Technical Contents

Engineering Guide: Premium Cnc Lathe Machines For Production

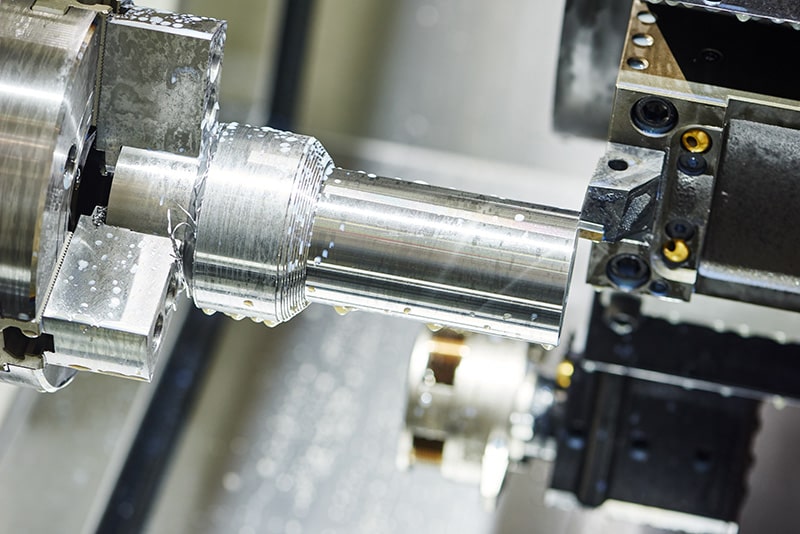

Engineering Insight Precision in Production CNC Lathe Operations

Achieving micron-level consistency is not merely an engineering aspiration in high-volume precision manufacturing; it is the absolute foundation of operational viability and profitability. When producing critical components for aerospace, medical devices, or advanced automation systems, even sub-micron deviations translate directly into scrap, rework, assembly failures, and ultimately, damaged reputations. Premium CNC lathe machines designed for continuous production must transcend basic dimensional accuracy. They require exceptional thermal stability to maintain tolerances through extended shifts, robust structural integrity to resist deflection under heavy cuts, and sophisticated closed-loop control systems capable of real-time error compensation. The cost of inadequate precision extends far beyond the immediate workpiece; it disrupts production flow, consumes valuable engineering time troubleshooting variability, and erodes the trust essential in high-stakes supply chains. True production-grade precision demands machines engineered from the ground up for repeatability under relentless operational demands, not just isolated peak performance.

Wuxi Lead Precision Machinery understands this imperative at the deepest level. Our engineering philosophy is forged through delivering components where failure is not an option. We have supplied mission-critical parts requiring tolerances tighter than ±2μm for precision timing systems used in Olympic Games events, where split-second accuracy defines global competition. Similarly, our facilities consistently meet the rigorous, documented traceability and reliability standards demanded by defense sector partners for sensitive guidance and propulsion components. This experience instills a unique discipline: we design and build our premium production lathes with the same uncompromising focus on deterministic, long-term precision that these elite applications require. It is not about achieving a specification once in a controlled environment, but guaranteeing it thousands of times, shift after shift, in the demanding reality of your factory floor.

The following specifications represent the core precision capabilities engineered into our flagship production lathe series, validated under sustained operational conditions per ISO 230-2 and ISO 230-3 standards:

| Specification Parameter | Performance Value | Industry Standard Benchmark | Significance for Production |

|---|---|---|---|

| Positioning Accuracy (X/Z) | ±1.5 μm | ±3.0 μm – ±5.0 μm | Ensures consistent feature location across all parts, eliminating assembly fit issues |

| Repeatability (X/Z) | ≤0.8 μm | ≤1.5 μm | Guarantees part-to-part uniformity essential for high-volume assembly lines |

| Thermal Growth Compensation | < 2.0 μm/°C (Z) | Typically 5-10 μm/°C | Maintains dimensional stability through ambient temperature shifts during long runs |

| Spindle Runout (TIR) | ≤0.5 μm | ≤1.0 μm | Critical for achieving sub-micron surface finishes and geometric forms on critical diameters |

| Volumetric Compensation | Full 3D Applied | Often Basic Linear Only | Corrects for inherent machine geometry errors across the entire working envelope |

This commitment to measurable, sustainable precision engineering translates directly into your production efficiency. Reduced scrap rates, minimized process validation downtime, extended tool life due to stable cutting conditions, and the confidence to bid on the most demanding contracts are the tangible outcomes. At Wuxi Lead, we engineer premium CNC lathes not just to meet specifications, but to deliver the unwavering precision your production line depends on, day after day. Your requirement for zero-failure output is our fundamental design constraint.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision CNC Lathe Manufacturing

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the rigorous demands of high-volume, high-precision production environments. Our investment in state-of-the-art 5-axis CNC lathe technology enables us to deliver complex, multi-faceted components with exceptional accuracy and repeatability. These machines integrate simultaneous multi-axis motion control, allowing for intricate geometries to be machined in a single setup. This reduces cumulative error, improves part consistency, and significantly enhances production efficiency—critical advantages for industries such as aerospace, medical device manufacturing, and high-performance automotive systems.

