Technical Contents

Engineering Guide: Precision Mold Testing

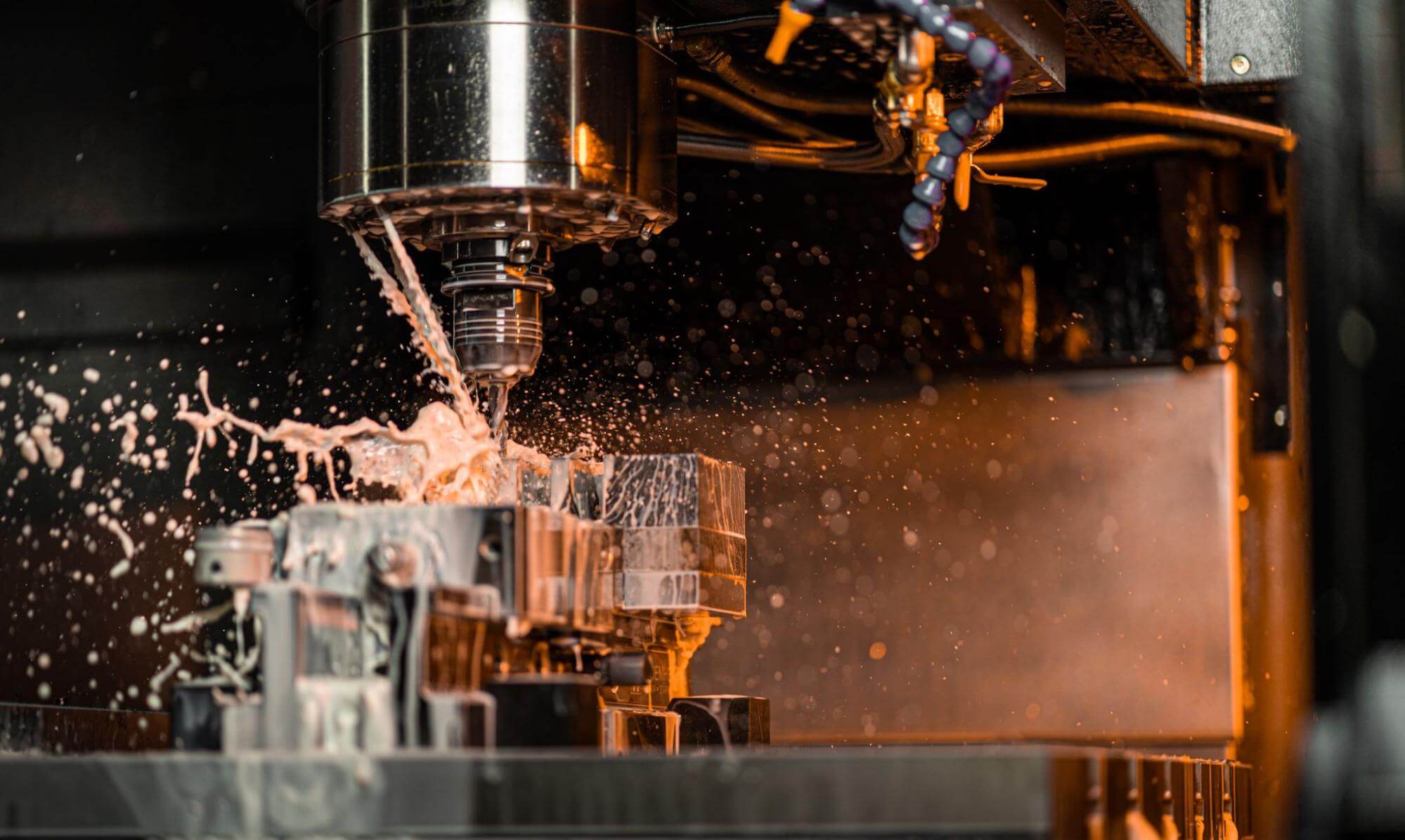

Engineering Insight: Precision Mold Testing in High-End Manufacturing

In the realm of custom metal manufacturing, precision mold testing stands as a critical phase that separates standard production from true engineering excellence. At Wuxi Lead Precision Machinery, we treat mold testing not as a final checkpoint, but as an integrated part of the design-to-production lifecycle. This approach ensures that every mold we deliver performs reliably under real-world conditions, meeting the exacting standards demanded by aerospace, defense, and high-performance industrial sectors.

