Technical Contents

Engineering Guide: Price Cnc

Engineering Insight: The True Cost of Precision in CNC Machining

When industrial buyers search for “price cnc,” they often overlook the critical relationship between precision engineering and long-term value. At Wuxi Lead Precision Machinery, we recognize that quoting CNC services solely on cost per hour ignores the hidden expenses of inadequate tolerances, material waste, and production delays. True value emerges when micron-level accuracy aligns with your application’s functional demands—especially in sectors where failure is not an option.

Precision CNC machining transcends basic part fabrication. It demands rigorous control over thermal stability, tool deflection, and material behavior. For instance, aerospace components operating at Mach 2 require tolerances tighter than ±0.001mm to prevent catastrophic fatigue. Similarly, medical implants must achieve surface finishes below Ra 0.4µm to ensure biocompatibility. Compromising on these parameters inflates total cost through scrap rates, secondary operations, and field failures. Our engineering team quantifies these variables during quoting, ensuring your “price cnc” reflects engineered reliability—not just machine time.

Wuxi Lead’s 15-year specialization in mission-critical projects underscores this philosophy. We engineered titanium structural components for the Beijing Winter Olympics’ bobsled track timing system, where sub-millisecond synchronization demanded absolute dimensional consistency. For military clients, we produce radar housing assemblies with EMI-shielding tolerances held to ±0.0005mm across 600mm spans—requirements impossible without our in-house metrology lab and 24/7 process validation. These projects prove that precision isn’t a luxury; it’s the foundation of operational integrity.

Our technical capabilities enable this standard across diverse applications. The table below outlines core specifications achievable without premium surcharges when designed for manufacturability:

| Parameter | Capability Range | Industry Benchmark |

|---|---|---|

| Positional Tolerance | ±0.001mm to ±0.005mm | ±0.01mm |

| Surface Finish (Ra) | 0.2µm to 1.6µm | 3.2µm |

| Material Range | Ti-6Al-4V, Inconel 718, PEEK, 7075-T73 | Standard alloys only |

| Max Work Envelope | 1,200 x 800 x 650mm | 800 x 500 x 400mm |

| In-Process Metrology | On-machine probing + CMM | Post-process only |

When evaluating “price cnc,” consider the cost of inaccuracy. A 0.01mm tolerance deviation in a hydraulic manifold can cause 12% flow loss, triggering system overheating and downtime. At Wuxi Lead, we embed precision into every process—from material certification to final inspection—using ISO 2768-mK compliant workflows. Our Olympic and military-grade discipline ensures your components perform as designed, eliminating the hidden costs that erode ROI. Partner with an engineer, not just a vendor. Let us demonstrate how precision-priced CNC machining delivers uncompromised value.

