Technical Contents

Engineering Guide: Pp Moulding

Engineering Insight: Precision in PP Moulding for Demanding Industrial Applications

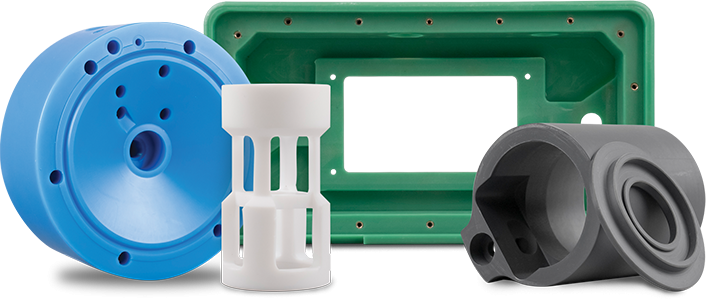

In the field of custom metal manufacturing, polypropylene (PP) moulding stands as a critical process for producing high-performance, chemically resistant, and lightweight components. While PP is inherently a thermoplastic polymer, its integration with precision metal tooling and support structures in hybrid manufacturing systems demands the same level of engineering rigor as traditional metal forming. At Wuxi Lead Precision Machinery, we recognize that the success of PP moulded components in aerospace, defense, and high-spec industrial applications hinges on dimensional accuracy, material consistency, and process control—hallmarks of true precision engineering.

PP moulding, when executed at scale and under tight tolerances, requires advanced mold design, temperature regulation, and cycle optimization. Even minor deviations in cavity pressure or cooling rates can lead to warpage, sink marks, or inconsistent wall thickness—failures that are unacceptable in mission-critical environments. This is where our engineering discipline becomes decisive. With over a decade of experience in high-integrity manufacturing, Wuxi Lead has applied its expertise to support projects for Olympic-standard facilities and military-grade equipment, where failure is not an option. These projects demanded not only compliance with ISO and MIL specifications but also the ability to replicate exacting geometries across thousands of cycles—proof of our mastery in precision-driven processes.

Our approach begins with finite element analysis (FEA) to simulate mold flow and thermal behavior, ensuring optimal gate placement and cooling channel design. We utilize hardened steel molds with tight tolerances (±0.02 mm), CNC-machined in-house to maintain full control over quality. Each mold undergoes rigorous validation through first-article inspection and statistical process control (SPC) during production. This level of oversight ensures that every PP component meets the mechanical and dimensional requirements of its intended application, whether it’s a sealed enclosure for field-deployable electronics or a corrosion-resistant duct for industrial ventilation.

Beyond tooling, our facility integrates real-time monitoring systems that track injection pressure, melt temperature, and clamp force, enabling immediate correction and full traceability. This data-driven methodology aligns with Industry 4.0 standards and reflects our commitment to continuous improvement in high-mix, low-volume production environments.

The following table outlines key specifications and capabilities for PP moulding at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material Compatibility | Homopolymer & copolymer PP, filled grades |

| Typical Tolerance Range | ±0.02 mm to ±0.05 mm |

| Mold Steel Types | H13, P20, 1.2344, Stainless (custom) |

| Maximum Clamp Force | 1,200 tons |

| Part Weight Range | 5 g – 1,500 g |

| Surface Finish Options | SPI-S1, SPI-A2, texture, bead blast |

| Process Control | Real-time monitoring with SPC & FEA support |

| Certification Standards | ISO 9001, MIL-STD-810 (application-specific) |

Precision in PP moulding is not merely about shaping plastic—it is about engineering reliability into every component. At Wuxi Lead Precision Machinery, our legacy in serving elite industrial and defense sectors underscores our ability to deliver beyond expectations. When performance, repeatability, and integrity are paramount, our precision systems ensure success.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for PP Molding Applications

Wuxi Lead Precision Machinery delivers the exacting metal component precision required for high-performance polypropylene (PP) molding operations. Our core strength lies in transforming complex engineering designs into dimensionally stable, long-lasting mold bases, cavities, cores, and critical ancillary tooling through advanced metal manufacturing processes. This precision is non-negotiable for achieving consistent part quality, minimizing flash, ensuring proper ejection, and maximizing mold life in demanding PP production environments. We understand that the thermal stability and geometric accuracy of the metal mold directly dictate the dimensional integrity and surface finish of the final PP component.

