Technical Contents

Engineering Guide: Precision Machining Company Georgia

Engineering Insight: The Critical Role of Precision in Modern Manufacturing

In the realm of custom metal manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and innovation are built. For industries ranging from aerospace and defense to medical and high-performance automotive, the margin for error is effectively zero. A deviation of even a few microns can compromise structural integrity, disrupt system functionality, or lead to catastrophic failure in mission-critical applications. This uncompromising demand for accuracy defines the standard by which leading precision machining companies operate, particularly those serving high-stakes markets such as Georgia’s growing advanced manufacturing sector.

Georgia has emerged as a strategic hub for industrial innovation, with increasing demand for domestic and international partners capable of delivering tight-tolerance components under rigorous quality protocols. While local capabilities continue to expand, global leaders like Wuxi Lead Precision Machinery provide a vital extension of capacity, combining advanced CNC machining technologies with decades of engineering discipline. Our facility in Wuxi, China, operates under ISO 9001 and AS9100 certifications, ensuring compliance with international aerospace and defense standards—credentials that align seamlessly with the expectations of Georgia-based OEMs and Tier-1 suppliers.

Precision machining transcends the capability of high-end equipment; it is rooted in process control, material science expertise, and engineering foresight. At Wuxi Lead, our experience includes manufacturing components for Olympic-level sports technology, where performance under extreme conditions demands micron-level consistency, and for military-grade systems, where component failure is not an option. These projects require more than just machining accuracy—they demand a culture of precision that permeates every stage from design validation to final inspection.

Our approach integrates multi-axis CNC milling, turning, and grinding with in-process metrology and 3D laser scanning, ensuring that every part conforms to specification. We specialize in difficult-to-machine alloys such as Inconel, titanium, and hardened steels, materials commonly specified in Georgia’s defense and energy sectors. Furthermore, our rapid prototyping and low-volume production services enable agile development cycles, supporting innovation without sacrificing quality.

The following table outlines key capabilities that define our precision machining performance:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.001 mm to ±0.005 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centers; CNC turning centers |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (custom finishes available) |

| Quality Standards | ISO 9001, AS9100, GD&T compliant |

| Secondary Operations | Heat treatment, anodizing, passivation, precision grinding |

For Georgia’s precision machining partners, collaboration with globally certified suppliers like Wuxi Lead Precision Machinery ensures access to scalable, high-integrity manufacturing solutions. In an era where performance is measured in microns, precision is not optional—it is imperative.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision for global clients seeking advanced custom metal manufacturing solutions. Our core strength lies in mastering complex geometries and stringent tolerances demanded by aerospace, medical, energy, and defense sectors. Central to this capability is our integrated manufacturing and quality ecosystem, engineered for repeatability and traceability from raw material to finished component.

