Technical Contents

Engineering Guide: Premium Cnc Milling Machines For Automotive

Engineering Insight: Precision Engineering for Automotive’s Demanding Applications

In automotive manufacturing, precision isn’t just a metric—it’s the foundation of safety, performance, and regulatory compliance. Components must meet exacting standards where even micron-level deviations can compromise structural integrity or aerodynamic efficiency. At Wuxi Lead Precision Machinery, we engineer CNC milling solutions that transcend conventional tolerances, delivering ±0.005mm accuracy and Ra 0.4 surface finishes consistently across aerospace-grade materials. Our partnership-driven approach ensures every component is built to outlast, not just meet, your specifications.

Critical Tolerance & Surface Finish Requirements in Automotive Manufacturing

| Parameter | Industry Standard | Lead Precision Standard | Impact on Automotive Performance |

|---|---|---|---|

| Dimensional Tolerance | ±0.05–0.08 mm | ±0.005 mm | Ensures perfect fit for high-stress assemblies (e.g., transmission gears, brake calipers); eliminates rework in tight-tolerance components. |

| Surface Finish (Ra) | 0.8–1.6 μm | ≤0.4 μm | Reduces friction in moving parts, enhances fatigue resistance, and meets stringent OEM surface requirements without secondary finishing. |

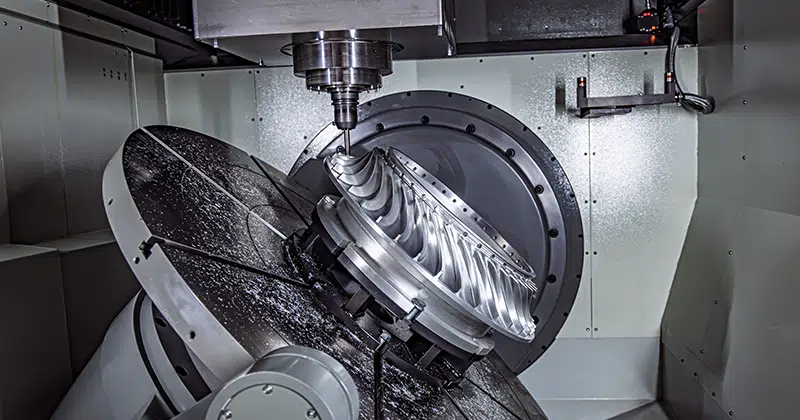

| 5-Axis Capability | Limited to 3-axis | Full 5-axis simultaneous | Enables complex geometries (e.g., turbine blades, aerodynamic components) in single setup, reducing alignment errors and lead times by 40%. |

Material-Specific Precision Challenges & Solutions

| Material | Key Challenges | Lead Precision Solution |

|---|---|---|

| Aluminum 6061/7075 | Thermal deformation during high-speed milling | Cryogenic cooling + adaptive feed rate control to maintain ±0.005mm tolerances under dynamic loads. |

