Technical Contents

Engineering Guide: Plastic Prototypes

Engineering Insight: The Critical Role of Precision in Plastic Prototypes

In the realm of advanced manufacturing, plastic prototypes serve as the foundational step in validating design intent, functionality, and manufacturability. While often perceived as preliminary models, these prototypes demand the same level of engineering rigor as final production parts—particularly when developed for high-stakes industries such as aerospace, defense, and precision instrumentation. At Wuxi Lead Precision Machinery, we approach plastic prototyping not as a simple modeling exercise, but as a precision engineering discipline where tolerances, material behavior, and structural integrity must be meticulously controlled.

Precision in plastic prototypes is non-negotiable. Even minor deviations in dimensional accuracy can lead to assembly failures, performance inefficiencies, or costly redesigns downstream. Plastics, by nature, exhibit higher thermal expansion and lower rigidity compared to metals, making them more susceptible to warping, shrinkage, and deformation during and after processing. This behavior necessitates advanced simulation, precise tooling, and expert process control—capabilities deeply embedded in our engineering DNA.

Wuxi Lead Precision Machinery brings over a decade of experience in high-precision metal manufacturing to the domain of plastic prototyping. Our expertise, honed through critical projects for Olympic-standard equipment and military-grade systems, ensures that every prototype meets exacting performance benchmarks. Whether supporting the development of lightweight structural components for unmanned systems or precision housings for sensitive optical devices, our team applies metrology-grade validation and CNC-driven accuracy to every phase of prototype production.

Our process integrates multi-axis machining, injection molding with micro-tolerance control, and real-time quality inspection using coordinate measuring machines (CMM) and 3D scanning. This allows us to achieve repeatability within ±0.005 mm—a standard derived from our work in mission-critical metal components and now fully applied to polymer-based prototypes.

Below are key technical specifications that define our plastic prototyping capabilities:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.02 mm (depending on geometry) |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm (machined) |

| Maximum Part Size | 600 mm × 400 mm × 300 mm |

| Materials Supported | ABS, PC, POM, PEEK, PMMA, Nylon, PSU |

| Prototyping Methods | CNC Machining, Rapid Tooling, Injection Molding |

| Lead Time | 5–15 days (depending on complexity) |

| Quality Assurance | Full CMM report, First Article Inspection (FAI) |

| Industry Standards Compliant | ISO 9001:2015, MIL-STD-810 (for military apps) |

By leveraging our precision metal manufacturing heritage, Wuxi Lead ensures that plastic prototypes are not just visual aids, but functional, testable components capable of withstanding real-world conditions. This engineering-first approach reduces time-to-market, mitigates risk, and delivers confidence in every design iteration.

Precision Specs & Tolerances

Technical Capabilities for Precision Plastic Prototyping

Wuxi Lead Precision Machinery leverages its core expertise in high-precision metal manufacturing to deliver exceptional plastic prototyping services. Our engineering approach treats plastic materials with the same rigorous standards applied to aerospace-grade alloys, ensuring dimensional stability and functional accuracy critical for validation testing. This cross-disciplinary proficiency stems from deep material science understanding and advanced process control, eliminating common pitfalls like thermal deformation or surface integrity issues inherent in plastic machining.

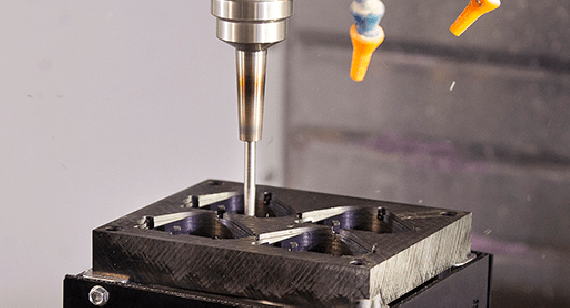

Our 5-axis CNC machining centers form the backbone of this capability. Equipped with high-speed spindles (up to 24,000 RPM) and thermal compensation systems, these machines execute complex geometries in a single setup—essential for prototypes requiring undercuts, organic contours, or tight internal features. Precision-ground carbide tooling optimized for specific polymers minimizes chatter and burring, while adaptive toolpath strategies maintain consistent chip load to prevent melting or delamination in thermoplastics. Crucially, our programmers apply metal-machining discipline to plastic workflows: feed rates and spindle speeds are meticulously calibrated per material ductility, and vacuum-assisted chip evacuation prevents re-cutting that compromises surface finish.

