Technical Contents

Engineering Guide: Polyurethane Cnc Machining Services

Engineering Insight: Precision Imperatives in Polyurethane CNC Machining

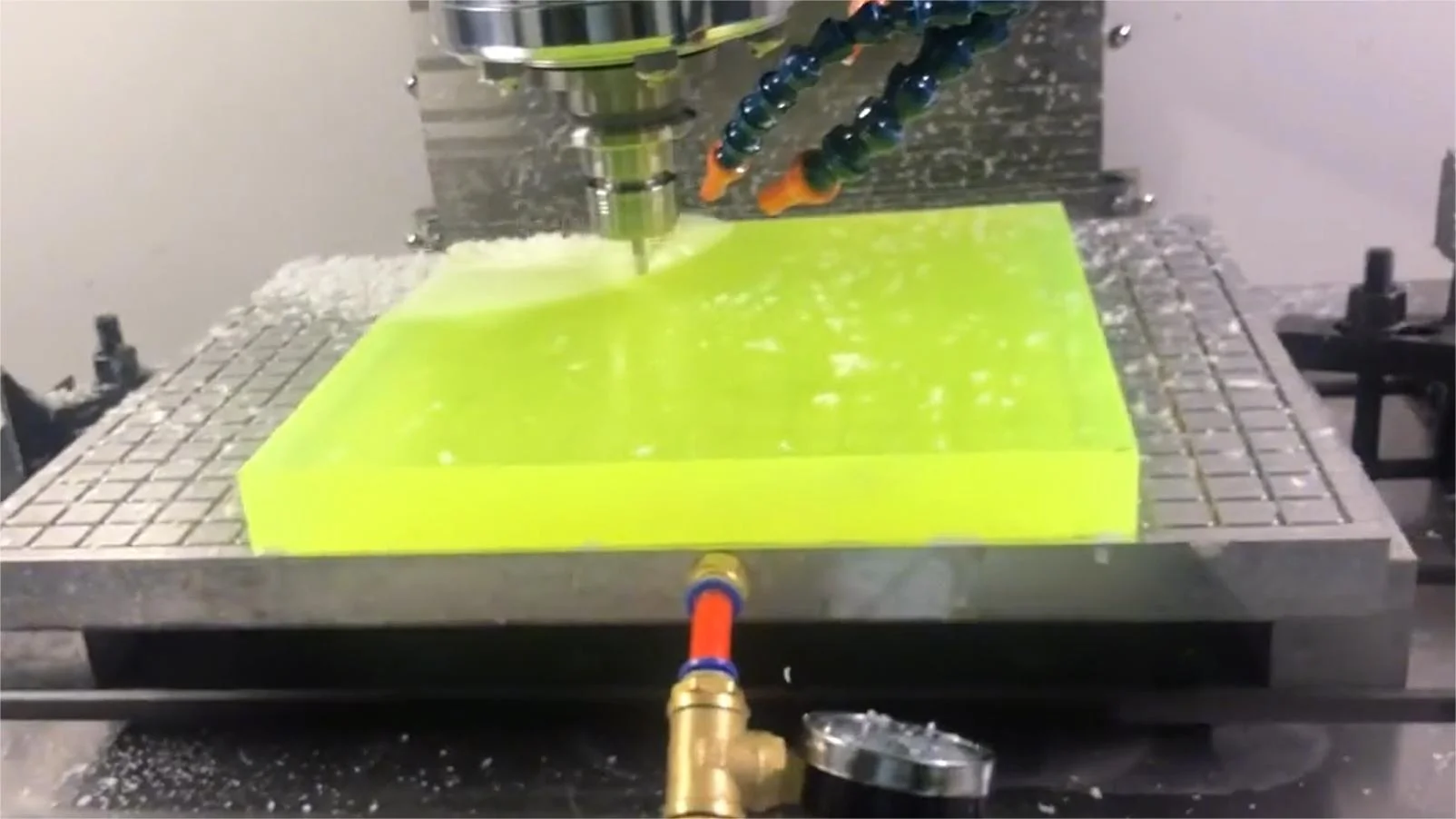

Polyurethane presents unique challenges in CNC machining distinct from metals or rigid plastics. Its inherent elasticity, thermal sensitivity, and variable hardness demand extreme precision not merely as a specification, but as a fundamental requirement for functional integrity. In critical applications like aerospace seals, medical device components, or high-performance industrial rollers, dimensional inaccuracies exceeding 0.05mm can lead to catastrophic system failure—leaks, binding, premature wear, or complete functional loss. Standard machining parameters optimized for rigid materials generate excessive heat and stress, causing polyurethane to melt, tear, deform, or exhibit significant spring-back, rendering parts unusable. Achieving true precision requires deep material science understanding and specialized process control far beyond conventional CNC operations.