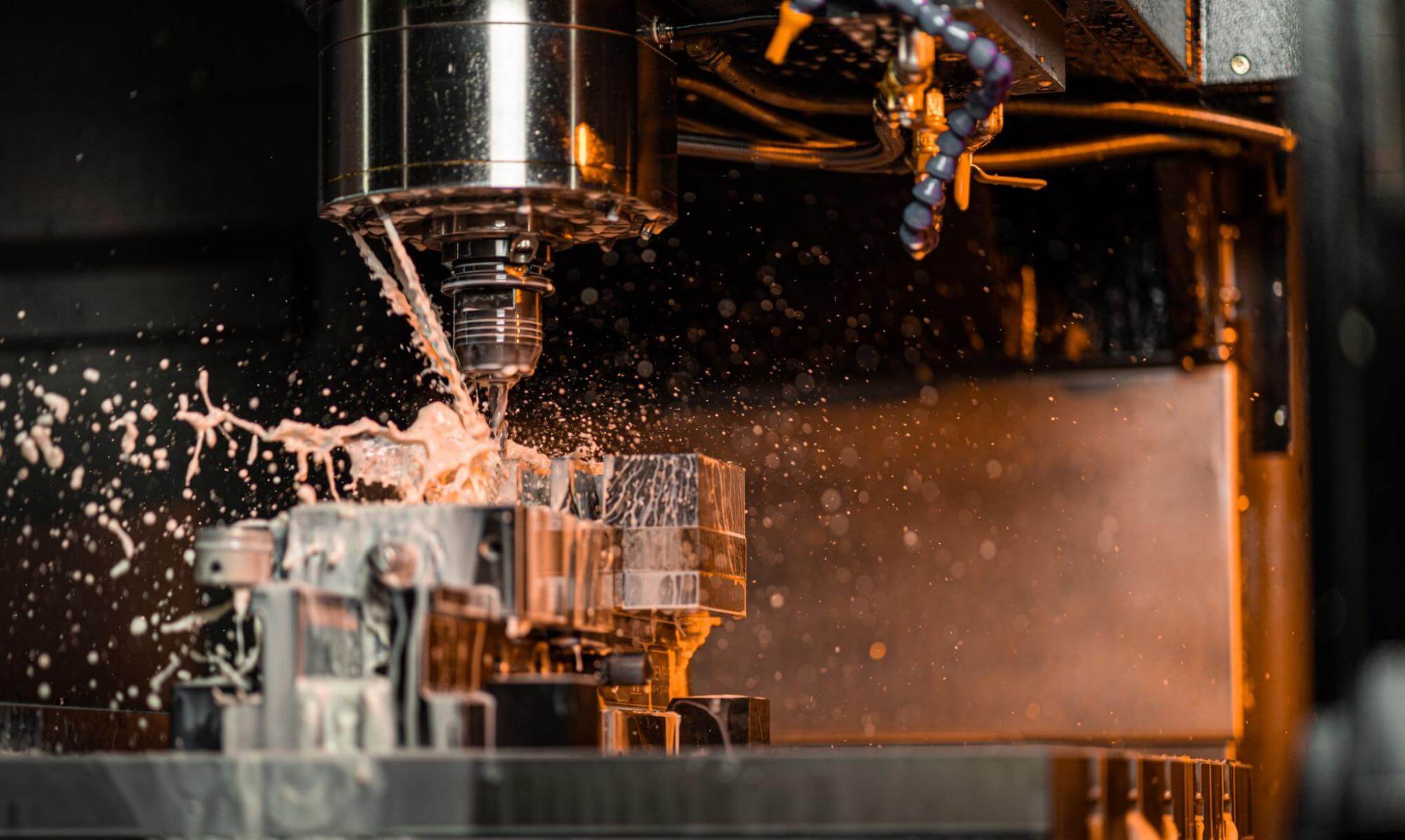

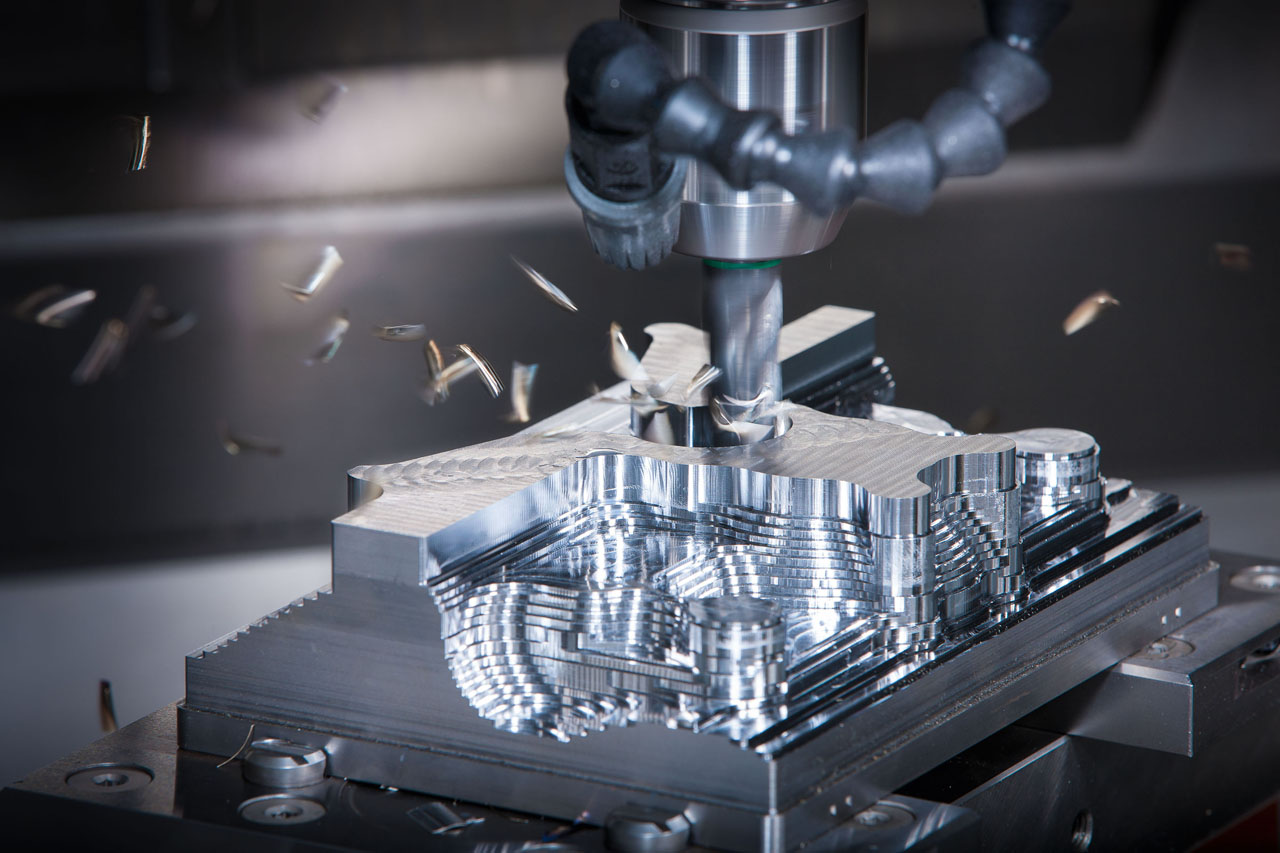

Central to our capability is a comprehensive fleet of state-of-the-art 5-axis CNC machining centers. These systems enable us to machine intricate mold geometries—deep ribs, undercuts, complex contours, and fine surface textures—in a single setup. Simultaneous 5-axis interpolation ensures exceptional part accuracy by minimizing cumulative errors from multiple fixturing operations. We utilize high-rigidity machines equipped with precision spindles, thermal compensation systems, and Renishaw probing for in-process verification. This allows us to efficiently produce molds requiring tight tolerances on critical features like parting lines, shut-offs, and cooling channels, essential for managing PP’s specific flow and cooling characteristics. Our programming leverages advanced CAM software to optimize toolpaths for material removal rates while maintaining surface integrity on hardened tool steels like H13 or S136.

Quality control is rigorously integrated throughout the manufacturing process, not merely a final checkpoint. Every critical component undergoes comprehensive inspection using certified Coordinate Measuring Machines (CMM). Our Zeiss CONTURA and similar high-accuracy CMMs provide full 3D dimensional verification against the original CAD model, ensuring conformity to all specified datums and geometric tolerances. This includes meticulous validation of cavity/core matching, ejector pin locations, guide pin alignment, and cooling channel positioning. Surface finish is verified using profilometers to meet the stringent Ra values required for optimal PP release and surface aesthetics. All inspection data is documented in detailed reports, providing full traceability for our clients and enabling proactive process refinement.