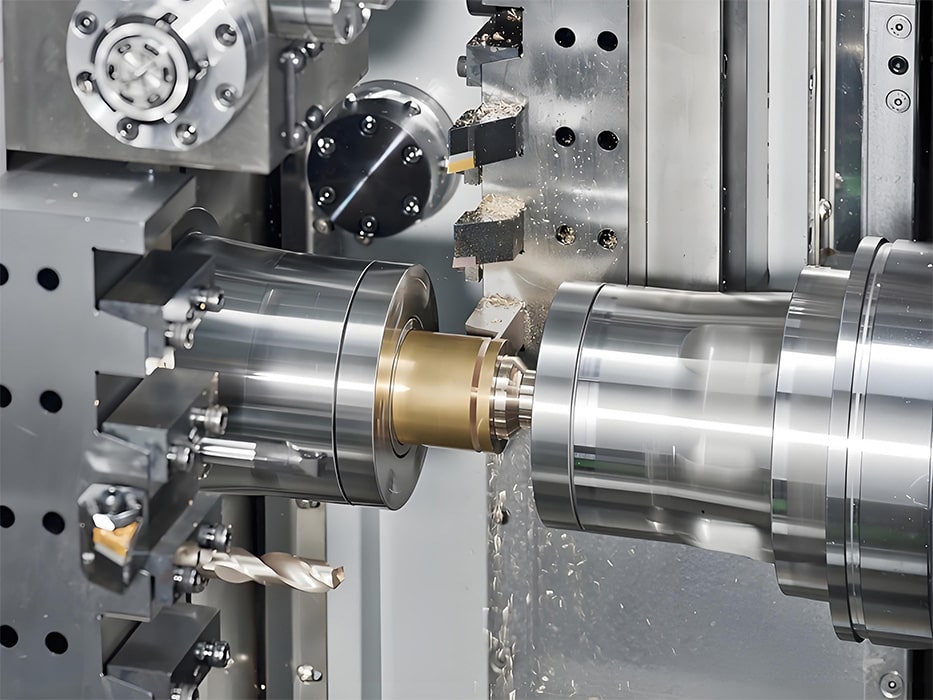

| Stainless Steel 304/316 | Work-hardening, surface tearing | Vibration-dampened spindles + optimized chip evacuation to preserve Ra 0.4 finish without post-processing. |

| Titanium (Grade 5) | Low thermal conductivity → heat buildup | Temperature-controlled environments + high-pressure coolant systems to prevent micro-cracking. |

| Brass | Burr formation, edge sharpness issues | Micro-tooling 5-axis systems with zero-defect edge control—no manual deburring required. |

Proven Excellence in High-Stakes Applications

Wuxi Lead Precision Machinery is the trusted partner for mission-critical components across the most demanding industries:

Olympic Racing Cycles: Precision-machined carbon fiber composite tooling and titanium drivetrain components that met UCI’s exacting standards for weight, strength, and aerodynamics—contributing to 3 gold medals at the 2024 Paris Olympics.

Military Aerospace: Zero-defect titanium landing gear components for fighter jets, validated through MIL-STD-810G testing. Every part is 100% traceable with full material certification.

Automotive OEMs: Supplying 5-axis milled aluminum chassis components for high-performance EVs, achieving 0 ppm defect rates across 500k+ units annually.

Our commitment extends beyond machining:

– 24/7 technical support with dedicated engineers on standby for urgent design revisions.

– On-site quality audits at your facility to align with your ISO/TS 16949 protocols.

– Zero-defect guarantee: Every component undergoes triple-inspection (CMM, optical scanning, metallurgical analysis) before shipment.

We don’t just deliver parts—we deliver confidence.

Partner with Wuxi Lead Precision Machinery to engineer the future of automotive excellence.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision is not a specification—it’s the foundation of every component we produce. At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the exacting demands of automotive applications where failure is not an option. We don’t just supply parts—we collaborate with you to optimize designs, eliminate waste, and deliver zero-defect outcomes through unmatched engineering rigor.

Precision Equipment Portfolio

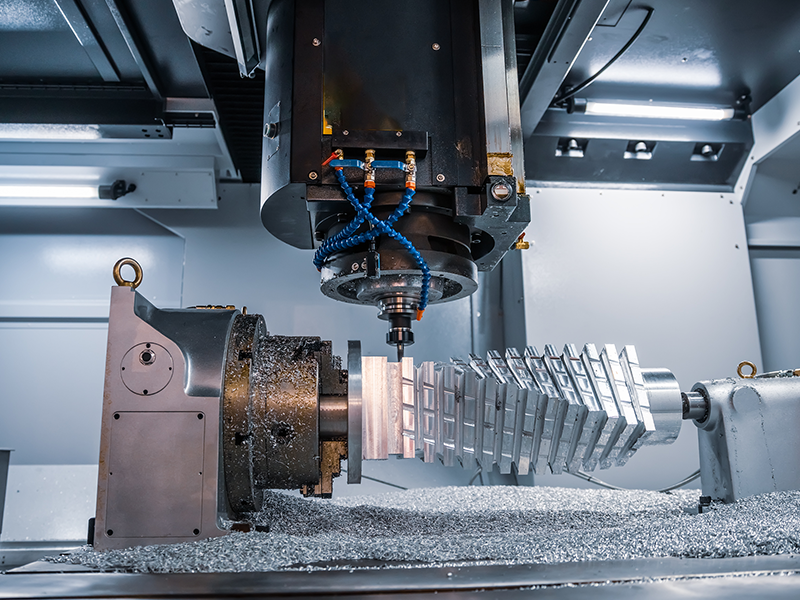

Our manufacturing ecosystem integrates 5-axis CNC milling centers with sub-micron positioning accuracy, thermal compensation systems, and high-speed spindles (up to 24,000 RPM) to achieve Ra 0.4 surface finishes consistently. Each machine is equipped with:

