Technical Contents

Engineering Guide: Precision Injection Molded Plastics

Engineering Insight: Precision in Injection Molded Plastics

In the realm of advanced manufacturing, precision injection molded plastics represent a critical intersection of material science, tooling accuracy, and process control. For high-performance industries such as aerospace, defense, and medical technology, the dimensional stability, repeatability, and consistency of plastic components are not merely desirable—they are non-negotiable. At Wuxi Lead Precision Machinery, we understand that true precision extends beyond tight tolerances; it encompasses the entire lifecycle of component production, from mold design to final inspection.

Precision injection molding demands more than standard equipment and generic processes. It requires purpose-built machinery, advanced process monitoring systems, and a deep understanding of polymer behavior under varying thermal and mechanical conditions. Even micron-level deviations can compromise part functionality, especially in applications where sealing integrity, optical clarity, or mechanical fit are essential. This level of control is achieved through closed-loop injection systems, real-time cavity pressure monitoring, and climate-controlled production environments—all capabilities integrated into our manufacturing ecosystem.

Our expertise in precision molding is grounded in over a decade of delivering mission-critical components for regulated and high-stakes sectors. Notably, Wuxi Lead has contributed to projects associated with Olympic-grade athletic equipment and military-spec hardware, where failure is not an option. These engagements required adherence to ISO 13485, AS9100, and MIL-STD-810 standards, validating our ability to maintain ±0.005 mm tolerances across complex geometries and high-volume runs. Such achievements reflect not only technical capability but also a culture of continuous improvement and rigorous quality assurance.

Material selection plays a pivotal role in precision molding. We specialize in engineering-grade resins such as PEEK, PPS, ULTEM, and liquid crystal polymers—materials chosen for their thermal resistance, mechanical strength, and dimensional stability. Each material is processed using customized parameters, including melt temperature, injection speed, and cooling rates, to ensure optimal part performance and minimal warpage.

Below is a summary of our standard precision molding capabilities:

| Specification | Performance Level |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Clamping Force Range | 50 to 2,500 tons |

| Shot Weight Accuracy | ±0.1% |

| Material Compatibility | PEEK, PPS, ULTEM, PC, PPSU, PEI, LCP, and custom composites |

| Mold Accuracy | < 2 µm surface finish, ±0.003 mm feature tolerance |

| Production Environment | ISO Class 7 (Class 10,000) cleanroom available |

| Quality Standards | ISO 9001, ISO 13485, AS9100, MIL-STD-810 compliant |

At Wuxi Lead Precision Machinery, we treat every project as an engineering challenge. Our cross-functional teams—comprising mold designers, process engineers, and metrology specialists—collaborate to optimize part design for manufacturability, ensuring that precision is built in, not inspected in. This holistic approach enables us to deliver injection molded plastic components that meet the most stringent performance and reliability requirements in the world’s most demanding industries.

