Technical Contents

Engineering Guide: Price Of Injection Molding

Engineering Insight: Precision as the Core Determinant of Injection Molding Cost

Understanding the true price of injection molding requires moving beyond simplistic per-part calculations. At Wuxi Lead Precision Machinery, we emphasize that precision is the fundamental engineering driver dictating cost structure in high-end custom metal manufacturing. While raw material and machine time contribute, the tolerances, surface finishes, geometric complexity, and material properties demanded by the application exponentially influence the resources required to achieve zero-defect production. Achieving micron-level accuracy consistently demands superior tooling, advanced process control, rigorous material certification, and multi-stage metrology – each layer adding necessary value but also significant cost. Compromising on precision to meet an artificially low initial price inevitably leads to higher total costs through part rejection, assembly failures, field recalls, and premature tool wear. The engineering reality is clear: the required precision level directly scales the manufacturing effort and expertise required, forming the bedrock of a sustainable, high-value solution.

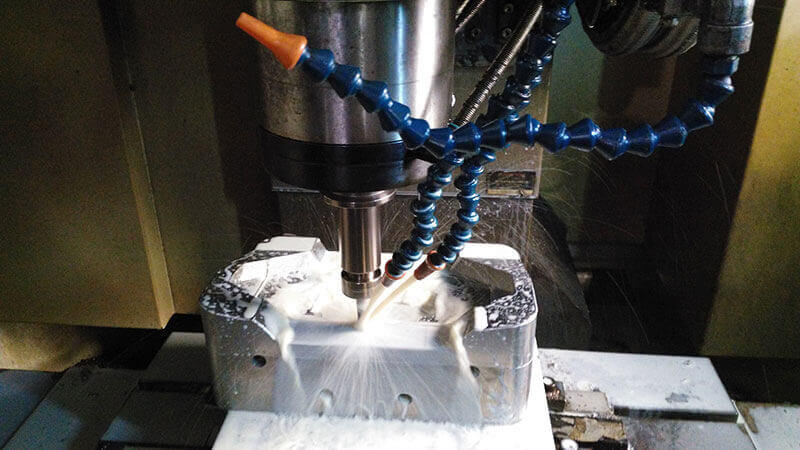

The cost implications manifest across the entire production chain. Ultra-precision tooling, crafted from hardened specialty steels using multi-axis CNC grinding and EDM, represents a major capital investment far exceeding standard mold costs. Processing such tools necessitates high-pressure, temperature-stable molding machines with closed-loop control systems capable of holding tight parameters shot-to-shot. Material selection becomes critical; aerospace-grade alloys or medical-certified polymers command premium prices and require specialized drying and handling. Crucially, quality assurance escalates from basic sampling to 100% inspection using CMMs, vision systems, and in-process sensors, demanding skilled metrology personnel and significant cycle time allocation. Our experience delivering mission-critical components for Olympic infrastructure projects and stringent military applications validates this principle. These programs demanded zero-defect delivery under extreme environmental conditions, requiring tolerance stack-up analysis, material traceability to the ingot level, and validation protocols that inherently define the project’s cost baseline from inception.

Wuxi Lead Precision Machinery’s engineering approach focuses on optimizing this precision-cost equation for maximum client value. We collaborate early in the design phase to identify critical-to-quality features, allowing intelligent allocation of precision resources where they matter most, avoiding unnecessary cost on non-critical dimensions. Our decades of experience in high-tolerance sectors ensure tooling longevity and process stability, spreading the initial investment over higher part volumes with minimal scrap. The following specifications illustrate the tangible requirements inherent in premium precision molding that directly influence project costing:

| Critical Parameter | Standard Molding Range | Wuxi Lead Precision Standard | Impact on Cost Factor |

|---|---|---|---|

| Dimensional Tolerance | ±0.1 mm to ±0.05 mm | ±0.005 mm to ±0.01 mm | 3x-5x Tooling/Process |

| Surface Roughness (Ra) | 1.6 μm to 3.2 μm | 0.2 μm to 0.8 μm | 2x-4x Polishing/Process |

| Material Certification | Basic Mill Cert | Full Traceability + ASTM/AMS | 1.5x-3x Material Cost |

| In-Process Inspection | Random Sampling | 100% CMM + Vision System | 2x-3x Labor/Cycle Time |

| Tool Steel Hardness | HRC 48-52 | HRC 58-62 (Pre-Hardened) | 2.5x-4x Tooling Cost |

The price of injection molding is ultimately the price of guaranteed performance. Wuxi Lead Precision Machinery’s proven capability in delivering Olympic and military-grade components underscores our commitment to embedding precision into every process step. This engineering discipline ensures not just meeting specifications, but delivering parts that perform reliably in the most demanding applications, providing true long-term value that transcends the initial quote. Partner with us to transform precision requirements into a competitive manufacturing advantage.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the rigorous demands of high-performance industries such as aerospace, medical, automotive, and industrial automation. At the core of our production infrastructure is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to produce complex, high-precision components with exceptional accuracy and repeatability. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring and feature integration. This capability significantly reduces the need for multiple setups, minimizing cumulative tolerances and enhancing geometric consistency across intricate part designs.