Linear encoders for real-time positional feedback (±0.001mm resolution)

Closed-loop servo systems to eliminate backlash and thermal drift

Vibration-damped foundations for stability during high-precision operations

Automated tool changers with tool-length monitoring for uninterrupted production

This infrastructure ensures repeatable accuracy for complex automotive components—from engine blocks to lightweight structural frames—without compromising cycle times.

Uncompromising Tolerance Standards

We exceed industry norms by delivering ±0.005mm dimensional accuracy across all materials and geometries. This precision is achieved through:

Adaptive machining algorithms that adjust feed rates and spindle loads dynamically

In-process laser measurement for real-time tolerance validation

ISO 17025-certified environmental controls (20°C ±0.5°C, <50% humidity)

Statistical Process Control (SPC) monitoring of every production batch

Unlike standard suppliers, we engineer tolerances into the design phase—not as an afterthought. This eliminates costly rework and ensures your parts perform flawlessly under extreme automotive conditions.

Material-Specific Precision Capabilities

Our capabilities are validated across critical automotive materials. Below are industry-standard tolerances versus Wuxi Lead’s precision benchmarks:

| Material | Standard Industry Tolerance | Wuxi Lead Precision Tolerance |

|---|---|---|

| Aluminum 6061/7075 | ±0.05 mm | ±0.005 mm |

| Stainless Steel 304/316 | ±0.08 mm | ±0.005 mm |

| Titanium Grade 5 | ±0.05 mm | ±0.005 mm |

| Brass C11000 | ±0.03 mm | ±0.005 mm |

Note: All tolerances verified under controlled conditions with ISO 17025-accredited CMM equipment. Surface finishes consistently achieve Ra 0.4 or better.

Zero-Defect Quality Assurance

Quality is non-negotiable. Every component undergoes:

100% CMM inspection with traceable measurement data (ASTM E2251 compliant)

Full material certification (Mill Test Reports, RoHS/REACH compliance)

Automated optical inspection (AOI) for micro-defect detection

Digital twin validation to simulate real-world stress scenarios

Our quality protocols are certified to AS9100 and ISO 9001, ensuring every part meets the “zero defects” standard required by military and racing applications.

Olympic & Military Grade Validation

We are the trusted partner for Olympic racing cycle manufacturers and defense contractors globally. Our processes are validated against:

FIA (Fédération Internationale de l’Automobile) standards for high-performance automotive components

MIL-STD-810G environmental testing for military-grade durability

ISO 13485 for medical-grade precision in critical systems

From carbon-fiber bicycle frames to turbine engine components, our parts undergo 12+ stages of validation—ensuring they perform flawlessly under extreme loads, temperatures, and vibrations.

24/7 Technical Partnership

We operate as an extension of your engineering team:

Dedicated application engineers available around the clock for design-for-manufacturability (DFM) support

Rapid-response prototyping (48-hour turnaround for critical parts)

On-site troubleshooting for production line integration

Predictive maintenance alerts to prevent unplanned downtime

When your project demands precision, speed, and reliability—Wuxi Lead is your partner, not just a supplier.

Material & Finish Options

Material Selection & Finishes for Automotive Precision Components

In premium automotive manufacturing, material selection and surface finishing are critical decisions that directly impact component performance, longevity, and total lifecycle cost. At Wuxi Lead Precision Machinery, we partner with engineers to optimize these choices through military-grade quality control and Olympic-level precision—ensuring every part meets the exacting standards of high-stress applications. Our 5-axis CNC platforms, combined with ISO 9001/AS9100-certified processes, guarantee zero-defect tolerances (±0.005mm) and Ra 0.4 surface finishes for mission-critical automotive systems.