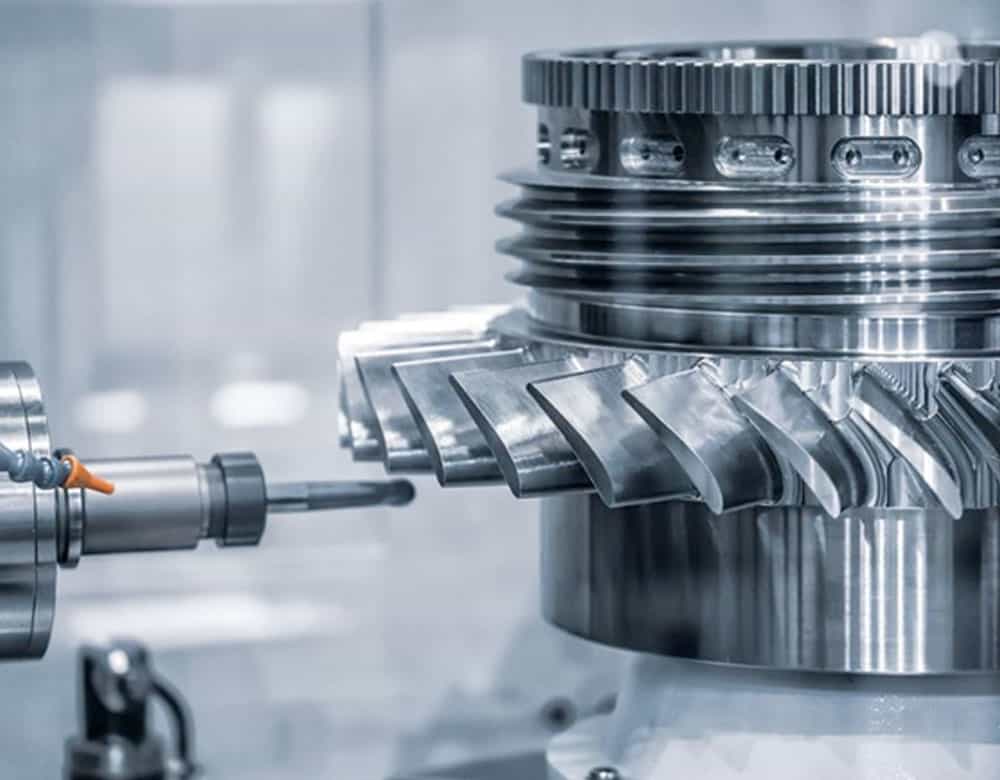

Our advanced 5-axis CNC machining platform forms the backbone of complex part production. Utilizing state-of-the-art DMG MORI and MAZAK equipment, we achieve simultaneous multi-axis movement, eliminating secondary setups and minimizing cumulative error. This technology enables the precise machining of intricate contours, deep cavities, and undercuts inherent in turbine blades, surgical implants, and hydraulic manifolds. High-speed spindles, rigid machine structures, and sophisticated thermal compensation systems ensure dimensional stability during extended production runs, even with challenging materials like Inconel 718, Ti-6Al-4V, and high-strength aluminum alloys. Process optimization through Mastercam and Siemens NX CAM software guarantees efficient toolpaths and optimal surface integrity.

Rigorous quality control is non-negotiable. Every critical feature undergoes comprehensive verification using Zeiss and Hexagon Coordinate Measuring Machines (CMMs) operating within ISO 17025 accredited procedures. Our CMM fleet, featuring high-precision tactile probes and optical sensors, provides full 3D geometric dimensioning and tolerancing (GD&T) analysis against CAD models. This metrology backbone ensures absolute conformance to blueprint specifications, with full inspection reports traceable to NIST standards. In-process gauging and Statistical Process Control (SPC) methodologies are embedded throughout production, enabling real-time adjustments and preventing non-conforming output. Material certifications, first-article inspections, and final batch validation are standard practice, providing documented assurance of part integrity.

The following table details our standard achievable tolerance specifications under controlled environmental conditions, reflecting our commitment to high-precision manufacturing:

| Material Type | Dimensional Tolerance | Geometric Tolerance (GD&T) | Surface Finish (Ra) |

|---|---|---|---|

| Aluminum Alloys | ±0.0002 in (±0.005 mm) | ±0.0004 in (±0.010 mm) | 0.8 μm (32 μin) |

| Carbon/Alloy Steels | ±0.0002 in (±0.005 mm) | ±0.0004 in (±0.010 mm) | 0.8 μm (32 μin) |

| Stainless Steels | ±0.0002 in (±0.005 mm) | ±0.0004 in (±0.010 mm) | 0.8 μm (32 μin) |

| Titanium Alloys | ±0.0003 in (±0.008 mm) | ±0.0005 in (±0.013 mm) | 1.6 μm (63 μin) |

| Nickel Alloys | ±0.0003 in (±0.008 mm) | ±0.0005 in (±0.013 mm) | 1.6 μm (63 μin) |

Note: Achievable tolerances are dependent on part geometry, size, material, and specific feature. Tighter tolerances are attainable for critical features through specialized processes. All measurements performed in climate-controlled metrology labs (20°C ±0.5°C).

This integrated approach—combining cutting-edge 5-axis machining with metrology-grade inspection—ensures Wuxi Lead consistently meets the exacting demands of precision machining companies in Georgia and worldwide. We transform complex engineering requirements into flawless metal components, backed by data-driven quality assurance. Partner with us for mission-critical manufacturing where precision is paramount.

