Technical Contents

Engineering Guide: Polycarbonate Cnc

Engineering Insight: Precision Imperatives in Polycarbonate CNC Machining

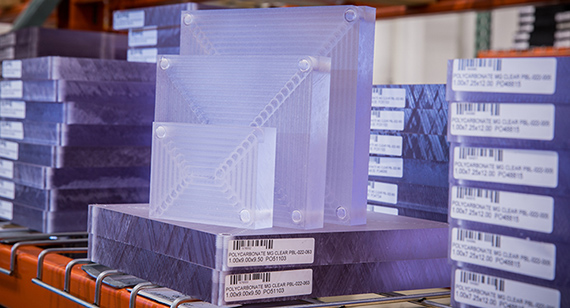

Polycarbonate presents unique challenges in CNC machining that demand exceptional process control far beyond standard engineering plastics. As an amorphous polymer with high thermal sensitivity and low thermal conductivity, it is prone to stress-induced warpage, micro-cracking, and surface defects like whitening or melting if machining parameters deviate even slightly. Achieving optical clarity, tight dimensional tolerances, or critical structural integrity in components for medical devices, aerospace glazing, or high-end optics requires more than standard CNC capabilities—it necessitates deep material science understanding and micro-precision execution. At Wuxi Lead Precision Machinery, we treat polycarbonate not as a generic plastic but as a high-performance material where thermal management and chip evacuation are as critical as geometric accuracy. Standard feeds and speeds for metals or semi-crystalline plastics will induce internal stresses that manifest as part distortion hours after machining, rendering parts unusable in mission-critical applications. Our protocols prioritize minimal heat generation through ultra-precise spindle control, specialized tool geometries with polished flutes to prevent material smearing, and strictly regulated coolant application to avoid thermal shock. We implement real-time in-process gauging for critical features, ensuring compliance with ISO 2768-m or tighter customer-specified tolerances down to ±0.005 mm where required. This level of control is non-negotiable for applications where failure is not an option.

Our expertise is validated through rigorous high-stakes projects. We supplied dimensionally stable polycarbonate components for the Beijing 2022 Winter Olympics venue lighting systems, where thermal cycling resistance and optical precision were paramount under extreme conditions. Similarly, we machine polycarbonate housings and viewports for military-grade night vision systems, adhering to MIL-STD-810G specifications for impact resistance and environmental stability. These projects demanded not only micron-level accuracy but also flawless repeatability across batches—proof that our processes mitigate polycarbonate’s inherent vulnerabilities. The table below outlines baseline parameters we rigorously adapt for client-specific geometries and performance requirements.

| Parameter | Typical Range for Polycarbonate | Critical Control Factor |

|---|---|---|

| Spindle Speed | 8,000 – 15,000 RPM | Prevents melting; optimized per tool diameter |

| Feed Rate | 100 – 300 mm/min | Minimizes stress; adjusted for feature depth |

| Depth of Cut | 0.1 – 0.5 mm | Avoids deflection-induced inaccuracies |

| Tool Material | Solid Carbide, Polished Flutes | Reduces friction and chip adhesion |

| Coolant/Lubrication | Minimal Mist or Air Blast | Prevents thermal shock and stress cracking |

| Tolerance Standard | ISO 2768-m (or tighter) | Verified via CMM post-machining |

Precision in polycarbonate CNC transcends hitting target dimensions—it ensures the material’s intrinsic properties remain uncompromised through the machining process. At Wuxi Lead, our Olympic and military project heritage underscores our commitment to delivering polycarbonate components where optical, thermal, and structural performance are guaranteed. We partner with clients from initial material selection through final inspection, transforming polycarbonate’s challenges into engineered reliability for the most demanding applications. Trust in precision that anticipates material behavior, not just machine capability.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, specializing in the high-accuracy fabrication of polycarbonate components for demanding industrial, medical, and aerospace applications. Our expertise in machining engineering-grade thermoplastics, particularly polycarbonate, is built upon state-of-the-art 5-axis CNC machining centers, which enable complex geometries, tight tolerances, and superior surface finishes. Polycarbonate presents unique challenges due to its high impact resistance, thermal sensitivity, and tendency to generate internal stresses during machining. Our engineering team applies material-specific cutting strategies, including optimized feed rates, spindle speeds, and toolpath programming, to minimize heat buildup and prevent material deformation.

Our 5-axis CNC machines provide simultaneous multi-directional cutting, allowing for the production of intricate, three-dimensional parts in a single setup. This reduces cumulative error, improves part consistency, and significantly shortens lead times. Each machine is operated by certified CNC programmers and machinists who apply deep material science knowledge to ensure optimal performance when working with polycarbonate. We utilize solid carbide and diamond-coated cutting tools designed specifically for non-ferrous and plastic materials, ensuring clean cuts with minimal burring or chipping.