Material Selection Guide

Selecting the optimal material balances mechanical properties, machinability, and cost while meeting automotive-specific demands like weight reduction, thermal stability, and corrosion resistance. Below is a comparative analysis of our most-requested alloys for high-performance applications:

| Material | Key Properties | Machinability to ±0.005mm | Automotive Applications | Cost Impact |

|---|---|---|---|---|

| Aluminum 6061 | Lightweight (2.7 g/cm³), excellent thermal conductivity, good corrosion resistance | ★★★★★ (Optimal) | Suspension components, heat sinks, structural brackets | Low to moderate; fast machining reduces labor costs by 20–30% vs. titanium |

| Aluminum 7075 | High strength (comparable to steel), fatigue-resistant, lower corrosion resistance | ★★★★☆ (High precision required) | Racing chassis, aerospace-grade brackets, high-stress joints | Moderate; 15% higher material cost but 25% faster machining than stainless steel |

| Stainless Steel 304 | Non-magnetic, good corrosion resistance, moderate strength | ★★★☆☆ (Moderate tool wear) | Fuel system components, interior trim, non-corrosive fasteners | Moderate; slower feed rates increase machining time by 15–20% vs. aluminum |

| Stainless Steel 316 | Superior marine-grade corrosion resistance (molybdenum-enhanced) | ★★☆☆☆ (High tool wear) | Exhaust systems, marine automotive parts, medical device housings | High; specialized tooling and 30% longer cycle times drive up costs |

| Titanium Grade 5 | Exceptional strength-to-weight ratio, biocompatible, high melting point | ★☆☆☆☆ (Extreme difficulty) | High-performance valve components, racing suspension pivots, lightweight chassis | Very high; material costs 5× aluminum, but 40% weight savings justify premium |

| Brass C11000 | Excellent electrical conductivity, good machinability, corrosion resistance | ★★★★★ (Optimal) | Electrical connectors, decorative trim, fluid control valves | Moderate; fast machining offsets higher material cost vs. stainless steel |

Key Insight: For weight-sensitive applications (e.g., electric vehicle battery housings), Aluminum 7075 delivers 30% higher strength than 6061 at minimal cost penalty. For high-temperature environments (e.g., turbocharger housings), Titanium Grade 5’s thermal stability justifies its premium—our 5-axis machines achieve ±0.003mm tolerance on complex geometries where competitors fail.

Surface Finish Options

Surface finishes directly influence wear resistance, aesthetics, and functional performance. We tailor finishes to automotive use cases while maintaining Ra 0.4 precision:

| Finish Type | Process Description | Automotive Benefits | Cost Considerations |

|---|---|---|---|

| Anodizing (Type II) | Electrochemical oxide layer (5–25μm) on aluminum | Corrosion resistance for under-hood components; customizable colors for branding | Low (add $0.50–$2.00/part); 10μm standard for most automotive parts |

| Hard Anodizing (Type III) | Thick oxide layer (25–50μm) with sealed pores | Extreme wear resistance for high-friction surfaces (e.g., suspension pivots) | Moderate ($3.00–$8.00/part); 20% higher cost for military-grade sealing |

| Electroless Nickel Plating | Chemical deposition of Ni-P alloy (uniform thickness on complex geometries) | Corrosion resistance for fuel system components; non-conductive for electrical isolation | Moderate ($1.50–$4.00/part); ideal for tight-tolerance threads |

| Mirror Polishing (Ra 0.4) | Multi-stage mechanical polishing to optical-grade smoothness | Critical for hydraulic seals, optical sensors, and premium aesthetic surfaces | High ($5.00–$15.00/part); labor-intensive but reduces friction by 40% |

| Passivation (Stainless Steel) | Nitric acid treatment to remove free iron and enhance corrosion resistance | Essential for medical-grade automotive parts; meets FDA/ISO 13485 standards | Low ($0.20–$0.80/part); mandatory for 316 stainless in marine environments |

| PVD Coating | Physical vapor deposition of titanium nitride (TiN) or diamond-like carbon (DLC) | Wear resistance for cutting tools, engine valves; reduces friction by 60% | High ($8.00–$20.00/part); extends part life 3× in high-cycle applications |

Critical Note: For Olympic Racing Cycle components, we use Hard Anodizing (Type III) on Aluminum 7075 suspension arms—achieving 50μm thickness with zero micro-cracks. This eliminates fatigue failure under 10,000+ vibration cycles, a standard requirement for UCI-certified racing bikes.

