Technical Contents

Engineering Guide: Press Mold Ceramics

Engineering Insight: Precision in Press Mold Ceramics Manufacturing

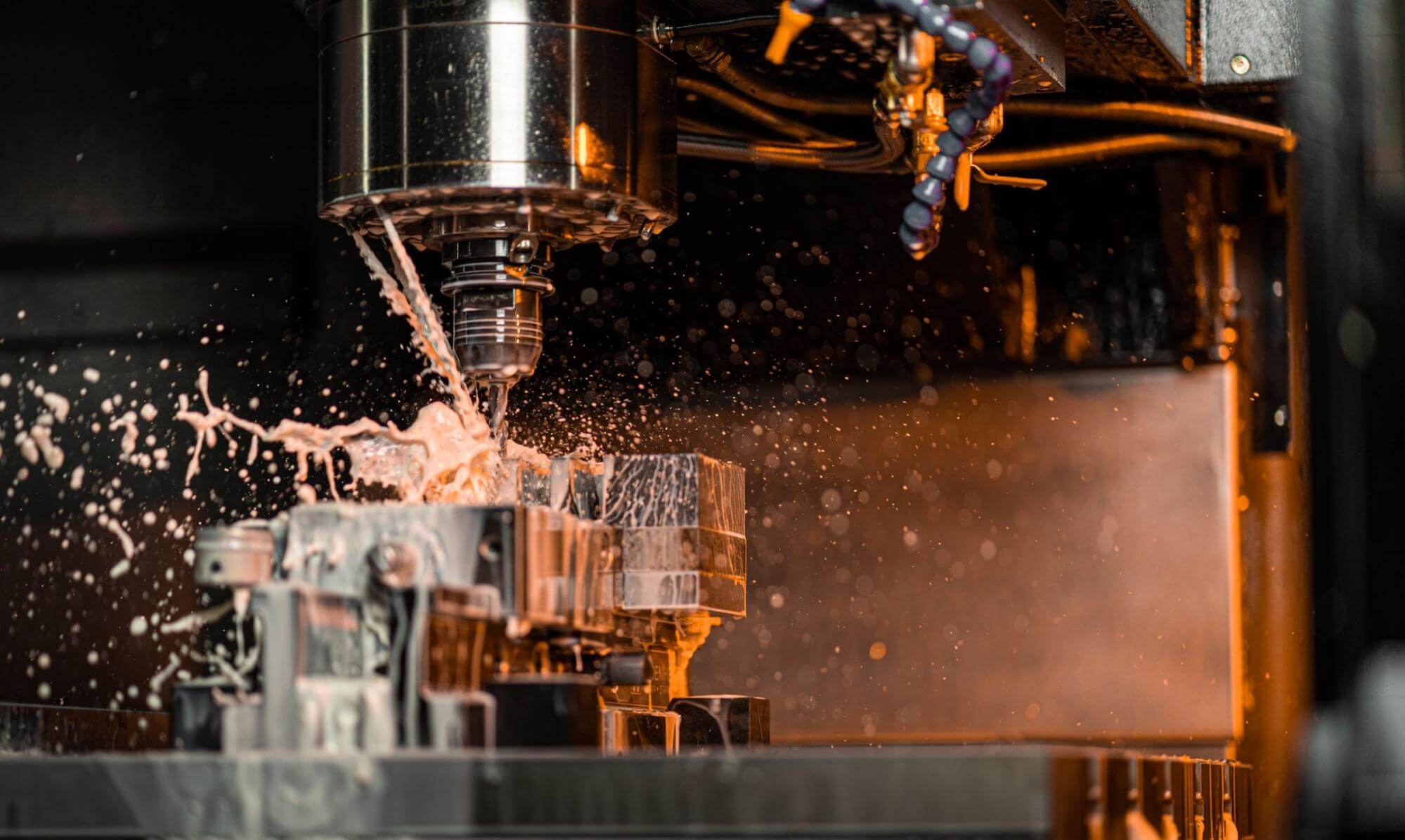

In the realm of advanced manufacturing, press mold ceramics represent a critical intersection of material science and high-precision engineering. These components are essential in applications demanding extreme thermal stability, electrical insulation, and mechanical durability—sectors such as aerospace, defense, and high-performance industrial equipment. At Wuxi Lead Precision Machinery, we recognize that the performance of ceramic components under operational stress is directly tied to the precision of their forming process, particularly during pressing and molding.

