Technical Contents

Engineering Guide: Plate Mold Ceramics

Engineering Insight Plate Mold Ceramics Precision as the Foundational Imperative

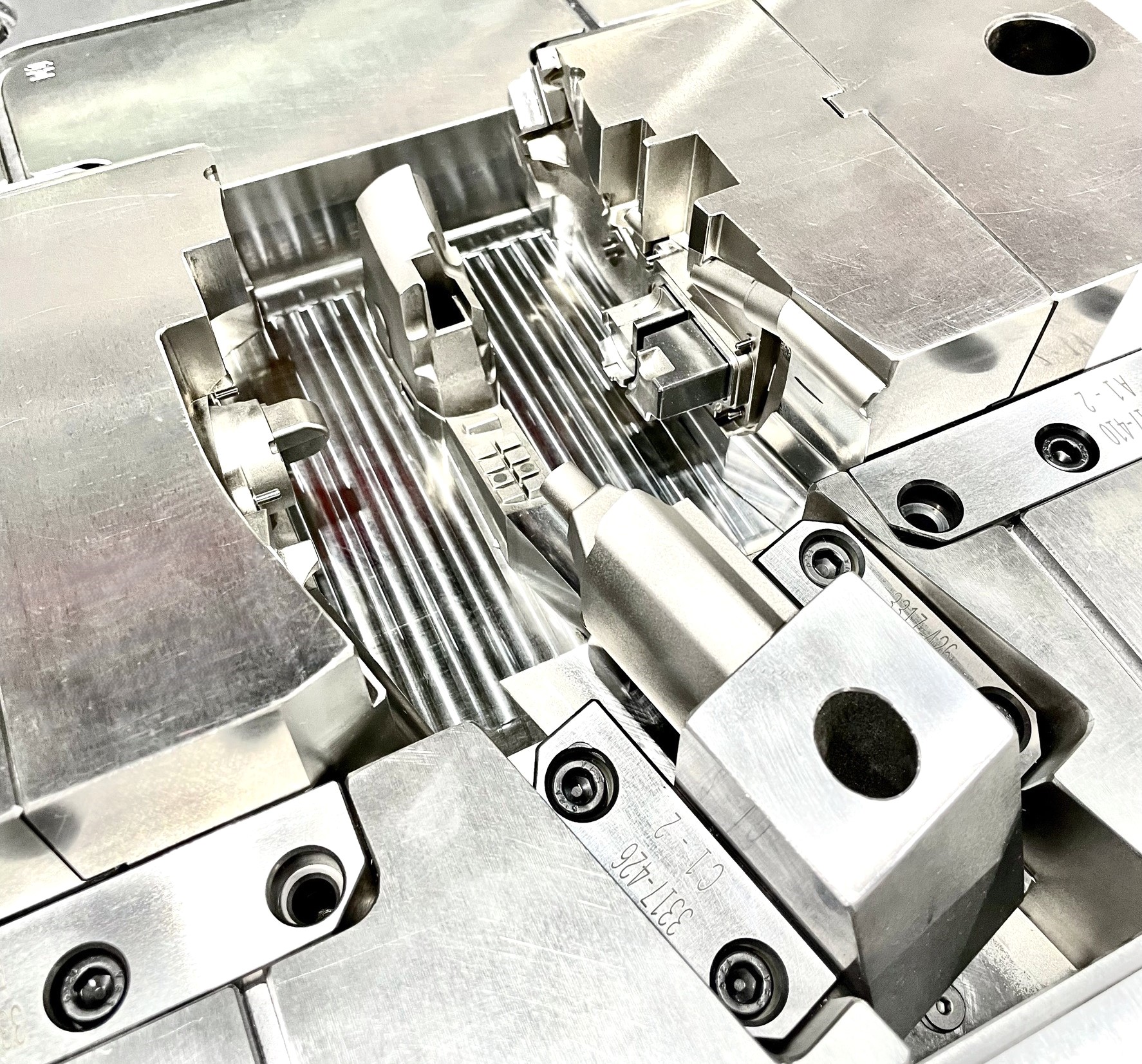

Plate mold ceramics represent a critical intersection of advanced materials science and ultra-precise manufacturing engineering. Unlike traditional metal stamping, ceramic molding demands exceptional dimensional stability and surface integrity from the mold itself. Ceramics possess inherent brittleness and are notoriously difficult to machine post-firing. Consequently, any imperfection or tolerance deviation in the plate mold transfers directly to the final ceramic component, often rendering it unusable. Achieving consistent part geometry, critical wall thicknesses, and flawless surface finishes requires mold cavities held to micron-level tolerances across the entire working surface. Thermal management during the molding cycle further compounds the challenge; minute variations in mold flatness or parallelism induce uneven shrinkage and warpage in the green state, leading to catastrophic failures during sintering. Precision here is not merely desirable; it is the absolute prerequisite for functional, high-yield ceramic production.