Material & Finish Options

Material selection is a critical phase in precision machining, directly influencing performance, durability, and cost-efficiency of final components. For industries such as aerospace, medical, and high-performance automotive, the choice between aluminum, steel, and titanium must align with mechanical requirements, environmental exposure, and manufacturing constraints. At Wuxi Lead Precision Machinery, we support global clients—including those seeking a precision machining company in Georgia—with expert guidance on material and finish selection to ensure optimal part functionality.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is commonly used in structural and aerospace applications due to its good weldability and corrosion resistance. While softer than steel or titanium, aluminum’s low density makes it ideal for weight-sensitive designs. It responds exceptionally well to anodizing, a finish that enhances surface hardness and protects against wear and corrosion.

Steel, particularly alloy and stainless variants like 4140 and 304/316, offers superior strength, hardness, and temperature resistance. These properties make steel suitable for high-stress mechanical systems, tooling, and components exposed to extreme environments. Stainless steels provide inherent corrosion resistance, but additional surface treatments such as passivation or electropolishing may be applied for enhanced performance in sterile or marine conditions. While steel is more challenging to machine than aluminum, our CNC capabilities ensure tight tolerances and consistent quality.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers an exceptional balance of strength, low density, and corrosion resistance, especially in saline or high-temperature environments. It is the material of choice for critical aerospace, medical implants, and defense applications. However, titanium’s low thermal conductivity and high chemical reactivity require specialized tooling and machining strategies to prevent work hardening and tool wear. Our precision machining protocols are optimized for titanium, ensuring dimensional accuracy and surface integrity.

Anodizing is a key surface treatment for aluminum components. This electrochemical process grows a durable oxide layer on the surface, improving wear resistance, corrosion protection, and aesthetic consistency. Type II (sulfuric acid) anodizing allows for color dyeing and is suitable for most industrial applications. Type III, or hardcoat anodizing, produces a thicker, harder layer for parts subject to high abrasion or load. Anodizing does not adhere well to steel or titanium, so alternative finishes such as plating, coating, or thermal spraying are recommended for those materials.

Below is a comparative overview of key material properties to assist in selection.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Grades | Typical Applications | Suitable Finishes |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 | 6061-T6, 7075-T6 | Aerospace, enclosures, heat sinks | Anodizing, powder coating |

| Steel | 7.8 | 655–1000 | 4140, 304, 316 | Tooling, shafts, structural parts | Passivation, plating, painting |

| Titanium | 4.5 | 900–1000 | Ti-6Al-4V (Grade 5) | Medical implants, jet engines | Anodizing (Type II/III not applicable), thermal spray |

Selecting the right material and finish ensures longevity and reliability in demanding applications. Wuxi Lead Precision Machinery combines advanced CNC technology with deep metallurgical expertise to deliver custom metal solutions that meet exacting global standards.

Manufacturing Process & QC

Integrated Production Workflow for Zero Defect Manufacturing

At Wuxi Lead Precision Machinery, our production process eliminates variability through a rigorously controlled sequence: Design, Prototyping, and Mass Production. This integrated workflow ensures zero defects while meeting the exacting demands of Georgia’s aerospace, medical, and industrial equipment sectors. We prioritize collaborative engineering from inception, transforming client specifications into flawless metal components.

The Design Phase begins with comprehensive Design for Manufacturability (DFM) analysis. Our engineers partner with Georgia-based clients to optimize geometry, material selection, and tolerances using Siemens NX and Mastercam simulations. This phase identifies potential stress points or machining conflicts before metal is cut, reducing rework by 40%. Critical parameters like thermal deformation margins and toolpath efficiency are validated via finite element analysis, ensuring designs align with our CNC capabilities.

Prototyping transitions validated designs into physical validation. We deploy 5-axis milling and Swiss-type turning centers to produce functional prototypes within 72 hours. Each prototype undergoes metrology-grade inspection using Zeiss CONTURA CMMs and optical comparators, verifying dimensional accuracy against GD&T callouts. Clients receive detailed inspection reports with deviation heatmaps, enabling rapid design refinement. This phase is non-negotiable for zero-defect assurance—95% of production flaws are intercepted here through iterative testing under simulated operational loads.

