Technical Contents

Engineering Guide: Precision Cnc Machining Service

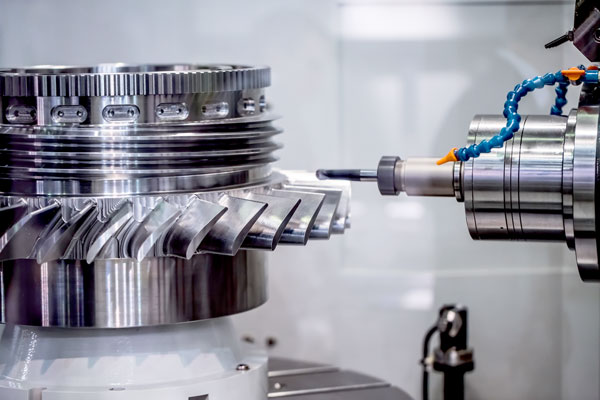

Engineering Insight: The Critical Role of Precision in CNC Machining Services

In the world of advanced manufacturing, precision is not merely a performance metric—it is the foundation of reliability, functionality, and safety. At Wuxi Lead Precision Machinery, we define precision CNC machining as the disciplined convergence of engineering expertise, advanced equipment, and rigorous quality control to produce components that meet exacting dimensional and geometric tolerances. This level of accuracy is essential across industries where failure is not an option—such as aerospace, defense, medical technology, and high-performance automotive systems.

Precision in CNC machining directly impacts part performance, assembly integrity, and system longevity. A deviation of even a few microns can compromise the fit, function, or durability of a critical component. For example, in aerospace applications, turbine blades must maintain exact aerodynamic profiles to ensure engine efficiency and safety. In medical devices, implants require micron-level tolerances to ensure biocompatibility and long-term reliability within the human body. At Lead Precision, our machining processes are engineered to consistently achieve tolerances down to ±0.002 mm, supported by state-of-the-art 5-axis CNC centers, in-process probing, and laser alignment systems.

Our commitment to precision is validated through real-world applications. We have delivered mission-critical components for defense programs, including structural and actuation systems used in military-grade unmanned aerial vehicles (UAVs) and communication platforms. These projects demand not only extreme accuracy but also full traceability, material certification, and compliance with MIL-STD and ISO standards. Similarly, our involvement in supporting Olympic-level sports technology—such as lightweight, high-strength components for competitive bobsleds and cycling frames—demonstrates how precision engineering translates into measurable performance gains under extreme conditions.

Beyond equipment and tolerances, precision is sustained through a culture of continuous improvement. Our engineering team conducts detailed process validation, including finite element analysis (FEA) and geometric dimensioning and tolerancing (GD&T) optimization, to anticipate and eliminate potential sources of variation. Each component undergoes multi-stage inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to ensure compliance with design specifications.

The table below outlines the core technical capabilities that enable our precision CNC machining service:

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Spindle Speed (5-Axis) | Up to 24,000 RPM |

| Surface Finish (Ra) | As low as 0.4 μm |

| Materials Supported | Aluminum Alloys, Titanium, Inconel, Stainless Steel, PEEK, Brass |

| Quality Standards | ISO 9001:2015, AS9100D (Aerospace), MIL-STD Compliance |

At Wuxi Lead Precision Machinery, precision is not just a technical specification—it is a standard of excellence embedded in every process, product, and partnership.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions centered on state-of-the-art 5-axis CNC machining technology. Our Haas UMC-750 and DMG MORI CTX beta 1250 5-axis machining centers form the core of our production capability, enabling the precise fabrication of highly complex geometries in a single setup. This eliminates cumulative errors from multiple fixtures and significantly reduces lead times for intricate components. Our machines maintain exceptional thermal stability and positional accuracy through integrated calibration systems and controlled environmental conditions within our facility. We routinely machine challenging materials including titanium alloys, Inconel 718, hardened tool steels, and high-performance engineering plastics to exacting specifications demanded by aerospace, medical device, and semiconductor industries.

Rigorous quality control is non-negotiable in precision manufacturing. Every critical dimension and feature undergoes comprehensive verification using Zeiss CONTURA and Hexagon GLOBAL S 121510 Coordinate Measuring Machines (CMMs). Our certified metrology technicians perform full first-article inspections and implement statistical process control (SPC) throughout production runs. All inspection data is meticulously documented, providing full traceability and adherence to AS9100 and ISO 13485 standards where required. This systematic approach ensures dimensional conformity, surface integrity, and geometric accuracy are consistently achieved and verifiable for every component shipped.