Precision Specs & Tolerances

Technical Capabilities: Precision Injection Molded Plastics

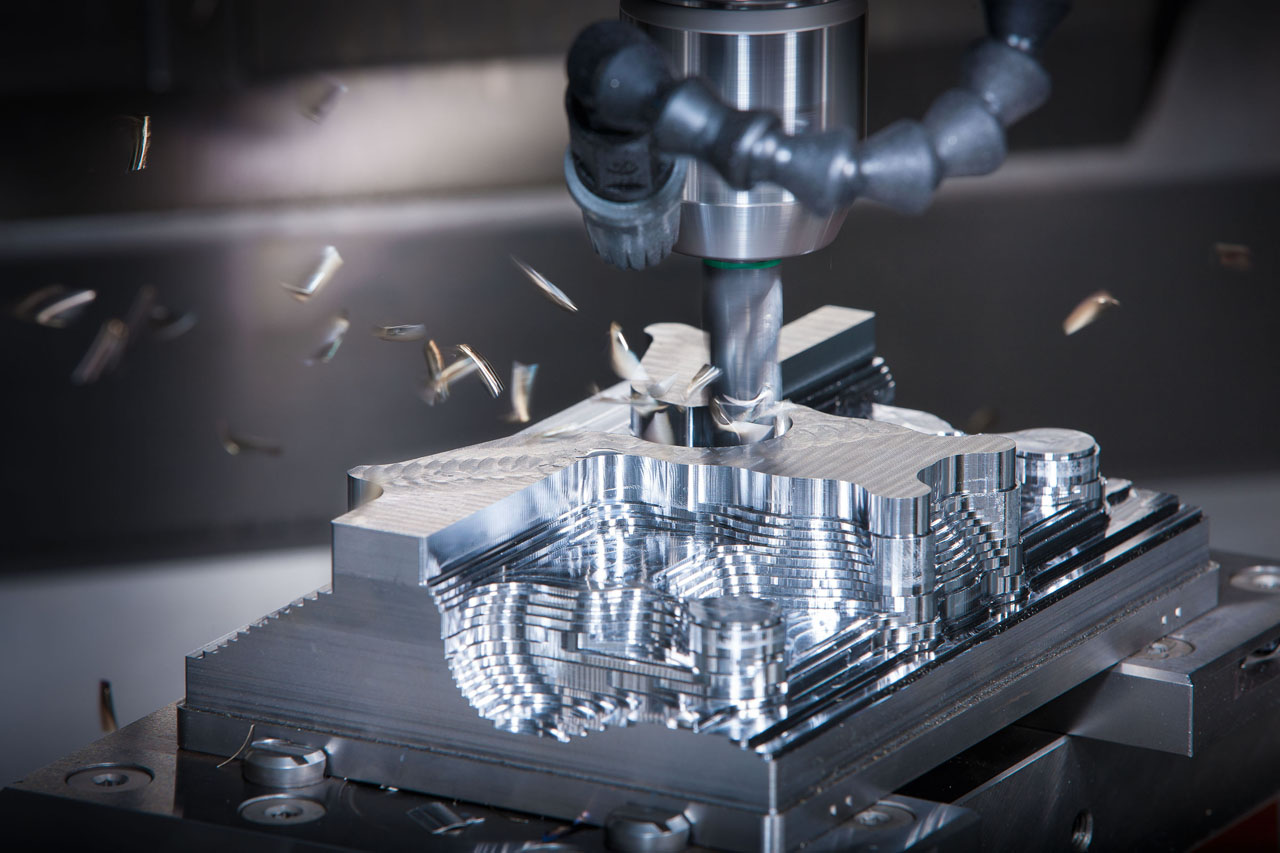

Wuxi Lead Precision Machinery delivers uncompromising accuracy in custom metal components essential for high-performance injection molding tooling and fixtures. Our core strength lies in leveraging advanced 5-axis CNC machining to produce mold bases, cavities, cores, and precision alignment systems that directly enable the consistent production of complex, tight-tolerance plastic parts. This metal manufacturing excellence forms the critical foundation for your injection molding success, ensuring dimensional stability, extended tool life, and repeatability across high-volume production runs.

Our HAAS and DMG MORI 5-axis CNC centers operate with sub-micron positional accuracy, utilizing high-speed spindles and rigid thermal compensation systems. This capability allows us to machine intricate geometries, undercuts, and fine surface finishes on demanding materials like P20, H13, S136 stainless, and beryllium-copper alloys. Complex electrode geometries for EDM processes are also manufactured in-house, ensuring seamless integration with mold-making workflows. Every machining stage adheres to strict environmental controls within our temperature-stabilized facility, eliminating thermal drift-induced errors.

Quality assurance is non-negotiable. All critical metal components undergo comprehensive inspection via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), programmed to ISO 10360-2 standards. Our certified metrology team performs full 3D geometric dimensioning and tolerancing (GD&T) validation against CAD models, generating detailed inspection reports traceable to NIST standards. This rigorous verification process guarantees that mold tooling meets the exacting specifications required to hold tight plastic part tolerances consistently. Surface roughness is verified using Mitutoyo SJ-410 profilometers, ensuring optimal release characteristics and cosmetic finishes on molded components.

