Technical Contents

Engineering Guide: Pmi Machining

Engineering Insight: The Non-Negotiable Imperative of Precision in PMI Machining

In high-stakes custom metal manufacturing, Precision Measurement and Inspection (PMI) machining transcends mere process specification; it is the foundational pillar determining functional integrity, safety, and ultimate product success. Minute deviations invisible to the naked eye—measured in microns—directly translate to catastrophic system failures in aerospace assemblies, compromised structural integrity in defense platforms, or unacceptable drift in scientific instrumentation. True precision machining demands more than capable equipment; it requires an ingrained engineering philosophy where every micron is accounted for, from initial material characterization through final verification. At Wuxi Lead Precision Machinery, we understand that tolerances specified on a drawing represent the absolute maximum permissible error, not a target. Our engineering rigor focuses relentlessly on achieving consistently tighter results, ensuring components perform flawlessly under extreme operational stresses where failure is not an option.

This uncompromising commitment to dimensional certainty is why global leaders in critical sectors rely on our expertise. Our facility has delivered mission-critical components for Olympic timing systems demanding microsecond synchronization and precision-engineered elements for advanced defense systems where survivability hinges on exacting geometries. These projects are not merely contracts; they are validations of our ability to operate at the absolute forefront of manufacturing capability. Success in such arenas requires seamless integration of advanced multi-axis CNC platforms, environmental controls eliminating thermal drift, and metrology-grade inspection protocols applied at every process stage—not just as a final checkpoint. It demands engineers who interpret GD&T not as constraints, but as the essential language of functional performance.

Our operational excellence is quantifiable through measurable capabilities consistently achieved across production runs. The following table outlines core specifications underpinning our PMI machining services:

| Feature | Capability | Typical Tolerance Range | Application Example |

|---|---|---|---|

| Linear Positioning | Multi-Axis CNC Milling/Turning | ±0.002 mm (±0.00008″) | Aerospace hydraulic manifolds |

| Geometric Accuracy | Complex Contouring & Features | ±0.003 mm (±0.00012″) | Medical implant surfaces |

| Surface Finish | Precision Grinding & Polishing | Ra 0.05 µm (2 µin) | Optical sensor housings |

| In-Process Verification | On-Machine Probing Systems | Real-time compensation | Large-scale structural castings |

| Final Certification | CMM & Optical Metrology | NIST-traceable reports | Defense system alignment brackets |

Achieving this level of consistency requires more than technology; it necessitates deep experiential knowledge. Our engineering team possesses decades of hands-on expertise solving the most complex dimensional challenges across titanium, Inconel, hardened steels, and exotic alloys. We proactively identify potential thermal deformation, residual stress, or fixturing-induced errors during the quoting phase—transforming potential risks into controlled process parameters. When your application demands absolute dimensional fidelity where performance and safety are paramount, Wuxi Lead Precision Machinery provides the proven engineering insight and execution capability to deliver certainty. Precision isn’t just what we measure; it’s the standard we engineer into every component.

Precision Specs & Tolerances

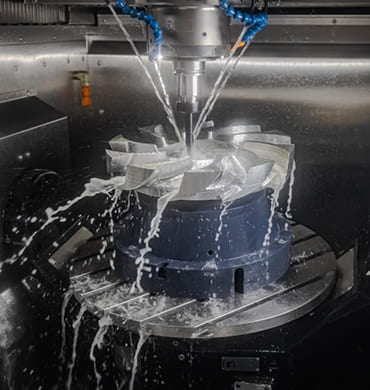

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the most demanding industries, including aerospace, medical, energy, and high-performance automotive. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform that enables the production of complex, high-precision components with exceptional repeatability and surface integrity. Our multi-axis machining centers eliminate the need for multiple setups, reducing production time while maintaining geometric accuracy across intricate contours and deep cavities.

Our 5-axis CNC systems operate with continuous tool-path control, allowing for optimal tool orientation and minimized tool deflection. This capability supports the efficient machining of advanced materials such as titanium alloys, Inconel, hardened steels, and high-strength aluminum, commonly used in mission-critical applications. With simultaneous motion across all five axes, we achieve superior part accuracy and surface finish, even on components with compound angles and organic geometries that are unattainable with conventional 3-axis methods.

Quality assurance is embedded into every phase of production. All machined components undergo comprehensive dimensional verification using state-of-the-art Coordinate Measuring Machines (CMM) equipped with high-resolution tactile probes and advanced CAD-based inspection software. This ensures full compliance with engineering specifications and international standards such as ISO 2768 and ASME Y14.5. Our CMM inspection process provides detailed first-article inspection (FAI) reports, production batch certifications, and real-time feedback for process correction, guaranteeing consistency across high-mix, low-volume, and full-scale production runs.