Precision Specs & Tolerances

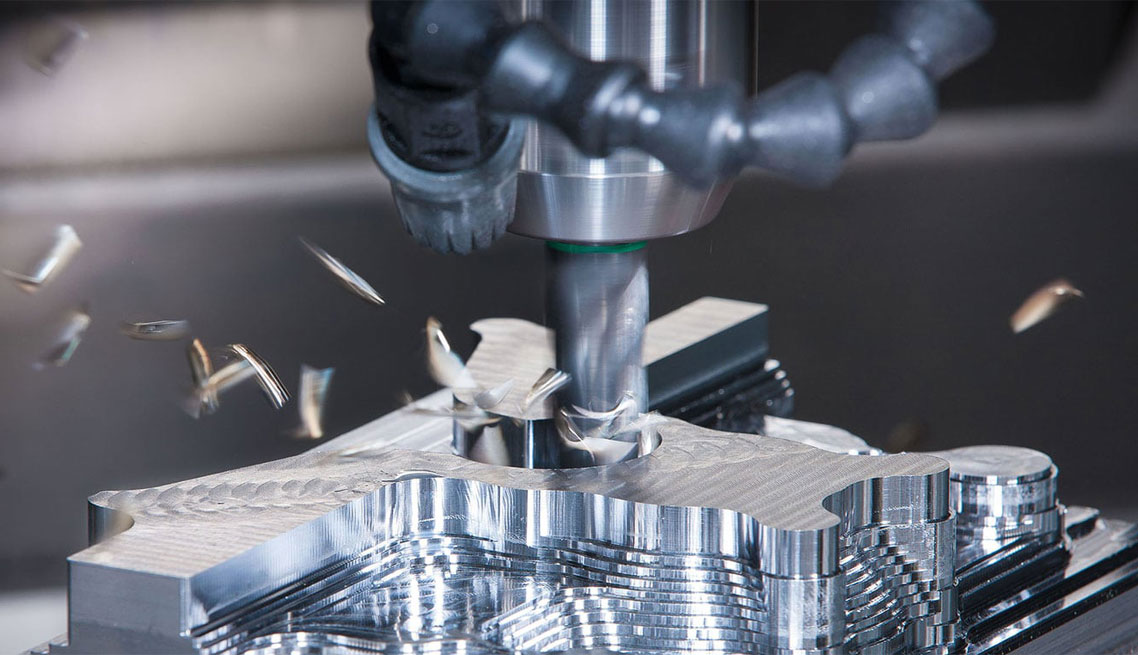

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services tailored for high-performance industries such as aerospace, medical, energy, and automation. At the core of our technical capabilities is a modern fleet of 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly reducing setup time and part handling while maintaining tight tolerances across intricate features. Our machine park includes state-of-the-art equipment from leading global manufacturers, ensuring reliability, repeatability, and superior material removal rates across a wide range of metals and engineering-grade plastics.

All machining operations are supported by in-house programming using advanced CAM software, ensuring optimized toolpaths, efficient cycle times, and full process control from prototype to production. Our engineers work closely with clients during the design-for-manufacturability (DFM) phase to identify potential improvements in part geometry, material selection, and machining strategy—ultimately reducing cost and lead time without compromising performance.

Quality assurance is integral to our manufacturing process. Every component undergoes rigorous inspection using a Zeiss DuraMax and CONTURA G2 coordinate measuring machine (CMM), providing non-contact and tactile measurement with micron-level precision. These systems verify critical dimensions, geometric tolerances, and surface profiles in full compliance with ISO 10360 standards. In addition to CMM inspection, we employ optical comparators, surface roughness testers, and micrometry tools to validate part conformity. All inspection data is documented in detailed first-article inspection reports (FAIR) and available upon request, ensuring full traceability and compliance with industry-specific quality requirements.

Our facility is ISO 9001:2015 certified, reflecting our commitment to continuous improvement and consistent product quality. With a controlled environment and skilled technicians overseeing every stage of production, Wuxi Lead Precision Machinery ensures that each component meets or exceeds customer specifications.

The following table outlines typical machining capabilities and achievable tolerances under standard production conditions:

| Parameter | Specification |

|---|---|

| Machine Types | 5-Axis CNC Machining Centers |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Linear Tolerance (Machining) | ±0.01 mm (typical), down to ±0.005 mm (tight) |

| Geometric Tolerance (GD&T) | ±0.008 mm (form, position, runout) |

| Surface Roughness (Ra) | 0.8 μm (standard), down to 0.2 μm (polished) |

| Materials | Aluminum, Stainless Steel, Titanium, Inconel, PEEK, Brass, Tool Steels |

| Inspection Equipment | Zeiss CMM, Optical Comparator, Surface Tester |

Wuxi Lead Precision Machinery combines cutting-edge technology, stringent quality control, and engineering expertise to deliver precision-machined components that meet the most demanding technical challenges.

Material & Finish Options

Material Selection for Precision CNC Machined Components

Material selection directly impacts performance durability and cost efficiency in precision CNC machining. At Wuxi Lead Precision Machinery we prioritize aligning material properties with functional requirements to avoid over-engineering and unnecessary expenses. This section details critical considerations for aluminum steel and titanium alongside essential finishing processes like anodizing.

