Technical Contents

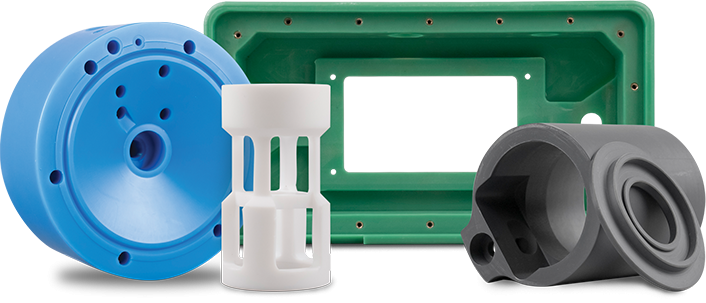

Engineering Guide: Plastics Machining

Engineering Insight: Precision in Plastics Machining

In the realm of advanced manufacturing, plastics machining demands a level of precision that rivals, and in many cases exceeds, that of metalworking. While plastics offer advantages such as low weight, corrosion resistance, and electrical insulation, their inherent material properties—thermal expansion, creep, and variable stiffness—introduce unique challenges in achieving tight tolerances and repeatable results. At Wuxi Lead Precision Machinery, we recognize that success in plastics machining lies not only in advanced equipment but in deep engineering insight, process control, and material understanding.

Unlike metals, many engineering-grade thermoplastics such as PEEK, PTFE, and ULTEM exhibit significant dimensional changes under temperature fluctuations and mechanical load. This behavior necessitates a machining strategy that accounts for stress relief, controlled cutting parameters, and post-machining stabilization. Even minor deviations in spindle speed, feed rate, or tool geometry can result in burring, delamination, or out-of-tolerance features. Our CNC machining centers are calibrated specifically for polymer processing, utilizing low-vibration spindles, non-contact tool measurement, and climate-controlled environments to maintain dimensional stability throughout production.

Wuxi Lead Precision Machinery brings over 15 years of experience in high-precision component manufacturing, serving sectors where failure is not an option—Olympic-grade sports equipment and defense-critical systems. In these applications, plastic components must perform under extreme conditions, whether enduring repetitive stress in high-speed mechanical assemblies or maintaining integrity in harsh environmental exposure. Our work on polymer-based guidance elements for military reconnaissance drones and wear-resistant bushings in Olympic bobsled runners underscores our capability to deliver micron-level accuracy in non-metallic materials.

Precision is not just a specification—it is a process. From initial material selection and fixture design to in-process inspection and final metrology, every step is engineered to minimize variation. Our engineers collaborate directly with clients to optimize part geometry for machinability, avoiding thin walls or deep cavities that could lead to warpage or tool deflection. We employ coordinate measuring machines (CMM) and laser scanning to validate critical dimensions, ensuring compliance with ISO 2768-m or customer-specific standards.

The following table outlines typical machining capabilities for engineering plastics at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish (Ra) | 0.4 µm to 3.2 µm |

| Maximum Part Size | 800 mm × 600 mm × 400 mm |

| Common Materials | PEEK, PTFE, PAI, PC, PMMA, POM |

| CNC Equipment | 3-axis, 4-axis, and 5-axis mills |

| In-Process Inspection | On-machine probing, CMM validation |

| Lead Time (Prototype) | 7–12 working days |

At Wuxi Lead Precision Machinery, we treat plastics not as an alternative to metal, but as a high-performance material system requiring its own precision discipline. Our track record in mission-critical applications reflects our commitment to engineering excellence—where every micron matters.

Precision Specs & Tolerances

Technical Capabilities: Precision Plastics Machining at Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery leverages its deep expertise in high-precision metal manufacturing to deliver exceptional custom plastics machining services. While our core foundation is metal, we recognize the critical demand for complex, tight-tolerance plastic components across aerospace, medical, and semiconductor industries. Our approach integrates rigorous metal machining discipline with specialized knowledge of polymer behavior, ensuring parts meet exacting functional and dimensional requirements where material properties like thermal expansion and creep are paramount.