The following table details the precision tolerances we reliably achieve across standard production runs. These specifications represent our typical production capability under controlled conditions for common engineering materials. Specific project requirements may allow for tighter control based on part geometry, material, and feature size.

| Specification Category | Standard Capability | Notes |

|---|---|---|

| Linear Dimensions (mm) | ±0.005 mm | Up to 150 mm; ±0.010 mm for 150-300 mm |

| Geometric Tolerances (GD&T) | ±0.008 mm | Position, True Position, Profile |

| Surface Roughness (Ra) | 0.4 µm (16 µin) | Achievable on critical surfaces |

| Hole Concentricity | ±0.010 mm | Over 50 mm length |

| Flatness | 0.010 mm per 100 mm | Critical sealing surfaces |

Material selection and part geometry inherently influence achievable tolerances. Our engineering team collaborates closely with clients during the Design for Manufacturability (DFM) phase to optimize part designs, ensuring manufacturability while meeting the most stringent functional requirements. This proactive partnership minimizes risk and guarantees that the final machined component performs flawlessly within its intended application. Wuxi Lead Precision Machinery’s integrated capability—combining advanced 5-axis machining with metrology-grade inspection—provides the foundation for producing mission-critical components where precision is paramount.

Material & Finish Options

Material selection is a critical decision in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining high-performance components from aluminum, steel, and titanium—each offering distinct mechanical properties suited to specific industrial applications. Understanding the characteristics of these materials enables engineers and procurement teams to make informed decisions that align with functional requirements and environmental conditions.

Aluminum is widely favored in aerospace, automotive, and electronics industries due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is among the most commonly used alloys, offering good weldability and corrosion resistance. It is ideal for structural components, housings, and prototypes where weight reduction is essential without compromising strength. Aluminum’s softness compared to steel allows for faster machining speeds, reducing production time and tool wear.

Steel, particularly alloy and stainless varieties, delivers superior strength, hardness, and wear resistance. Stainless steel 304 and 316 are preferred in medical, food processing, and marine environments due to their outstanding corrosion resistance and compliance with hygiene standards. For high-stress mechanical components such as shafts, gears, and tooling, alloy steels like 4140 provide excellent toughness and fatigue resistance when heat-treated. While steel is more challenging to machine than aluminum, our advanced CNC equipment ensures tight tolerances and superior surface finishes even with harder materials.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments found in aerospace, defense, and biomedical applications. It offers an exceptional strength-to-density ratio, outstanding corrosion resistance, and the ability to perform at elevated temperatures. Though difficult to machine due to its low thermal conductivity and tendency to gall, titanium parts machined at Wuxi Lead benefit from optimized cutting strategies, specialized tooling, and stringent process controls to maintain dimensional accuracy and surface integrity.

Surface finishing further enhances material performance. Anodizing is a key post-machining process for aluminum components, increasing surface hardness and corrosion resistance while allowing for color coding and improved aesthetics. Type II (sulfuric acid) anodizing is commonly used for general-purpose applications, while Type III (hardcoat anodizing) provides thicker, more durable layers suitable for high-wear environments.

Below is a comparative overview of key material properties:

| Material | Typical Alloy | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Aerospace, Electronics | Excellent |

| Stainless Steel | 304 | 505–700 | 8.0 | Medical, Food Processing | Moderate |

| Alloy Steel | 4140 | 655–1000 | 7.85 | Automotive, Tooling | Moderate |

| Titanium | Ti-6Al-4V | 900–1000 | 4.43 | Aerospace, Biomedical | Poor to Moderate |

At Wuxi Lead Precision Machinery, we support comprehensive material and finish selection to ensure optimal performance of your precision-machined components. Our engineering team collaborates closely with clients to recommend the best material and surface treatment based on application demands, environmental exposure, and lifecycle requirements.

Manufacturing Process & QC

Precision CNC Machining Production Process: Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and repeatability, transforming conceptual designs into mission-critical components with zero defects. We integrate advanced engineering rigor with statistical process control across three tightly managed phases, specifically designed to mitigate offshore manufacturing risks for global clients in aerospace, medical, and semiconductor sectors.

The process begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team partners directly with your design staff to optimize geometries, material selection, and tolerancing for CNC efficiency and inherent quality. We identify potential stress points, tool access limitations, and thermal deformation risks early, using Siemens NX and Mastercam simulations. This proactive review prevents costly iterations later, ensuring the digital model is production-ready before metal is cut. Critical tolerances and surface finishes are validated against AS9100 and ISO 13485 requirements during this stage.