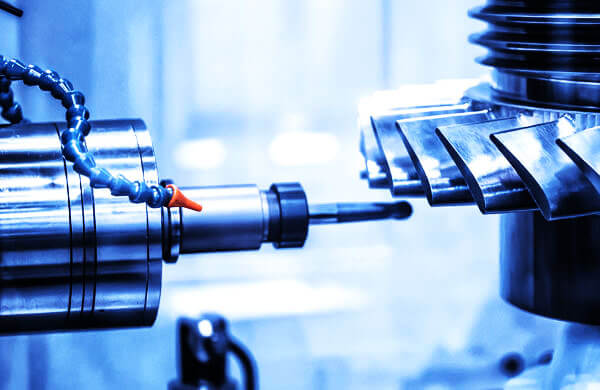

Our 5-axis CNC lathes are equipped with high-speed spindles, advanced tool changers, and real-time adaptive control systems that dynamically adjust cutting parameters based on load and material conditions. This ensures optimal tool life, superior surface finishes, and minimal cycle times. The integration of Y-axis and sub-spindle functionality further expands our machining envelope, enabling off-center milling, drilling, and contouring operations without secondary setups. This level of flexibility is essential for producing complex turned-milled components that require both rotational symmetry and precision features on multiple planes.

To maintain the highest standards of quality, every production batch undergoes rigorous inspection using Coordinate Measuring Machines (CMM). Our metrology lab is equipped with Zeiss and Mitutoyo CMM systems, capable of micron-level accuracy and full 3D geometric dimensioning and tolerance (GD&T) verification. These inspections are not limited to final parts; in-process checks are conducted at critical stages to ensure deviations are identified and corrected in real time. Our quality management system is ISO 9001 certified, and we maintain full traceability for materials, tooling, and inspection data.

Material versatility is another cornerstone of our technical capability. We process a wide range of engineering-grade materials, including aerospace aluminum alloys, titanium, stainless steels, Inconel, and high-performance polymers. Each material is supported by customized cutting strategies, tooling selection, and fixturing solutions designed to minimize deformation and maximize dimensional stability.

The combination of advanced machinery, stringent quality control, and deep process expertise allows Wuxi Lead Precision Machinery to consistently achieve tight tolerances across diverse production runs. Below is a summary of our standard and precision tolerance capabilities.

| Feature | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm | CMM, High-Precision Micrometers |

| Diameter Tolerance (mm) | ±0.01 mm | ±0.003 mm | Air Gaging, CMM |

| Positional Accuracy | ±0.015 mm | ±0.005 mm | CMM, Optical Comparator |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Surface Roughness Tester |

| Angular Tolerance | ±0.05° | ±0.02° | Precision Angle Blocks, CMM |

| Concentricity | 0.02 mm | 0.005 mm | CMM, Dial Indicator (Rotational) |

These capabilities are not static; they are continuously refined through process validation, statistical process control (SPC), and ongoing operator training. Wuxi Lead Precision Machinery remains committed to delivering production-grade CNC lathe solutions that meet the highest benchmarks in precision, reliability, and performance.

Material & Finish Options

Material Selection for Premium CNC Lathe Production

Material choice fundamentally impacts machining strategy, tool life, surface integrity, and final part performance in high-volume CNC lathe operations. At Wuxi Lead Precision Machinery, we engineer our premium lathes specifically to handle the demanding requirements of aerospace, medical, and automotive production materials with exceptional stability and precision. Understanding the interplay between material properties and machine capability is critical for optimizing throughput and part quality.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are prevalent due to their excellent machinability, strength-to-weight ratio, and thermal conductivity. These alloys allow for high spindle speeds and feed rates on capable CNC lathes, enabling rapid material removal. However, achieving consistent surface finishes, especially on complex geometries, requires exceptional machine rigidity to prevent chatter and precise thermal management to avoid dimensional drift. Our lathes feature reinforced cast iron beds and advanced thermal compensation systems specifically tuned for aluminum’s characteristics, ensuring micron-level consistency batch after batch.

Carbon and alloy steels like 4140 and 1045 present higher cutting forces and generate significant heat. Stainless steels, such as 303 and 17-4PH, add work-hardening challenges. Machining these effectively demands robust machine construction, high-torque spindles, and superior coolant delivery. Wuxi Lead lathes incorporate high-stiffness box ways or linear guides with preloaded ball screws, coupled with powerful spindle motors, to maintain accuracy under heavy cuts and resist deflection during deep grooving or threading operations common in steel components.