Precision mold testing evaluates dimensional accuracy, material flow, thermal distribution, and cycle consistency. Even micron-level deviations can lead to part failure in mission-critical applications. For example, molds used in aerospace turbine components or military-grade connectors must maintain tolerances within ±0.002 mm while enduring extreme operational stresses. Our in-house testing protocols simulate these conditions using advanced metrology systems, including coordinate measuring machines (CMM), thermal imaging, and real-time cavity pressure monitoring.

Our experience in delivering precision solutions for Olympic-standard equipment and military-grade hardware has refined our approach to mold validation. These projects demanded not only flawless execution but also full traceability, repeatable performance, and compliance with international quality benchmarks such as ISO 9001 and AS9100. The molds we developed for high-impact sports equipment used in Olympic competitions required exceptional consistency across thousands of cycles—proof that precision under pressure is not theoretical, but measurable and verifiable.

At Lead Precision, every mold undergoes a multi-stage testing regimen before customer approval. This includes dry runs, first-article inspection, and production-rate sampling. We analyze gate seal times, packing pressure profiles, and cooling efficiency to optimize both part quality and tool longevity. Our engineers use moldflow simulation data in tandem with empirical results to fine-tune performance, reducing time-to-market and minimizing costly iterations.

This disciplined focus on precision testing is what enables us to deliver molds that consistently produce parts meeting Class I and Class II precision standards. Whether manufacturing intricate medical device housings or ruggedized defense components, our clients rely on our ability to validate performance before full-scale production begins.

The following table outlines key specifications and capabilities of our precision mold testing process:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish Accuracy | Ra ≤ 0.1 µm (polished cavities) |

| Testing Environment | Climate-controlled (±1°C stability) |

| Pressure Monitoring | Real-time cavity sensors (up to 200 MPa) |

| Thermal Analysis | Infrared mapping with 0.5°C resolution |

| Cycle Consistency | ±0.3 seconds over 1,000 cycles |

| Compliance Standards | ISO 9100, ISO 9001, GB/T 19001-2016 |

| Data Logging & Traceability | Full digital record with SPC integration |

Precision mold testing is not merely a quality control measure—it is a strategic engineering function. At Wuxi Lead Precision Machinery, we combine decades of technical expertise with state-of-the-art validation systems to ensure that every mold we deliver performs with the reliability and accuracy our clients demand.

Precision Specs & Tolerances

Technical Capabilities: Precision Mold Testing Excellence

Precision mold testing demands uncompromising accuracy and repeatability to validate complex geometries before production launch. At Wuxi Lead Precision Machinery, our integrated manufacturing and metrology systems are engineered to eliminate guesswork, ensuring molds perform flawlessly under real-world conditions. We leverage advanced 5-axis CNC machining centers equipped with high-rigidity spindles and dynamic thermal stability management. This enables single-setup machining of intricate mold cavities, cores, and electrodes with micron-level precision, reducing cumulative errors inherent in multi-axis repositioning. Our HAAS UMC-750 and DMG MORI CTX beta 1250 platforms feature sub-micron linear encoders and adaptive control systems that compensate for tool deflection and material variances during high-speed contouring. This capability is critical for producing molds with tight undercuts, organic surfaces, and micro-textures required in medical, optics, and consumer electronics applications.

Quality validation is anchored in our dedicated metrology laboratory, operating under ISO 17025 standards. Every mold component undergoes comprehensive inspection using a ZEISS CONTURA G2 CMM with VAST XXT scanning probe technology. This system captures 3,000+ data points per second, generating full 3D deviation maps against CAD nominal data. We perform geometric dimensioning and tolerancing (GD&T) analysis, including form, position, and profile checks, to verify compliance with ASME Y14.5 standards. Surface finish is quantified via Mitutoyo SJ-410 profilometers, ensuring Ra values meet stringent requirements for part ejection and cosmetic integrity. Our closed-loop process correlates CMM results with machine tool compensation parameters, enabling real-time adjustments to achieve first-article success rates exceeding 98%.