Quality assurance is non-negotiable. Every prototype undergoes full CMM inspection against the original CAD model using Zeiss CONTURA systems with 1.9 μm volumetric accuracy. This isn’t limited to basic dimensional checks; we validate geometric tolerances (GD&T), surface roughness (Ra ≤ 0.8 μm achievable), and critical feature relationships. Our inspection protocols include thermal soak testing to confirm stability across operational temperature ranges—a necessity for plastics prone to creep or moisture absorption. Data from each inspection is compiled into a comprehensive report, providing clients with actionable insights for design iteration.

Material selection is strategically guided by our metallurgical team’s knowledge of polymer behavior. We machine engineering-grade plastics including PEEK, Ultem, Acetal, and Polycarbonate, with process parameters adjusted for each material’s unique thermal expansion coefficient and machinability. For instance, acrylic requires specialized coolant strategies to avoid stress cracking, while nylon demands controlled humidity during machining to prevent dimensional drift. This material-specific expertise ensures prototypes behave predictably in real-world applications.

The following table details achievable tolerances across common prototype materials under controlled workshop conditions (20±1°C):

| Material Category | Standard Tolerance (mm) | Precision Tolerance (mm) | Ultra-Precision Tolerance (mm) |

|---|---|---|---|

| ABS, Polypropylene | ±0.10 | ±0.05 | ±0.025 |

| Acetal (POM), Nylon | ±0.08 | ±0.04 | ±0.02 |

| Polycarbonate, PMMA | ±0.07 | ±0.035 | ±0.015 |

| PEEK, Ultem, PPS | ±0.06 | ±0.03 | ±0.01 |

Note: Tolerances assume features within 150mm cube; larger geometries require engineering review. Ultra-precision tolerances necessitate stress-relieved stock and additional CMM validation cycles.

By integrating metal-manufacturing rigor with polymer-specific process mastery, Wuxi Lead transforms plastic prototypes into reliable predictors of end-part performance. This capability accelerates time-to-market while de-risking design validation—proving that precision engineering transcends material boundaries.

Material & Finish Options

Material selection is a critical step in the development of high-performance plastic prototypes, particularly when metal components are integrated for structural support, heat dissipation, or precision fit. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing that complements advanced plastic prototyping, ensuring optimal functionality, durability, and manufacturability. The most commonly used metals in such applications are aluminum, steel, and titanium, each offering distinct mechanical and thermal properties suited to specific engineering demands.

Aluminum is widely preferred for plastic prototype integration due to its lightweight nature, excellent thermal conductivity, and good machinability. It is ideal for applications requiring weight reduction without sacrificing strength, such as in aerospace, automotive, and consumer electronics. Grade 6061-T6 is frequently used for its balanced mechanical properties and weldability, while 7075-T6 offers higher strength for more demanding structural roles. Aluminum also responds exceptionally well to anodizing, a finishing process that enhances surface hardness, corrosion resistance, and aesthetic quality. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard options, with the latter providing a thicker, wear-resistant layer suitable for high-stress environments.

Steel, particularly stainless steel grades such as 304 and 316, is selected when superior strength, wear resistance, and corrosion performance are required. These materials are commonly used in medical devices, industrial tooling, and fluid-handling systems where hygiene and longevity are paramount. While heavier than aluminum, steel offers exceptional dimensional stability and can be precision-machined to tight tolerances. Finishing options include passivation to enhance corrosion resistance and electropolishing for improved surface smoothness, especially in sanitary applications.

Titanium, specifically Grade 5 (Ti-6Al-4V), is employed in high-end applications where an exceptional strength-to-density ratio and resistance to extreme environments are necessary. Its biocompatibility makes it ideal for medical implants, while its performance under high temperatures benefits aerospace and defense sectors. Though more challenging to machine, titanium’s long-term durability often justifies the added manufacturing complexity. Surface treatments such as anodizing can also be applied for color coding or minor improvements in surface hardness.

Below is a comparative overview of key properties for these materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good | Anodizing, Sandblasting | Consumer electronics, Automotive |

| Stainless Steel 304 | 8.0 | 505 | Excellent | Passivation, Polishing | Medical devices, Food processing |

| Titanium Ti-6Al-4V | 4.4 | 900 | Excellent | Anodizing, Bead blasting | Aerospace, Implants |

Choosing the right metal and finish ensures seamless integration with plastic components, enhances product performance, and supports scalability from prototype to production. At Wuxi Lead Precision Machinery, we work closely with engineering teams to recommend optimal material and surface treatment combinations based on functional requirements, environmental exposure, and lifecycle expectations.