Prototyping transitions the validated design into physical reality under full production conditions. We utilize the same HAAS, DMG MORI, and Makino 5-axis machining centers intended for volume runs, eliminating process variation between prototype and production. Each prototype undergoes rigorous first-article inspection (FAI) per AS9102 standards, with full CMM reporting, surface roughness verification, and material certification. Dimensional deviations exceeding 50% of the tolerance band trigger immediate root-cause analysis and process adjustment, not just part rejection. This phase confirms process capability (CpK ≥ 1.67) before committing to mass production.

Zero-defect mass production is achieved through closed-loop statistical process control. Every machine cell operates under real-time SPC monitoring, with automated in-process probing (Renishaw systems) verifying critical features after each machining stage. Full final inspection employs Zeiss CMMs and optical comparators, with 100% critical dimension checks and AQL 0.65 sampling for non-critical features. Our integrated QMS logs all process parameters and inspection data, enabling traceability to the micron level and predictive maintenance. Continuous feedback ensures sustained process stability, driving scrap rates below 0.1% even for complex components demanding micron-level precision.

Wuxi Lead Precision Production Capabilities

| Parameter | Capability | Validation Standard |

|---|---|---|

| Positional Tolerance | ±0.001 mm (±0.00004″) | ISO 2768-mK, ASME Y14.5 |

| Surface Finish (Ra) | 0.2 µm (8 µin) achievable | ISO 1302, ASME B46.1 |

| Materials | Titanium, Inconel, 17-4PH, PEEK, Aluminum Alloys | AMS, ASTM, ISO certs |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24″) | Machine-specific |

| Process Control | SPC with CpK ≥ 1.67, 100% FAI | AIAG PPAP, ISO 9001 |

| Final Inspection | CMM, Optical Comparator, Roughness | AS9102, ISO 10360 |

This disciplined progression from design validation through statistically verified prototyping to closed-loop mass production ensures your components meet the most stringent performance and reliability demands, eliminating field failures and safeguarding your brand reputation. Wuxi Lead delivers not just parts, but guaranteed process integrity.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and engineering confidence. As a global leader in high-accuracy CNC machining services, we specialize in turning complex designs into flawless, production-ready components for industries where failure is not an option. From aerospace and medical devices to semiconductor equipment and advanced automation, our machining solutions meet the most stringent technical demands.

Our commitment begins with capability. Our facility in Wuxi, China, is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machining centers, Swiss-type lathes, and multi-tasking machines that ensure micron-level accuracy and repeatability. With ISO 9001:2015 certification and a fully integrated quality management system, every component we produce undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. This ensures dimensional integrity and surface finish consistency across every batch.

We understand that precision is more than just tight tolerances—it’s about partnership. Our engineering team collaborates closely with clients from initial design review through final delivery, offering Design for Manufacturability (DFM) feedback to optimize part geometry, reduce lead times, and lower overall production costs. Whether you require rapid prototyping, low-volume custom runs, or high-volume production, our scalable infrastructure and agile manufacturing processes adapt to your project’s unique requirements.

Material versatility is another cornerstone of our service. We machine a broad range of metals and engineering plastics, including aluminum alloys, stainless steel, titanium, Inconel, brass, PEEK, and Delrin, ensuring compatibility with extreme environments, corrosive exposure, or high-stress applications. Surface treatments such as anodizing, passivation, plating, and powder coating are available to enhance durability and performance.

Our global clients trust us not only for technical excellence but for transparency and responsiveness. With digital work order tracking, real-time production updates, and dedicated project management, you’re never left in the dark. We pride ourselves on on-time delivery rates exceeding 98%, even for the most complex, multi-stage components.

For mission-critical applications, compromise is not an option. At Wuxi Lead Precision Machinery, we engineer certainty into every process, every part, every time.

| Specification | Capability |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, turning, multi-axis milling/turning |

| Tolerances | ±0.005 mm (±0.0002″) |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Materials | Aluminum, Stainless Steel, Titanium, Inconel, Brass, PEEK, Delrin, and more |

| Finishing Options | Anodizing, Passivation, Plating, Powder Coating, Polishing |

| Quality Standards | ISO 9001:2015, Full CMM Inspection, First Article Inspection (FAI) |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Ready to elevate your manufacturing outcomes? Contact us today at [email protected] to speak with a precision engineering specialist. Let Wuxi Lead Precision Machinery be your trusted partner in high-performance CNC machining.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.