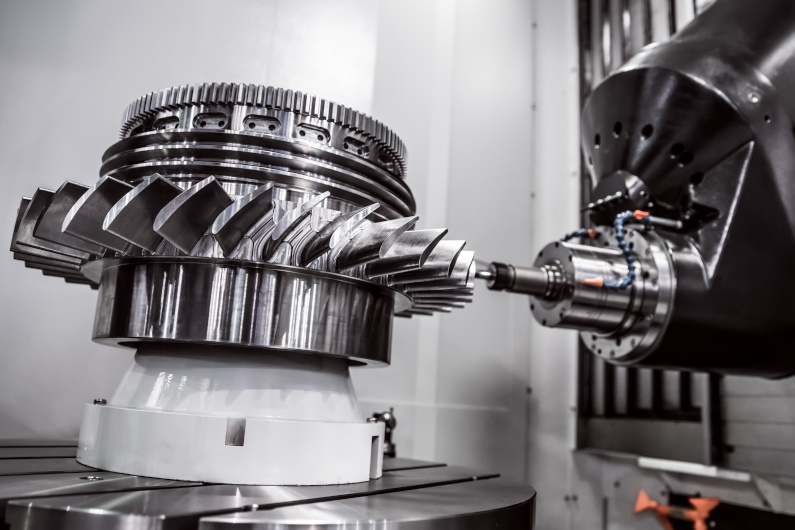

Our dedicated plastics machining capability centers on advanced 5-axis CNC milling and turning centers. These machines provide the simultaneous multi-axis motion essential for producing intricate geometries, deep cavities, and undercuts common in high-performance plastic components, all within a single setup. This minimizes handling, reduces cumulative error, and significantly enhances part accuracy and surface finish. Crucially, our programming and operations teams apply specialized toolpath strategies and thermal management protocols specifically developed for diverse engineering plastics. We understand that materials like PEEK, PTFE, Ultem, and Acetal require distinct cutting parameters, tool geometries, and fixturing approaches compared to metals to prevent melting, burring, or internal stress. Our equipment features high-speed spindles with precise coolant control options, including air blast and minimal quantity lubrication (MQL) systems tailored to optimize chip evacuation and part integrity for sensitive polymers.

Quality assurance for plastics demands methodologies beyond standard metal inspection. We utilize state-of-the-art Coordinate Measuring Machines (CMM) housed within a temperature-stabilized metrology laboratory (20°C ±0.5°C). This controlled environment is non-negotiable for plastics, mitigating measurement drift caused by ambient temperature fluctuations that significantly impact polymer dimensions. Our inspection protocols include specialized probe styli and scanning routines designed for the lower modulus of plastics, preventing part deflection during measurement. We implement rigorous first-article inspection (FAI) and in-process checks using calibrated optical comparators and micrometers, with all data traceable to international standards. Material certification and lot traceability are standard practice, ensuring full compliance for regulated sectors.

Achieving consistent tolerances in plastics requires acknowledging material-specific behavior. The table below reflects our typical achievable capabilities under controlled conditions, recognizing that final tolerances are always influenced by part geometry, material selection, and environmental factors in the end-use application.

| Feature Type | Standard Capability (mm) | High-Precision Capability (mm) | Critical Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 | ±0.025 | Highly dependent on material stability & part size |

| Geometric (Flatness, Roundness) | 0.05 | 0.02 | Requires optimal fixturing and stress relief |

| Hole Diameter | +0.05 / -0.00 | +0.025 / -0.00 | Tolerance direction critical for press-fits |

| Positional | ±0.05 | ±0.025 | Minimized via single-setup 5-axis machining |

We emphasize proactive collaboration during the design phase. Our engineering team provides detailed Design for Manufacturability (DFM) feedback specific to plastics, addressing potential challenges like wall thickness uniformity, draft angles, and stress concentration points before machining begins. This integrated approach, combining advanced 5-axis technology, polymer-specific process expertise, and metrology-grade quality control, ensures Wuxi Lead delivers plastics components that perform reliably in the most demanding applications. Consultation on material suitability and tolerance feasibility is always recommended for optimal project outcomes.