Aluminum alloys notably 6061-T6 and 7075-T6 dominate aerospace and electronics due to their optimal strength-to-weight ratio thermal conductivity and corrosion resistance. These grades machine exceptionally well enabling tight tolerances and fine surface finishes. However aluminum lacks the hardness required for high-wear applications without post-machining treatments. Its lower density reduces shipping costs and assembly complexity making it ideal for weight-sensitive components.

Carbon and alloy steels such as 4140 and 1018 provide superior strength hardness and wear resistance for structural parts tooling and heavy machinery. Steel maintains dimensional stability under extreme loads and elevated temperatures. Yet its higher density increases part weight and machining time leading to greater tool wear and cost. Proper heat treatment is often essential to achieve required mechanical properties post-machining.

Titanium Ti-6Al-4V excels in corrosive environments high-stress scenarios and extreme temperatures common in medical implants and aerospace systems. Its exceptional strength-to-weight ratio surpasses steel while resisting saltwater and chemical degradation. Titanium machining demands specialized tooling slower feed rates and rigid setups due to low thermal conductivity and work hardening tendencies. These factors significantly elevate production costs justifying its use only where alternatives fail.

Anodizing remains the premier surface treatment for aluminum enhancing corrosion resistance wear performance and aesthetic control. Type II (sulfuric acid) anodizing offers moderate thickness and dye compatibility for consumer goods. Type III (hardcoat) anodizing delivers thicker harder coatings up to 100 µm for industrial components requiring abrasion resistance. Note anodizing applies exclusively to aluminum; steel and titanium require alternative finishes like passivation or PVD coatings.

Material properties must be evaluated holistically against application demands. The table below summarizes key metrics for common alloys:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Relative Cost |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | Excellent (A) | Low |

| Steel 4140 | 7.85 | 655 | Moderate | Good (B) | Medium |

| Titanium Ti-6Al-4V | 4.43 | 900 | Exceptional | Fair (C) | High |

Selecting the right material requires balancing performance needs with manufacturability. Over-specifying titanium for non-critical parts inflates costs unnecessarily while under-specifying aluminum in high-stress roles risks premature failure. Our engineering team collaborates with clients to validate material choices against operational parameters ensuring optimal lifecycle value. Contact Wuxi Lead Precision Machinery for material consultation tailored to your precision CNC project.

Manufacturing Process & QC

From Concept to Consistency: The Wuxi Lead Precision CNC Production Process

At Wuxi Lead Precision Machinery, we understand that precision is not achieved by chance—it is engineered through a disciplined, tightly controlled production process. Our approach spans three critical phases: Design, Prototyping, and Mass Production. Each stage is engineered to eliminate variability and ensure zero defects in every component we deliver.

The journey begins with Design, where engineering excellence meets application-specific requirements. Our technical team collaborates closely with clients to translate concepts into manufacturable designs. Utilizing advanced CAD/CAM software, we conduct thorough design for manufacturability (DFM) analysis, identifying potential challenges in geometry, material selection, and tolerance stack-up before any metal is cut. This proactive evaluation reduces risk, optimizes toolpaths, and ensures the final design is both functionally robust and production-efficient.

Once the design is validated, we proceed to Prototyping. This phase is not merely a proof of concept—it is a full-scale rehearsal of the production process. Using the same CNC machines, tooling, and quality control protocols intended for volume manufacturing, we produce initial samples under real-world conditions. This allows us to verify dimensional accuracy, surface finish, material performance, and assembly compatibility. Any deviations are analyzed using root-cause methodologies, and process adjustments are implemented before scaling. Clients receive fully documented inspection reports, including CMM (Coordinate Measuring Machine) data, ensuring complete transparency and confidence in the prototype’s fidelity.

With prototype approval, we transition seamlessly into Mass Production. Our automated CNC machining cells, staffed by certified operators and monitored by real-time process control systems, maintain consistent output with minimal human intervention. Every workpiece is machined under controlled environmental conditions, with tool wear monitored via in-process sensors and automated tool compensation. Statistical Process Control (SPC) is applied continuously, ensuring process capability remains within defined limits. At no stage is quality an afterthought—our inline inspection stations perform periodic checks, and final inspection includes full dimensional reporting, material certification, and surface integrity analysis.