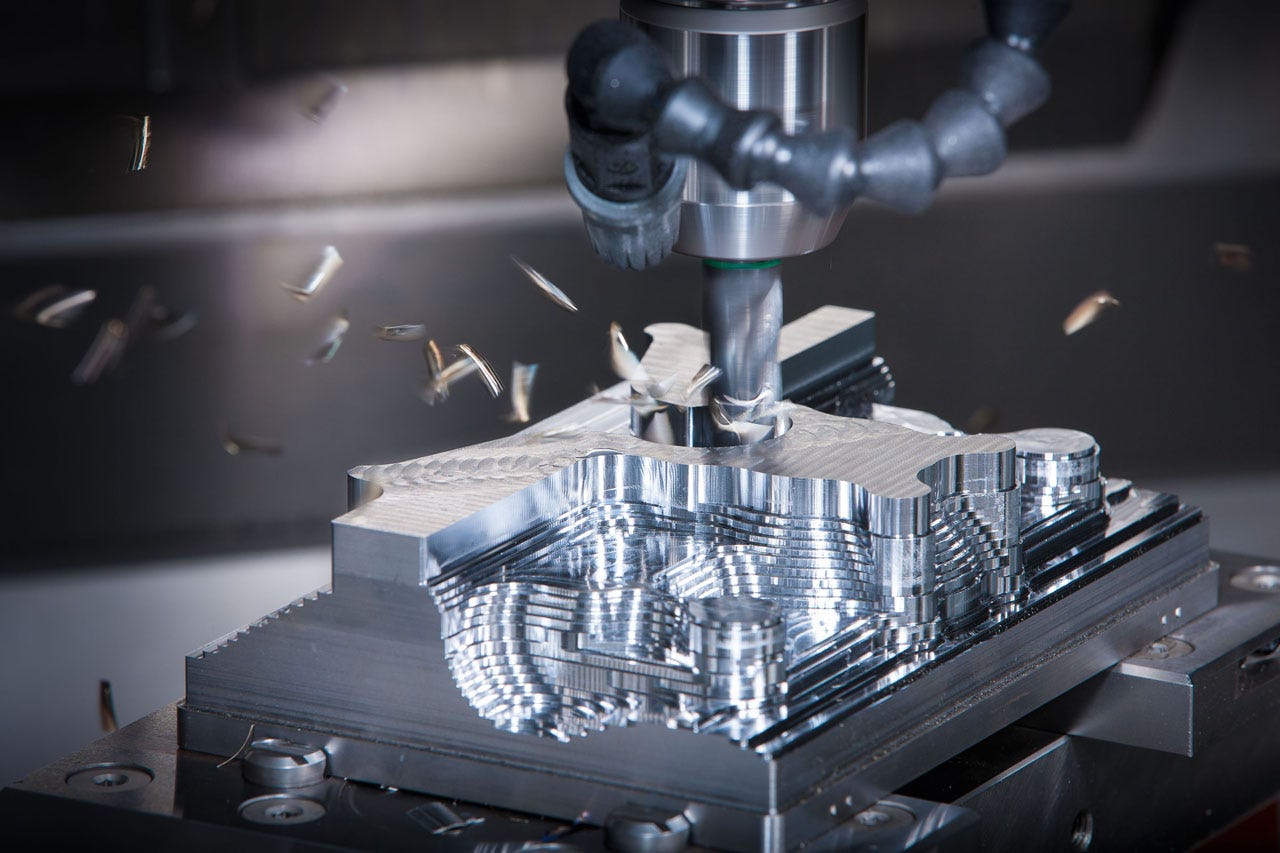

Press mold ceramics are formed under high pressure using precision-engineered dies and molds that define the final geometry and structural integrity of the part. Even micron-level deviations in mold dimensions can result in warpage, density variation, or cracking during sintering—leading to part failure in mission-critical environments. This is why dimensional accuracy, surface finish consistency, and repeatability are non-negotiable in mold fabrication.

Our engineering team at Wuxi Lead applies decades of expertise in custom metal manufacturing to produce molds with tolerances as tight as ±0.002 mm. Utilizing advanced CNC machining centers, coordinate measuring machines (CMM), and 3D metrology systems, we ensure every mold meets exacting specifications. Our proprietary process control protocols allow for consistent replication across large production runs, a capability validated through our contributions to Olympic-standard equipment and military-grade systems.

The materials used in press mold ceramics—such as alumina, zirconia, and silicon nitride—exhibit low ductility and high brittleness, making uniform compaction during pressing essential. A poorly engineered mold can lead to uneven green density, resulting in differential shrinkage and catastrophic failure during sintering. Our molds are designed with optimized cavity geometry, precise venting, and wear-resistant coatings to ensure uniform pressure distribution and extended service life.