At Wuxi Lead Precision Machinery, we engineer plate molds where tolerance control transcends standard industry practice. Our proprietary CNC machining and grinding processes, developed over 15 years of specialization in mission-critical components, consistently achieve flatness tolerances below 0.0002 inches (5 microns) and parallelism within 0.0001 inches (2.5 microns) across large surface areas. This level of precision is non-negotiable for applications demanding absolute reliability. Our methodologies have been rigorously validated through projects supplying molds for precision ceramic components in next-generation military avionics systems, where failure is not an option, and for the production molds used in manufacturing Olympic medal blanks, requiring perfect symmetry and surface perfection for millions of impressions. We understand that the mold is the master; its precision defines the product’s capability.

The following table details the core precision specifications achievable with Lead Precision’s plate mold ceramic manufacturing process for critical applications:

| Specification Parameter | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Surface Flatness (per sq. inch) | ≤ 0.0004 in (10 µm) | ≤ 0.0002 in (5 µm) | Optical Interferometry |

| Parallelism (across face) | ≤ 0.0002 in (5 µm) | ≤ 0.0001 in (2.5 µm) | Coordinate Measuring Machine (CMM) |

| Surface Roughness (Ra) | ≤ 8 µin (0.2 µm) | ≤ 4 µin (0.1 µm) | Profilometry |

| Dimensional Tolerance (±) | ±0.0005 in (13 µm) | ±0.0002 in (5 µm) | CMM with Thermal Compensation |

| Material Compatibility | Alumina, Zirconia, AlN, Si3N4 | Specialized Coatings for Aggressive Slurries | Material Science Analysis |

This precision foundation directly translates to our clients’ success. Reduced scrap rates, extended mold life, and the ability to produce complex ceramic geometries with consistent quality are tangible outcomes. When your application demands ceramics that perform under extreme conditions, the integrity of the plate mold is paramount. Wuxi Lead Precision Machinery delivers the engineered precision that transforms ceramic design concepts into reliable, high-performance reality. Contact our engineering team to discuss your specific plate mold ceramics requirements and leverage our validated expertise.