Material & Finish Options

Material Selection for High-Precision Plastics Machining Components

In the field of custom metal manufacturing for plastics machining applications, material selection plays a pivotal role in determining performance, longevity, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in delivering high-precision components engineered to meet the rigorous demands of plastic processing equipment. The most commonly used materials—aluminum, steel, and titanium—each offer distinct advantages depending on the operational requirements, such as wear resistance, thermal stability, and structural integrity.

Aluminum is widely favored for its excellent machinability, lightweight properties, and good thermal conductivity. It is particularly suitable for components that require rapid heat dissipation or reduced inertia, such as mold bases, fixture plates, and housing parts. While aluminum lacks the wear resistance of steel, its performance can be significantly enhanced through surface treatments like anodizing. Hard anodizing, especially Type III anodizing, increases surface hardness up to 60 HRC, improves corrosion resistance, and reduces galling in moving parts.

Steel, particularly tool steels like H13 and P20, remains the standard for high-wear applications such as mold cores, cavities, and ejector systems. These alloys offer superior hardness, excellent dimensional stability under thermal cycling, and long service life in high-volume production environments. Stainless steel variants are selected when corrosion resistance is critical, such as in medical or food-grade plastic processing. While heavier than aluminum, steel’s durability justifies its use in demanding operational conditions.

Titanium stands out for its exceptional strength-to-density ratio and outstanding resistance to corrosion and fatigue. Though less common due to higher material and machining costs, titanium is ideal for specialized components exposed to aggressive environments or where weight reduction is essential without compromising strength. Applications include precision guide pins, inserts for high-temperature molds, and aerospace-related tooling. Its low thermal expansion coefficient also makes it suitable for high-accuracy positioning elements.

Surface finishing, particularly anodizing, is a critical consideration in material performance. Anodizing not only enhances wear and corrosion resistance but also allows for color coding and improved aesthetic finish. For aluminum components, Type II (sulfuric acid) anodizing is standard for general protection, while Type III (hardcoat) anodizing is recommended for functional surfaces subject to friction or load.

The following table summarizes key mechanical and finishing properties of the materials discussed:

| Material | Tensile Strength (MPa) | Hardness (HB) | Density (g/cm³) | Common Anodizing Type | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 95 | 2.7 | Type II, Type III | Mold bases, fixtures |

| H13 Tool Steel | 1,500 | 235 | 7.8 | Not applicable | Mold cores, cavities |

| Stainless Steel 316 | 570 | 150 | 8.0 | Not applicable | Corrosion-resistant parts |

| Titanium Grade 5 | 900 | 360 | 4.5 | Not applicable | High-strength inserts, aerospace tooling |

Selecting the right material and finish requires a detailed understanding of the application environment, load conditions, and lifecycle expectations. At Wuxi Lead Precision Machinery, we support clients in making informed decisions backed by engineering expertise and precision manufacturing capabilities.

Manufacturing Process & QC

Plastics Machining Excellence: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our plastics machining process integrates aerospace-grade discipline with polymer-specific expertise to deliver flawless components. Unlike metals, plastics demand acute attention to thermal behavior, chip evacuation, and residual stress. Our phased methodology—Design, Prototyping, Mass Production—ensures defects are engineered out before metal meets material, not detected after. This systematic approach eliminates costly rework and guarantees performance in mission-critical applications.

The Design phase begins with rigorous Design for Machinability (DFM) analysis. Our engineers collaborate with clients to optimize geometry, wall thickness, and tolerances specific to the polymer’s properties—whether PEEK, PTFE, or Ultem. We simulate thermal expansion and clamping forces to prevent warpage, ensuring the digital model translates to physical reality. Material certification and traceability are non-negotiable; every resin batch undergoes validation against ASTM D638 standards. This upfront rigor prevents 90% of potential failures by aligning design intent with manufacturability.

