Technical Contents

Engineering Guide: Polyethylene Molding

Engineering Insight: Polyethylene Molding and the Role of Precision in Custom Metal Manufacturing

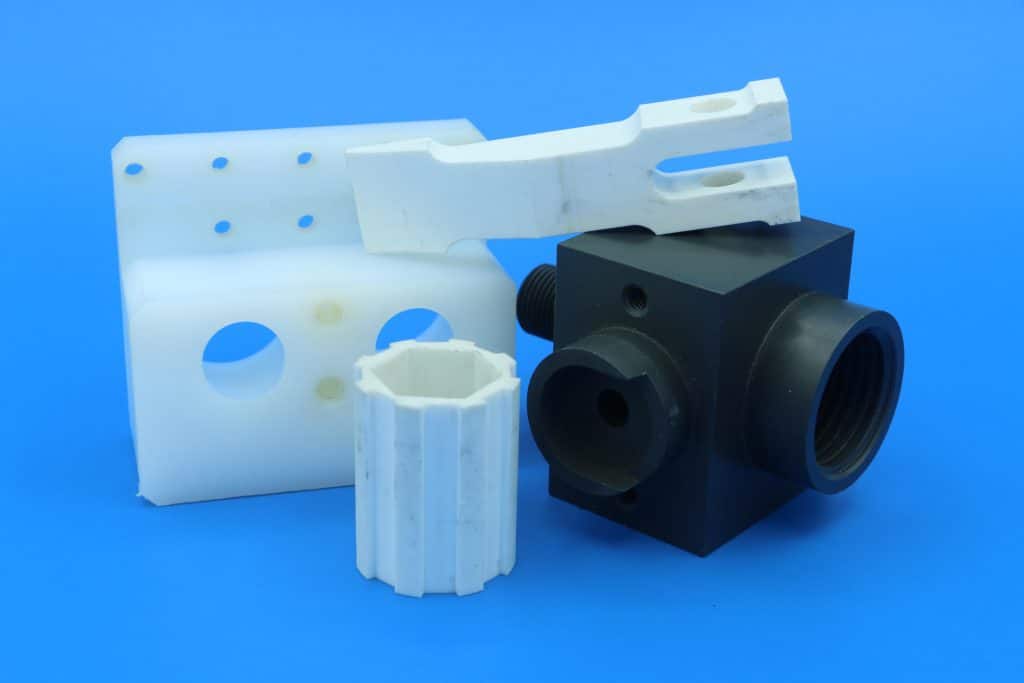

Polyethylene molding is a critical process in the production of high-performance components across industries such as defense, aerospace, medical, and industrial equipment. While polyethylene itself is a thermoplastic known for its durability and chemical resistance, the success of the molding process hinges not only on material selection but on the precision of the tooling and machinery used. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal manufacturing solutions that ensure the highest levels of accuracy, repeatability, and reliability—essential for advanced polyethylene molding applications.

Precision in mold design directly impacts part consistency, dimensional stability, and surface finish. Even minor deviations in cavity geometry or thermal control can result in warping, incomplete filling, or part failure under operational stress. This is especially critical in sectors where safety and performance are non-negotiable. Our engineering team leverages decades of experience in high-tolerance machining to produce molds with micron-level accuracy, ensuring optimal flow dynamics and cooling efficiency during the polyethylene molding cycle.

Wuxi Lead Precision Machinery has supported mission-critical projects, including components used in Olympic-standard equipment and military-grade systems. These applications demand materials and manufacturing processes that can withstand extreme environments, repeated stress, and stringent regulatory standards. Our involvement in such high-profile programs underscores our capability to deliver tooling and components that meet the most exacting specifications.

Our approach integrates advanced CNC machining, computer-aided design (CAD), and finite element analysis (FEA) to simulate molding behavior before production begins. This predictive engineering reduces trial-and-error, accelerates time-to-market, and ensures first-article compliance. Additionally, we apply strict quality control protocols, including coordinate measuring machine (CMM) inspections and real-time process monitoring, to maintain consistency across production batches.