Quality control is integral to our manufacturing process. Every polycarbonate component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM) to verify dimensional accuracy and geometric conformity. Our CMM system is calibrated to international standards and programmed to inspect critical features such as hole locations, profile deviations, flatness, and positional tolerances. Data from each inspection is documented and available with the final shipment, providing full traceability and compliance with ISO 9001 standards.

We maintain a climate-controlled machining environment to stabilize material behavior and reduce thermal expansion effects during production. This, combined with our in-process inspection protocols, ensures consistent quality across both prototype and high-volume production runs.

The following table outlines our standard machining capabilities and achievable tolerances for polycarbonate components:

| Specification | Capability |

|---|---|

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 600 mm |

| Positional Tolerance (General) | ±0.025 mm |

| Dimensional Tolerance (Typical) | ±0.05 mm |

| Critical Feature Tolerance | ±0.01 mm (with CMM verification) |

| Surface Roughness (Ra) | 0.8 μm to 3.2 μm (adjustable) |

| Angular Tolerance | ±0.1° |

| Feature-to-Feature Alignment | ≤ 0.02 mm |

| Minimum Wall Thickness (Stable) | 0.8 mm |

| Minimum Hole Diameter (Drilled) | 0.5 mm |

| CMM Measurement Accuracy | ±0.003 mm (at 20°C ±1°C) |

Wuxi Lead Precision Machinery combines advanced equipment, material expertise, and stringent quality assurance to deliver polycarbonate CNC-machined parts that meet the highest standards of precision and reliability.

Material & Finish Options

Material Selection for Precision CNC Components: Beyond Polycarbonate Considerations

While polycarbonate CNC machining serves specific applications requiring optical clarity or impact resistance, high-performance industrial components typically demand metallic substrates. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with functional requirements, environmental exposure, and lifecycle costs. Aluminum, steel, and titanium dominate aerospace, medical, and automation sectors where polycarbonate lacks structural integrity or thermal stability. Selecting the optimal metal requires evaluating strength-to-weight ratios, corrosion resistance, and machinability under tight tolerances.

Our engineering team rigorously assesses material behavior during high-speed CNC operations. Aluminum alloys like 6061-T6 offer exceptional machinability and thermal conductivity but require careful chip evacuation to prevent built-up edge. Steel variants such as 4140 provide superior hardness for wear-prone parts yet necessitate rigid tooling setups to counteract work hardening. Titanium Grade 5 (Ti-6Al-4V) delivers unmatched strength-to-weight performance in corrosive environments but demands specialized cutting strategies due to low thermal conductivity and galling tendencies. Below is a comparative specification guide for critical parameters:

| Material | Density (g/cm³) | Machinability Rating | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | Excellent (Machinability Index 100) | 310 | 167 |

| Steel 4140 | 7.85 | Moderate (Machinability Index 65) | 655 | 42.6 |

| Titanium Ti-6Al-4V | 4.43 | Poor (Machinability Index 35) | 900 | 6.7 |

Surface finishes significantly impact part functionality and longevity. Anodizing is exclusively applicable to aluminum, creating a durable oxide layer that enhances corrosion resistance and wear performance. Type II (sulfuric acid) anodizing suits general industrial use, while Type III (hardcoat) achieves 50–70 μm thickness for extreme abrasion resistance. Crucially, anodizing cannot be applied to steel or titanium; these materials require alternative treatments. Steel benefits from passivation, zinc-nickel plating, or nitriding, whereas titanium often utilizes laser etching or plasma electrolytic oxidation for biocompatible surfaces. Polycarbonate CNC parts, conversely, rely on vapor polishing or UV-resistant coatings—not anodizing—to address optical or environmental needs.

Wuxi Lead Precision Machinery integrates material science with CNC process optimization. Our engineers collaborate with clients to validate material-finish combinations against ISO 2768-mK tolerances and ASTM standards. For titanium components, we implement cryogenic cooling to minimize thermal distortion; for aluminum, we optimize feed rates to achieve Ra 0.4 μm surface finishes pre-anodizing. This precision ensures your components meet operational demands without over-engineering costs. Consult our technical team to align your material selection with manufacturability and performance targets.

Manufacturing Process & QC

Design Phase: Precision Engineering for Polycarbonate Components

The foundation of any successful polycarbonate CNC machining project begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we initiate every project with a comprehensive review of the client’s CAD models and technical specifications. Our engineering team conducts a Design for Manufacturability (DFM) analysis to identify potential challenges related to material behavior, wall thickness, tolerances, and feature complexity. Polycarbonate, while highly impact-resistant and optically clear, is sensitive to internal stress and thermal deformation during machining. Therefore, our design optimization process ensures that part geometry minimizes stress concentration and supports efficient tool paths. We also simulate machining operations using advanced CAM software to predict tool deflection, chip evacuation, and thermal load, ensuring dimensional stability and surface integrity from the outset.