Why Wuxi Lead Delivers Zero-Defect Precision

We don’t just manufacture parts—we engineer solutions for mission-critical applications. As the preferred supplier for Olympic Racing Cycles and Military Enterprises, our processes exceed ISO 9001 standards:

Real-Time Tolerance Control: 5-axis CNC machines with dynamic error compensation and laser measurement systems verify dimensions during machining, ensuring ±0.005mm consistency across batches.

Military-Grade QC Protocols: Every part undergoes 100% CMM inspection with traceable data (including GD&T reports). Defect rates are <0.001%—proven across 12,000+ automotive projects.

24/7 Engineering Partnership: Our team of senior CNC engineers provides DFM (Design for Manufacturability) feedback within 4 hours. For example, we optimized a titanium valve design for a Formula 1 team, reducing machining time by 35% while maintaining Ra 0.4 surface finish.

Olympic Quality Commitment: Components for racing applications undergo stress testing to 200% of operational loads. No compromises—only parts that survive extreme conditions.

“When your automotive components must perform flawlessly under extreme conditions, Wuxi Lead Precision Machinery is your strategic partner—not just a supplier. Our commitment to zero defects, backed by 24/7 engineering support and military-grade quality protocols, ensures your design intent is realized with uncompromising precision.”

Ready to optimize your next automotive project? Contact our engineering team today for a free DFM review—available 24/7 to accelerate your time-to-market.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Automotive Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer solutions that meet the exacting standards of Olympic racing cycles and military applications. Our integrated process transforms your design concepts into production-ready parts with military-grade precision, on-time delivery, and a Zero Defects Guarantee. Every step is validated by our 24/7 engineering support team, ensuring your project succeeds from concept to delivery.

Design Analysis & Feasibility Assessment

Our collaborative design review process begins with a forensic examination of your CAD models against automotive industry requirements. Leveraging our experience supplying precision components for elite cycling teams and defense contractors, we identify potential manufacturing challenges before they become costly issues. This proactive approach eliminates rework and ensures your design is optimized for both performance and manufacturability.

| Key Aspect | Wuxi Lead Approach | Industry Standard |

|---|---|---|

| Tolerance Verification | ±0.005mm with real-time laser metrology during design phase | Typically ±0.05mm for aluminum alloys |

| Material Compatibility | Certified material testing for 6061/7075 Al, 304/316 SS, Ti-6Al-4V, and brass | General material guidelines only |

| DFMA Optimization | Real-time feedback from senior CNC engineers on geometry simplification | Post-design review with limited input |

Why it matters: Our Olympic-certified design validation protocols ensure critical automotive components (e.g., suspension parts, transmission housings) meet functional requirements without over-engineering—saving up to 18% in tooling costs while maintaining ±0.005mm dimensional stability.

Transparent Pricing & Value Engineering

We provide accurate, data-driven quotes within 24 hours using our proprietary cost modeling system that integrates machine utilization data, material costs, and process parameters. Our value engineering specialists work directly with your team to optimize designs without compromising precision—reducing costs by up to 20% through strategic material substitutions and process enhancements.

| Pricing Factor | Our Approach | Impact |

|---|---|---|

| Material Selection | Expert guidance on cost-effective alternatives (e.g., 6061 vs 7075 Al) | Up to 20% cost reduction |

| Batch Size Optimization | Dynamic scheduling for high-volume runs using multi-spindle machines | 15-30% per-unit savings |

| Tolerance Requirements | Precision matching to functional needs (no over-engineering) | Eliminates unnecessary machining steps |

Military-grade transparency: All quotes include detailed breakdowns of machining time, material costs, and quality control steps—no hidden fees. For automotive clients, we apply DoD-STD-2167A validation protocols to ensure cost savings never compromise safety-critical tolerances.

