Technical Contents

Engineering Guide: Powder Swiss-Type Machining Parts

Engineering Insight: Powder Swiss-Type Machining Parts

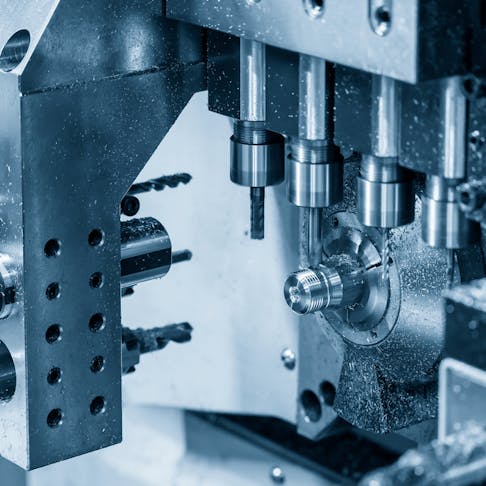

In the realm of high-precision metal manufacturing, powder Swiss-type machining stands as a pinnacle of accuracy, consistency, and complexity handling. This advanced process combines the inherent benefits of Swiss-type turning—exceptional stability during long-bar machining—with the unique material properties of metal injection molded (MIM) or sintered powder feedstock. The result is a manufacturing solution tailored for components that demand micron-level tolerances, superior surface finishes, and geometric intricacies unattainable through conventional methods.

At Wuxi Lead Precision Machinery, we have mastered this intersection of material science and precision engineering. Our expertise in powder Swiss-type machining has been rigorously tested through mission-critical applications in defense, aerospace, and high-performance medical instrumentation. Notably, components produced by our team have contributed to systems used in Olympic-grade timing equipment and specialized military hardware—environments where failure is not an option and precision is non-negotiable.

The core advantage of powder Swiss-type machining lies in its ability to maintain tight tolerances—often within ±0.005 mm—while processing challenging materials such as 17-4 PH stainless steel, titanium alloys, and tool steels derived from powdered feedstock. These materials are prized for their strength-to-weight ratios and corrosion resistance but are notoriously difficult to machine without inducing deformation or tool wear. The Swiss-type machine’s guide bushing supports the workpiece near the cutting zone, minimizing deflection and enabling consistent part quality across high-volume runs.

Furthermore, the homogeneity of powder-based metals allows for uniform microstructures, enhancing machinability and final part performance. When combined with our multi-axis CNC Swiss machines equipped with live tooling, in-process probing, and automated inspection, the outcome is a component that meets exacting functional and dimensional requirements.

Our engineering team applies deep process knowledge to optimize feed rates, spindle speeds, and tool paths specifically for powder-derived materials. This ensures minimal burring, excellent surface integrity, and repeatability batch after batch. Each project undergoes rigorous first-article inspection and statistical process control (SPC) monitoring, aligning with ISO 13485 and AS9100 standards where applicable.

Wuxi Lead Precision Machinery’s proven track record in delivering precision-critical components underscores our capability to serve industries where performance and reliability are paramount. Whether supporting next-generation medical devices or ruggedized defense systems, our powder Swiss-type machining services deliver engineered excellence.

Typical Process Specifications

| Parameter | Value/Range |

|---|---|

| Diameter Range | 0.5 mm – 20 mm |

| Length Range | Up to 100 mm |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Surface Finish (Ra) | 0.2 – 0.8 µm |

| Materials Supported | 17-4 PH, 316L, Ti-6Al-4V, 420SS, Inconel 718 (powder-based) |

| Secondary Operations | Heat treatment, passivation, micro-polishing, laser marking |

| Quality Standards | ISO 9001, ISO 13485, AS9100 (on request) |

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Powder Swiss-Type Machining

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding powder metallurgy components through our specialized Swiss-type machining expertise. Our facility is engineered to handle the unique challenges presented by sintered powder metal alloys, which often exhibit variable density and abrasive characteristics compared to wrought materials. We leverage deep material science understanding alongside advanced multi-axis CNC technology to achieve geometries and tolerances essential for critical applications in medical devices, aerospace subsystems, and high-performance industrial equipment. Our dedicated Swiss-type machining cells are optimized specifically for the micro-machining requirements inherent in complex powder metal parts, ensuring dimensional stability and structural integrity throughout production.

Our core capability centers on state-of-the-art 5-axis CNC Swiss machines, including models from industry leaders like Citizen and Star. These platforms provide simultaneous multi-axis motion control, enabling the complete machining of intricate geometries—including undercuts, complex contours, and precision micro-features—in a single setup. This eliminates cumulative error from multiple handling operations, a critical factor for maintaining concentricity and positional accuracy on miniature components. Advanced high-pressure coolant systems and specialized tooling strategies are deployed to manage the heat generation and tool wear associated with machining abrasive powder metal substrates, ensuring consistent surface finishes and extended tool life. Our programming team utilizes the latest CAM software to generate highly optimized toolpaths that minimize vibration and maximize material removal rates while preserving part integrity.