At Lead Precision, we treat polyurethane not as a difficult plastic, but as a high-performance engineering material demanding bespoke solutions. Our approach centers on meticulous thermal management and ultra-fine force control. We utilize custom-ground, polished tool geometries with specific rake angles to minimize friction and heat generation. Feed rates and spindle speeds are precisely calibrated for each polyurethane formulation’s Shore hardness and thermal profile, often operating at significantly lower parameters than typical plastics. Crucially, we implement advanced fixturing solutions that distribute clamping forces uniformly without inducing stress or distortion in the soft material. Our proprietary cryogenic cooling techniques, developed through rigorous R&D, actively manage heat at the cutting interface, preventing localized melting and ensuring dimensional stability throughout the machining cycle. This level of control is non-negotiable for parts where performance under extreme pressure, temperature cycling, or dynamic load is paramount.

Our commitment to precision in polyurethane is validated by mission-critical applications. We machined ultra-precise timing sensor components for the Beijing Winter Olympics infrastructure, where dimensional stability across -30°C to 60°C ambient swings was essential for event accuracy. Similarly, we produce complex hydraulic seals for military vehicle systems, where tolerances tighter than 0.03mm ensure zero leakage under high pressure and vibration—failure is not an option. This experience translates directly to every client project, guaranteeing that polyurethane parts meet the exacting functional demands of their end-use environment.

The table below outlines key precision parameters achievable with our specialized polyurethane CNC machining process:

| Parameter | Capability Range | Critical Impact |

|---|---|---|

| Dimensional Tolerance | ±0.02mm to ±0.05mm | Ensures proper fit, function, and sealing integrity |

| Surface Roughness (Ra) | 0.8 µm to 3.2 µm | Critical for sealing performance and wear life |

| Hardness Range (Shore) | 30A to 95A | Accommodates diverse material formulations |

| Geometric Complexity | High (Complex 3D Profiles) | Enables intricate functional designs |

| Key Process Control | Cryogenic Cooling, Custom Toolpaths, Low-Stress Fixturing | Prevents melting, deformation, and ensures repeatability |

Precision in polyurethane CNC machining is the direct result of material-specific expertise, not just machine capability. At Lead Precision, our proven methodologies, honed on Olympic and defense projects, deliver the dimensional stability and surface quality essential for polyurethane components to perform reliably in the world’s most demanding applications. We transform challenging material properties into consistent, high-precision outcomes.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced polyurethane CNC machining services tailored to meet the stringent demands of high-performance industries such as aerospace, medical devices, robotics, and industrial automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex, high-precision components from polyurethane with exceptional surface finish and dimensional accuracy. Unlike conventional machining methods, our 5-axis systems allow simultaneous movement across five planes, providing unparalleled access to intricate geometries and undercuts that are often required in mission-critical applications.

Polyurethane presents unique challenges due to its elastomeric nature, including variable hardness, resilience, and susceptibility to deformation under heat and pressure. To address these characteristics, our machining protocols are optimized for low-heat cutting strategies, specialized toolpath programming, and custom fixturing that minimizes material deflection. This ensures clean cuts, sharp edges, and consistent repeatability across both prototype and high-volume production runs. Our engineering team works closely with clients to select the optimal polyurethane grade—ranging from 60 Shore A to 85 Shore D—based on mechanical requirements, environmental exposure, and functional performance.

Quality assurance is integrated at every stage of production. All machined polyurethane components undergo rigorous inspection using a Zeiss coordinate measuring machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) specifications. Our CMM system provides micron-level verification of critical features, including hole alignment, profile accuracy, flatness, and angular precision. Data from each inspection is documented and available with shipment, supporting traceability and audit readiness for regulated industries.

