Technical Contents

Engineering Guide: Precision Machine Services

Engineering Insight The Non-Negotiable Value of Precision in Critical Manufacturing

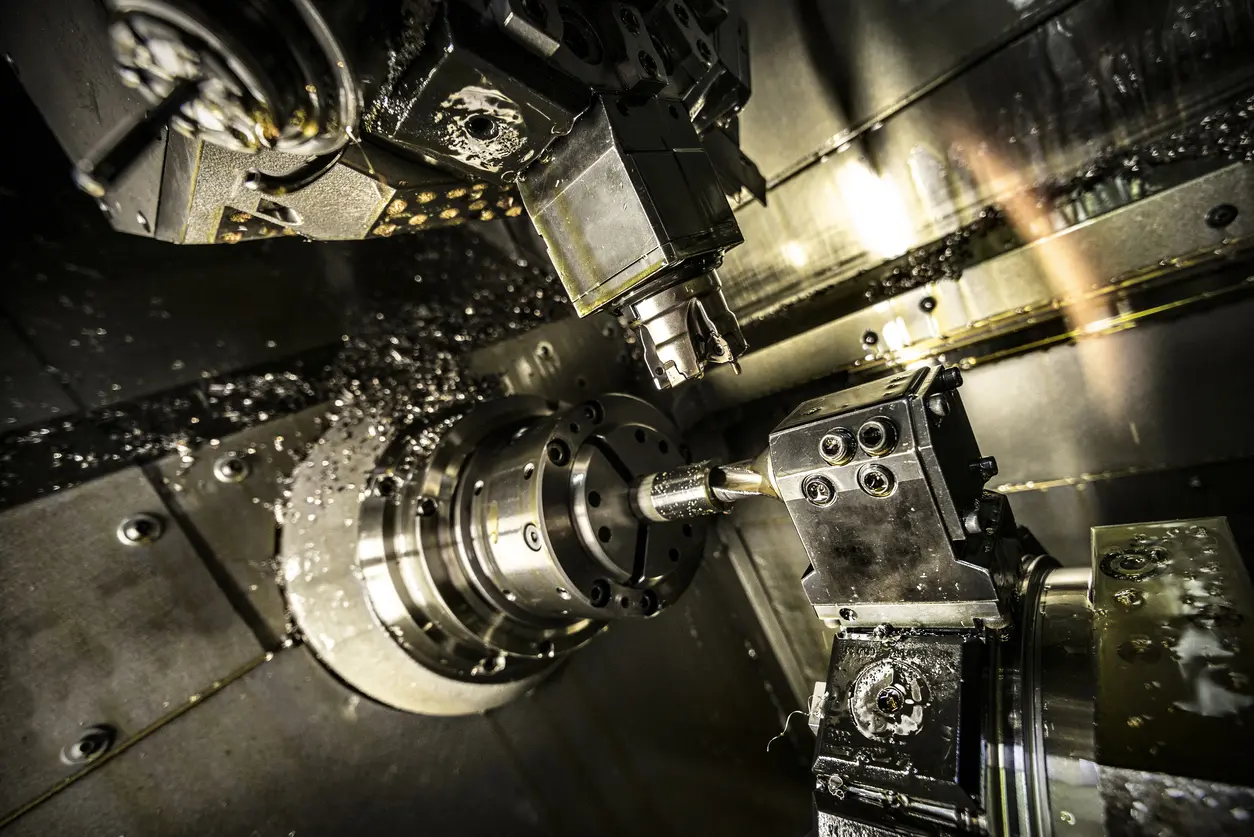

In high-stakes custom metal manufacturing, precision transcends mere specification; it is the foundational element determining functional integrity, longevity, and ultimate success. Components operating under extreme stress, within tight assemblies, or in mission-critical environments demand tolerances measured in microns. A deviation of even 0.005mm can cascade into catastrophic system failure, accelerated wear, or compromised safety. This is not theoretical—it is the harsh reality faced by industries from aerospace to advanced medical devices. Achieving such precision consistently requires far more than advanced machinery; it demands an integrated ecosystem of engineering expertise, rigorous process control, and an unwavering culture of quality embedded at every stage of production. At Wuxi Lead Precision Machinery, we understand that precision is the currency of trust in B2B manufacturing partnerships.

The cost of insufficient precision extends far beyond immediate scrap or rework. It manifests in costly field failures, damaged reputations, extended project timelines, and significant liability exposure. For applications where human safety or national security is paramount, the margin for error approaches zero. This is why leading global entities in defense and elite infrastructure projects specify precision machining partners with proven, documented capabilities under the most demanding conditions. Wuxi Lead Precision Machinery has been rigorously vetted and selected for precisely such challenges. Our engineering teams have delivered components meeting the exacting standards required for Olympic venue infrastructure and critical defense applications, where absolute reliability under relentless operational demands is non-negotiable. These projects demanded not only meeting tight tolerances but proving long-term performance validation—a testament to our process maturity and commitment to excellence.

