Technical Contents

Engineering Guide: Precision Milled Parts

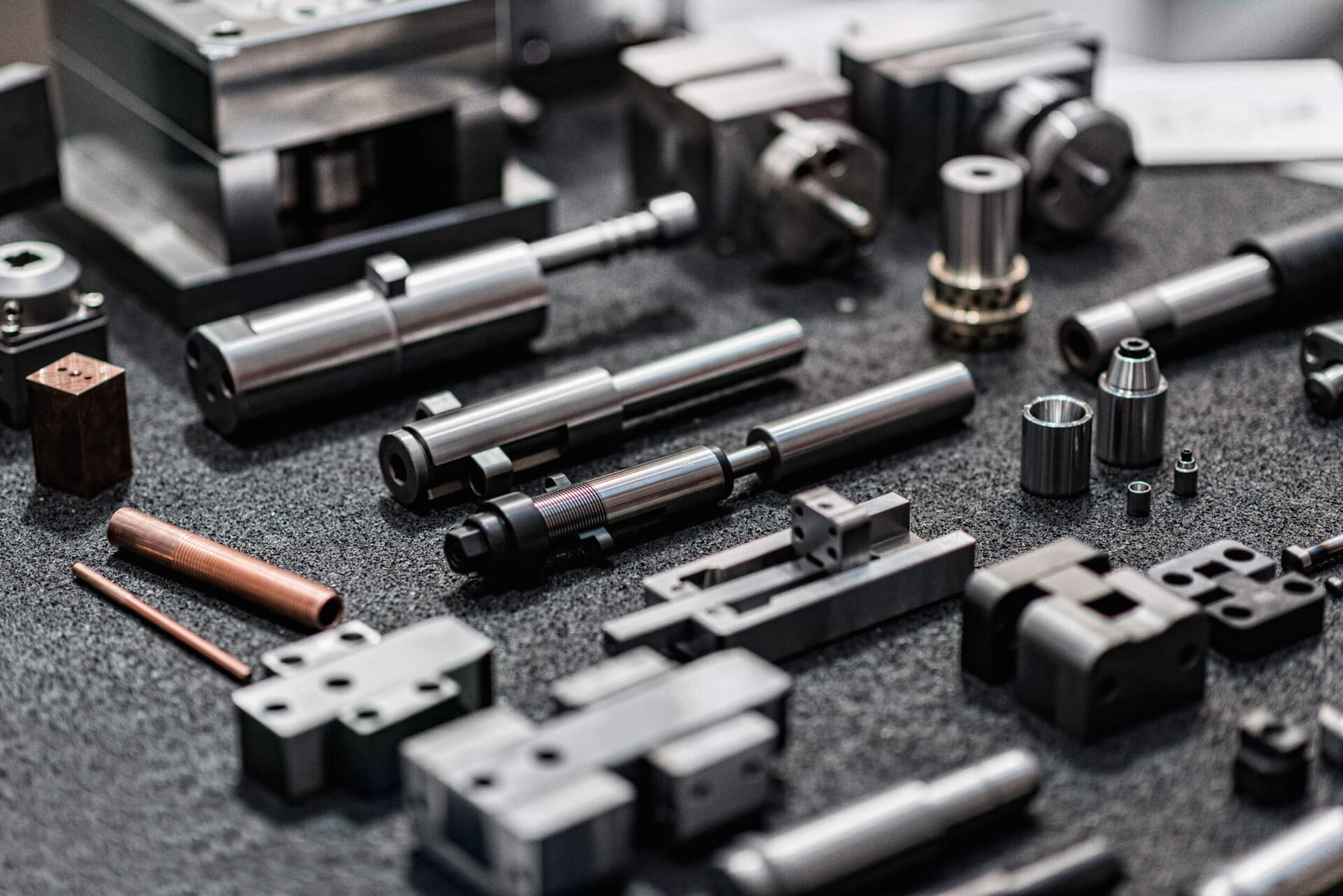

Engineering Insight Precision Milled Parts

Precision in milled components transcends mere dimensional accuracy; it is the foundational element determining functional integrity, assembly success, and ultimate product lifecycle performance. In high-stakes industries like aerospace, medical device manufacturing, and advanced defense systems, tolerances measured in microns directly impact safety, efficiency, and regulatory compliance. A deviation of even 0.005mm in a critical turbine blade or surgical implant interface can cascade into catastrophic system failure, costly field recalls, or compromised patient outcomes. This relentless demand for perfection defines the modern precision milling landscape, where consistency across micro-scale features and complex geometries is non-negotiable. Achieving this requires marrying advanced multi-axis CNC technology with deep metallurgical understanding and rigorous process control – capabilities honed through decades of solving the most demanding manufacturing challenges.