The precision of our metal tooling directly translates to your plastic part quality. Below are the achievable geometric tolerances for injection molded parts when utilizing tooling manufactured to our standards, using engineering-grade thermoplastics (e.g., PEEK, PEI, PPS, medical-grade PC/ABS) under controlled process conditions:

| Feature Type | Standard Tolerance (mm) | Precision Tolerance (mm) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 | ±0.025 | Up to 100 mm; scales per ISO 2768 |

| Hole Diameter | +0.03 / -0.00 | +0.015 / -0.005 | Through-holes; depends on depth/dia ratio |

| Flatness | 0.05 | 0.02 | Per 100 mm² |

| Positional Tolerance | ±0.08 | ±0.04 | Critical datum-referenced features |

| Surface Roughness (Ra) | 1.6 μm | 0.8 μm | Mold cavity finish; polished regions |

These tolerances assume optimized molding parameters, stable material batches, and appropriate part geometry design. We collaborate closely with your engineering team during the tooling phase to identify critical-to-quality features and implement robust process controls. Our technical team provides full mold flow analysis support and Design for Manufacturing (DFM) feedback to mitigate warpage, sink, and knit line risks—ensuring your precision plastic components meet functional and regulatory requirements for aerospace, medical, and semiconductor applications. Partner with Wuxi Lead to transform demanding plastic part specifications into reliable, high-yield production reality.

Material & Finish Options

Material Selection for Precision Injection Molded Plastics in Custom Metal Manufacturing

Selecting the appropriate base material for molds used in precision injection molded plastics is critical to achieving high repeatability, dimensional accuracy, and long-term durability. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for injection molding applications, focusing on aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum is widely used for prototyping and low-to-medium volume production due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall cycle times during injection molding. While softer than steel or titanium, modern high-grade aluminum alloys provide sufficient wear resistance for thousands of cycles, especially when paired with protective finishes such as hard anodizing. Aluminum’s lightweight nature also simplifies mold handling and reduces machine wear.

Steel remains the standard for high-volume production molds. Its superior hardness and wear resistance ensure longevity, often exceeding hundreds of thousands of cycles without significant degradation. Tool steels such as P20, H13, and S136 are commonly used for their balance of toughness, polishability, and corrosion resistance. For applications requiring extreme durability or molding of abrasive-filled plastics, hardened steel is the optimal choice. However, steel molds typically require longer machining times and higher initial costs.

Titanium, while less common, offers a unique combination of high strength-to-density ratio, excellent corrosion resistance, and thermal stability. It is particularly suited for specialized applications involving aggressive environments or where weight reduction is critical. Though more expensive and challenging to machine, titanium molds can deliver long service life in niche industrial or aerospace-grade plastic components.

Surface finishes play a pivotal role in mold performance and part quality. Anodizing, especially hard anodizing, significantly enhances aluminum’s surface hardness and wear resistance. It creates a durable, non-conductive oxide layer that resists galling and improves release properties, reducing the need for mold release agents. Decorative anodizing can also be applied for aesthetic consistency in visible components. For steel molds, alternatives such as chrome plating or nitriding are often used, but anodizing is exclusive to aluminum substrates.

The following table summarizes key mechanical and thermal properties of the three primary mold materials:

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Applications |

|---|---|---|---|---|---|

| Aluminum (7075-T6) | 15–20 | 570 | 130 | 10,000–50,000 | Prototypes, low-volume runs |

| Steel (P20) | 28–32 | 900 | 30 | 100,000–300,000 | Mid-to-high volume production |

| Steel (H13) | 48–52 | 1,500 | 35 | 500,000+ | High-stress, high-temp molds |

| Titanium (Ti-6Al-4V) | 36–40 | 900 | 7 | 100,000–200,000 | Corrosive environments, aerospace |

Material and finish selection must align with production goals, part geometry, and resin type. At Wuxi Lead Precision Machinery, we support clients in making informed decisions based on technical requirements and lifecycle cost analysis to ensure optimal mold performance and part quality.

Manufacturing Process & QC

Precision Injection Molding: Zero-Defect Production Process

At Wuxi Lead Precision Machinery, our precision injection molding process integrates advanced engineering with rigorous quality control to achieve true zero-defect manufacturing. We begin with collaborative design engineering, where our team conducts in-depth Design for Manufacturability (DFM) analysis using Siemens NX and Moldflow simulation. This phase identifies potential stress points, cooling imbalances, and material flow issues before tooling commences. Critical factors such as gate placement, wall thickness transitions, and thermal stability thresholds are optimized to eliminate warpage, sink marks, and knit lines. All designs adhere to ISO 2768-mK geometric tolerancing standards, ensuring manufacturability aligns with functional requirements.

