Technical Contents

Engineering Guide: Plastic Precision Machining

Engineering Insight: The Non-Negotiable Standard of Precision in Plastic Machining

Precision in plastic machining transcends mere dimensional accuracy; it is the fundamental determinant of functional integrity, assembly success, and ultimate product performance. Unlike metals, engineering plastics present unique challenges: significant thermal expansion coefficients, variable material homogeneity, and susceptibility to stress-induced deformation during and after machining. A tolerance deviation of even 0.02mm can render a medical fluidic manifold leak-prone, compromise the optical clarity of a sensor housing, or prevent the seamless integration of aerospace interior components. At Wuxi Lead Precision Machinery, we recognize that achieving true precision in plastics demands far more than advanced CNC equipment. It requires deep material science understanding, meticulously calibrated processes accounting for hygroscopic swelling and creep, and environmental controls that mitigate ambient fluctuations. This level of control is not optional for mission-critical applications; it is the baseline requirement.

Our commitment to this standard is forged through rigorous real-world validation. We have engineered components for Olympic-standard timing systems, where nanosecond synchronization relies on flawless optical path stability within polymer housings machined to sub-micron repeatability. Similarly, we supply precision-machined polymer elements for classified military communication and targeting systems, where environmental resilience and absolute dimensional stability under extreme conditions are non-negotiable. These projects demanded not only adherence to stringent tolerances but also mastery over material behavior across temperature extremes and vibration profiles. Success in these arenas stems from our integrated approach: material-specific calibration protocols, in-process metrology with traceable CMM verification, and a culture where every machinist understands the end-use consequence of a micron.

The tangible output of this methodology is consistent achievement of tight tolerances across diverse engineering polymers, directly translating to client value through reduced scrap, accelerated assembly, and enhanced product reliability. Below details our core machining capabilities for high-performance plastics:

| Parameter | Standard Capability | High-Precision Capability | Key Materials Supported |

|---|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.005 mm | PEEK, PEI, PPSU, PTFE, Acetal, Ultem |

| Surface Roughness (Ra) | 1.6 µm | 0.2 µm | Polycarbonate, PMMA, Nylon variants |

| Geometric Tolerance | ±0.1 mm | ±0.01 mm | PPS, PVDF, PBI, Custom Composites |

| Feature Complexity | Moderate | High (Multi-axis) | |

| Primary Equipment | 3-Axis CNC | 5-Axis CNC (Makino, DMG) |

This precision foundation enables our clients across medical, aerospace, and semiconductor sectors to confidently specify complex plastic components. Wuxi Lead Precision Machinery delivers not just parts, but guaranteed performance through engineering discipline validated at the highest levels of global industry demand. The cost of imprecision in critical plastic components is measured in field failures and reputational damage; our process ensures it is a risk you never incur.

Precision Specs & Tolerances

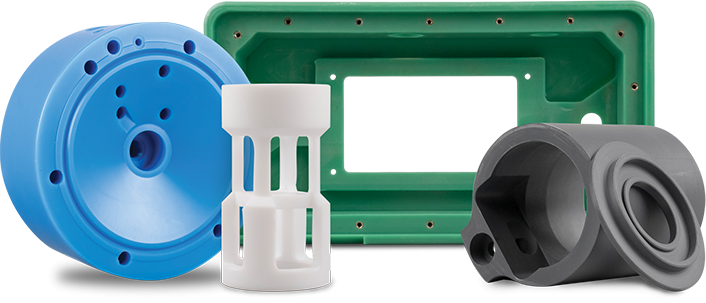

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision machining for complex plastic components. Our expertise lies in producing mission-critical parts for industries such as medical devices, semiconductor, aerospace, and automation, where dimensional accuracy, material integrity, and repeatability are non-negotiable. At the core of our production floor is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to execute intricate geometries with superior surface finish and minimal setup changes.

Our 5-axis CNC systems provide simultaneous multi-directional cutting, allowing for the precise fabrication of contoured features, undercuts, and deep cavities that are unattainable with conventional 3-axis machines. This capability significantly reduces lead times and enhances part consistency by minimizing manual interventions. We work with a broad spectrum of engineering-grade thermoplastics, including PEEK, PPS, ULTEM, PTFE, and POM, ensuring material compatibility with high-performance operational environments. Each machining program is optimized using advanced CAM software, with toolpath simulation and collision detection to ensure process reliability and part accuracy.

Quality is embedded into every stage of production. All machined components undergo rigorous inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), which delivers micron-level verification of critical dimensions, form, and positional tolerances. Our CMM inspection routines are fully programmable and traceable, supporting first-article inspection (FAI) reports and production batch validation per customer-specific requirements. Additionally, environmental controls and calibrated metrology equipment ensure measurement stability across shifts and production runs.