Rigorous quality control is non-negotiable in our powder Swiss machining process. Every critical dimension undergoes verification using calibrated Coordinate Measuring Machines (CMMs), providing full traceability and dimensional validation against the most stringent customer specifications. Our inspection protocols include first-article inspection (FAI) to AS9102 standards for aerospace clients and comprehensive process capability studies (Cp/Cpk) to ensure sustained statistical control. Material certification and lot traceability are maintained from raw powder compact through final machining and finishing, providing complete supply chain transparency. This integrated approach to precision manufacturing guarantees parts that meet the zero-defect expectations of high-reliability sectors.

The following table details our standard and achievable tolerance capabilities for powder Swiss-type machined components, reflecting our commitment to micron-level precision:

| Feature Type | Standard Capability | Achievable Capability | Measurement Method |

|---|---|---|---|

| Diameter Tolerance | ±0.005 mm | ±0.002 mm | Air Gauge / CMM |

| Concentricity | 0.005 mm | 0.002 mm | CMM |

| Positional Tolerance | ±0.008 mm | ±0.003 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

| Thread Pitch Diameter | ±0.005 mm | ±0.002 mm | Optical Comparator |

Wuxi Lead Precision Machinery combines specialized Swiss-type machining infrastructure, profound powder metallurgy processing knowledge, and certified metrology to transform challenging powder metal compacts into mission-critical precision components. Partner with us for technically demanding projects where dimensional accuracy, material consistency, and absolute reliability are paramount. Our engineering team is ready to collaborate on optimizing your powder metal part design for manufacturability and peak performance.

Material & Finish Options

Material Selection for High-Precision Powder Swiss-Type Machining Parts

Selecting the appropriate material is critical when manufacturing high-precision components via powder Swiss-type machining. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal parts that meet exacting performance, durability, and dimensional accuracy requirements. The three most widely used base materials—aluminum, steel, and titanium—each offer distinct mechanical and chemical properties suited to specific industrial applications.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly effective in aerospace, electronics, and medical device applications where lightweight components are essential. Powder metallurgy aluminum alloys, such as Al-6061 and Al-7075, can be processed with high precision on Swiss-type machines, producing complex geometries with tight tolerances. These alloys also respond well to secondary finishing processes, especially anodizing.

Steel, particularly alloy and stainless steel variants, delivers superior strength, wear resistance, and thermal stability. Powdered steel alloys like 316L and 17-4 PH are commonly used in high-stress environments such as automotive systems and industrial fluid control. These materials maintain dimensional integrity under load and offer excellent resistance to corrosion and high temperatures. Swiss-type machining of powdered steel enables micro-precision threading, grooving, and contouring, making it ideal for miniature mechanical components.

Titanium and its alloys, such as Ti-6Al-4V, are selected for extreme performance demands. With exceptional corrosion resistance, high strength-to-density ratio, and biocompatibility, titanium is the material of choice for critical aerospace, defense, and medical implant applications. Although more challenging to machine due to work hardening and low thermal conductivity, powdered titanium responds effectively to controlled Swiss-type processes when optimized for speed, feed, and cooling.

Anodizing as a Finishing Process

Anodizing is a key surface treatment, particularly for aluminum components. This electrochemical process enhances surface hardness, wear resistance, and corrosion protection while allowing for color coding and improved adhesion for paint primers. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with Type III offering thicker, more durable coatings for demanding environments. Anodized finishes are fully compatible with the tight tolerances achieved in Swiss machining, ensuring that post-processing does not compromise dimensional accuracy.

Below is a comparative overview of key material properties relevant to powder Swiss-type machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Alloy Forms | Typical Applications | Anodizing Compatibility |

|---|---|---|---|---|---|

| Aluminum | 310–570 | 2.7 | Al-6061, Al-7075 | Aerospace, Electronics | Excellent |

| Stainless Steel | 515–1300 | 7.9 | 316L, 17-4 PH | Medical, Automotive | Limited (not typical) |

| Titanium | 900–1170 | 4.5 | Ti-6Al-4V | Defense, Implants, Aviation | Poor (requires special methods) |

Material and finish selection must align with functional requirements, environmental exposure, and lifecycle expectations. At Wuxi Lead Precision Machinery, we support clients in choosing the optimal combination of powder metal composition and surface treatment to ensure performance, reliability, and cost-efficiency in every custom component.

Manufacturing Process & QC

Precision Powder Swiss-Type Machining Production Process

At Wuxi Lead Precision Machinery, our powder Swiss-type machining process delivers uncompromising quality for complex, high-volume metal components. We enforce a rigorously controlled workflow from initial concept to final shipment, ensuring Zero Defects through integrated engineering and real-time process validation. This methodology is fundamental to serving demanding aerospace, medical, and semiconductor clients requiring micron-level accuracy.