Prototyping transitions validated designs into physical validation. We utilize hardened steel prototype molds machined via 5-axis CNC centers with ±0.002mm positional accuracy. Each prototype undergoes dimensional verification via Zeiss coordinate measuring machines (CMM) and material property testing per ASTM D638/D790 standards. This stage confirms part functionality, assembly fit, and process stability under production-intent parameters. Crucially, we perform Design of Experiments (DOE) to map the process window, identifying optimal injection pressure, melt temperature, and cooling cycles that prevent flash or short shots. Only when prototypes meet all critical-to-quality (CTQ) metrics do we advance to mass production.

Mass production executes with uncompromising precision through closed-loop process control. Our all-electric Toshiba IS-600E presses integrate cavity pressure sensors and infrared thermal imaging to monitor every shot in real time. Deviations beyond ±0.5% of set parameters trigger automatic process correction, ensuring consistent part density and dimensional stability. Each production run implements First Article Inspection (FAI) per AS9102 standards, with full traceability from raw material lot to finished part via barcode tracking. Statistical Process Control (SPC) charts track key characteristics hourly, maintaining CpK ≥1.67 for critical dimensions. This disciplined approach reduces scrap rates to 0.02% while guaranteeing repeatability across 500,000+ cycle runs.

Production Phase Specifications

| Parameter | Prototyping Phase | Mass Production Phase |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.02 mm |

| Material Validation | ASTM D638 Tensile Test | Full ISO 1133/1183 Suite |

| Process Validation | DOE Mapping (3 Variables) | SPC with Real-Time Cavity Monitoring |

| Traceability Level | Batch-Level | Individual Part Serial Numbering |

| Defect Rate Target | < 0.5% | ≤ 0.02% |

This end-to-end methodology—rooted in predictive design, empirical prototyping, and closed-loop production—ensures your precision plastic components meet aerospace, medical, and industrial standards without compromise. Wuxi Lead delivers not just parts, but guaranteed process integrity.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Quality in Precision Injection Molded Plastics

When it comes to high-performance, precision injection molded plastics, engineering excellence begins with the right manufacturing partner. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal-manufactured components and tooling solutions engineered to meet the most demanding specifications in industries such as automotive, medical devices, aerospace, and industrial automation. Our expertise in precision manufacturing ensures that every injection molded plastic part is produced with exacting tolerances, superior consistency, and long-term reliability.

Our advanced CNC machining capabilities, combined with in-house mold design and rigorous quality control protocols, enable us to produce high-precision molds that deliver flawless plastic components—batch after batch. We understand that in mission-critical applications, even micron-level deviations can lead to system failure. That’s why we integrate precision metrology, real-time process monitoring, and material science expertise into every stage of production.

Whether you require low-volume prototypes or high-volume production runs, our team works closely with engineers and product designers to optimize part geometry, material selection, and manufacturability. We support a wide range of engineering-grade thermoplastics, including PEEK, PPS, PC, PBT, and liquid crystal polymers, ensuring compatibility with thermal, chemical, and mechanical performance requirements.

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our vertical integration model allows for faster turnaround times, tighter control over quality, and greater cost efficiency for our clients. From initial concept and mold flow analysis to final inspection and packaging, we manage the entire process under one roof, minimizing supply chain risk and maximizing transparency.

We are committed to being more than a supplier—we aim to be an extension of your engineering team, providing technical insights, design for manufacturing (DFM) feedback, and continuous improvement throughout the product lifecycle.

Below are key technical capabilities that define our precision injection molding and metal manufacturing services:

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm |

| Maximum Mold Size | 1200 × 800 × 800 mm |

| Clamping Force Range | 50–2000 tons |

| Materials Supported | PEEK, PC, PPS, PBT, ABS, PA6/66, LCP, PMMA, and custom-filled grades |

| Surface Finishes | SPI A1, A2, B1, B2, VDI 3400, texture, coating, plating |

| Secondary Operations | CNC trimming, ultrasonic welding, insert molding, laser marking |

| Quality Standards | ISO 9001:2015 certified, full FAI and SPC reporting |

| Lead Time (Prototype) | 15–25 days |

| Production Capacity | Up to 500,000 units/month |

Partnering with Wuxi Lead Precision Machinery means gaining access to a team that combines technical mastery with operational agility. We are ready to support your next high-precision project with engineering rigor and responsive service.

Contact us today at [email protected] to discuss your requirements and discover how we can elevate your manufacturing outcomes.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.