The table below details our standard and enhanced achievable tolerances for critical mold features relevant to PP molding. Note that specific capabilities can be optimized based on part geometry, material selection, and client requirements; consultation with our engineering team is recommended for mission-critical applications.

| Feature Category | Standard Capability | Enhanced Capability (Consultation Required) |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

| Angular Features | ±0.05° | ±0.02° |

| Geometric Tolerances (Position, Flatness, Profile) | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Cavity/ Core Matching | 0.020 mm | 0.010 mm |

Achieving optimal results in PP molding demands metal components manufactured to exacting standards. Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with rigorous CMM-based quality assurance to deliver the dimensional fidelity and surface quality essential for your PP molding success. We partner with clients to translate design intent into robust, high-precision tooling that ensures production efficiency and part consistency.

Material & Finish Options

Material Selection in High-Performance PP Moulding Applications

In precision manufacturing for polypropylene (PP) moulding tooling, selecting the appropriate base material is critical to ensuring long-term durability, dimensional accuracy, and thermal efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal solutions tailored to the demanding requirements of PP injection moulding. The choice between aluminum, steel, and titanium depends on production volume, part complexity, thermal management needs, and cost-efficiency targets.

Aluminum alloys, particularly 7075 and 6061-T6, offer excellent machinability and superior thermal conductivity, making them ideal for prototyping and low-to-medium volume production runs. Their lightweight nature reduces cycle times and energy consumption during operation. While not as wear-resistant as steel, aluminum moulds are often preferred when rapid iteration and fast time-to-market are priorities. With proper surface treatment such as hard anodizing, aluminum can achieve enhanced surface hardness and corrosion resistance, significantly extending service life in aggressive polymer environments.

Steel, especially pre-hardened tool steels like P20 and H13, remains the standard for high-volume PP moulding due to its exceptional toughness, wear resistance, and longevity. These materials withstand repeated thermal cycling and mechanical stress, maintaining dimensional stability over hundreds of thousands of cycles. Stainless steel variants are recommended when corrosion resistance is paramount, such as in medical or food-grade applications. Although steel moulds require longer lead times and higher initial costs, their durability offers a lower total cost of ownership in mass production scenarios.

Titanium alloys, while less common, are emerging in niche applications requiring extreme strength-to-density ratios and outstanding corrosion resistance. While prohibitively expensive for most standard moulding tools, titanium finds use in specialized cores, inserts, or heating elements where weight reduction and performance under harsh conditions are critical. Its biocompatibility also makes it suitable for medical-grade PP components.

Surface finishing plays a pivotal role in part ejection, surface quality, and maintenance intervals. Anodizing, particularly Type III (hard anodizing), is widely applied to aluminum moulds to create a dense, wear-resistant oxide layer. This treatment improves release properties, reduces galling, and enhances resistance to chemical degradation from molten PP and release agents. For steel, alternatives such as nitriding or chrome plating are typically used, though anodizing is not applicable.

Below is a comparative overview of key material properties relevant to PP moulding applications.

| Material | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Hardness (HB) | Typical Use Case | Surface Treatment Compatibility |

|---|---|---|---|---|---|

| Aluminum 7075 | 540–570 | 130 | 150 | Prototyping, low-volume runs | Hard Anodizing, Alodine |

| P20 Steel | 950–1100 | 30 | 280–320 | High-volume production | Nitriding, Chrome Plating |

| H13 Steel | 1000–1200 | 35 | 340–380 | High-temperature applications | PVD Coating, Nitriding |

| Titanium Gr5 | 900–1000 | 7 | 360 | Specialized inserts, medical | Anodizing (non-standard), Plating |

Material selection directly impacts tool performance, maintenance frequency, and final part quality in PP moulding. At Wuxi Lead Precision Machinery, we support clients in matching material and finish to application demands, ensuring optimal balance between performance and cost.

Manufacturing Process & QC

Precision PP Molding: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, we engineer the foundation for flawless polypropylene (PP) component manufacturing. Our integrated process transcends basic molding, embedding precision engineering and rigorous quality control from the earliest design phase through to high-volume production. This systematic approach, powered by our advanced CNC-machined molds and process control systems, is the cornerstone of achieving true zero-defect outcomes for demanding industrial applications.

The journey begins with collaborative design optimization. Our engineering team conducts comprehensive Design for Manufacturing (DFM) and Mold Flow Analysis on all customer CAD models. We scrutinize wall thickness transitions, gate locations, cooling channel layouts, and ejection strategies specific to PP’s unique thermal properties and shrinkage characteristics. This critical stage identifies potential sinks, warpage, or knit lines before metal is cut, ensuring the mold design inherently supports dimensional stability and structural integrity. Material selection guidance for specific PP grades (homopolymer, copolymer, filled) is provided based on the part’s functional requirements and environmental exposure.