To maintain consistency and exceed customer expectations, we adhere to strict tolerance standards across linear, angular, and geometric dimensions. The following table outlines our standard achievable tolerances for precision-machined plastic components:

| Feature Type | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm |

| Angular Dimensions | ±0.1° | ±0.05° |

| Flatness | 0.05 mm | 0.01 mm |

| Roundness | 0.02 mm | 0.005 mm |

| Positional Tolerance | ±0.03 mm | ±0.01 mm |

| Surface Finish (Ra) | 3.2 µm | 0.8 µm |

These specifications reflect our commitment to precision and repeatability, validated through continuous process monitoring and SPC methodologies. With in-house tooling, rapid prototyping, and full-scale production capacity, Wuxi Lead Precision Machinery ensures that every plastic component meets the highest standards of engineering excellence. Our technical team collaborates closely with design and engineering partners to optimize manufacturability, reduce costs, and accelerate time-to-market—delivering precision, performance, and reliability on every project.

Material & Finish Options

Material Selection for Precision Metal Machining

Selecting the optimal material is foundational to achieving performance, longevity, and cost-efficiency in precision machined components. At Wuxi Lead Precision Machinery, our expertise in CNC machining demands a rigorous understanding of material characteristics relative to your specific application requirements. Aluminum, steel, and titanium represent the core high-performance alloys for demanding industrial sectors, each offering distinct advantages. Misalignment between material properties and operational demands leads to premature failure or unnecessary expense. Critical factors include required strength-to-weight ratio, environmental exposure (corrosion, temperature), machinability, regulatory compliance, and final part function.

Aluminum alloys dominate where weight reduction is paramount without sacrificing significant strength. Series 6061 offers excellent weldability and moderate strength for structural frames and housings, while 7075 provides aerospace-grade strength for critical load-bearing components. Its natural corrosion resistance and high thermal conductivity are significant benefits. Steel variants deliver unmatched strength and wear resistance. Low-carbon 1018 is highly machinable for general fixtures and non-critical parts. For enhanced strength and hardness, 4140 chrome-moly steel is preferred in tooling and shafts. Stainless steels like 303 (free-machining) and 316 (superior corrosion resistance with molybdenum) are essential for medical, food processing, and marine environments. Titanium, primarily Grade 5 (Ti-6Al-4V), provides an exceptional strength-to-weight ratio exceeding steel while being inherently corrosion-resistant and biocompatible. It is the material of choice for aerospace critical structures, high-performance automotive, and surgical implants, though its challenging machinability requires specialized tooling and processes.

Surface finish selection, particularly anodizing for aluminum, is not merely aesthetic but a critical performance enhancer. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and a base for dyeing, suitable for many industrial applications. Type III (Hardcoat) anodizing creates a significantly thicker, harder, and more wear-resistant ceramic layer essential for parts subject to abrasion, friction, or demanding sealing requirements. The correct anodizing type directly impacts component lifespan in harsh conditions.

Below is a comparative overview of key material properties relevant to precision machining decisions:

| Material | Key Properties | Common Grades | Primary Applications |

|---|---|---|---|

| Aluminum | Low density, high strength-to-weight, excellent thermal conductivity, good corrosion resistance, highly machinable | 6061, 7075, 2024 | Aerospace structures, heat sinks, enclosures, automotive components |

| Steel | High strength, excellent wear resistance, good machinability (varies), magnetic properties (most grades) | 1018, 4140, 303, 316 | Tooling, shafts, fasteners, medical devices, structural parts |

| Titanium | Exceptional strength-to-weight ratio, outstanding corrosion resistance, biocompatible, high temperature performance, challenging machinability | Gr 2, Gr 5 (Ti-6Al-4V) | Aerospace critical parts, medical implants, high-performance automotive, chemical processing |

Material and finish selection must be an integrated engineering decision, not an afterthought. Wuxi Lead Precision Machinery leverages decades of CNC machining experience with these core alloys to provide actionable guidance. We collaborate closely with your engineering team during the design phase to ensure the chosen material and surface treatment deliver optimal performance, manufacturability, and value for your precision metal component. Contact our engineering team for a detailed material suitability assessment tailored to your project’s exact specifications and operational environment.

Manufacturing Process & QC

From Concept to Perfection: The Plastic Precision Machining Workflow at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components, but our expertise extends into advanced plastic precision machining where tight tolerances, material integrity, and repeatable accuracy are non-negotiable. Our end-to-end production process is engineered for zero defects, ensuring that every component meets the exacting standards of industries such as medical devices, aerospace, and semiconductor manufacturing.

The journey begins with Design Engineering, where our technical team collaborates closely with clients to analyze CAD models, assess material compatibility, and optimize geometries for manufacturability. Using advanced simulation software, we evaluate thermal behavior, stress points, and dimensional stability to prevent potential failures before a single cut is made. This proactive approach eliminates costly revisions and ensures design integrity from the outset.