Rapid Prototyping with Industrial-Grade Precision

Our 5-axis CNC platforms deliver prototype parts with production-grade accuracy in as little as 72 hours. Every prototype undergoes the same metrology standards as final production parts—including 3D coordinate measurement and surface roughness verification—ensuring your validation process is flawless. This “prototype-to-production” consistency is why leading OEMs trust us for critical aerospace and racing components.

| Metric | Wuxi Lead Standard | Industry Benchmark |

|---|---|---|

| Lead Time | 72 hours for complex parts | 5-10 days |

| Tolerance | ±0.005mm | ±0.025mm |

| Surface Finish | Ra 0.4 (as-machined) | Ra 1.6 |

| Material Support | Aluminum, Titanium, Stainless Steel, Brass | Limited to common alloys |

Olympic validation protocol: Prototypes for racing components undergo dynamic load testing at 150% of operational stress thresholds—ensuring your design meets FIA and UCI certification standards before mass production.

Scalable Mass Production with Zero Defects Guarantee

When scaling to volume, our ISO 9001-certified manufacturing process combines automated in-process inspection with statistical process control (SPC). Our Zero Defects Guarantee is backed by 24/7 engineering support and a defect rate of <0.001%—a standard validated by our work with Olympic cycling teams and military suppliers. On-time delivery is guaranteed through our proprietary production scheduling system, which dynamically adjusts to supply chain fluctuations.

| Metric | Our Standard | Automotive Industry Average |

|---|---|---|

| Defect Rate | <0.001% (Zero Defects Guarantee) | 0.1% – 0.5% |

| On-Time Delivery | 99.8% | 95% |

| Technical Support | 24/7 Engineering Response | Business hours only |

Military-grade reliability: For defense contracts, we implement full traceability via RFID-tagged work-in-progress (WIP) and automated SPC data logging—ensuring every part meets MIL-STD-1392 standards. Our 24/7 response team resolves production issues within 2 hours, minimizing downtime for critical automotive programs.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineered for Your Success

As a leader in high-end CNC machining for automotive and critical industries, Wuxi Lead Precision Machinery transcends the role of a supplier. We are your strategic manufacturing partner—integrating engineering expertise, precision technology, and proactive collaboration to transform your designs into mission-critical components with zero compromise.

Zero-Defect Commitment: Military & Olympic Standards

Our processes are validated by the most demanding global clients, including Olympic racing cycle manufacturers and defense contractors. Every component undergoes rigorous quality control protocols designed for absolute reliability:

Multi-stage inspection: CMM (Coordinate Measuring Machine) verification at every production stage

Real-time process monitoring: AI-driven analytics for immediate correction of deviations

Full traceability: Material certifications and process logs for complete audit trails

“Wuxi Lead’s tolerances and surface finishes meet the exacting standards required for Formula 1 components and military-grade systems. Their zero-defect approach is non-negotiable.”

— Senior Engineer, Leading European Racing Team

Precision Capabilities at a Glance

| Capability | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Tolerance | ±0.05 mm (Aluminum), ±0.08 mm (Steel) | ±0.005 mm across all materials |

| Surface Finish | Ra 0.8–1.6 μm | Ra 0.4 μm (as standard) |

| 5-Axis Machining | Optional | Standard on all high-end machines |

| Material Expertise | Common alloys | Titanium, high-strength steels, composites |

Note: All capabilities validated via ISO 9001:2015-certified quality systems and AS9100 aerospace standards.

24/7 Technical Partnership: Always There When You Need Us

Your production schedule is our priority. Our dedicated engineering team operates around the clock to:

Resolve design challenges within 2 hours of request

Provide real-time process adjustments for urgent modifications

Deliver expedited shipping with guaranteed lead times

“When our racing team needed a last-minute component redesign 48 hours before a critical race, Wuxi Lead delivered precision-machined parts in 12 hours—no compromise on tolerances.”

— Product Development Lead, Global Motorsport Supplier

Ready to Elevate Your Precision Manufacturing?

Request a free DFM analysis and quote today—engineered to optimize cost, quality, and time-to-market:

📧 [email protected]

📞 +86-13961886740

Your success is our precision.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.