Manufacturing Process & QC

Precision Plastic Prototyping to Zero-Defect Metal Production

At Wuxi Lead Precision Machinery, we engineer plastic prototypes not as an end goal but as a critical validation step toward flawless metal mass production. Our integrated process ensures design integrity transitions seamlessly from concept to high-volume manufacturing, eliminating costly errors. We begin with rigorous Design for Manufacturability (DFM) analysis, where our engineers scrutinize 3D models for structural viability, material compatibility, and CNC machining constraints. This phase identifies potential weaknesses—such as undercuts or thin walls—that could compromise metal part performance, allowing redesign before tooling begins.

Prototyping leverages rapid techniques like CNC-machined ABS or polypropylene to physically validate form, fit, and function. However, plastic’s inherent flexibility and thermal behavior differ significantly from final metal components. Thus, our prototypes serve solely to verify geometry and assembly—not material-specific performance. We enforce strict dimensional checks against CAD data using coordinate measuring machines (CMMs), ensuring tolerances align with initial design intent. Any deviation triggers immediate design iteration, preventing downstream failures.

The true value emerges when transitioning to metal mass production. Here, Wuxi Lead’s zero-defect mandate takes precedence. We deploy multi-axis CNC milling and turning centers with sub-micron repeatability, processing aerospace-grade aluminum, stainless steel, and titanium. Every production run undergoes in-process inspections at critical stages: raw material certification, first-article validation, and statistical process control (SPC) monitoring. Our closed-loop feedback system adjusts tool paths in real time, compensating for thermal drift or tool wear. Crucially, plastic prototyping de-risks this phase by confirming that the design—not the manufacturing process—is production-ready.

Below outlines key distinctions between prototyping and production stages, emphasizing where precision shifts from validation to perfection:

| Process Stage | Material Scope | Typical Tolerance | Lead Time | Primary Objective |

|---|---|---|---|---|

| Plastic Prototyping | ABS, Nylon, Polypropylene | ±0.1 mm | 3-7 days | Geometric validation and assembly testing |

| Metal Mass Production | Aluminum 6061, SS 304, Titanium Gr5 | ±0.005 mm | 2-4 weeks | Zero-defect functional parts meeting MIL-STD/AS9100 |

This disciplined approach transforms prototyping from a cost center into a strategic safeguard. By isolating design flaws early with plastic models, we ensure metal production focuses exclusively on executing perfection. Wuxi Lead’s CNC systems operate within ISO 14644 Class 7 cleanrooms, with 100% post-production CMM reporting and traceable material certifications. The result is not merely defect reduction but absolute elimination—where every component meets the uncompromising standards demanded by automotive, aerospace, and medical device OEMs. Your design’s journey ends not with a prototype, but with confidence in every量产 part.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing for Plastic Prototypes

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision metal components tailored to the exacting demands of plastic prototype development. Our advanced manufacturing capabilities bridge the gap between concept and production, ensuring your prototypes are not only accurate but also optimized for performance, durability, and scalability. As a trusted partner in the global manufacturing ecosystem, we bring decades of engineering excellence to every project—whether you’re developing injection molds, precision tooling, or functional prototype housings.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, wire EDM, grinding systems, and 3D metrology equipment. This enables us to produce complex metal parts with tolerances as tight as ±0.002 mm, critical for ensuring seamless integration with plastic components during prototyping. We work with a wide range of materials including hardened steels, aluminum alloys, stainless steel, and specialty tool steels, ensuring optimal performance under real-world conditions.

What sets us apart is our deep understanding of the interplay between metal tooling and plastic part formation. We don’t just manufacture metal parts—we engineer solutions that enhance the efficiency and accuracy of your plastic prototyping process. From initial design consultation to final inspection, our team collaborates closely with engineers and product developers to anticipate challenges, reduce cycle times, and accelerate time-to-market.

We support rapid turnaround without compromising quality, offering prototyping lead times as fast as 7–10 days for machined components. Our quality management system is ISO 9001:2015 certified, and every part undergoes rigorous inspection using coordinate measuring machines (CMM) and optical comparators to ensure compliance with your technical specifications.

Below are key technical capabilities that define our service offering:

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 600 mm |

| Materials Supported | P20, 718, H13, S136, Aluminum 6061/7075, Stainless Steel 304/316, Tool Steels |

| Surface Finish | Ra 0.8 µm standard, down to Ra 0.2 µm with polishing |

| Lead Time (Prototypes) | 7–14 days depending on complexity |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Reports (FAIR) |

| Secondary Operations | Heat treatment, nitriding, texturing, coating coordination |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic advantage in precision, speed, and technical insight. We are committed to supporting your innovation with reliable, repeatable, and high-performance metal components designed specifically for plastic prototype applications.

For immediate assistance or to submit a prototype request, contact us at [email protected]. Let’s build the future of manufacturing—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.