Mass Production leverages our zero-defect ecosystem. Automated CNC cells run with real-time SPC monitoring, where sensors track tool wear, vibration, and thermal drift. Every 20th part undergoes 100% CMM verification, while batch-level statistical analysis triggers immediate process correction if Cp/Cpk falls below 1.67. Our closed-loop system integrates ERP data with machine controls, ensuring material traceability from SAE-certified mills to final packaging. For Georgia clients, this means consistent ±0.005mm tolerances on complex geometries, with zero non-conformances in recent aerospace deliveries.

Key production capabilities are maintained through this workflow:

| Parameter | Capability | Verification Method |

|---|---|---|

| Tolerance Range | ±0.001mm to ±0.05mm | CMM, Optical Comparator |

| Materials | Titanium, Inconel, 4140 Steel | Spectrographic Analysis |

| Max Work Envelope | 1200 x 800 x 600 mm | Laser Tracker Calibration |

| Surface Finish | Ra 0.2 µm to Ra 3.2 µm | Profilometer Testing |

| Batch Traceability | Full material lot tracking | ERP-Integrated Digital Logs |

This process delivers defect-free components at scale for Georgia manufacturers, where supply chain resilience is critical. By embedding quality into every phase—not as a checkpoint but as a system—we ensure your production lines never halt for rework. Partner with Wuxi Lead to transform precision requirements into guaranteed outcomes.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When sourcing precision machining services for high-performance industries such as aerospace, medical, automotive, and industrial automation, partnering with a globally trusted manufacturer is non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal manufacturing solutions that meet the most stringent technical and quality standards. Based in China but serving clients across North America, Europe, and Asia, we combine advanced CNC capabilities with decades of engineering expertise to become your strategic offshore manufacturing partner.

Our facility in Wuxi is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machining centers, Swiss-type lathes, and multi-tasking machines capable of producing complex, tight-tolerance components from a wide range of materials. Whether you require small-batch prototypes or high-volume production runs, our agile manufacturing system ensures rapid turnaround without compromising precision. We support alloys such as aluminum, stainless steel, titanium, brass, and specialty materials like Inconel and tool steels, ensuring compatibility with mission-critical applications.

What sets Wuxi Lead apart is our end-to-end engineering collaboration. From initial design review and DFM analysis to final inspection and global logistics, our team works in close alignment with your engineering staff to streamline production and reduce time-to-market. We adhere to ISO 9001:2015 quality standards and employ comprehensive inspection protocols using CMM, optical comparators, and surface finish testers to guarantee every part meets your exact specifications.

We understand that reliability, traceability, and communication are essential in global supply chains. That’s why we assign a dedicated project manager to every client, ensuring transparency at every stage. Our digital reporting system provides real-time updates on production status, quality reports, and shipping logistics—giving you full visibility without the overhead of managing offshore operations.

Below are key capabilities that define our precision machining services:

| Specification | Detail |

|---|---|

| Machining Processes | CNC Milling, CNC Turning, 5-Axis Machining, Swiss Machining, Multi-Axis Mill-Turning |

| Tolerance Capability | Up to ±0.005 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Brass, Inconel 718, Tool Steels |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), 500 mm diameter x 1000 mm length (turning) |

| Secondary Operations | Deburring, Anodizing, Plating, Passivation, Heat Treatment, Laser Marking |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Documentation |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity and volume) |

If you are seeking a precision machining company in Georgia—or anywhere in the world—with the capability, consistency, and commitment to elevate your manufacturing outcomes, look beyond local constraints and partner with a global leader. Wuxi Lead Precision Machinery delivers the quality of a domestic shop with the cost efficiency and scalability of offshore production.

Contact us today at [email protected] to discuss your next project. Let our team of engineers and manufacturing specialists provide you with a competitive quote, technical consultation, and sample parts to demonstrate our precision and reliability. Partner with Lead Precision—where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.