At Wuxi Lead Precision Machinery, we operate at this exacting threshold daily. Our engineering philosophy centers on eliminating variability at every process stage, from raw material certification through thermal stress management and final metrology. This discipline is proven in applications where failure is not an option. We have supplied mission-critical components for Olympic-caliber timing systems demanding nanosecond synchronization accuracy and fabricated structural elements for next-generation military platforms subjected to extreme environmental stresses. These projects exemplify the convergence of ultra-precise machining, material science expertise, and uncompromising quality assurance protocols required to meet Tier 1 aerospace and defense specifications. Our clients achieve not just parts, but certified, traceable solutions that integrate seamlessly into their highest-value assemblies.

The tangible output of this commitment is reflected in our core manufacturing capabilities, consistently delivered across diverse client programs:

| Critical Parameter | Capability Range | Industry Standard Context |

|---|---|---|

| Dimensional Tolerance | ±0.001mm to ±0.005mm | Exceeds ISO 2768-mK, AS9100 |

| Surface Roughness (Ra) | 0.1µm to 0.8µm | Meets aerospace sealing specs |

| Geometric Tolerance | Positional ±0.003mm | Critical for multi-component |

| Flatness 0.001mm/100mm | assemblies in medical devices | |

| Material Range | Titanium alloys, Inconel, | Supports extreme environment |

| Stainless steels, Aluminum | applications | |

| (Aerospace grades), Tool Steels |

True precision engineering demands more than machinery; it requires a culture where every spindle rotation and probe measurement is treated as mission-critical. Wuxi Lead Precision Machinery leverages its proven experience in Olympic and military-grade production to deliver this level of reliability for all precision milled parts. We transform complex engineering drawings into flawless physical realities, ensuring your components perform exactly as designed – every time. This is the standard for which high-performance industries settle.

Precision Specs & Tolerances

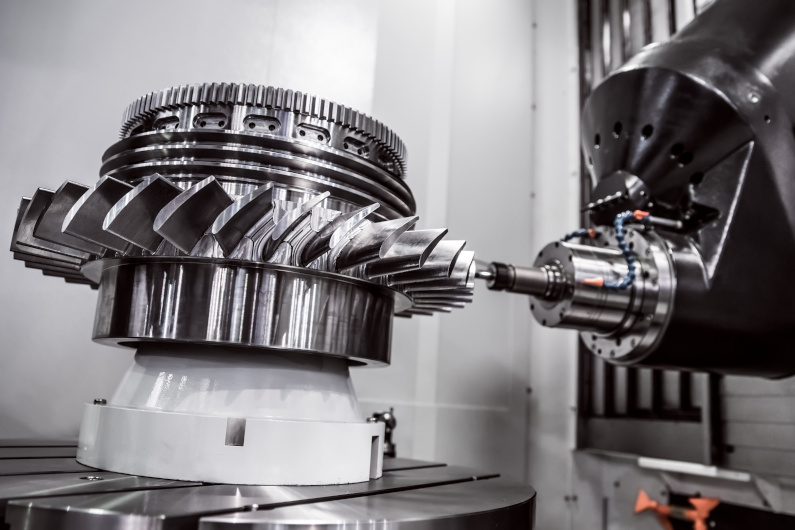

Advanced 5-Axis CNC Machining for Precision Milled Parts

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the most demanding requirements in high-precision metal manufacturing. We specialize in custom precision milled parts using state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. Our machining platforms integrate simultaneous multi-axis motion, allowing for intricate contours, undercuts, and compound angles that are unattainable with conventional 3-axis systems. This advanced capability significantly reduces the need for multiple setups, minimizing cumulative tolerances and improving part consistency.

Our 5-axis CNC machines are equipped with high-speed spindles, automated tool changers, and real-time tool wear compensation, ensuring optimal performance across a wide range of materials—including aluminum alloys, stainless steel, titanium, and high-performance engineering alloys. Each machine is operated by certified CNC programmers and machinists who utilize industry-leading CAM software to generate optimized toolpaths, ensuring efficient material removal and superior dimensional control. The integration of dynamic workholding solutions and in-process probing further enhances setup repeatability and machining precision.