Wuxi Lead’s experience in high-stakes manufacturing environments has refined our approach to quality assurance. Every mold undergoes rigorous in-process inspection and final validation to ensure compliance with international standards, including ISO 9001 and AS9100 for aerospace applications. Our clients benefit from reduced scrap rates, improved cycle times, and superior end-part reliability.

We continue to invest in research and development to stay at the forefront of press mold technology, integrating simulation software for stress analysis and flow dynamics to predict and correct potential defects before production begins.

| Specification | Performance Metric |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.05 – 0.2 µm |

| Material Compatibility | Alumina, Zirconia, Silicon Nitride, SiAlON |

| Mold Life (typical) | 50,000 – 100,000 cycles |

| Inspection Equipment | CMM, 3D Laser Scanning, Optical Profilometry |

| Standards Compliance | ISO 9001, AS9100, GB/T 19001-2016 |

Precision in press mold ceramics is not merely a manufacturing objective—it is a foundational requirement for performance, safety, and reliability. At Wuxi Lead Precision Machinery, we engineer every mold with the rigor demanded by the most challenging industrial applications.

Precision Specs & Tolerances

Technical Capabilities for Precision Press Mold Ceramics Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision in the production of press molds for advanced ceramics, where dimensional accuracy directly dictates final part integrity and performance. Our integrated manufacturing ecosystem is engineered specifically to address the unique challenges of ceramic forming processes, including high compaction pressures, stringent surface finish requirements, and the critical need to minimize micro-fractures during ejection. We understand that sub-micron deviations in mold geometry translate directly to unacceptable variations in sintered ceramic components, impacting functionality in demanding applications like semiconductor substrates, medical implants, and aerospace insulators.

Our core competency centers on advanced 5-axis CNC machining, utilizing state-of-the-art HAAS UMC-750 and DMG MORI CTX beta 1250 machines. These platforms provide the simultaneous multi-axis motion essential for creating the complex compound curves, undercuts, and micro-textured surfaces inherent in high-performance ceramic press molds. Integrated Renishaw probing systems enable in-process verification and thermal drift compensation, ensuring consistent accuracy throughout extended machining cycles. Machine tool stability is paramount; our facilities maintain strict environmental controls (±0.5°C) and utilize granite-bed machines with hydrostatic guideways to eliminate vibration-induced errors during the fine finishing passes required for mirror-polished cavity surfaces (Ra < 0.05 µm).

Quality assurance is not a final step but an embedded process. Every critical feature undergoes rigorous validation using our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), equipped with advanced ceramic-tipped probes and VAST XT gold sensor technology. This system performs full 3D geometric dimensioning and tolerancing (GD&T) analysis, including complex profile tolerances, flatness, and positionality across entire mold assemblies. Our CMM programming leverages Calypso software to generate detailed inspection reports traceable to NIST standards, providing clients with unequivocal verification of conformance before mold shipment. This closed-loop process—combining precision machining with metrology-grade verification—ensures molds perform reliably over thousands of pressing cycles, reducing scrap rates and extending tool life significantly.

Material science expertise further enhances our capability. We apply proprietary thermal compensation algorithms during CNC programming, specifically calibrated for the coefficient of thermal expansion (CTE) of common mold materials like H13 tool steel and high-purity tungsten carbide. This proactive adjustment counteracts dimensional shifts occurring during the high-temperature sintering phase of ceramic production, guaranteeing the final pressed green part meets target dimensions post-sintering. Our engineers collaborate closely with clients to understand the specific ceramic compound and pressing parameters, tailoring mold geometry to account for predicted material flow and shrinkage behavior.

The following table details our standard achievable tolerance ranges for critical press mold features, validated under controlled production conditions:

| Feature Type | Dimensional Range | Standard Tolerance (mm) | Precision Tolerance (mm) | Measurement Method |

|---|---|---|---|---|

| Cavity Diameter | 10 – 100 mm | ±0.005 | ±0.002 | CMM / Air Gage |

| Core Diameter | 5 – 80 mm | ±0.004 | ±0.0015 | CMM / Optical Comparator |

| Flatness (Cavity Base) | < 150 mm² | 0.003 | 0.001 | CMM / Optical Flat |

| Profile (Complex) | Full Contour | 0.008 | 0.003 | CMM (3D Scan) |

| Hole Position | Any Location | ±0.005 | ±0.002 | CMM |

This commitment to measurable precision, from initial material selection through final metrology, establishes Wuxi Lead as the strategic partner for manufacturers requiring press molds that deliver exceptional ceramic part consistency, yield, and performance in the most exacting industrial environments.