Our 5-axis CNC technology supports a wide range of materials, including aluminum alloys, stainless steels, titanium, tool steels, and high-temperature superalloys. This versatility ensures that we can meet diverse functional and environmental requirements without compromising dimensional integrity. Advanced toolpath strategies and high-speed machining protocols further optimize surface finish and cycle time, delivering components that meet both performance and production efficiency goals.

To guarantee the highest level of quality, every manufacturing stage is supported by a comprehensive quality control system anchored in CMM (Coordinate Measuring Machine) inspection. Our metrology lab is equipped with high-precision CMM systems capable of full 3D geometric dimensioning and tolerance (GD&T) verification. These inspections are conducted in accordance with international standards, including ISO 9001 and AS9100, ensuring traceability and compliance across all deliverables. Real-time data feedback from CMM reports is integrated into our process control loops, allowing immediate correction and continuous improvement throughout production runs.

We maintain strict adherence to dimensional tolerances, with capabilities that meet or exceed industry benchmarks. The following table outlines our standard and advanced tolerance specifications across key machining parameters.

| Feature Type | Standard Tolerance | High-Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometer, Caliper |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | CMM, Optical Comparator |

| Flatness | 0.02 mm | 0.005 mm | CMM, Surface Plate + Dial |

| Circular Runout | 0.02 mm | 0.003 mm | CMM, V-Block + Dial |

| Surface Finish (Ra) | 1.6 µm | 0.2 µm | Surface Roughness Tester |

These capabilities are further enhanced by our in-house design and process engineering team, which collaborates closely with clients to optimize part geometry, material selection, and manufacturability. From prototype development to high-volume production, Wuxi Lead Precision Machinery ensures technical excellence at every stage, delivering components that reflect the highest standards of precision, reliability, and value.

Material & Finish Options

Material Selection: Critical Drivers for Injection Mold Cost and Performance

Material choice fundamentally dictates the cost structure and longevity of injection molds. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with your production volume, part complexity, and surface finish requirements. Selecting suboptimal materials inflates total cost of ownership through premature wear, extended cycle times, or secondary processing. Aluminum offers rapid prototyping and low-volume economics but lacks durability for high-cavitation runs. Tool steels dominate medium-to-high volume production, balancing machinability with wear resistance. Titanium excels in corrosive environments but imposes significant machining costs and lead time penalties. Below is a comparative analysis of core mold materials:

| Material | Hardness Range (HRC) | Machinability Rating | Expected Tool Life (Cycles) | Relative Cost Factor |

|---|---|---|---|---|

| Aluminum 7075 | 15-22 | Excellent (90-100%) | 10,000 – 100,000 | 1.0x |

| P20 Steel | 28-32 | Good (70-85%) | 100,000 – 500,000 | 1.8x |

| H13 Steel | 48-52 | Moderate (50-65%) | 500,000 – 1,000,000+ | 2.5x |

| Titanium Gr5 | 32-36 (as-machined) | Poor (20-35%) | 200,000 – 750,000 | 4.0x |

Aluminum 7075 enables 30-50% faster machining versus steel, reducing initial tooling costs by up to 40% for prototypes or short runs under 50,000 cycles. Its thermal conductivity accelerates cooling but necessitates protective coatings for abrasive resins. P20 pre-hardened steel provides the optimal balance for 100k+ cycle production, supporting nitriding or PVD coatings to extend service life. For aggressive engineering polymers like glass-filled nylons, H13 hot-work steel is non-negotiable—its 50+ HRC surface hardness withstands erosion while maintaining toughness at elevated temperatures. Titanium’s niche application lies in medical or chemical molding where chloride resistance outweighs its 4x material cost and complex EDM requirements.