We maintain strict environmental controls within our metrology lab to ensure measurement stability, with temperature regulation to ±0.5°C. In addition to CMM, we employ optical comparators, surface roughness testers, and calibrated hand tools to verify critical features. Our quality management system is ISO 9001 certified, reflecting our commitment to traceability, continuous improvement, and customer-specific requirements.

The following table outlines our standard machining capabilities and achievable tolerances:

| Feature | Specification |

|---|---|

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 700 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (per ISO 2768-m) | ±0.05 mm |

| Angular Tolerance | ±0.05° |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Material Compatibility | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Brass, Plastics |

| Typical Production Batch Size | 1–5,000 units |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality control to deliver precision-engineered metal components that meet the highest industry benchmarks. Our technical expertise ensures that every part is manufactured to exacting standards, on time and with full documentation traceability.

Material & Finish Options

Material Selection for Precision Machined Components

Material choice fundamentally impacts performance, cost, and manufacturability in precision CNC machining. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with your application’s mechanical, environmental, and regulatory demands. Below we detail critical considerations for aluminum, steel, and titanium, alongside anodizing as a key finishing process for aluminum.

Aluminum alloys dominate aerospace, electronics, and consumer goods due to their exceptional strength-to-weight ratio and corrosion resistance. 6061-T6 and 7075-T6 are industry standards, offering good machinability and weldability. Aluminum’s softness enables high-speed machining with tight tolerances but requires careful tool geometry to prevent built-up edge. Its low density reduces part weight significantly, though hardness limitations restrict use in high-wear scenarios. Anodizing is essential for aluminum, creating a durable oxide layer that enhances corrosion resistance, wear performance, and aesthetic options while maintaining electrical insulation.

Steel variants like 304 stainless and 4140 alloy steel deliver superior strength, hardness, and heat resistance for industrial machinery, automotive, and oil/gas applications. Stainless steels provide excellent corrosion resistance but generate significant heat during machining, demanding rigid setups and specialized tooling to avoid work hardening. Alloy steels like 4140 offer high tensile strength after heat treatment but require slower cutting speeds. Steel’s machinability varies widely by grade; free-machining steels (e.g., 12L14) improve throughput but sacrifice weldability and corrosion resistance.

Titanium alloys, particularly Grade 5 (Ti-6Al-4V), are critical for medical implants, aerospace, and marine components where extreme strength-to-weight ratios and biocompatibility are non-negotiable. Titanium’s low thermal conductivity causes heat concentration at the cutting edge, accelerating tool wear and requiring lower speeds, high-pressure coolant, and rigid CNC platforms. Despite machining challenges, its unparalleled corrosion resistance in saline environments justifies the premium cost for mission-critical parts.

Material Property Comparison for CNC Machining

| Material | Tensile Strength (MPa) | Machinability Rating | Common Grades | Key Applications |

|---|---|---|---|---|

| Aluminum | 290–570 | Excellent (A) | 6061-T6, 7075-T6 | Aerospace frames, heat sinks |

| Steel | 500–2000 | Moderate to Poor (B–D) | 304, 4140, 12L14 | Hydraulic manifolds, shafts |

| Titanium | 900–1100 | Poor (D) | Ti-6Al-4V (Grade 5) | Aircraft landing gear, surgical tools |

Anodizing remains the premier finish for aluminum components, transforming the surface into a hard, porous aluminum oxide layer. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with color dyeing options, while Type III (hardcoat) delivers 50–100μm thickness for extreme abrasion resistance in military and industrial contexts. Proper pre-treatment ensures uniform adhesion, and sealing in hot deionized water closes pores for maximum environmental protection.

Selecting the optimal material-finishing combination prevents costly redesigns and production delays. Wuxi Lead leverages ISO 9001-certified processes and material traceability to ensure your components meet exact performance criteria. Consult our engineering team early in design to optimize material selection for manufacturability, cost, and longevity.

Manufacturing Process & QC

Design: Precision Engineering from Concept to CAD

At Wuxi Lead Precision Machinery, every manufacturing journey begins with a rigorously defined design phase. Our engineering team collaborates closely with clients to translate conceptual requirements into detailed 3D CAD models and technical drawings. Utilizing advanced software such as SolidWorks, AutoCAD, and Siemens NX, we ensure dimensional accuracy, material compatibility, and manufacturability from the outset. Design for Manufacturability (DFM) analysis is conducted early to identify potential production challenges, optimize part geometry, and reduce cycle times. This proactive approach eliminates costly revisions and ensures that every component meets both functional and regulatory standards. All designs undergo internal peer review and client validation before progression to prototyping.