Titanium alloys (e.g., Ti-6Al-4V) pose the greatest challenge due to low thermal conductivity, high chemical reactivity, and propensity for galling. Successful titanium turning requires precise control of cutting parameters, specialized tooling, and absolutely stable machines to avoid vibrations that cause premature tool failure or surface defects. Our premium lathes utilize vibration-dampening structures and ultra-precise servo systems to deliver the smooth, chatter-free machining essential for titanium, significantly extending tool life and ensuring critical surface integrity.

Anodizing is a vital secondary process for aluminum parts, enhancing corrosion resistance, wear properties, and aesthetics. Type II (sulfuric acid) anodizing provides good general protection and dyeing capability, while Type III (hard coat) anodizing delivers superior thickness and abrasion resistance for demanding applications. Achieving optimal anodizing results starts with a flawless machined surface; any micro-roughness, tool marks, or smearing from subpar machining will be amplified during the anodizing process. Our lathes produce the mirror-like finishes required for high-grade anodized components directly off the machine.

Key material properties directly influencing CNC lathe performance requirements include:

| Material | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Key Machining Challenge | Wuxi Lead Lathe Requirement Emphasis |

|---|---|---|---|---|

| Aluminum 6061 | 310 | 167 | Chatter control, thermal drift | Thermal stability, high-speed rigidity |

| Steel 4140 | 655 | 42 | Cutting forces, work hardening | High torque spindle, machine stiffness |

| Ti-6Al-4V | 900 | 7.2 | Heat concentration, galling | Vibration damping, ultra-precise control |

Selecting the right material necessitates matching it with a CNC lathe engineered for its specific demands. Wuxi Lead Precision Machinery delivers the foundation for success – our premium lathes provide the unwavering stability, precision, and power required to machine aluminum, steel, and titanium to the tightest tolerances and finest finishes demanded by high-end production environments, ensuring your anodized or bare metal components meet the most stringent quality standards.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for premium CNC lathe machines is engineered to deliver uncompromising precision, repeatability, and zero-defect performance. Every machine we manufacture follows a rigorously controlled workflow that begins with advanced design and culminates in high-volume production, ensuring each unit meets the exacting standards of global industrial clients.

The process begins with design engineering, where our team of specialists utilizes advanced CAD/CAM and finite element analysis (FEA) software to develop machine architectures optimized for stiffness, thermal stability, and dynamic performance. Each design is validated through simulation to predict structural behavior under operational loads, ensuring long-term reliability. Material selection focuses on high-grade cast iron for the base and critical components, providing superior damping characteristics and dimensional stability.

Once the design is finalized, we proceed to prototyping. A fully functional prototype is built in-house using the same CNC equipment intended for mass production. This ensures consistency and allows for real-world validation of performance metrics such as spindle accuracy, positioning repeatability, and tool change speed. The prototype undergoes 200+ hours of continuous operation under simulated production loads, with all data logged and analyzed. Any deviations are addressed through iterative refinement, ensuring the design is production-ready before scaling.