The following table outlines key specifications and capabilities relevant to our polyethylene molding support services:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish (Mold Cavity) | Ra ≤ 0.2 µm (mirror finish available) |

| Maximum Mold Size | 2,500 mm × 1,800 mm × 1,200 mm |

| Materials Supported | P20, H13, S136, 718HH, Stainless & Tool Steels |

| Cooling Channel Precision | ±0.01 mm positional accuracy |

| Lead Time (Standard Mold) | 4–8 weeks (varies by complexity) |

| Quality Certification | ISO 9001:2015, Full Inspection Reporting |

At Wuxi Lead Precision Machinery, we understand that precision is not a feature—it is a foundation. Our commitment to engineering excellence ensures that every mold we produce enables superior polyethylene molding performance, meeting the demands of the most challenging industrial applications.

Precision Specs & Tolerances

Technical Capabilities for Polyethylene Molding Tooling

Wuxi Lead Precision Machinery delivers the critical metal foundation for high-performance polyethylene molding operations. Our core expertise lies in manufacturing the precision molds, cores, cavities, and ancillary tooling components essential for producing consistent, high-quality polyethylene parts. We bridge the gap between polymer science and metal fabrication, ensuring your molding process achieves optimal efficiency and part integrity. Our advanced manufacturing ecosystem is purpose-built to meet the stringent demands of polyethylene applications, where thermal management, surface finish, and dimensional stability directly impact final product performance and cycle times.