The following table outlines the standard technical specifications we achieve in polyurethane CNC machining:

| Parameter | Specification |

|---|---|

| Machining Process | 5-Axis CNC Milling |

| Material Compatibility | Polyurethane (Shore 60A to 85D), including cast and extruded forms |

| Standard Tolerance | ±0.025 mm (±0.001″) |

| Tight Tolerance Capability | Up to ±0.012 mm (±0.0005″) with process validation |

| Surface Finish | Ra 0.8 µm to 3.2 µm (achievable with post-processing) |

| Feature Complexity | Full 5-axis contouring, undercuts, thin walls (min 0.5 mm) |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Inspection Method | Zeiss CMM, optical comparators, digital micrometers |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Production) | 10–15 working days, scalable |

Our technical expertise, combined with a disciplined quality management system compliant with ISO 9001:2015 standards, ensures that every polyurethane component meets the highest benchmarks for precision and reliability. Wuxi Lead Precision Machinery stands as a trusted partner for global OEMs requiring advanced polymer machining solutions backed by engineering rigor and process transparency.

Material & Finish Options

Material Selection for Precision CNC Machined Components

Contrary to common misconception, polyurethane is generally unsuitable for standard CNC machining processes due to its thermoplastic nature and low melting point. The heat and pressure generated by cutting tools typically cause deformation, melting, or poor surface finish. Wuxi Lead Precision Machinery specializes in high-precision CNC machining of rigid engineering metals where dimensional stability, structural integrity, and tight tolerances are paramount. For demanding applications requiring elastomeric properties, alternative fabrication methods like casting or molding are recommended. Our core expertise lies in machining aluminum, steel, and titanium alloys, each offering distinct advantages for specific industrial requirements.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are favored for their excellent strength-to-weight ratio, superior machinability, and good corrosion resistance. They are ideal for aerospace components, enclosures, and prototypes where weight savings are critical. Steel alloys, including 303, 304, and 4140, provide exceptional strength, hardness, and wear resistance. They are the standard choice for high-stress mechanical parts, tooling, and applications demanding long service life in harsh environments. Titanium Grade 5 (Ti-6Al-4V) offers an outstanding strength-to-weight ratio exceeding steel, exceptional corrosion resistance, and biocompatibility. It is essential for critical aerospace, medical implant, and marine components, though its lower thermal conductivity presents unique machining challenges requiring specialized tooling and parameters.

Material selection directly impacts production economics, lead time, and final part performance. Key properties influencing machinability and suitability are summarized below. Understanding these characteristics ensures optimal component design and manufacturing efficiency.

| Material | Typical Hardness (HB) | Machinability Rating | Key Strengths | Common Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 95 | Excellent (Machinability Index 100%) | Lightweight, corrosion resistant, weldable | Aerospace brackets, heat sinks |

| Steel 4140 | 217 | Good (Machinability Index 65%) | High strength, wear resistance, tough | Shafts, gears, tooling fixtures |

| Titanium Ti-6Al-4V | 36 | Fair (Machinability Index 30-40%) | High strength/weight, corrosion proof | Aircraft structural parts, medical implants |

Surface finish selection is equally critical. Anodizing is the predominant finish for aluminum components, significantly enhancing surface hardness, wear resistance, and corrosion protection while providing an excellent base for adhesion or dyeing. Type II (sulfuric acid) anodizing offers a standard protective layer, while Type III (hard coat) anodizing delivers superior abrasion resistance for high-wear applications. For steel components, zinc plating, passivation, or powder coating are typical choices depending on environmental exposure. Titanium naturally forms a protective oxide layer; however, specialized treatments like acid etching or plasma spray may be applied for specific biocompatibility or adhesion needs.

Selecting the optimal material and finish requires balancing performance requirements, environmental factors, regulatory standards, and cost targets. Wuxi Lead Precision Machinery’s engineering team collaborates closely with clients during the design phase to recommend the most efficient and cost-effective material and finishing solution, ensuring components meet exacting functional and longevity demands. Consult our technical specialists for application-specific guidance.

Manufacturing Process & QC

Polyurethane CNC Machining: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our polyurethane CNC machining services are engineered for clients demanding high precision, repeatability, and zero-defect performance across industries such as medical devices, automation, and high-performance sealing systems. Our production process follows a rigorous, closed-loop methodology that integrates design validation, precision prototyping, and scalable mass production—all anchored in our ISO 13485 and ISO 9001 certified quality management system.

The process begins with design optimization, where our engineering team collaborates directly with client CAD models to evaluate material compatibility, structural integrity, and manufacturability. Polyurethane presents unique challenges due to its elasticity, abrasion resistance, and variable durometer ratings (Shore A 10 to 95). Our engineers analyze wall thickness, draft angles, and tool engagement paths to prevent deformation during machining. Finite element analysis (FEA) is applied when necessary to simulate performance under operational stress, ensuring the final component meets functional requirements before any material is cut.