Material & Finish Options

Material Selection for Press Mold Ceramics in High-Precision Metal Manufacturing

Selecting the appropriate base material for press mold ceramics is critical in achieving optimal performance, longevity, and dimensional accuracy in high-volume production environments. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that integrate advanced material science with precision engineering. For press mold applications involving ceramics, three primary metals stand out: Aluminum, Steel, and Titanium. Each offers distinct mechanical properties, thermal behaviors, and compatibility with ceramic forming processes.

Aluminum is often the preferred choice for prototyping and medium-cycle production due to its excellent machinability, lightweight nature, and superior thermal conductivity. These characteristics allow for faster cooling cycles and reduced energy consumption during operation. However, aluminum’s lower hardness and wear resistance limit its use in high-stress, long-run molding applications. It performs best when paired with non-abrasive ceramic materials and when rapid thermal response is a priority.

Steel, particularly tool steel grades such as H13 or S7, provides exceptional durability, hardness, and resistance to thermal fatigue. This makes it ideal for high-volume press molding of advanced ceramics where dimensional stability and surface finish consistency are paramount. Steel molds maintain structural integrity under repeated thermal cycling and mechanical loading, ensuring longer service life despite higher initial machining costs and longer lead times.

Titanium offers a unique combination of high strength-to-density ratio, excellent corrosion resistance, and thermal stability. While less commonly used due to its high cost and challenging machinability, titanium is advantageous in specialized applications involving aggressive ceramic slurries or elevated operating temperatures. Its resistance to oxidation and galling also makes it suitable for molds requiring minimal maintenance in corrosive environments.

Surface finishing plays a crucial role in mold performance, particularly in preventing ceramic adhesion and facilitating part release. Anodizing is a widely adopted post-processing technique for aluminum molds. This electrochemical process enhances surface hardness, improves wear resistance, and allows for controlled surface porosity, which can be beneficial in managing lubrication or release agent retention. Hard anodizing (Type III) is especially effective, producing a thick, durable oxide layer capable of withstanding repeated molding cycles without degradation.

For steel and titanium molds, alternative surface treatments such as nitriding, PVD coatings, or plasma spraying are typically recommended, as anodizing is not applicable to these materials.

The following table summarizes key mechanical and thermal properties of the three materials:

| Material | Density (g/cm³) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Max Operating Temp (°C) | Typical Use Case |

|---|---|---|---|---|---|

| Aluminum (6061) | 2.7 | 30–35 | 167 | 180 | Prototyping, low-cycle molding |

| Steel (H13) | 7.8 | 48–52 | 35 | 600 | High-volume ceramic pressing |

| Titanium (Ti-6Al-4V) | 4.4 | 36–40 | 7.2 | 600 | Corrosive or high-temp environments |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on production volume, ceramic composition, and operational demands. Our engineering team ensures every mold is tailored for performance, reliability, and cost-efficiency in press mold ceramic applications.

Manufacturing Process & QC

Press Mold Ceramics Production Process: Zero Defects Precision

At Wuxi Lead Precision Machinery, our press mold ceramics manufacturing process for custom metal tooling adheres to uncompromising standards, ensuring flawless ceramic components for demanding industrial applications. We execute a rigorously controlled sequence from initial design through prototyping to high-volume production, with Zero Defects as the core operational mandate. This integrated approach minimizes risk, accelerates time-to-market, and guarantees consistent part integrity under extreme operational conditions.

The Design Phase begins with collaborative engineering utilizing advanced CAD/CAM suites and finite element analysis (FEA). We model mold geometry, material flow dynamics, and thermal behavior specific to the ceramic compound and pressing parameters. Critical tolerances, draft angles, and ejection systems are optimized virtually to prevent common failure modes like cracking, warpage, or density variation. Material selection for the mold steel—typically high-grade H13 or PM-series tool steels—is validated for wear resistance, thermal fatigue life, and dimensional stability under repeated high-tonnage pressing cycles. All designs undergo rigorous internal review against ISO 2768-mK standards before release.

Prototyping transitions virtual models into physical validation. We machine initial mold sets using 5-axis CNC milling and grinding with sub-micron repeatability. These prototypes undergo extensive functional testing on our in-house hydraulic presses, simulating production parameters. Ceramic blanks are pressed, sintered, and subjected to destructive and non-destructive testing (NDT), including CMM verification, X-ray density mapping, and mechanical strength assays. Any deviations trigger immediate design or process correction loops. This phase is non-negotiable for validating form, fit, and function, ensuring the mold design achieves target ceramic density (>99.5% theoretical) and geometric accuracy before committing to full production tooling.