Precision Specs & Tolerances

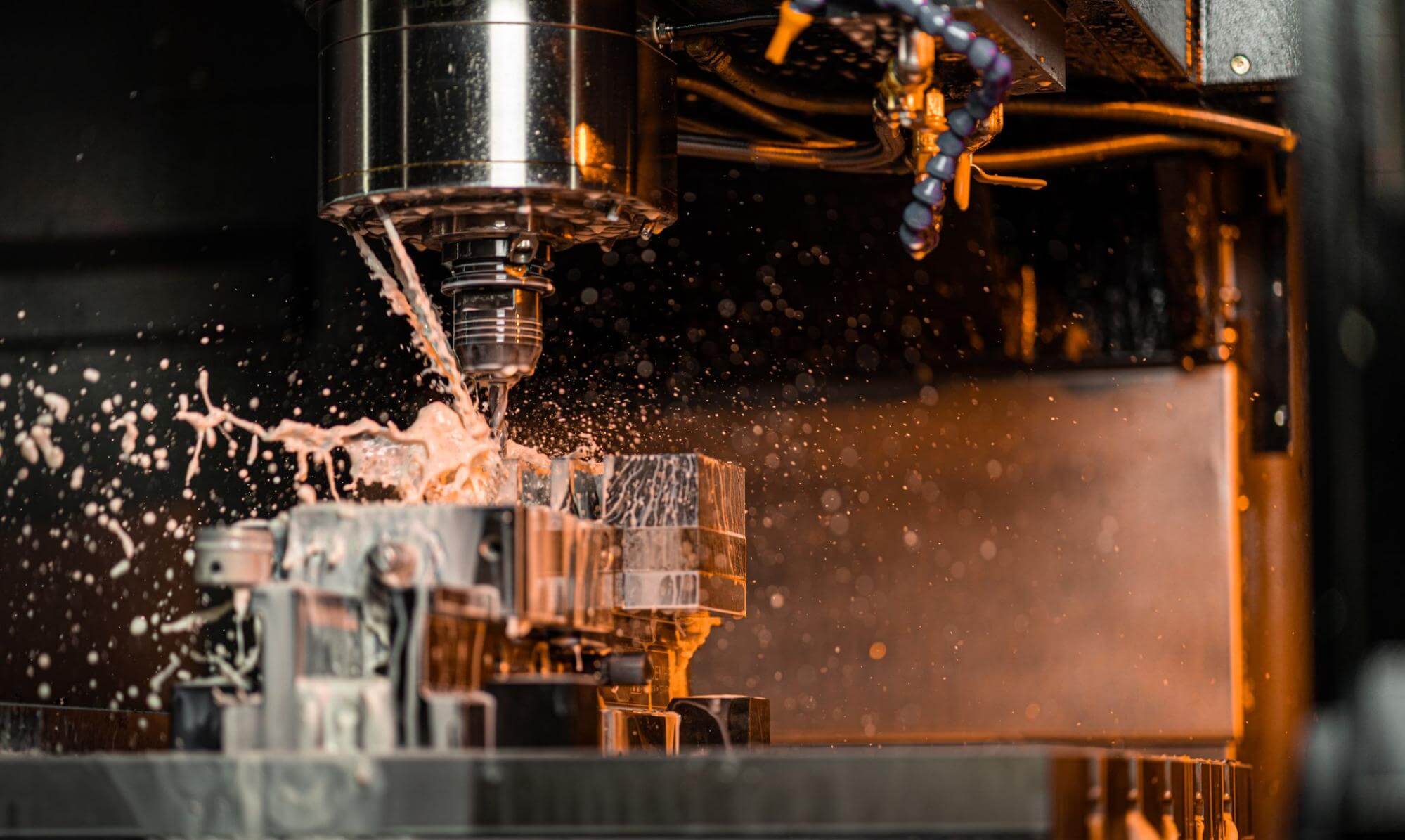

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for demanding industrial applications including plate mold ceramics. Our integrated production ecosystem leverages state-of-the-art 5 Axis CNC machining technology to achieve complex geometries, superior surface finishes, and consistent dimensional accuracy. This capability is essential for producing molds and tooling used in ceramic forming processes, where precision directly influences product integrity and performance.

Our 5 Axis CNC machining centers operate with simultaneous multi-axis motion, enabling the fabrication of intricate contours and undercuts without requiring multiple setups. This not only enhances geometric accuracy but also reduces cycle times and minimizes human error. The machines are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems to ensure process stability and repeatability. Materials commonly processed include hardened steels, stainless alloys, aluminum, and specialty tooling alloys—all selected based on thermal stability, wear resistance, and compatibility with ceramic molding environments.

Quality assurance is embedded at every stage of production. All critical components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM), which provides traceable, high-resolution metrology data. Our CMM system is calibrated to international standards and programmed to validate complex profiles, positional tolerances, and surface relationships with micron-level precision. This metrological rigor ensures that every plate mold or ceramic forming component meets stringent customer specifications and industry compliance requirements.

In addition to advanced hardware, Wuxi Lead employs a team of experienced process engineers who optimize toolpaths, fixturing, and material selection to maximize efficiency and part performance. We support full prototyping through high-volume production, with digital documentation and First Article Inspection (FAI) reports available upon request. Our facility operates under ISO 9001-certified quality management protocols, reinforcing our commitment to consistency, traceability, and continuous improvement.

The following table outlines the standard technical specifications and achievable tolerances for our 5 Axis CNC machining and inspection processes:

| Parameter | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm (up to 500 mm) |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finishes) |

| Angular Tolerance | ±0.05° |

| Feature-to-Feature Tolerance | ±0.012 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| CMM Measurement Accuracy | ±(2.5 + L/300) µm, L in mm |

| Material Compatibility | Tool Steel, Stainless Steel, Aluminum, Brass, Bronze, Titanium |

| Lead Time (Typical) | 10–25 days, depending on complexity |

Wuxi Lead Precision Machinery is engineered for precision, reliability, and scalability. By combining 5 Axis CNC excellence with rigorous CMM-based quality control, we provide mission-critical components that meet the exacting demands of advanced ceramic manufacturing and other high-technology sectors.