Anodizing transforms aluminum mold components into viable long-term solutions. Type III hard anodizing delivers a 50-75 µm ceramic layer at 500-700 HV, doubling wear resistance and enabling 250,000+ cycles in non-abrasive applications. This finish eliminates galling in sliding cores and reduces ejection forces by 15-20% versus bare aluminum. Crucially, anodized molds maintain dimensional stability where plating would induce hydrogen embrittlement in steel. At Wuxi Lead, we integrate anodizing parameters directly into mold design—specifying masking zones, voltage gradients, and sealing processes to prevent micro-cracking during thermal cycling.

Material selection is never isolated from manufacturing capability. Our CNC grinding and wire EDM centers optimize steel hardening sequences to minimize distortion, while our titanium specialists employ cryogenic milling to achieve ±0.002mm tolerances. Partner with us to convert material science into cost-per-part advantage—where every HRC point and micron of coating thickness drives your bottom line. Request our full material compatibility matrix for 200+ resins.

Manufacturing Process & QC

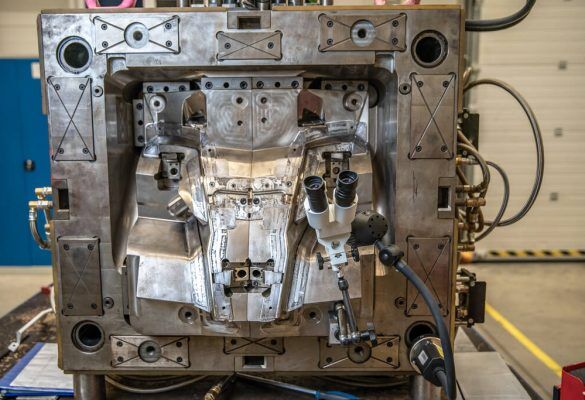

The injection molding process at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect output in custom metal manufacturing. Our end-to-end workflow ensures seamless transition from concept to mass production, maintaining strict quality standards at every phase. The process begins with design, where our engineering team collaborates closely with clients to translate functional requirements into optimized mold geometries. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we simulate material flow, cooling rates, and stress distribution to preemptively resolve potential defects such as warping, sink marks, or voids. Design for manufacturability (DFM) reviews are conducted to ensure moldability, reduce cycle time, and enhance part consistency.

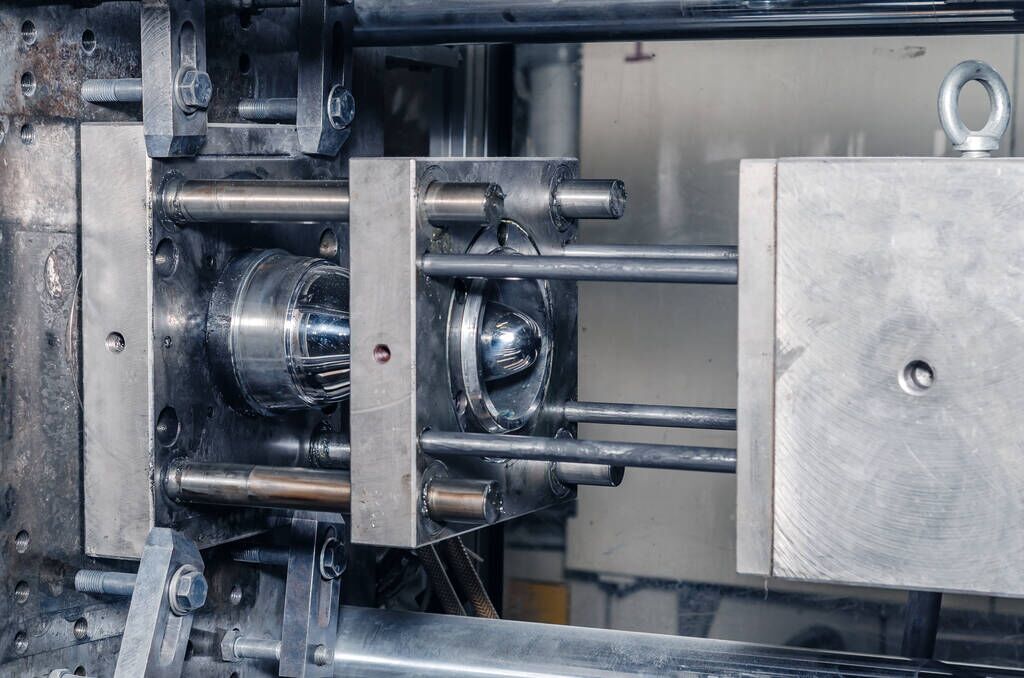

Once the design is finalized, we proceed to prototyping. This stage is critical for validating both the mold functionality and the final component’s dimensional accuracy. We fabricate prototype molds using high-grade tool steels and employ CNC machining and electrical discharge machining (EDM) to achieve tolerances within ±0.005 mm. These molds undergo rigorous trial runs on our state-of-the-art hydraulic and electric injection molding machines. Each prototype part is subjected to comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and 3D scanning to verify conformity to specifications. Feedback from this stage is used to fine-tune the mold design, gating system, and process parameters before transitioning to full-scale production.