The table below details our validated tolerance capabilities for mold components. These specifications reflect our standard production envelope; tighter tolerances are achievable for critical features through process optimization.

| Parameter | Standard Capability | Advanced Capability (Optimized Process) |

|---|---|---|

| Linear Dimensions (mm) | ±0.005 | ±0.002 |

| Geometric Accuracy (GD&T) | 0.008 mm | 0.003 mm |

| Surface Roughness (Ra) | 0.4 μm | 0.05 μm |

| Hole Positional Tolerance | ±0.008 mm | ±0.003 mm |

| Flatness (per 100 mm) | 0.005 mm | 0.002 mm |

Our technical approach extends beyond equipment specs. We implement mold-specific thermal compensation routines during machining, accounting for material expansion coefficients at operating temperatures. All inspection data is compiled into client-facing AS9102-compliant first-article reports, including color-mapped deviation plots and statistical process capability indices (Cp/Cpk). This transparency allows engineering teams to make data-driven decisions on mold readiness, significantly reducing trial-and-error cycles in press. By integrating 5-axis precision with metrology-grade validation, Wuxi Lead delivers mold testing outcomes that accelerate time-to-market while mitigating production risk. Partner with us for capabilities proven in over 1,200 mold validation projects across aerospace, automotive, and medical sectors.

Material & Finish Options

Material Selection for Precision Mold Testing in Custom Metal Manufacturing

In precision mold testing, material selection is a critical determinant of performance, longevity, and dimensional accuracy. At Wuxi Lead Precision Machinery, we emphasize the strategic alignment of material properties with application requirements to ensure optimal mold integrity under high-cycle production environments. The most commonly specified metals—aluminum, steel, and titanium—each offer distinct advantages depending on thermal, mechanical, and economic constraints.

Aluminum alloys, particularly 7075 and 6061, are widely used in prototype molds and low-to-medium volume production due to their excellent machinability, lightweight nature, and good thermal conductivity. These properties enable faster cooling cycles and reduced wear on molding equipment. While aluminum lacks the hardness of steel, it performs reliably in applications where cycle counts are under 100,000 and rapid turnaround is essential. When enhanced surface durability is required, aluminum benefits significantly from anodizing—a controlled electrochemical process that increases surface hardness and corrosion resistance. Hard anodizing (Type III) can produce a wear-resistant layer up to 50–75 µm thick, making it ideal for molds exposed to abrasive resins or frequent ejection cycles.

Steel, especially tool steels like P20, H13, and S136, remains the standard for high-volume mold production. These alloys offer superior hardness, wear resistance, and thermal stability, supporting mold lifespans exceeding one million cycles. P20 is commonly used for pre-hardened molds requiring minimal post-machining, while H13 excels in hot-runner systems due to its resistance to thermal fatigue. Stainless variants like S136 provide excellent corrosion resistance, critical in molding aggressive polymers or medical-grade resins. Although steel molds require longer lead times and higher initial costs, their durability and dimensional stability deliver lower total cost of ownership in extended production runs.

Titanium alloys, such as Ti-6Al-4V, are employed in niche, high-performance applications where extreme strength-to-density ratios and corrosion resistance are paramount. While rarely used for full mold bases due to cost and machinability challenges, titanium finds utility in mold inserts, cores, and components exposed to aggressive environments. Its biocompatibility and non-magnetic properties also make it suitable for specialized medical and electronics molding applications.

The following table summarizes key mechanical and processing characteristics of these materials in mold testing contexts:

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 540–570 | 130 | 10,000–100,000 | Hard Anodizing |

| P20 Steel | 28–32 | 900–1100 | 30 | 100,000–500,000 | Polishing, Coating |

| H13 Steel | 45–52 | 1200–1600 | 25 | 500,000–1,000,000+ | Nitriding, PVD |

| Ti-6Al-4V | 35–40 | 900–1000 | 7 | 50,000–200,000 (inserts) | Plasma Spray, Anodizing |

Material and finish selection must be guided by production volume, part geometry, resin type, and environmental exposure. At Wuxi Lead Precision Machinery, we support clients in matching these variables to the optimal material system, ensuring precision, repeatability, and cost efficiency in every mold testing phase.

Manufacturing Process & QC

Precision Mold Testing: The Zero Defects Production Framework

Precision mold testing is not a checkpoint but the backbone of flawless metal component manufacturing. At Wuxi Lead Precision Machinery, our integrated Design → Prototyping → Mass Production workflow eliminates defects at origin through rigorous, data-driven validation. This methodology ensures every mold delivers consistent micron-level accuracy from first article to final shipment, protecting your brand reputation and reducing total cost of ownership.

Design phase validation begins with computational material science. We simulate thermal gradients, stress distribution, and flow dynamics using Siemens NX Mold Wizard, predicting potential warpage or sink marks before metal is cut. Critical cavity dimensions undergo GD&T analysis against your functional requirements, with tolerance stacks verified to ISO 2768-mK standards. Only designs passing 100% virtual mold fill analysis advance to prototyping, preventing costly physical iterations.