Material & Finish Options

Material Selection for High-Performance Plate Mold Ceramics

Selecting the optimal base material for plate molds in ceramic manufacturing directly impacts tool longevity, dimensional stability, and final part quality. At Wuxi Lead Precision Machinery, we prioritize materials that withstand extreme thermal cycling, resist abrasive wear from ceramic slurries, and maintain micron-level precision over extended production runs. Aluminum, steel, and titanium each offer distinct advantages depending on your ceramic composition, production volume, and thermal requirements.

Aluminum Alloys excel in rapid prototyping and medium-volume production due to superior thermal conductivity and machinability. Alloys like 6061-T6 or 7075-T6 dissipate heat 3–5× faster than steel, reducing cycle times for low-to-medium temperature ceramic processes (e.g., alumina or zirconia green-state forming). However, aluminum’s lower hardness (95–135 HB) limits its use in abrasive ceramic formulations or high-pressure molding. Anodizing is critical here—hard anodizing (Type III) creates a 25–50 μm wear-resistant oxide layer, enhancing surface hardness to 500+ HV while providing electrical insulation for electro-ceramic applications.

Tool Steels (e.g., H13, S7, or P20) are the standard for high-volume, high-temperature ceramic molding (e.g., sintering above 1,200°C). Their high hardness (200–250 HB annealed, 45–52 HRC hardened) and thermal stability prevent deformation under prolonged heat exposure. Steels resist abrasive wear from coarse ceramic particles better than aluminum but require precise heat treatment to avoid micro-cracking during thermal cycling. Nitriding or PVD coatings (e.g., TiN) are preferred over anodizing for steel, as they add surface hardness without compromising dimensional tolerances.

Titanium Alloys (e.g., Ti-6Al-4V) serve niche applications demanding absolute corrosion resistance and minimal thermal expansion, such as molds for aggressive ceramic chemistries (e.g., bismuth titanate) or ultra-precision optical ceramics. Titanium’s biocompatibility also makes it ideal for biomedical ceramic components. While costly and challenging to machine, its strength-to-weight ratio and stability at 300–400°C outperform aluminum and steel in specific scenarios. Anodizing titanium achieves decorative or mild corrosion-resistant finishes but does not significantly enhance wear resistance; plasma electrolytic oxidation (PEO) is recommended for critical wear surfaces.

Critical Material Properties Comparison

| Material | Typical Hardness (HB) | Thermal Conductivity (W/m·K) | Relative Cost | Best For Ceramics |

|---|---|---|---|---|

| Aluminum 6061-T6 | 95–105 | 167 | Low | Low-temp forming, prototypes |

| H13 Tool Steel | 210–230 (annealed) | 28 | Medium | High-temp sintering, high volume |

| Ti-6Al-4V | 330–360 | 7.2 | High | Corrosive chemistries, precision optics |

Anodizing remains indispensable for aluminum molds in ceramic production—not merely for aesthetics but for functional performance. Our engineered hard anodizing process ensures uniform pore sealing to prevent ceramic slurry penetration, directly extending mold life by 40–60% in alumina and zirconia applications. For steel or titanium, alternative surface treatments must be evaluated based on thermal and chemical exposure.

Partner with Wuxi Lead to match your ceramic process parameters with the optimal material-finish combination. Our engineers analyze your thermal profiles, abrasive loads, and tolerance requirements to eliminate costly trial-and-error, ensuring maximum ROI on your mold investment. Contact us for a technical consultation with material certification and lifecycle cost analysis.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the production of plate mold ceramics begins with a rigorous design phase, where engineering excellence meets application-specific requirements. Our team of senior design engineers collaborates directly with clients to analyze technical drawings, performance demands, and operational environments. Utilizing advanced CAD/CAM software, including SolidWorks and AutoCAD, we develop 3D models that incorporate thermal expansion coefficients, mechanical stress points, and dimensional tolerances as tight as ±0.005 mm. Finite Element Analysis (FEA) is applied to simulate real-world conditions, ensuring structural integrity under high-temperature and high-pressure molding cycles. Every design is validated through cross-functional review, integrating feedback from materials science, manufacturing, and quality assurance teams to eliminate potential failure points before physical development begins.