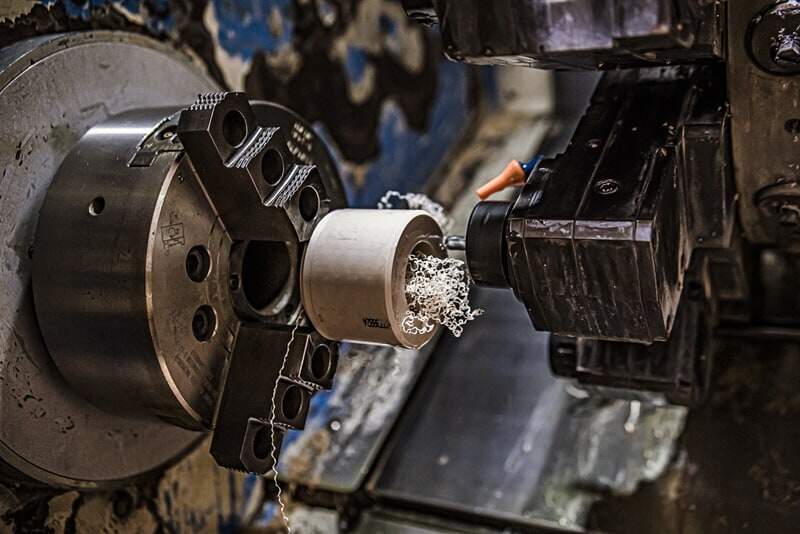

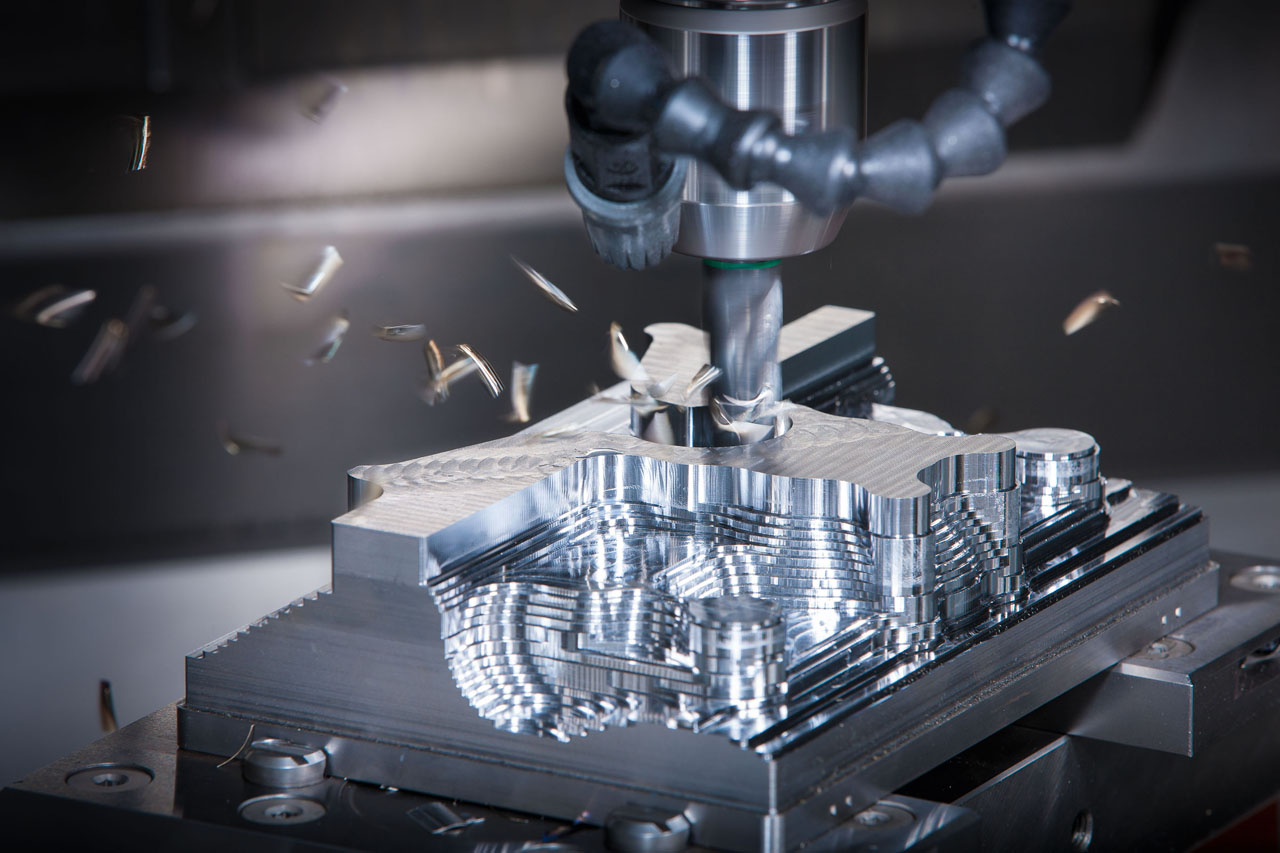

Our facility centers on state-of-the-art 5-axis CNC machining centers. This technology is non-negotiable for complex polyethylene mold geometry, enabling single-setup machining of intricate contours, undercuts, and conformal cooling channels. Conformal cooling is particularly vital for polyethylene, as its semi-crystalline nature requires precise, uniform thermal control during solidification to minimize warpage and internal stresses. Our 5-axis capability ensures exceptional accuracy on freeform surfaces and tight internal features common in advanced mold designs, significantly reducing secondary operations and lead times. All machining adheres to strict material-specific protocols for the tool steels and alloys used in polyethylene tooling, optimizing cut parameters to prevent thermal damage and ensure superior surface integrity critical for part release and aesthetics.

Rigorous quality control is embedded at every stage. Comprehensive Coordinate Measuring Machine (CMM) inspection is mandatory for all critical mold components and finished assemblies. Our CMMs, calibrated to ISO 17025 standards, provide full 3D verification against the original CAD model, measuring complex geometries, positional tolerances, and surface profiles impossible to validate with traditional methods. This data-driven approach guarantees that mating surfaces achieve the necessary fit for zero flash molding, cooling channels are positioned for optimal thermal transfer, and parting lines are perfectly aligned – factors directly influencing polyethylene part consistency, cycle time, and scrap rates. Dimensional stability across the entire mold assembly is verified under controlled conditions to account for operational thermal expansion.

The table below details our standard achievable tolerances for polyethylene molding tooling components, reflecting the capability of our integrated 5-axis CNC and CMM processes. These tolerances are fundamental to achieving the dimensional accuracy and surface quality required in demanding polyethylene applications.

| Feature Type | Standard Tolerance | Critical Feature Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | Up to 300 mm; larger dims scale per ISO 2768 |

| Geometric (Flatness) | 0.015 mm | 0.008 mm | Per 100 mm² surface area |

| Geometric (Roundness) | 0.010 mm | 0.005 mm | Critical bores and pins |

| Positional | ±0.012 mm | ±0.006 mm | Hole patterns, core/cavity alignment |

| Surface Roughness (Ra) | 0.4 µm | 0.2 µm | Critical sealing/parting surfaces |

| Conformal Cooling | ±0.025 mm | ±0.015 mm | Channel path and diameter |

These capabilities translate directly into your production success. Precision-machined molds from Wuxi Lead ensure faster cycle times through efficient cooling, reduced part rejection due to consistent dimensions and surface quality, and extended tool life. We understand that in polyethylene molding, the metal tool is the ultimate determinant of plastic part performance. Partner with us to transform your molding challenges into competitive advantages through uncompromising metal precision.