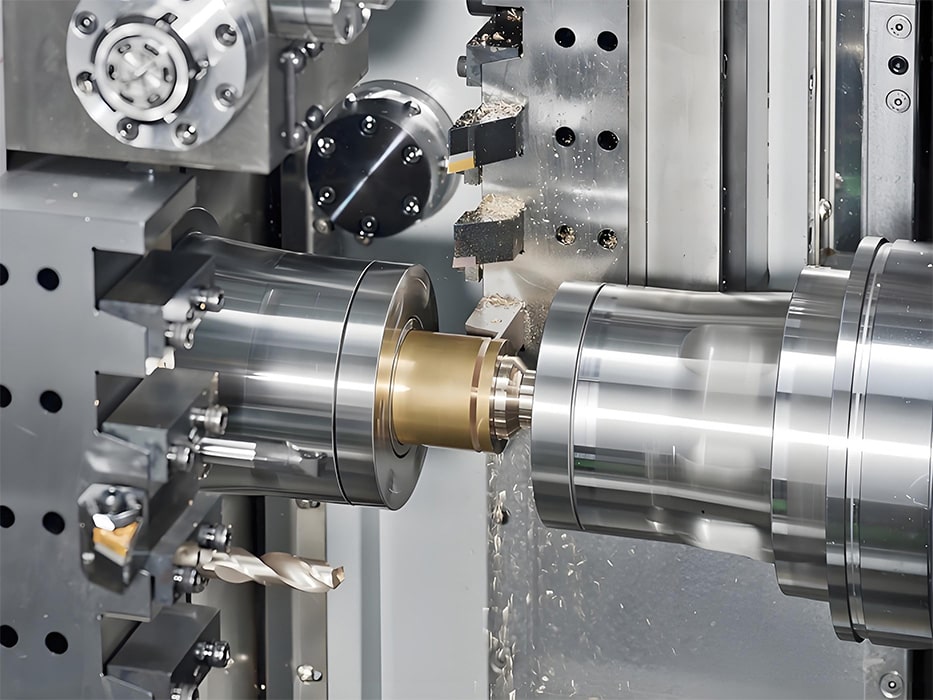

Mass production is executed on a dedicated assembly line staffed by certified technicians following standardized work instructions. Each CNC lathe is assembled in a climate-controlled environment to minimize thermal variation. Critical stages—including spindle mounting, linear guide installation, and ball screw alignment—are performed using laser interferometers and precision measuring instruments to guarantee micron-level accuracy. Every machine undergoes a full diagnostic test cycle, including no-load running, thermal growth analysis, and dynamic positioning verification.

Our zero-defect philosophy is enforced through a multi-tiered quality assurance system. In-process inspections are conducted at 12 key checkpoints, and final inspection includes a 48-hour endurance test under maximum load conditions. Only machines that pass all criteria are released for shipment.

This disciplined approach—from design to delivery—ensures that every premium CNC lathe from Wuxi Lead delivers unmatched performance, durability, and precision in high-volume manufacturing environments.

| Specification | Detail |

|---|---|

| Spindle Runout | ≤ 0.001 mm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Bed Material | Meehanite M30 Cast Iron |

| Linear Guide Type | High-precision preloaded roller guides |

| Spindle Speed Range | Up to 6,000 rpm (optional 12,000 rpm) |

| Tool Turret Capacity | 12, 16, or 24 stations (optional Y-axis) |

| Control System | Fanuc, Siemens, or Mitsubishi (customer-selectable) |

| Cooling System | Dual-circuit, temperature-regulated |

| Vibration Damping | Active mass damper (optional) |

Why Choose Wuxi Lead Precision

Elevate Your Production Floor with Strategic Partnership

In high-volume precision manufacturing, machine tool selection transcends procurement—it defines your operational ceiling. Substandard CNC lathes introduce hidden costs: unplanned downtime erodes throughput, inconsistent thermal performance compromises part quality, and inadequate support strains engineering resources. Wuxi Lead Precision Machinery exists to eliminate these constraints. We engineer premium CNC lathe solutions where reliability, micron-level accuracy, and lifecycle value converge—ensuring your production line operates at peak efficiency, shift after shift.

Our commitment begins with understanding your unique production challenges. Whether machining aerospace turbine components requiring ±2μm tolerances or high-mix medical devices demanding rapid changeovers, Lead Precision delivers tailored solutions. Our machines integrate proprietary thermal compensation systems, rigid cast-iron beds with vibration damping, and Siemens or Fanuc controls optimized for 24/7 operation. This translates to sustained sub-micron repeatability, even in fluctuating shop environments, reducing scrap rates by up to 30% and extending tool life through intelligent feed/spindle synchronization.

Critical Production Specifications at a Glance

| Feature | Lead Precision Advantage | Production Impact |

|---|---|---|

| Positioning Accuracy | ±1.5μm (ISO 230-2 validated) | Zero rework on critical diameters |

| Thermal Stability | Dual-axis compensation system | <3μm drift over 8-hour shift |

| Tool Magazine Capacity | 12/24/40-station options | Unattended runs up to 72 hours |

| Spindle Throughput | 6,000 RPM (C-axis standard) | 22% faster cycle times vs. industry avg |

Partnering with Lead Precision means accessing more than hardware. You gain a dedicated engineering team fluent in global manufacturing standards—from ISO 9001 to AS9100—providing proactive maintenance planning, operator training customized to your workflows, and real-time remote diagnostics. Our global service network ensures 95% spare parts availability within 72 hours, minimizing line stoppages. This holistic approach transforms your capital investment into a predictable, high-yield production asset.

The true measure of a machine tool lies not in its specifications alone, but in its contribution to your bottom line. When uptime, precision, and total cost of ownership are non-negotiable, settle for nothing less than engineered excellence. Contact our production engineering team today to schedule a confidential production analysis. We will assess your current workflow, quantify potential efficiency gains, and propose a solution calibrated to your throughput targets.

Initiate your precision transformation: Email [email protected] with subject line “Production Analysis Request”. Our engineers respond within 24 business hours to discuss your specific volume, material, and tolerance requirements. Partner with certainty—where Lead Precision delivers not just machines, but measurable production outcomes.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.