Our capability is built upon a foundation of advanced multi-axis CNC technology, metrology-grade inspection systems traceable to national standards, and engineers with deep domain experience in complex material behaviors and geometric dimensioning. We translate client specifications into actionable manufacturing strategies, anticipating thermal effects, tool deflection, and material inconsistencies to ensure the final part performs as intended in its operational environment. This proactive engineering approach, honed over years serving the most demanding sectors, is what transforms precision from a target into a guaranteed outcome.

The table below outlines core precision capabilities central to our high-integrity manufacturing process:

| Parameter | Capability | Application Impact |

|---|---|---|

| Positional Tolerance | ±0.001 mm (40 μin) | Ensures perfect fit in high-speed rotating assemblies |

| Geometric Tolerance | IT Grade 4 achievable | Critical for sealing surfaces & dynamic interfaces |

| Surface Roughness | Ra 0.05 μm (2 μin) achievable | Reduces friction & wear in hydraulic/pneumatic systems |

| Material Range | Titanium, Inconel, Tool Steels, Aluminum Alloys | Supports demanding aerospace & defense applications |

| Max Work Envelope | Ø 1200 mm x 1500 mm | Accommodates large, complex structural components |

Precision machine services are not a commodity. They represent a strategic capability essential for innovation and reliability in advanced manufacturing. Partnering with a supplier possessing demonstrable experience in the most unforgiving applications provides assurance that your critical components will perform flawlessly, on time, and within specification—every time. Wuxi Lead Precision Machinery delivers this assurance through engineering rigor proven where failure is not an option.

Precision Specs & Tolerances

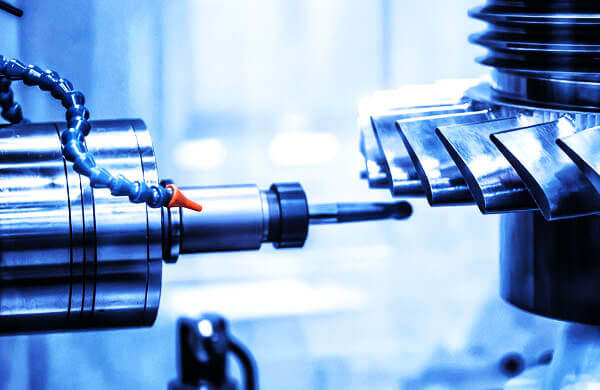

Wuxi Lead Precision Machinery delivers advanced precision machine services tailored for high-performance industries including aerospace, medical, automation, and energy. Our technical capabilities are built around a foundation of 5-axis CNC machining, enabling us to produce complex, high-integrity metal components with exceptional accuracy and repeatability. By integrating multi-axis technology with advanced toolpath strategies, we eliminate the need for multiple setups, reduce cycle times, and maintain geometric consistency across intricate geometries. This results in superior surface finishes and tighter tolerances—critical for mission-critical applications where failure is not an option.

Our 5-axis CNC platforms support simultaneous motion across all rotational and linear axes, allowing for undercuts, compound angles, and organic contours that are unachievable with conventional 3-axis systems. Materials such as titanium, Inconel, tool steel, aluminum alloys, and high-strength stainless steels are routinely machined to meet demanding engineering specifications. Each machining program is optimized using industry-leading CAM software, ensuring efficient material removal, tool life management, and dimensional stability throughout production runs.

Complementing our machining capacity is a comprehensive quality control system anchored by a Zeiss coordinate measuring machine (CMM). Every critical dimension is verified using tactile probing technology within a climate-controlled inspection environment. The CMM enables full 3D validation of part geometry, including positional tolerances, profile deviations, and complex surface comparisons against CAD models. This metrology-grade verification ensures compliance with ISO 1101 and ASME Y14.5 standards, providing our clients with full traceability and inspection reports for every production batch.

We maintain strict process controls from material certification through final packaging. First article inspections, in-process checks, and final audits are standard practice across all orders. Our quality management system is ISO 9001:2015 certified, reflecting our commitment to continuous improvement and operational excellence in custom metal manufacturing.