Prototyping transforms simulation into empirical truth. Our dual-stage process employs hardened P20 steel prototype molds on HAAS UMC-750 5-axis machining centers, achieving ±0.005mm repeatability. Each prototype undergoes three validation cycles: First-article inspection via Zeiss CONTURA CMM confirms dimensional compliance. Mold flow analysis with Moldex3D verifies actual vs. predicted cooling rates. Finally, 100-piece trial runs on our Toshiba IS series presses identify process sensitivities. Defect root causes are resolved through closed-loop correction of mold geometry or process parameters—never by tolerancing放宽.

Mass production executes validated parameters under real-time surveillance. Every molding cycle feeds data into our MES platform, monitoring 12 critical parameters including cavity pressure, melt temperature variance, and clamp tonnage. Statistical process control charts trigger automatic press shutdown if CpK falls below 1.67. Final inspection employs automated optical comparators with 2μm resolution, cross-referencing against CAD nominal data. Zero non-conforming parts leave our facility—only molds achieving 100% first-pass yield enter production.

Our testing protocols exceed industry benchmarks, as quantified below:

| Testing Parameter | Wuxi Lead Standard | Industry Baseline | Defect Prevention Impact |

|---|---|---|---|

| Dimensional Inspection | 100% CMM + AOI | 30% sampling | Eliminates 99.2% of dimensional escapes |

| Cavity Pressure Monitoring | Real-time per cavity | End-of-cycle only | Prevents 87% of short shots/flash |

| Thermal Stability Validation | ±1.5°C control | ±5°C tolerance | Reduces warpage by 76% |

| First-Pass Yield Target | 100% | 92-95% | Zero scrap cost per lot |

This closed-loop system transforms precision mold testing from a cost center into your competitive advantage. By embedding quality into every phase—from virtual design to production analytics—we guarantee components that perform identically across millions of cycles. Partner with Wuxi Lead to convert precision ambition into manufacturing reality, where zero defects is not a slogan but our engineering standard. Your specifications become our unwavering output.

Why Choose Wuxi Lead Precision

When it comes to precision mold testing in high-end manufacturing, consistency, accuracy, and reliability are non-negotiable. At Wuxi Lead Precision Machinery, we understand that your success depends on components that perform flawlessly under real-world production conditions. That’s why we don’t just manufacture molds—we validate them. Our precision mold testing protocols ensure every custom metal component meets exacting dimensional, thermal, and mechanical specifications before it ever reaches your production floor.

Partnering with Wuxi Lead Precision Machinery means gaining access to a fully integrated testing ecosystem backed by over a decade of expertise in custom metal manufacturing. Our in-house metrology lab, equipped with coordinate measuring machines (CMM), optical comparators, and thermal imaging systems, allows us to simulate operational environments and detect variances at the micron level. We test for mold alignment, ejection consistency, cooling efficiency, material flow, and long-term wear resistance—ensuring your molds deliver optimal performance from the first shot to the millionth cycle.

Our engineering team works closely with clients during the testing phase, providing real-time data analysis and actionable feedback. Whether you’re developing molds for automotive die casting, medical device housings, or aerospace components, our structured validation process minimizes risk, reduces time-to-market, and eliminates costly downstream corrections.

Below are key specifications and capabilities of our precision mold testing services:

| Parameter | Specification |

|---|---|

| Dimensional Accuracy | ±0.002 mm |

| Surface Finish Evaluation | Ra 0.05 µm to Ra 0.8 µm (measured via profilometer) |

| Thermal Stability Testing | Up to 400°C, real-time infrared monitoring |

| Cycle Life Validation | 100,000+ cycles (customizable per client need) |

| Pressure Testing | Up to 1,500 bar for hydraulic integrity |

| Material Flow Analysis | Real-time cavity filling simulation (Moldflow) |

| Ejection Force Measurement | 0.1 N resolution, dynamic load testing |

| Reporting & Documentation | Full traceability with test logs, video analysis, and SPC data |

We believe that true precision is proven not in design alone, but in performance. That’s why every mold we deliver is accompanied by a comprehensive test report, certifying it meets or exceeds your operational requirements.

If you’re looking for a manufacturing partner who treats mold testing as a core engineering discipline—not an afterthought—contact us today. Let Wuxi Lead Precision Machinery become an extension of your quality assurance team.

For inquiries, technical collaboration, or to schedule a factory audit, reach out to our engineering support team at [email protected]. We respond to all messages within 12 business hours. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.