Next, precision prototyping is executed using 5-axis CNC milling and micro-turning centers with sub-micron positioning accuracy. Prototypes are machined from the same grade of polyurethane intended for production—whether aromatic, aliphatic, or cast—ensuring material behavior is accurately represented. Each prototype undergoes dimensional verification via coordinate measuring machines (CMM) and surface finish testing to validate conformity to geometric dimensioning and tolerancing (GD&T) specifications. Clients receive a comprehensive report including first article inspection (FAI) documentation, enabling swift design sign-off or iterative refinement.

Upon approval, the project transitions to zero-defect mass production. Our automated CNC cells operate under strict environmental controls to minimize thermal drift and material variability. In-process inspections are conducted at defined intervals using laser probes and vision systems, feeding real-time data into our statistical process control (SPC) platform. Any deviation triggers immediate corrective action, ensuring process capability (Cp/Cpk) remains above 1.67. Every batch is traceable to raw material lot numbers, machine parameters, and inspection records, supporting full compliance for regulated industries.

Our commitment to zero defects is reinforced through 100% visual inspection and抽 spot-checking of critical dimensions. Components are packaged in ESD-safe, cleanroom-compatible materials to preserve surface integrity during transit.

Typical Machining Specifications for Polyurethane Components

| Parameter | Capability |

|---|---|

| Material Types | Aromatic, Aliphatic, Cast Polyurethane |

| Shore Hardness Range | Shore A 10 – 95 |

| Dimensional Tolerance | ±0.025 mm (±0.001″) |

| Surface Finish (Ra) | 0.8 – 3.2 µm (32 – 125 µin) |

| Maximum Part Size | 600 x 400 x 300 mm |

| Minimum Feature Size | 0.5 mm diameter holes, 0.3 mm wall |

| Production Volume | 1 – 50,000+ units annually |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Production) | 10–20 working days based on volume |

By integrating engineering rigor with advanced process control, Wuxi Lead ensures every polyurethane component meets the highest standards of precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineered Excellence in Polyurethane CNC Machining

At Wuxi Lead Precision Machinery, we transform the complexities of polyurethane CNC machining into your competitive advantage. As an ISO 9001:2015 certified manufacturer with 15 years of specialized expertise, we address the unique challenges of machining polyurethane—material softness, thermal sensitivity, and dimensional stability—through proprietary methodologies. Our dedicated engineering team develops custom toolpath strategies and temperature-controlled processes to prevent deformation, ensuring your critical components meet exacting functional requirements. This precision is non-negotiable for applications in medical devices, aerospace seals, and industrial automation where failure is not an option.

Polyurethane demands more than standard CNC protocols. We deploy carbide tooling with specialized geometries and variable spindle speeds to minimize heat generation while maintaining surface integrity. Our climate-controlled machining cells stabilize ambient conditions, eliminating moisture-related inconsistencies inherent in elastomeric materials. Every project undergoes rigorous in-process metrology using Zeiss coordinate measuring machines, validating tolerances before final inspection. This systematic approach delivers repeatability you can rely on for high-volume production or one-off prototypes.

Our technical capabilities are engineered for your most demanding specifications. The table below details our polyurethane machining performance envelope:

| Specification Parameter | Capability Range |

|---|---|

| Maximum Part Dimensions | 1200 mm × 800 mm × 600 mm |

| Tolerance Precision | ±0.005 mm (standard) |

| Surface Finish (Ra) | 0.4 μm to 3.2 μm |

| Material Hardness Range | 30A to 95A Shore Durometer |

| Lead Time (Prototype) | 7–10 business days |

| Key Process Innovation | Material-Specific Toolpath Optimization |

Partnering with Lead Precision means accessing a technical collaborator, not just a supplier. Our engineers engage during your design phase to optimize manufacturability, reducing costs and accelerating time-to-market. We maintain full material traceability and provide comprehensive documentation packages compliant with AS9100 and FDA standards. For global supply chains, our export logistics team ensures seamless delivery with customs expertise across 30+ countries.

Initiate your precision polyurethane project with a technical consultation. Email [email protected] with your CAD files and requirements. Our engineering team will respond within 72 hours with a detailed process plan, tolerance analysis, and competitive quotation. Specify “Polyurethane CNC Consultation” in your subject line to prioritize review. Trust Wuxi Lead Precision Machinery to deliver components where material performance and dimensional accuracy converge—exactly as engineered. Your next breakthrough in polyurethane applications starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.