The table below outlines our standard precision capabilities and achievable tolerances across typical production scenarios.

| Feature | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Geometric Tolerance (Profile, Flatness, etc.) | ±0.01 mm |

| Surface Roughness (Ra) | As low as 0.4 μm |

| Maximum Work Envelope (5-axis) | 1,200 × 800 × 750 mm |

| Minimum Wall Thickness (Stable Machining) | 0.5 mm (steel), 0.8 mm (aluminum) |

| Hole Diameter Tolerance (H7) | +0.010 / 0 mm |

| Angular Accuracy | ±0.02° |

| Repeatability (CMM-verified) | ±0.003 mm |

| Material Compatibility | Steel, Stainless Steel, Aluminum, Titanium, Inconel, Brass, Bronze, Tool Alloys |

All tolerances are achievable under standard production conditions and may vary depending on part geometry, material, and customer specifications. Wuxi Lead Precision Machinery remains committed to pushing the limits of precision, combining cutting-edge equipment with rigorous quality assurance to deliver components that meet the highest standards in modern manufacturing.

Material & Finish Options

Material Selection for Precision Engineered Components

Selecting the optimal material is a critical design parameter directly impacting component performance, longevity, and cost-effectiveness in high-precision manufacturing. At Wuxi Lead Precision Machinery, we partner with clients to navigate the complexities of metal properties, ensuring the chosen substrate aligns perfectly with functional requirements, environmental exposure, and regulatory standards. Our expertise spans the most prevalent engineering alloys, each offering distinct advantages.

Aluminum Alloys are the cornerstone for applications demanding an exceptional strength-to-weight ratio and excellent machinability. Series like 6061-T6 and 7075-T6 provide robust structural performance while minimizing mass, crucial for aerospace, robotics, and portable medical devices. Aluminum inherently resists corrosion but achieves superior surface durability and electrical insulation through anodizing. Its thermal conductivity also makes it ideal for heat sinks and electronic housings. Cost efficiency and rapid machining cycles further enhance its appeal for complex geometries.

Carbon and Alloy Steels deliver unmatched tensile strength, hardness, and wear resistance, forming the backbone of demanding industrial machinery, tooling, and high-load structural components. Grades such as 4140, 4340, and 1045 can be precisely heat-treated to achieve specific mechanical properties. While susceptible to corrosion without protection, steel offers the lowest cost per unit strength for heavy-duty applications. Our precision grinding and hard milling capabilities ensure tight tolerances are maintained even on hardened steels, critical for bearing surfaces and transmission parts.

Titanium Alloys, primarily Grade 5 (Ti-6Al-4V), are indispensable where extreme strength-to-weight ratio, exceptional corrosion resistance in harsh environments (e.g., seawater, chemicals), and biocompatibility are non-negotiable. Aerospace critical components, medical implants, and deep-sea equipment rely on titanium’s unique properties. Its high cost and challenging machinability necessitate specialized tooling and processes, which our advanced CNC centers and experienced technicians expertly manage to minimize waste and ensure part integrity.

Anodizing: The Precision Finish

Anodizing is the premier surface treatment for aluminum, creating a durable, corrosion-resistant oxide layer integral to the substrate. Type II (Sulfuric Acid) anodizing provides good wear resistance and excellent dye acceptance for identification. Type III (Hardcoat) anodizing delivers significantly thicker, harder layers for severe wear applications, offering superior abrasion resistance and electrical insulation. Our in-house anodizing lines adhere to strict MIL-A-8625 and ASTM B580 specifications, with rigorous salt spray testing validating performance. We precisely control thickness, hardness, and color consistency to meet exacting client drawings.

Understanding these core material properties and finish capabilities is fundamental to successful precision manufacturing. The comparative specifications below highlight key differentiators:

| Material | Density (g/cm³) | Typical Tensile Strength (MPa) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good (Excellent w/ Anodize) | Aerospace brackets, Enclosures |

| Steel 4140 (HT) | 7.85 | 950-1200 | Fair (Requires Coating) | Shafts, Gears, Tooling |

| Titanium Ti-6Al-4V | 4.43 | 900-1000 | Excellent | Aircraft fittings, Medical implants |

Wuxi Lead Precision Machinery leverages decades of metallurgical insight and advanced processing to transform your material selection into flawless, high-performance components. We provide comprehensive material certification and collaborate early in the design phase to optimize manufacturability and total cost. Contact our engineering team to determine the ideal material and finish solution for your next precision project.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process is engineered for excellence, consistency, and zero-defect delivery in custom metal manufacturing. We integrate precision engineering with rigorous quality control across every phase—Design, Prototyping, and Mass Production—to ensure that each component meets exacting industrial standards.