Material & Finish Options

Material Selection for Polyethylene Molding Tools: A Precision Engineering Guide

In the production of polyethylene molding tools, material selection is a critical determinant of tool longevity, dimensional accuracy, and overall manufacturing efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored for high-performance molding applications. The choice between aluminum, steel, and titanium must align with production volume, part complexity, and environmental conditions. Each material offers distinct mechanical properties and responds uniquely to finishing processes such as anodizing, which further enhances surface durability and corrosion resistance.

Aluminum is widely used for prototyping and low- to medium-volume production due to its excellent machinability and thermal conductivity. Its lightweight nature allows for faster mold cycling, reducing energy consumption and cycle times. However, aluminum’s lower hardness makes it less suitable for long production runs involving abrasive additives or high-pressure environments. When anodized, aluminum develops a hard, wear-resistant oxide layer that improves surface hardness and reduces galling, especially in molds with sliding components.

Steel, particularly tool steels like P20 or H13, is the preferred choice for high-volume polyethylene molding. Its superior hardness and wear resistance ensure dimensional stability over tens of thousands of cycles. Stainless steel variants offer additional corrosion resistance, essential when processing additives or operating in humid environments. While steel is more challenging to machine than aluminum, modern CNC techniques at Wuxi Lead ensure precise cavity and core fabrication. Although steel cannot be anodized, alternative surface treatments such as nitriding or chrome plating are effective in enhancing surface performance.

Titanium is selected for specialized applications requiring extreme strength-to-density ratios and exceptional corrosion resistance. Though rarely used for full mold bases due to cost and machining complexity, titanium alloys are ideal for critical mold inserts or ejector components exposed to aggressive conditions. Its biocompatibility and inertness make it suitable for medical-grade polyethylene molding. Titanium does not anodize in the conventional sense but can undergo plasma electrolytic oxidation to achieve a ceramic-like surface layer.

The following table summarizes key mechanical and processing properties of these materials in the context of polyethylene molding tools.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Anodizing Capability | Typical Use Case |

|---|---|---|---|---|---|

| Aluminum (7075) | 15–20 | 500–570 | 130–150 | Yes (Type III hard anodizing recommended) | Prototypes, low-volume production |

| Steel (P20) | 28–32 | 900–1100 | 28–36 | No (requires alternative coatings) | High-volume molds, complex geometries |

| Titanium (Ti-6Al-4V) | 35–40 | 900–1000 | 6–7 | Limited (requires PEO for surface enhancement) | Corrosive environments, medical molds |

Material selection must be integrated with precision engineering practices to maximize mold performance. At Wuxi Lead Precision Machinery, we combine advanced CNC manufacturing with material science expertise to deliver optimized molding solutions. Partnering early in the design phase ensures the right balance of cost, durability, and performance for your polyethylene molding requirements.

Manufacturing Process & QC

Precision Polyethylene Molding: The Wuxi Lead Zero-Defect Production Framework

While polyethylene molding produces plastic components, the foundation of zero-defect outcomes lies in the precision of the metal tooling and process control systems. At Wuxi Lead Precision Machinery, we engineer the critical metal infrastructure – molds, cores, cavities, and auxiliary tooling – that enables flawless polyethylene part production. Our integrated process eliminates defects at origin through rigorous engineering and manufacturing discipline.

The journey begins with collaborative Design for Excellence. Our engineers utilize advanced mold flow simulation software alongside client specifications to model polymer behavior under exact pressure, temperature, and cooling parameters. This phase identifies potential sink marks, weld lines, or warpage risks before metal is cut. Material science expertise ensures optimal gate design, runner systems, and venting are integrated into the mold architecture, directly targeting defect prevention at the source. Tolerances and surface finishes are defined to ISO 2768-mK standards or tighter, based on part criticality.

Prototyping transitions simulation into physical validation. We manufacture initial mold inserts and components using our high-precision CNC machining centers, achieving micron-level accuracy. These prototypes undergo rigorous metrology-grade validation against CAD models using coordinate measuring machines (CMM) and optical scanners. Short-run molding trials with the client’s specific polyethylene grade occur under controlled conditions. Every dimensional characteristic, surface texture, and functional attribute is measured against the zero-defect target. Data from this phase feeds immediate design refinements, ensuring the final tool geometry guarantees repeatability.