To guarantee compliance with stringent quality standards, every precision milled part undergoes comprehensive inspection using coordinate measuring machines (CMM). Our metrology lab is equipped with high-accuracy CMM systems capable of full 3D geometric dimensioning and tolerancing (GD&T) verification. This closed-loop quality control process ensures that all components meet or exceed customer-specified tolerances. Inspection reports are fully documented and traceable, supporting industries such as aerospace, medical devices, and high-performance automotive, where reliability and compliance are non-negotiable.

We maintain strict environmental controls in both machining and inspection areas to minimize thermal variation, a critical factor in sustaining micron-level accuracy. In addition to CMM inspection, we employ additional quality assurance methods including surface roughness testing, optical comparison, and first-article inspection (FAI) reporting upon request.

The following table outlines our standard machining capabilities and achievable tolerances:

| Specification | Capability |

|---|---|

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 750 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Linear Tolerance (ISO 2768-m) | ±0.05 mm |

| Precision Tolerance (Custom) | ±0.005 mm |

| Geometric Tolerance (Flatness, Perpendicularity) | 0.01 mm per 100 mm |

| Surface Roughness (Ra) | As low as 0.4 μm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, Inconel, Tool Steels, Engineering Plastics |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality control to deliver precision milled parts that meet the highest standards of performance and reliability. Our technical expertise ensures that every component is manufactured to exacting specifications, supporting innovation and excellence in advanced manufacturing applications.

Material & Finish Options

Material Selection for Precision Milled Components: Engineering Performance First

Selecting the optimal material is foundational to achieving precision, durability, and cost efficiency in custom milled parts. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your functional requirements, environmental exposure, and lifecycle demands. Aluminum, steel, and titanium dominate high-performance applications, each offering distinct advantages. Understanding their metallurgical behavior during CNC milling ensures dimensional stability and surface integrity.

Aluminum alloys, particularly 6061 and 7075, deliver an exceptional strength-to-weight ratio and thermal conductivity. They machine rapidly with minimal tool wear, making them ideal for aerospace brackets, heat sinks, and automotive housings where weight reduction is critical. However, 7075’s higher strength comes with reduced corrosion resistance versus 6061, necessitating protective finishes in harsh environments.

Carbon and alloy steels like 4140 and 303 stainless provide superior hardness, wear resistance, and structural integrity. 4140 excels in high-stress applications such as shafts and tooling after heat treatment, while 303 stainless offers excellent machinability and corrosion resistance for medical or marine components. Steel’s higher density and thermal expansion require precise thermal compensation during milling to maintain tight tolerances.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are indispensable for extreme conditions demanding high strength, fatigue resistance, and biocompatibility. Common in aerospace landing gear and medical implants, titanium’s low thermal conductivity challenges heat dissipation during milling, increasing tooling costs. Its corrosion immunity often justifies the premium for mission-critical parts exposed to saltwater or chemicals.

Surface finishes further enhance performance and longevity. Anodizing is the gold standard for aluminum, creating a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing accepts dyes for identification and moderate wear resistance, while Type III (hard coat) anodizing delivers exceptional abrasion resistance for hydraulic components or fixtures. Note that anodizing adds 5–25µm per surface, requiring pre-finishing to final dimensions.

Below is a comparative overview of key material properties for precision milling:

| Material | Key Alloys | Tensile Strength (MPa) | Machinability Rating (1-5) | Primary Applications |

|---|---|---|---|---|

| Aluminum | 6061, 7075 | 310, 572 | 4.5, 3.0 | Aerospace, heat management, enclosures |

| Steel | 4140, 303 SS | 655, 620 | 3.5, 2.5 | Tooling, shafts, medical devices |

| Titanium | Ti-6Al-4V | 900 | 1.5 | Aircraft structures, implants |

Material choice directly impacts manufacturability, lead time, and total cost. At Wuxi Lead, our engineering team collaborates early in your design phase to model material behavior under CNC processes, ensuring optimal selection without over-engineering. We rigorously validate material certifications to ISO 9001 standards, guaranteeing traceability from raw stock to finished component. Partner with us to transform material science into precision reality.

Manufacturing Process & QC

Precision Milled Parts: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, the production of precision milled parts follows a rigorously controlled sequence designed to ensure absolute dimensional accuracy, repeatability, and zero defects. Our process integrates advanced engineering with real-time quality assurance across three core phases: Design, Prototyping, and Mass Production.

The journey begins with collaborative design engineering. Our technical team works directly with client specifications, utilizing CAD/CAM software to model parts with micron-level tolerances. This stage includes material selection, geometric dimensioning, and tolerance analysis (GD&T), ensuring manufacturability and performance under operational conditions. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are conducted to preempt potential structural or machining challenges. This proactive engineering approach eliminates costly revisions later in the production cycle.