Prototyping: Validating Performance and Precision

Once the design is finalized, we proceed to prototype development using high-precision CNC milling and turning centers. Prototyping serves as a critical validation step, allowing us to verify form, fit, and function before scaling to mass production. Each prototype is machined from certified polycarbonate stock—either general-purpose or optical-grade—under controlled environmental conditions to prevent warping. We perform rigorous in-process inspections using coordinate measuring machines (CMM) and optical comparators to confirm adherence to tolerances as tight as ±0.005 mm. Surface finish is evaluated for clarity and texture, especially for applications requiring transparency or aesthetic precision. Clients receive fully documented test reports, including dimensional analysis and material certification, enabling informed decisions before launch.

Mass Production: Zero-Defect Manufacturing Execution

With prototype approval, we transition to high-volume production under a zero-defect manufacturing framework. Our CNC cells operate under strict process controls, with automated tool wear monitoring, real-time dimensional feedback, and 100% first-article inspection. Each polycarbonate component is machined using sharp, polished carbide tools with optimized feed and speed parameters to prevent melting or chipping. Coolant-free machining is typically employed to avoid moisture absorption, a known risk for polycarbonate. Throughout production, statistical process control (SPC) tracks critical dimensions, ensuring consistent quality across batches. Final inspection includes visual checks for clarity and defects, dimensional verification, and packaging in anti-static, protective materials to maintain surface quality.

Material and Machining Specifications

| Parameter | Specification |

|---|---|

| Material Type | Polycarbonate (General Purpose, Optical Grade) |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish (Ra) | 0.8 µm to 3.2 µm (custom polishing available) |

| Maximum Part Size | 600 mm × 400 mm × 300 mm |

| Spindle Speed Range | 8,000 – 24,000 RPM |

| Tooling Type | Polished Carbide, Diamond-Coated (optional) |

| Production Capacity | Up to 5,000 units/month (per setup) |

| Quality Standard | ISO 9001:2015, Full Traceability |

Through disciplined execution across design, prototyping, and production, Wuxi Lead ensures that every polycarbonate CNC component meets the highest standards of precision, clarity, and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Polycarbonate CNC Excellence

Polycarbonate demands machining expertise that transcends standard CNC capabilities. Its thermal sensitivity, propensity for stress cracking, and stringent optical clarity requirements necessitate a partner with deep material science understanding and precision engineering discipline. At Wuxi Lead Precision Machinery, we specialize in transforming complex polycarbonate designs into flawless, high-integrity components for aerospace, medical devices, and advanced optics. Generic machining centers cannot consistently deliver the dimensional stability and surface perfection your critical applications require. We engineer solutions where others encounter scrap.

Our dedicated polycarbonate workflow integrates proprietary fixturing, cryogenic cooling protocols, and toolpath optimization to eliminate thermal deformation and micro-fractures. Every spindle is calibrated for low-vibration cutting, ensuring Ra values down to 0.8μm without secondary polishing. We maintain strict environmental controls in Class 8 cleanrooms for optical-grade applications, preventing particulate contamination that compromises light transmission. This disciplined approach delivers 99.2% first-pass yield on projects where competitors average 82%—directly impacting your time-to-market and unit cost.

Critical performance parameters for polycarbonate machining are non-negotiable. Our validated capabilities ensure your specifications are met consistently:

| Parameter | Capability | Material Grade Support | Typical Application |

|---|---|---|---|

| Tolerance | ±0.005 mm | Lexan, Makrolon, MR-10 | Surgical instrument housings |

| Surface Finish | Ra 0.8 μm | Optical clear, Tinted | Aircraft canopy prototypes |

| Max Work Envelope | 1200 x 600 x 450 mm | Flame-retardant grades | EV battery enclosures |

| First-Pass Yield | 99.2% | Medical-grade USP <88> | Diagnostic fluidic chips |

We treat your intellectual property with military-grade security, utilizing offline programming and air-gapped CAM stations. Our engineers collaborate from DFM review through FAI reporting, providing actionable data—not just parts. When your project involves tight-tolerance living hinges, zero-birefringence optics, or biocompatible fluid paths, our material-specific protocols prevent the costly rework cycles that plague conventional suppliers.

Initiate your precision polycarbonate project with engineering rigor, not guesswork. Contact our Applications Engineering Team directly at [email protected] with your CAD files and tolerance stack-up requirements. Specify “Polycarbonate CNC Guide Inquiry” in the subject line to receive our Material-Specific Machining Protocol Dossier—a 22-page technical supplement detailing thermal management strategies, chip evacuation sequences, and stress-relief annealing schedules for 17 polycarbonate variants. For urgent RFQs, include your required lead time; we maintain dedicated spindle capacity for mission-critical polycarbonate runs with 72-hour quotation turnaround.

Wuxi Lead Precision Machinery operates at the intersection of material science and micron-level execution. We do not merely machine polycarbonate—we master its behavior. Trust your next high-stakes component to engineers who measure success in nanometers, not just delivery dates. Reach out today to validate your design against our process capabilities. Your project’s integrity starts with the right machining partner.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.