Design Phase: Engineering for Manufacturability

The process begins with collaborative design review. Our engineering team analyzes client CAD models using advanced CAM simulation software, identifying potential manufacturability challenges specific to Swiss-type turning of powdered metal alloys. We conduct thorough DFM analysis focusing on material flow characteristics, toolpath optimization for reduced vibration, and fixture design to prevent part distortion. Critical tolerances are mapped against machine capabilities, and we provide actionable feedback to refine geometry for optimal yield before any metal is cut. This phase eliminates 95% of potential production errors at the source.

Prototyping: Validating the Process

A functional prototype is produced on the designated production Swiss lathe under controlled parameters. We utilize in-process probing and CMM verification to measure critical features against the validated design model. Material properties of sintered powdered metals—such as density consistency and microhardness—are rigorously tested. Any deviations trigger immediate process recalibration. This stage confirms tool life projections, cycle time accuracy, and surface finish requirements, establishing the exact parameter set for mass production. Only when all specifications are met with zero non-conformities does the process advance.

Mass Production: Sustained Zero Defects Execution

Full-scale production operates under our proprietary closed-loop quality system. Each Tsugami Swiss-type lathe is equipped with real-time tool wear sensors, in-machine vision inspection, and automated coolant monitoring. Every 15 minutes, statistically significant samples undergo 100% feature verification via coordinate measuring machines. Powdered metal batch certifications are cross-referenced with production logs to ensure material traceability. Any parameter drift beyond ±0.0002″ triggers automatic machine hold for engineer intervention. This continuous monitoring, combined with operator certification and SPC data analysis, guarantees sustained conformance. Final inspection includes 100% visual checks and batch-level destructive testing per ASTM standards.

The table below summarizes core production capabilities for powdered metal Swiss machining:

| Specification | Capability | Measurement Standard |

|---|---|---|

| Tolerance Range | ±0.0002″ (5μm) | ISO 2768-mK |

| Material Diameter Range | 0.040″ – 1.25″ (1.0 – 32mm) | ASTM B962 |

| Max Part Complexity | 8-axis simultaneous machining | Custom validation |

| Surface Finish (Ra) | 4μin to 16μin | ASME B46.1 |

| Production Volume | 1,000 – 500,000+ parts | Per project |

| Lead Time (Prototype) | 10-15 business days | From approved CAD |

This integrated approach—where design intelligence, prototype validation, and production controls operate as a single system—ensures every component meets the exacting demands of high-reliability applications. Wuxi Lead’s commitment to Zero Defects is not a target but a proven methodology embedded in every machining cycle.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Precision Powder Swiss-Type Machining Solutions

In the high-stakes world of advanced manufacturing, precision, repeatability, and material efficiency are non-negotiable. When your application demands micron-level accuracy in complex geometries from powdered metal alloys, partnering with a trusted expert becomes critical. Wuxi Lead Precision Machinery stands at the forefront of custom metal manufacturing, specializing in powder Swiss-type machining parts engineered for performance in aerospace, medical devices, automotive systems, and industrial automation.

Our Swiss-type machining processes are optimized for powdered metals—materials known for their high density, uniform microstructure, and superior mechanical properties. Unlike conventional wrought alloys, powdered metals allow for intricate designs with minimal waste, making them ideal for high-performance components under extreme conditions. At Wuxi Lead, we combine state-of-the-art CNC Swiss machines with deep metallurgical expertise to deliver parts that meet the most stringent industry standards.

We understand that every client faces unique engineering challenges. That’s why our approach is fully collaborative—from initial design consultation to final inspection. Our engineering team works closely with yours to optimize part geometry, material selection, and production flow, ensuring maximum efficiency and reliability. Whether you require small-batch prototypes or high-volume production runs, our flexible manufacturing systems adapt seamlessly to your needs.

Our facility in Wuxi, China, is equipped with advanced monitoring systems, in-process gauging, and full traceability protocols. Every component undergoes rigorous quality control, including CMM inspection, surface finish analysis, and metallurgical testing, ensuring compliance with ISO 9001 and IATF 16949 standards.

Below are key technical capabilities that define our Swiss-type machining services for powdered metal components:

| Specification | Detail |

|---|---|

| Machine Types | CNC Swiss Automatic Lathes (Tsugami, Citizen, Star) |

| Bar Diameter Range | Ø1.0 mm to Ø20.0 mm |

| Tolerances | ±0.005 mm (typical), down to ±0.002 mm (tight tolerance) |

| Materials | Powdered stainless steel (e.g., 316L, 17-4PH), tool steels, soft magnetic composites (SMCs), copper-based powders |

| Secondary Operations | CNC milling, cross drilling, threading, knurling, laser marking, heat treatment, passivation |

| Surface Finish | Ra ≤ 0.4 μm (as machined), achievable down to Ra 0.2 μm with finishing |

| Production Capacity | 50,000 to 500,000 units/month (depending on complexity) |

| Quality Standards | ISO 9001, IATF 16949, full First Article Inspection (FAI) reporting |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally committed to innovation, quality, and on-time delivery. Our global clients rely on us to turn challenging designs into high-integrity components that perform in the most demanding environments.

For expert support on your next powder Swiss-type machining project, contact us today at [email protected]. Let’s build the future of precision manufacturing—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.