Once the design is finalized, we proceed to prototyping. Using 5-axis CNC milling centers, we produce functional prototypes from the specified production-grade material—typically aluminum alloys, stainless steel, titanium, or engineered brass. These prototypes undergo comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional reports and first-article inspection (FAI) documentation are provided to the client for approval. This stage validates not only the part geometry but also the machining strategy, tooling setup, and quality control protocols.

Upon client sign-off, we transition to mass production. Our facility leverages automated CNC machining cells with tool presetters, in-process probing, and real-time monitoring systems to maintain consistency across high-volume runs. Each operation is governed by standardized work instructions and statistical process control (SPC) metrics. Every batch undergoes 100% critical dimension inspection, with non-destructive testing (NDT) applied where required. Our quality management system is ISO 9001:2015 certified, and we adhere to Six Sigma principles to drive toward zero-defect output.

Traceability is maintained through serialized part tracking and digital process logs. Final parts are cleaned, deburred, and packaged per client requirements, with full inspection reports delivered with each shipment.

Typical Production Specifications

| Parameter | Capability |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Roughness (Ra) | 0.4 µm to 3.2 µm |

| Maximum Part Size | 800 mm × 600 mm × 500 mm |

| Minimum Feature Size | 0.5 mm diameter (milled holes/pockets) |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass (C3604), Copper, and Engineering Alloys |

| Production Volume Range | 1 – 100,000+ units |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Mass Production) | 15–30 days (volume-dependent) |

Our end-to-end process ensures that every precision milled part meets the highest standards of quality, performance, and reliability—delivered on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Components

When your application demands uncompromising accuracy in precision milled parts, partnering with a manufacturer possessing deep engineering expertise and advanced capabilities is non-negotiable. Wuxi Lead Precision Machinery delivers beyond standard CNC machining services. We specialize in complex, tight-tolerance components for aerospace, medical device, semiconductor, and energy sectors where failure is not an option. Our integrated approach combines decades of experience in high-mix, low-volume production with cutting-edge multi-axis CNC technology and rigorous quality systems. We understand that your success hinges on parts that perform flawlessly under extreme conditions, meet stringent regulatory requirements, and arrive on schedule.

Our facility operates under AS9100D and ISO 13485 certifications, ensuring every process—from material sourcing to final inspection—is controlled and traceable. We invest continuously in 5-axis milling centers, high-speed machining, and in-process probing systems to achieve micron-level precision consistently. Unlike volume-focused shops, we prioritize engineering collaboration. Our team engages early in your design phase, providing actionable Design for Manufacturability (DFM) feedback to optimize part geometry, reduce costs, and accelerate time-to-market. This proactive partnership prevents costly revisions and production delays, transforming your technical challenges into reliable, high-performance solutions.

The table below outlines our core capabilities for precision milled components:

| Specification Category | Capability Detail |

|---|---|

| Material Expertise | Titanium (Gr 2, 5), Inconel 718/625, Stainless Steel (316L, 17-4PH), Aluminum (7075, 6061), Tool Steels, Exotic Alloys |

| Dimensional Tolerance | ±0.0002″ (5 µm) standard; ±0.00008″ (2 µm) achievable with special processes |

| Maximum Work Envelope | 2000 x 1000 x 800 mm (78.7 x 39.4 x 31.5 in) |

| Surface Finish | As low as Ra 0.4 µm (16 µin); micro-milling for critical sealing surfaces |

| Secondary Operations | Precision grinding, honing, laser marking, passivation, anodizing coordination |

| Quality Assurance | 100% CMM inspection reports, GD&T analysis, material certification, first-article inspection (FAI) per AS9102 |

We eliminate the risks associated with offshore manufacturing through transparent communication, real-time production visibility, and dedicated engineering support. Our commitment to quality is embedded in every spindle rotation, ensuring your components meet the most demanding specifications without compromise. When prototype validation transitions to production, our scalable processes maintain consistency across batches, providing the reliability your supply chain requires.

Do not let subpar machining partners jeopardize your product’s performance or reputation. Contact Wuxi Lead Precision Machinery today to discuss your most challenging precision milled part requirements. Email [email protected] to request a confidential design review and DFM analysis. Our engineering team will respond within 24 business hours with actionable insights tailored to your project. Partner with us to transform precision into performance—and accelerate your time-to-market with confidence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.