Mass production is executed on automated, closed-loop monitored injection molding lines. Our facility integrates real-time process control systems that continuously track injection pressure, temperature, clamp force, and cycle duration. Any deviation beyond predefined thresholds triggers immediate alerts, ensuring non-conforming parts are never produced. In-line vision systems and automated sorting further enforce zero-defect standards. All molds are maintained under a preventive maintenance schedule, and production batches are traceable through our digital manufacturing execution system (MES), allowing full accountability from raw material to finished component.

Throughout the entire process, Wuxi Lead Precision Machinery adheres to ISO 9001 and IATF 16949 quality management standards. Our commitment to precision, material integrity, and process control ensures that every component meets the highest performance and reliability requirements for industries such as automotive, aerospace, and medical devices.

| Parameter | Specification |

|---|---|

| Material Options | Stainless Steel (316L, 17-4PH), Titanium, Tool Steels, Superalloys |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2 – 1.6 µm (polished, as-machined, or textured) |

| Mold Life | 100,000 – 1,000,000 cycles (depending on material and complexity) |

| Production Capacity | Up to 500,000 units/month |

| Quality Standards | ISO 9001, IATF 16949, RoHS compliant |

| Inspection Tools | CMM, 3D Scanner, Optical Comparator, In-line Vision System |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Transparent, High-Value Injection Molding

Understanding the true price of precision metal injection molding requires more than a surface-level quote. Hidden variables—material volatility, secondary operation complexities, and tolerance-driven rework—often inflate initial estimates, derailing budgets and timelines. At Wuxi Lead Precision Machinery, we eliminate this uncertainty through engineering-led cost modeling. Our approach begins with rigorous design analysis, identifying cost drivers before a single pellet is melted. We integrate material science expertise with real-time production data to deliver fixed-fee proposals, not speculative ranges. This precision ensures your budget reflects only value-added manufacturing, not contingency padding.

Our facility in Wuxi operates under ISO 9001-certified processes, leveraging 15+ years of specialization in high-complexity metal injection molding (MIM) for aerospace, medical, and energy sectors. Unlike commodity-focused suppliers, we prioritize dimensional stability and material integrity at every stage—from feedstock formulation to sintering and CNC finishing. This reduces scrap rates by up to 30% compared to industry averages, directly lowering your per-part cost. The table below outlines how our engineering controls translate to predictable pricing:

| Specification Category | Industry Standard Variation | Lead Precision Control | Cost Impact Mitigation |

|---|---|---|---|

| Dimensional Tolerance (±mm) | 0.05–0.20 | 0.02–0.05 | Eliminates post-mold machining for 75% of features |

| Material Yield Loss | 8–15% | 3–6% | Reduces raw material cost by 12–22% |

| Secondary Operations | 2–5 processes | 0–2 processes | Cuts labor and handling by 18–35% |

| First-Pass Yield Rate | 65–80% | 92–97% | Avoids rework costs averaging $45–$120/hour |

This level of control stems from our closed-loop manufacturing ecosystem. Our in-house CNC centers, metallurgy lab, and sintering furnaces operate on a unified digital platform, enabling real-time adjustments that prevent cost escalations. When you partner with Lead Precision, you gain access to engineering teams who co-develop solutions—not just execute drawings. We optimize part geometry for moldability during the RFQ phase, ensuring manufacturability aligns with your budget from day one.

Stop accepting vague pricing that risks project viability. Request a precision quote engineered for your exact requirements. Our technical sales team will analyze your CAD files within 48 hours, delivering a fixed-cost proposal with zero hidden fees. This is how global leaders like Siemens Energy and Stryker maintain supply chain integrity without sacrificing innovation.

Contact us today to lock in your project economics. Email [email protected] with your part specifications and target volume. Specify “Precision Quote Request” in the subject line to receive a detailed cost breakdown, material sourcing strategy, and production timeline within one business day. Let Wuxi Lead Precision Machinery become your transparent, high-precision manufacturing partner—where every dollar invested delivers measurable engineering value.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.