Prototyping is not merely a form check; it is a vital process validation step. Using molds crafted with the same precision CNC techniques as production tools, we produce functional prototypes under controlled conditions mirroring the final process. These parts undergo rigorous metrology, including CMM inspection against GD&T callouts, material property verification, and assembly fit testing. Process parameters—melt temperature, injection speed, packing pressure, cooling time—are meticulously dialed in and documented. This phase validates the DFM analysis, confirms the mold’s capability, and provides tangible data to secure customer approval, eliminating costly surprises later.

Transitioning to mass production, Wuxi Lead implements closed-loop process control systems integrated with our high-precision molding machines. Real-time monitoring of critical parameters ensures consistency far beyond standard industry tolerances. Every cycle is verified against the validated prototype process window. Our zero-defect mandate is enforced through multi-stage inspection: 100% automated vision checks for surface defects and critical dimensions on the line, coupled with statistical process control (SPC) sampling for deeper dimensional analysis and material properties. Traceability links each part batch to its specific machine parameters and raw material lot. This relentless focus on process stability and verification, built upon the robust foundation of our initial design and prototyping phases, guarantees parts that consistently meet the most stringent aerospace, medical, and industrial specifications.

Key Process Specifications Comparison

| Parameter | Prototyping Phase | Mass Production Phase |

|---|---|---|

| Typical Tolerance | ±0.10 mm | ±0.05 mm or tighter |

| Cycle Time Focus | Parameter validation | Optimized for efficiency & consistency |

| Material Grade | Customer-specified prototype grade | Certified production grade |

| Primary Validation | Functional fit, initial metrology | SPC, 100% automated inspection, material certs |

| Output Volume | 10-100 parts | 10,000+ parts per run |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced PP Moulding Solutions in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance manufacturing solutions tailored to the evolving demands of the industrial sector. As a trusted leader in custom metal manufacturing, we integrate precision engineering with advanced polymer processing to offer unmatched PP (polypropylene) moulding capabilities. Our expertise ensures that every component we produce meets stringent quality standards, offering durability, chemical resistance, and thermal stability—critical attributes for demanding industrial applications.

PP moulding is not just about shaping materials; it’s about engineering performance. At Lead Precision, we understand the technical nuances of polymer behavior under high-stress environments. Our in-house design team collaborates closely with clients to develop moulds and components that align perfectly with functional requirements, production volume, and environmental conditions. Whether you require complex enclosures, fluid-handling components, or high-impact structural parts, our process optimization ensures repeatability, dimensional accuracy, and long-term reliability.

Our state-of-the-art facility in Wuxi is equipped with advanced injection moulding machines, precision CNC machining centers, and rigorous quality control systems. We maintain strict ISO-certified protocols throughout production, from raw material inspection to final product validation. This commitment to excellence has positioned us as a preferred partner for global OEMs and engineering firms seeking dependable, scalable manufacturing support.

We offer full-service project management, from concept and prototyping to mass production and after-sales support. Our engineers utilize simulation software to predict mould flow, minimize defects, and reduce time-to-market. By integrating metal fabrication with polymer moulding, we provide hybrid solutions that enhance mechanical performance and reduce assembly complexity—delivering cost savings and improved system efficiency.

Below are key technical specifications that define our PP moulding capabilities:

| Specification | Detail |

|---|---|

| Material Compatibility | Polypropylene (homopolymer and copolymer), filled and reinforced variants |

| Moulding Process | High-pressure injection moulding with multi-cavity tooling |

| Part Weight Range | 5 g to 1,200 g |

| Tolerance | ±0.1 mm (standard), ±0.05 mm (precision) |

| Mould Life | Up to 1 million cycles (hardened steel tooling) |

| Surface Finish | Matte, textured, polished, or custom |

| Secondary Operations | CNC trimming, ultrasonic welding, insert moulding, assembly |

| Quality Standards | ISO 9001:2015, RoHS compliant, full traceability |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally focused on innovation, precision, and long-term value. We are committed to supporting your engineering goals with responsive service, technical depth, and scalable production capacity.

Contact us today at [email protected] to discuss your next PP moulding project. Let Lead Precision be the foundation of your manufacturing success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.