Prototyping transitions theory to validation. Using 5-axis CNC mills with sub-micron toolpath control, we produce functional prototypes mirroring production conditions. Critical dimensions are verified via CMM and optical comparators, while stress tests validate structural integrity under operational loads. Iterations are data-driven: thermal imaging identifies heat buildup zones, and surface profilometry confirms Ra values meet specifications. Only when prototypes pass all functional and dimensional checkpoints—typically within 72 hours—do we approve the process for scale.

Mass Production executes with uncompromising zero-defect protocols. Statistical Process Control (SPC) monitors key parameters in real time: spindle load, coolant flow, and ambient humidity. Each component undergoes 100% automated in-process inspection, with deviations triggering immediate machine recalibration. Our closed-loop system ensures Cpk ≥1.67 for critical features, while batch traceability links every part to raw material certificates and operator logs. The result is consistent output where rejects are statistically impossible, not merely rare.

This seamless flow from design validation to high-volume execution minimizes client risk and total cost of ownership. Below are key specifications demonstrating our capability transition:

| Parameter | Prototyping Phase | Mass Production Phase |

|---|---|---|

| Tolerance Range | ±0.025 mm | ±0.010 mm |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm |

| Inspection Frequency | 100% per batch | 100% real-time SPC |

| Lead Time | 3-5 days | 10-15 days (1k units) |

| Process Capability | Cpk ≥1.33 | Cpk ≥1.67 |

Wuxi Lead’s process transforms plastics machining from a commodity operation into a strategic advantage. By embedding quality at every phase, we ensure your components perform flawlessly in the field—proving that zero defects is not an aspiration, but an engineered outcome.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Plastics Machining

At Wuxi Lead Precision Machinery, we understand that precision in plastics machining is not just about shaping materials—it’s about delivering performance, consistency, and reliability across mission-critical applications. As a leading provider of custom metal and plastic manufacturing solutions based in China, we specialize in high-tolerance machining of engineering-grade thermoplastics for industries where failure is not an option. From aerospace and medical devices to semiconductor equipment and advanced automation, our clients trust us to turn complex designs into high-performance components with zero compromise.

Our advanced CNC machining centers, combined with decades of material science expertise, enable us to work with a broad range of high-performance plastics such as PEEK, PTFE, ULTEM, PPS, and acetal. Each material is processed under controlled conditions to ensure dimensional stability, surface integrity, and long-term functional reliability. Unlike standard fabrication methods, our approach integrates precision tooling, in-process inspection, and strict environmental controls to eliminate variability and deliver components that meet the most demanding technical specifications.

We go beyond machining—we are your engineering partner. From initial design consultation to full-scale production, our team collaborates closely with your engineers to optimize part geometry, select the ideal material, and streamline manufacturability. This proactive collaboration reduces lead times, minimizes costs, and ensures that every component exceeds performance expectations.

Our facility is equipped with 3-, 4-, and 5-axis CNC machines, coordinate measuring machines (CMM), and laser scanning systems, enabling tight tolerances down to ±0.005 mm. With ISO 9001 certification and a commitment to continuous improvement, we maintain the highest standards in quality assurance and process traceability.

The following table outlines key capabilities for our plastics machining services:

| Specification | Detail |

|---|---|

| Material Types | PEEK, PTFE, ULTEM (PEI), PPS, Acetal (POM), Nylon, Polycarbonate, PMMA |

| Tolerance | ±0.005 mm (typical), up to ±0.002 mm with special process control |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Surface Finish | Ra 0.2 µm to Ra 3.2 µm (custom finishes available) |

| Machining Centers | 3-axis, 4-axis, 5-axis CNC milling and turning |

| Quality Control | CMM, optical comparators, laser scanning, first-article inspection |

| Certifications | ISO 9001:2015, RoHS compliant, material traceability (certificates available) |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally committed to your success. Whether you require rapid prototyping, low-volume specialty runs, or high-volume production, we deliver consistent quality with on-time delivery.

Contact us today at [email protected] to discuss your next plastics machining project. Let Lead Precision be the foundation of your most demanding applications.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.