Mass Production leverages our certified ISO 9001:2015 facility with integrated statistical process control (SPC). Each mold cavity is monitored in real-time via embedded sensors tracking pressure, temperature, and cycle time. Every 50th part undergoes automated optical inspection (AOI) against the master CAD model, with laser interferometry confirming critical dimensions. Closed-loop feedback adjusts press parameters instantaneously to maintain conformance. Our Zero Defects protocol mandates 100% traceability via serialized mold identifiers and digital process logs, enabling rapid root-cause analysis. This systematic control ensures sustained output meeting the most stringent aerospace and medical ceramics specifications.

Key production specifications guaranteeing Zero Defects outcomes are maintained throughout:

| Parameter | Capability Range | Measurement Standard | Control Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.025 mm | ISO 2768-mK | In-process CMM + SPC Charting |

| Surface Roughness (Ra) | 0.05 µm to 0.4 µm | ISO 1302 | Profilometer Sampling |

| Mold Hardness | 48-52 HRC | ASTM E18 | Rockwell Tester Verification |

| Ceramic Density | ≥99.5% Theoretical | Archimedes’ Principle | Batch NDT Testing |

| First-Pass Yield | ≥99.98% | Statistical Process Ctrl | Real-time AOI Monitoring |

This disciplined progression—from physics-based design through empirical prototyping validation to SPC-driven mass production—eliminates defects at their source. Wuxi Lead delivers press molds that consistently produce ceramic components meeting your exacting performance requirements, reducing scrap, rework, and total cost of ownership. Partner with us for precision where failure is not an option.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Press Mold Ceramics Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance custom metal manufacturing solutions tailored to the exacting demands of advanced industries. Our expertise in press mold ceramics positions us as a strategic partner for global manufacturers requiring precision, durability, and consistency in high-temperature and high-pressure environments. Whether you are developing components for semiconductor processing, aerospace systems, or energy applications, our engineering-driven approach ensures your molds meet the most rigorous technical standards.

Press mold ceramics demand more than just material expertise—they require a deep understanding of thermal dynamics, mechanical stress distribution, and dimensional accuracy. At Lead Precision, we integrate state-of-the-art CNC machining, advanced metrology, and proprietary surface treatment processes to produce molds that deliver repeatable performance under extreme conditions. Our in-house R&D team collaborates directly with clients to optimize mold geometry, cooling channel design, and ejection systems, ensuring maximum part integrity and production efficiency.

We manufacture using premium-grade ceramic materials such as silicon nitride, zirconia, and alumina, selected for their exceptional wear resistance, thermal stability, and electrical insulation properties. Each mold undergoes comprehensive quality verification, including CMM inspection, thermal cycling validation, and non-destructive testing, guaranteeing compliance with ISO 9001 and international industry standards.

Our manufacturing capabilities are supported by a fully integrated supply chain, allowing rapid prototyping, scalable production runs, and on-time delivery—critical advantages in today’s competitive landscape. From initial concept to final validation, we provide full technical documentation, including GD&T drawings, material traceability reports, and process capability studies.

Below are key technical specifications reflecting our press mold ceramics manufacturing capacity:

| Specification | Capability |

|---|---|

| Material Types | Alumina (Al₂O₃), Zirconia (ZrO₂), Silicon Nitride (Si₃N₄), Custom Composites |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on geometry and size) |

| Surface Finish | Ra ≤ 0.2 µm (polished), Ra 0.8–1.6 µm (machined) |

| Maximum Part Size | 600 mm × 400 mm × 300 mm |

| Minimum Feature Size | 0.3 mm internal radii, 0.5 mm holes |

| Secondary Processes | Laser marking, precision grinding, thermal shock testing |

| Quality Standards | ISO 9001:2015, Full inspection reporting, First article inspection (FAI) |

Partnering with Wuxi Lead Precision Machinery means gaining access to a team committed to engineering excellence and long-term collaboration. We understand that your success depends on reliability, innovation, and responsiveness—values embedded in every stage of our manufacturing process. Let us support your next generation of ceramic mold applications with precision-built solutions designed to exceed expectations.

For technical inquiries or project consultation, contact us at [email protected]. Our engineering team is ready to assist with material selection, design optimization, and production planning—ensuring your project moves seamlessly from concept to reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.