Prototyping: Validating Performance and Fit

Once the design is finalized, we move to precision prototyping—typically producing 1–5 units using the same CNC machining processes intended for mass production. This ensures that prototypes are not just visual mock-ups but fully functional parts with final material properties and surface finishes. Prototypes are subjected to comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. We validate dimensional accuracy, mechanical fit, and performance under real-world conditions. Feedback from client testing is incorporated swiftly, with rapid iteration cycles to achieve final approval. This stage is critical for mitigating risk, confirming tolerances, and ensuring seamless transition to full-scale manufacturing.

Mass Production: Scalable Precision with Zero Defects

With prototype approval, we initiate high-volume production under a Zero Defects framework. Our facility in Wuxi operates over 80 CNC machining centers—including 3-axis, 4-axis, and 5-axis mills, turning centers, and multi-tasking machines—enabling scalable output from hundreds to tens of thousands of units. Every production run is governed by standardized work instructions, first-article inspections, and statistical process control (SPC). In-process checks occur at defined intervals, and final inspection includes full dimensional reporting and material certification. Our quality management system is ISO 9001-certified, and we adhere to strict traceability protocols for every batch.

Production Capabilities and Specifications

| Parameter | Specification |

|---|---|

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Steel (4140, 1018), Brass, Titanium, and engineered alloys |

| Tolerances | ±0.005 mm (±0.0002″) standard; tight tolerances down to ±0.001 mm achievable |

| Surface Finish | Ra 0.8 µm standard; fine finishes down to Ra 0.2 µm available |

| Max Part Size | 1200 x 800 x 600 mm |

| Production Capacity | 50,000+ units/month (depending on complexity) |

| Lead Time (Mass Production) | 15–25 days after sample approval |

| Quality Standards | ISO 9001:2015, PPAP, FAI, SPC, CMM inspection reports |

Through seamless integration of design, prototyping, and high-precision mass production, Wuxi Lead ensures consistent delivery of defect-free components tailored to the most demanding industrial applications.

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership

In the demanding realm of precision metal manufacturing, component integrity directly impacts your product’s performance and reputation. Generic machining solutions cannot address the complex tolerances and material challenges inherent in high-stakes industries like aerospace, medical devices, and energy. Wuxi Lead Precision Machinery exists to bridge this gap. We operate at the intersection of advanced CNC engineering and uncompromising quality control, transforming your most intricate designs into reality. Our facility in Wuxi, China, is engineered for excellence, featuring climate-controlled production floors and metrology-grade inspection systems that meet global standards. Partnering with us means accessing a dedicated team that treats your project as a strategic extension of your own engineering objectives, not merely an outsourced task.

Technical Capabilities at a Glance

Our infrastructure supports the most stringent PMI machining requirements. Below are core specifications defining our production envelope:

| Parameter | Capability |

|---|---|

| Tolerance Range | ±0.0001″ (2.5μm) |

| Max Work Envelope | 2000 x 1200 x 1000 mm |

| Materials Expertise | Titanium, Inconel, 17-4PH, Tool Steels, Aluminum Alloys |

| Certifications | ISO 9001:2015, AS9100D, ISO 13485 |

| Process Control | SPC, In-Process Verification, Full FAI |

This technical foundation is augmented by proactive engineering collaboration. From initial design review to final shipment, our CNC engineers engage directly with your team to preempt manufacturing hurdles, optimize toolpaths for material integrity, and ensure seamless scalability. We implement rigorous first-article inspections and real-time process monitoring, providing documented traceability for every component. This eliminates costly rework cycles and accelerates time-to-market without sacrificing reliability.

Your partnership with Lead Precision transcends transactional manufacturing. We integrate into your supply chain as a value-driven extension of your quality assurance framework. Our project managers maintain transparent communication through every production phase, delivering detailed quality reports and actionable insights. Whether you require low-volume prototypes demanding micron-level precision or high-mix production runs, our flexible workflow adapts to your critical path while maintaining zero-defect accountability. This commitment has established us as the trusted partner for Tier-1 suppliers and innovators who refuse to compromise on performance.

Initiate your precision workflow with an engineering consultation tailored to your component’s unique demands. Contact our technical sales team at [email protected] to submit your specifications or request a capability dossier. Include your project timeline and critical tolerances for a rapid feasibility assessment. We respond within 24 business hours with actionable next steps—not generic proposals. Let Lead Precision become the definitive link in your high-integrity manufacturing chain. Your components deserve nothing less than engineered certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.