Prototyping: Validating Performance with Zero Defects in Mind

Once the digital model is approved, we proceed to prototype development using precision CNC machining and additive manufacturing techniques tailored for ceramic-grade materials such as alumina, zirconia, and silicon carbide. These prototypes are not merely visual models—they are fully functional components subjected to the same thermal, mechanical, and chemical conditions as final production units. Each prototype undergoes metrological inspection using coordinate measuring machines (CMM) and laser scanning to verify dimensional accuracy. We conduct cycle testing under simulated production loads, assessing wear resistance, surface finish consistency, and thermal stability. Any deviation—no matter how minor—is traced to its root cause through our Six Sigma-based quality protocol. This phase is critical to achieving zero defects in mass production, as it allows us to refine tool paths, adjust material sintering profiles, and optimize cooling channel layouts before full-scale manufacturing commences.

Mass Production: Scalable Excellence with Full Traceability

With prototype validation complete, we transition seamlessly into mass production using automated CNC machining centers, robotic handling systems, and in-line quality monitoring. Our ISO 9001-certified facility in Wuxi operates under strict process controls, with each ceramic plate mold tracked via a digital manufacturing execution system (MES) that logs every machining parameter, inspection result, and heat treatment cycle. Redundant inspection checkpoints are embedded throughout the production line, including post-sintering dimensional verification and ultrasonic flaw detection. Final products are packaged with full inspection reports and material certifications, ensuring complete traceability.

The result is a flawless batch of plate mold ceramics engineered for longevity, precision, and repeatable performance in high-demand industrial applications.

| Specification | Detail |

|---|---|

| Material Options | Alumina (Al₂O₃), Zirconia (ZrO₂), Silicon Carbide (SiC) |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra ≤ 0.4 µm (polished), Ra ≤ 3.2 µm (machined) |

| Max Component Size | 600 mm × 400 mm × 150 mm |

| Production Capacity | Up to 5,000 units/month |

| Quality Standards | ISO 9001, Six Sigma DMAIC, Full CMM Inspection |

Why Choose Wuxi Lead Precision

Elevate Your Ceramic Plate Mold Production Through Precision Engineering

Ceramic plate mold manufacturing demands uncompromising precision in metal components to ensure dimensional stability, thermal resilience, and flawless surface replication. Substandard tooling accelerates wear, introduces defects, and escalates production costs. At Wuxi Lead Precision Machinery, we engineer custom metal solutions specifically for high-performance ceramic molding applications, transforming material challenges into competitive advantages. Our integrated approach combines advanced CNC capabilities with deep metallurgical expertise to deliver molds that maximize yield and longevity.

We recognize that ceramic processing environments subject tooling to extreme thermal cycling, abrasive wear, and complex stress profiles. Standard mold bases or inserts often fail prematurely under these conditions. Lead Precision addresses this through proprietary material selection protocols and micron-level machining tolerances. Our engineers collaborate with clients from initial concept through validation, ensuring every component aligns with your ceramic formulation, press parameters, and lifecycle requirements. This partnership model eliminates guesswork and reduces time-to-market for critical tooling.

Our technical capabilities are validated through rigorous in-house testing and decades of field performance across aerospace, medical, and advanced electronics sectors. The following specifications demonstrate our capacity to meet the most demanding ceramic mold requirements:

| Capability | Specification | Application Relevance |

|---|---|---|

| Material Expertise | H13, S7, Maraging Steel, Inconel 718, Custom Alloys | Thermal fatigue resistance and wear performance in ceramic sintering environments |

| Dimensional Accuracy | ±0.002 mm (0.00008″) over 500 mm | Ensures consistent cavity geometry for zero-gap pressing and uniform density |

| Surface Finish | Ra 0.05 µm (2 µin) mirror polish achievable | Minimizes ceramic adhesion and surface defects in final parts |

| Complex Geometry | 5-axis simultaneous milling, micro-channeling, asymmetric contours | Enables intricate mold features for advanced ceramic substrates |

| Validation Process | CMM, optical metrology, thermal cycling simulation | Confirms performance under operational thermal loads before deployment |

Partnering with Lead Precision means accessing more than machinery—we provide a dedicated engineering resource committed to your production success. Our team analyzes your specific ceramic composition, pressing methodology, and quality targets to prescribe optimal mold architecture and material solutions. This proactive collaboration prevents costly iterations and ensures first-article compliance.

Do not compromise on the foundational elements of your ceramic manufacturing process. Contact our engineering team to discuss how precision metal components can enhance your plate mold performance, reduce scrap rates, and extend tool life. Submit your technical requirements or schedule a confidential consultation today.

Contact [email protected] to initiate a technical dialogue. Include your application details and target specifications for a tailored capability assessment within 24 business hours. Let Lead Precision become your strategic partner in advancing ceramic manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.