Our commitment to zero defects is reinforced by a closed-loop quality management system. Non-conformances are immediately flagged, contained, and analyzed using 8D problem-solving methods. Corrective actions are implemented across all affected batches, and process improvements are fed back into the system to prevent recurrence.

The result is a production pipeline where precision is repeatable, traceable, and guaranteed.

Typical Production Specifications at Wuxi Lead Precision Machinery

| Parameter | Capability |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Tolerance Range | ±0.003 mm to ±0.05 mm (depending on feature) |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, PEEK, Brass |

| Max Work Envelope | 1200 x 800 x 600 mm (3-axis/5-axis) |

| Production Volume Capacity | 1 – 100,000+ units per order |

| Lead Time (Mass Production) | 15–30 days (varies by complexity) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic CNC Manufacturing Advantage

In the high-stakes realm of precision manufacturing, where tolerances dictate success and timelines drive competitiveness, selecting the right CNC machining partner is not merely a procurement decision—it is a strategic imperative. At Wuxi Lead Precision Machinery, we understand that your components are the foundation of critical systems in aerospace, medical devices, energy, and advanced industrial equipment. Compromise on precision is not an option; it demands a partner whose engineering rigor matches your exacting standards and whose operational excellence ensures seamless integration into your supply chain. We deliver more than parts—we deliver certified precision, unwavering reliability, and collaborative engineering solutions that mitigate risk and accelerate your time-to-market.

Why Partner With Lead Precision? Our integrated approach combines cutting-edge technology with deep process mastery, specifically engineered for the most demanding applications. We operate beyond basic machining, providing full-spectrum solutions from complex 5-axis milling and turning to stringent quality assurance and value-added finishing. Our facility is purpose-built for precision, featuring climate-controlled environments, state-of-the-art metrology labs, and a team of veteran CNC engineers dedicated to optimizing every process parameter for your unique requirements. This commitment translates directly to reduced scrap rates, consistent first-pass yield, and components that perform flawlessly in assembly and service.

Our technical capabilities are structured to meet the most stringent global industry benchmarks. The core specifications underpinning our service delivery include:

| Capability Category | Specification Detail | Relevance to Your Project |

|---|---|---|

| Machining Precision | ±0.001 mm (±0.00004″) Tolerance | Ensures flawless fit and function in critical assemblies |

| Machine Fleet | 50+ CNC Centers (Mazak, DMG MORI, Haas); 3-5 Axis Milling/Turning | Handles complex geometries and high-mix production |

| Material Expertise | Titanium, Inconel, Stainless Steels, Aluminum Alloys, Engineering Plastics | Supports demanding material requirements |

| Quality Assurance | ISO 9001:2015 Certified; CMM, Optical Comparators, Surface Roughness Testers | Guarantees traceable, auditable quality control |

| Lead Time Optimization | Rapid Prototyping (72hr); Serial Production Efficiency | Reduces development cycles and inventory costs |

Partnering with Lead Precision means engaging a team that views your challenges as our own engineering puzzles to solve. We proactively identify potential manufacturability issues during the RFQ stage, recommend cost-saving design refinements without sacrificing performance, and maintain transparent communication throughout production. Our goal is to become a seamless extension of your engineering and operations teams, providing the stability and technical depth needed to navigate volatile supply chains and evolving regulatory landscapes.

The cost of a suboptimal machining partner extends far beyond the initial quote—it manifests in production delays, rework expenses, and reputational damage. Precision is non-negotiable in your industry; your machining partner must be equally uncompromising. Contact us today to discuss how Lead Precision can deliver the measurable performance, technical partnership, and supply chain resilience your high-value projects demand. Reach out to our engineering sales team directly at [email protected]. We respond to all technical inquiries within 24 hours and welcome the opportunity to conduct a confidential capability assessment for your most critical components. Let us prove why global leaders in precision manufacturing choose Lead Precision as their strategic CNC partner.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.