Mass Production leverages engineered process stability. Our fully CNC-machined production molds, manufactured to exacting specifications, are deployed with integrated process monitoring systems. Real-time sensors track cavity pressure, melt temperature, and cooling rates, feeding data into Statistical Process Control (SPC) software. Any parameter deviation beyond pre-defined control limits triggers automatic alerts or machine adjustments, preventing non-conforming parts from progressing. In-process inspections using calibrated gauges and automated vision systems provide continuous quality assurance. This closed-loop system, built upon our precision metal foundation, ensures consistent part conformance batch after batch.

Wuxi Lead’s commitment to zero defects is embedded in the metal integrity and dimensional perfection of the tooling we produce. The table below details the precision capabilities inherent in our mold manufacturing process, which directly enables defect-free polyethylene molding outcomes for our clients.

| Specification Parameter | Capability Range | Industry Standard Reference |

|---|---|---|

| Linear Dimensional Tolerance | ±0.005 mm to ±0.025 mm | ISO 2768-mK (Typical) |

| Geometric Tolerance (GD&T) | ±0.002 mm (Critical) | ISO 1101 |

| Surface Roughness (Cavity) | Ra 0.05 μm to Ra 0.8 μm | SPI-SPE Standards |

| Core/Cavity Hardness | HRC 48-52 (Typical) | ASTM A370 |

| Primary Machining Equipment | 5-Axis CNC Milling, Swiss-Type Lathes, EDM | ISO 230-2 |

This systematic approach – from predictive design through validated prototyping to monitored mass production – transforms zero defects from an aspiration into a measurable, sustainable reality for polyethylene molding operations. Wuxi Lead Precision Machinery delivers the metal precision that makes plastic perfection achievable.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Polyethylene Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance custom metal manufacturing solutions tailored to the evolving demands of the polyethylene molding industry. With over a decade of engineering excellence, we have established ourselves as a trusted partner for global manufacturers seeking precision, durability, and innovation in their production systems. Our expertise spans mold design, CNC-machined components, and fully integrated molding equipment built to meet the exact specifications of high-volume and high-pressure polyethylene applications.

Polyethylene molding presents unique challenges—material flow consistency, thermal control, and long-term tooling resilience. At Lead Precision, we engineer every component to withstand these challenges with uncompromising accuracy. Our in-house R&D team collaborates directly with clients to develop custom solutions that enhance cycle efficiency, reduce downtime, and improve part quality. Whether you require high-cavitation molds for thin-wall containers or robust blow molding tooling for industrial tanks, our manufacturing capabilities are backed by ISO 9001-certified processes and advanced metrology systems for quality assurance.

Our production facility in Wuxi integrates state-of-the-art CNC machining centers, wire EDM, and surface treatment technologies to deliver tooling with micron-level precision. We use premium-grade tool steels and specialized coatings to extend mold life, even under aggressive processing conditions. Every project is managed through a structured development cycle, from initial concept and 3D simulation to prototype validation and full-scale production support.

We understand that in polyethylene molding, performance is measured not just in output, but in reliability and total cost of ownership. That’s why our engineering team prioritizes modular designs that simplify maintenance and allow for rapid reconfiguration. Our clients benefit from faster time-to-market, reduced scrap rates, and long-term operational savings.

Below are key technical specifications that define our manufacturing capabilities:

| Specification | Detail |

|---|---|

| Maximum CNC Machining Size | 2,500 mm × 1,800 mm × 1,200 mm |

| Tolerance Range | ±0.005 mm |

| Material Compatibility | P20, H13, 718HH, S136, Stainless Steel, Aluminum Alloys |

| Surface Finish Options | Mirror polish (Ra ≤ 0.05 μm), Textured, Coated (TiN, CrN) |

| Molding Types Supported | Blow Molding, Injection Molding, Rotational Molding |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) Reports |

| Lead Time (Average) | 4–8 weeks, based on complexity |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic ally in precision manufacturing. We don’t just supply components—we deliver engineered solutions that elevate your production capabilities. Our global client base relies on us for responsive service, technical transparency, and consistent quality across every order.

For expert support in polyethylene molding tooling and custom metal fabrication, contact us today at [email protected]. Let Lead Precision be the foundation of your next high-performance manufacturing project.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.