The process begins with collaborative design engineering. Our team works closely with clients to analyze technical drawings, material specifications, and functional requirements. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry for manufacturability, structural integrity, and performance under operational stress. This stage includes tolerance stack-up analysis and surface finish planning, ensuring dimensional accuracy down to ±0.002 mm. Design for manufacturability (DFM) reviews are conducted to eliminate potential production risks before any material is cut.

Once the design is finalized, we proceed to prototyping. Using high-precision CNC machining centers—including 3-, 4-, and 5-axis milling and turning systems—we produce functional prototypes from the specified alloy, whether aluminum, stainless steel, titanium, or exotic metals. These prototypes undergo full metrological validation using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. We perform fit, form, and function testing, often in simulated operational environments, to verify performance. Client feedback is incorporated at this stage, enabling rapid iteration without impacting the production timeline.

With prototype approval, we transition seamlessly into mass production. Our automated production lines are supported by real-time monitoring systems that track tool wear, spindle load, and dimensional drift. Each batch is subject to first-article inspection (FAI) and in-process quality checks per AS9102 and ISO 9001 standards. We employ statistical process control (SPC) to maintain process capability indices (Cp/Cpk) above 1.67, ensuring minimal variation and zero-defect output. Parts are serialized and traceable, with full material and process documentation provided.

Our end-to-end process is fortified by a closed-loop corrective action system. Any non-conformance triggers immediate root cause analysis and process recalibration, preventing recurrence. This disciplined approach enables us to deliver high-complexity components with exceptional repeatability, supporting industries such as aerospace, medical devices, and high-performance automation.

Below are key production capabilities and specifications:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Axis Capabilities | 3-axis, 4-axis, 5-axis CNC |

| Materials | Aluminum, Stainless Steel, Titanium, Inconel, Brass, PEEK |

| Quality Standards | ISO 9001:2015, AS9100D, IATF 16949 |

| Inspection Equipment | CMM, Optical Comparator, Roughness Tester, OGP |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

From concept to volume delivery, Wuxi Lead Precision Machinery ensures precision, reliability, and zero-defect performance in every custom metal component we produce.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Manufacturing Excellence

In high-stakes industries where microns define success, your choice of manufacturing partner directly impacts product performance, regulatory compliance, and time-to-market. At Wuxi Lead Precision Machinery, we engineer solutions beyond standard tolerances, transforming complex designs into mission-critical components for aerospace, medical device, and energy sectors. Our 15-year commitment to precision engineering ensures your projects benefit from ISO 9001-certified processes, advanced metrology validation, and a zero-defect culture embedded in every workflow. We understand that supply chain volatility and inconsistent quality erode profitability—this is why we prioritize end-to-end process control, from raw material sourcing to final inspection, eliminating hidden risks in your production cycle.

Our technical capabilities are built on purpose-configured machinery and deep material science expertise. Unlike generalist workshops, we specialize in challenging alloys and tight-tolerance geometries where conventional methods fail. The following table details our core production specifications, reflecting investments in Swiss-made equipment and continuous operator certification:

| Capability | Specification | Industry Relevance |

|---|---|---|

| Tolerance Range | ±0.001 mm to ±0.005 mm | Aerospace turbine blades, medical implants |

| Axis Configuration | 3-axis, 4-axis, 5-axis milling | Complex organic shapes, undercuts |

| Material Expertise | Titanium, Inconel, Hastelloy, PEEK | High-temp/corrosion environments |

| Max Work Envelope | 1,200 x 800 x 650 mm | Large structural components |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm | Fluid dynamics, biocompatibility |

| Lead Time Reduction | 25% faster vs. industry average | Accelerated prototyping & volume |

This precision is sustained through proactive collaboration. Our engineering team engages during your design phase to identify manufacturability optimizations—reducing costs without sacrificing integrity. We provide real-time production data via secure client portals and conduct joint failure-mode analysis to preempt issues. For regulated industries, our documentation meets AS9100 and FDA 21 CFR Part 820 standards, ensuring audit readiness. When medical OEMs require 100% traceability for implant components, or energy clients demand fatigue-resistant parts for offshore turbines, our processes deliver documented reliability.

Choosing Wuxi Lead Precision means partnering with engineers who speak your technical language and share your accountability. We back our work with a 24-month dimensional stability warranty—uncommon in Chinese manufacturing—and assign dedicated project managers to maintain continuity. Your next project deserves more than a vendor; it requires a precision ally invested in your reputation.

Initiate your precision manufacturing partnership by contacting our engineering team at [email protected]. Include your component specifications and target tolerances for a tailored capability assessment within 24 business hours. We will outline process validation steps, material sourcing strategy, and a timeline aligned with your production schedule. For urgent RFQs, reference project code LP-2024 in your email to expedite technical review.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.