel 1045 | 570 | 7.85 | Low | Zinc Plating, Paint, Powder Coat |

| Stainless 304 | 515 | 8.0 | Excellent | Passivation, Electropolishing |

| Stainless 316 | 580 | 8.0 | Excellent | Passivation, Electropolishing |

| Titanium Ti-6Al-4V | 950 | 4.43 | Excellent | Anodizing (Decorative/Functional) |

Selecting the right material and finish requires a thorough understanding of operational environment, load conditions, and lifecycle expectations. Wuxi Lead Precision Machinery supports clients in making informed decisions through engineering consultation and prototyping services, ensuring every component meets exacting standards.

Manufacturing Process & QC

Precision Metal Manufacturing Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, we execute a rigorously defined production workflow for custom metal components, ensuring seamless transition from initial concept to flawless volume output. This integrated approach is fundamental to achieving zero defects for demanding applications, including critical parts for print shop machinery in Rapid City and beyond. Our process begins with collaborative engineering during the Design phase. Our CNC engineering team works directly with your specifications, utilizing advanced CAD/CAM software to develop optimized 3D models. Crucially, we conduct comprehensive Design for Manufacturability (DFM) analysis upfront, identifying potential production challenges, material constraints, and opportunities for cost-effective precision. This proactive engineering review prevents costly revisions later and establishes the foundation for dimensional accuracy and functional reliability.

Prototyping follows immediately upon design validation, utilizing our state-of-the-art 5-axis CNC milling and turning centers. We produce functional prototypes from your specified production-grade materials, not substitutes. This allows for rigorous real-world testing of form, fit, and function within your print equipment context. Rapid iteration is standard; we incorporate feedback swiftly, refining the digital model and machining parameters based on physical prototype performance. This stage is not merely a formality but a critical validation checkpoint where potential defects are eliminated before committing to full-scale production.

Mass Production leverages the perfected digital workflow and tooling. Our automated CNC cells, monitored by skilled technicians, execute high-precision machining with unwavering consistency. The cornerstone of our zero-defect commitment is integrated, multi-stage quality control. Every component undergoes 100% critical dimension inspection using calibrated CMMs, optical comparators, and surface roughness testers at defined process intervals. Real-time Statistical Process Control (SPC) data is continuously analyzed, enabling immediate micro-adjustments to maintain tolerances. Final inspection against your original specifications is mandatory before shipment. This systematic elimination of variation at every step ensures every part meets the exacting standards required for reliable, uninterrupted operation in your printing environment.

Key Production Specifications

| Parameter | Capability | Typical Tolerance | Lead Time (Prototype) |

|---|---|---|---|

| Materials | Aluminum Alloys, Stainless Steels (303, 304, 316), Brass, Carbon Steel, Titanium | ±0.005 mm (0.0002″) | 5-7 Working Days |

| Max Work Envelope | 850 x 500 x 450 mm (33.5″ x 19.7″ x 17.7″) | Surface Finish Ra 0.8 µm (32 µin) | Varies by Complexity |

| Primary Processes | 5-Axis Milling, Precision Turning, Mill-Turn | Positional Accuracy ±0.003 mm (0.0001″) | Mass Production Scalable |

| Quality Assurance | 100% Critical Dimension Inspection, SPC Monitoring, Full FAI Reports | Conformance to ISO 2768-mK | On-Time Delivery >98% |

This disciplined progression – validated design, rigorously tested prototyping, and tightly controlled mass production with embedded quality – is how Wuxi Lead guarantees zero-defect delivery. We understand that for your Rapid City print operation, component failure is not an option; our process is engineered to ensure your machinery runs with maximum uptime and precision. Partner with us for metal components built to perform, consistently.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Custom Metal Manufacturing Excellence

In the competitive landscape of precision manufacturing, selecting the right partner is not just a procurement decision—it’s a strategic advantage. At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components tailored to the exacting demands of global industries including aerospace, automotive, medical devices, and advanced industrial equipment. Our proven track record of engineering excellence, combined with state-of-the-art CNC machining capabilities, positions us as the ideal manufacturing partner for businesses seeking reliability, precision, and scalability.

Located in Wuxi, China, our ISO 9001-certified facility operates with a commitment to quality that is embedded in every stage of production. From prototype development to high-volume production runs, we provide end-to-end solutions that reduce lead times, minimize costs, and ensure consistent part integrity. Our team of experienced engineers collaborates directly with clients to optimize designs for manufacturability, ensuring that every component meets both functional requirements and international quality standards.

We leverage advanced 3-, 4-, and 5-axis CNC machining centers, automated inspection systems, and real-time process monitoring to maintain micron-level tolerances across diverse materials such as aluminum alloys, stainless steel, titanium, brass, and specialty engineering plastics. Whether you require complex geometries, tight tolerance components, or multi-material assemblies, our capabilities are engineered to exceed expectations.

Our partnership model is built on transparency, responsiveness, and long-term value. We understand that your success depends on on-time delivery, repeatable quality, and seamless communication. That’s why we assign dedicated project managers to every client, ensuring clear coordination, regular updates, and rapid resolution of any technical challenges.

To support your production needs with precision and reliability, we invite you to connect with our global sales team. Begin your collaboration with a partner who treats your project with the engineering rigor and operational discipline it deserves.

Contact us today at [email protected] to discuss your custom manufacturing requirements, request a quote, or schedule a virtual tour of our facility. Let Wuxi Lead Precision Machinery become your trusted extension in precision manufacturing.

| Specification | Capability |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, multi-axis Swiss machining |

| Tolerances | As tight as ±0.005 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Brass, Copper, Inconel, PEEK |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24 in) |

| Surface Finishes | As-machined, anodizing (Type II & III), powder coating, passivation, polishing, sandblasting |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP documentation available |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity and volume) |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.