Next, we move into Prototyping, a critical phase for validating form, fit, and function. Utilizing CNC milling, turning, and multi-axis machining centers, we produce functional prototypes in the actual production-grade engineering plastics—such as PEEK, PTFE, Ultem, and PPS—ensuring real-world performance data. Each prototype undergoes rigorous metrology inspection using CMM (Coordinate Measuring Machines), optical comparators, and surface roughness testers. Feedback from this stage is integrated into final design adjustments, guaranteeing that the transition to mass production is seamless and risk-free.

Once approved, the project enters High-Volume Mass Production, executed on automated, monitored machining lines with strict in-process quality controls. Our facility employs Statistical Process Control (SPC) systems that continuously track critical dimensions, tool wear, and environmental variables. Every batch is traceable, with full documentation including material certifications, inspection reports, and first-article test data. Our ISO 9001-certified quality management system ensures compliance at every touchpoint, supporting our zero-defect mission.

Throughout the entire workflow, we prioritize material consistency, environmental control, and operator expertise. Our machines are maintained to OEM standards, and our technicians undergo continuous training in precision techniques and quality protocols. This disciplined approach minimizes variability and maximizes yield, even for complex components with tolerances down to ±0.005 mm.

The result is a scalable, reliable manufacturing process that transforms innovative designs into high-performance plastic components—on time, to spec, and with uncompromising quality.

| Specification | Detail |

|---|---|

| Material Range | PEEK, PTFE, Ultem (PEI), PPS, Acetal, Nylon, PC, PMMA |

| Tolerance Capability | ±0.005 mm (standard), up to ±0.002 mm (tight tolerance) |

| Surface Finish | Ra 0.2 μm to 3.2 μm (customizable) |

| Maximum Part Size | 600 mm × 500 mm × 400 mm |

| Production Capacity | 1 to 100,000+ units per order |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Level 3 |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Mass Production) | 15–30 days (varies by volume) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Plastic Machining Excellence

In the demanding landscape of high-performance plastic components, selecting a manufacturing partner transcends simple procurement. It demands a strategic alliance grounded in technical mastery, process rigor, and unwavering commitment to dimensional integrity. Wuxi Lead Precision Machinery stands as your definitive solution for mission-critical plastic precision machining, where material science meets micron-level accuracy. We engineer outcomes, not just parts, ensuring your complex geometries in engineering-grade polymers perform flawlessly under extreme operational stress.

Our dedicated plastic machining division operates with the same stringent protocols applied to aerospace metals, leveraging advanced CNC Swiss turning, multi-axis milling, and wire EDM technologies. This disciplined approach guarantees repeatability and surface finishes unattainable through conventional methods. We specialize in challenging materials including PEEK, PPSU, Ultem, PVDF, and custom composites, understanding their unique thermal behaviors and machining characteristics to prevent warpage and maintain critical tolerances.

Core Plastic Machining Capabilities at a Glance

| Specification | Capability Detail | Material Examples |

|---|---|---|

| Tolerance Range | ±0.001mm to ±0.005mm | PEEK, PEI, PPSU, PTFE |

| Max Part Diameter | 150mm | PVDF, Acetal, Nylon |

| Min Wall Thickness | 0.2mm | Custom Polymer Blends |

| Surface Finish (Ra) | 0.4µm to 1.6µm | Medical-Grade Resins |

| Secondary Operations | Laser Marking, Cleanroom Assembly | ESD-Safe Polymers |

The true value of partnering with Lead Precision manifests in risk mitigation and accelerated time-to-market. Our integrated quality management system—certified to ISO 9001:2015 and adhering to AS9100 principles—embeds inspection at every process stage. Utilizing Zeiss CMMs, optical comparators, and real-time in-process gauging, we eliminate scrap and rework cycles common in high-precision plastic fabrication. This proactive quality culture translates directly to your bottom line: reduced NRE costs, guaranteed first-article approval, and seamless scalability from prototype to high-volume production.

For industries where polymer failure is not an option—medical device housings, semiconductor fluidics, or aerospace seals—our engineering team collaborates at the design phase. We provide actionable DFM feedback to optimize manufacturability without compromising function, leveraging material databases and thermal simulation tools to preempt challenges. This co-engineering model prevents costly redesigns and ensures your components meet stringent biocompatibility, chemical resistance, or vacuum requirements from day one.

Your next breakthrough component demands a partner who treats plastic machining with the same gravity as titanium or Inconel. At Wuxi Lead Precision Machinery, we merge decades of CNC mastery with polymer-specific expertise to deliver precision you can measure and reliability you can trust. Do not compromise on the integrity of your critical plastic parts.

Reach out today to initiate a technical consultation. Contact our engineering team directly at [email protected]. Specify your material, tolerance requirements, and application context for a tailored capability assessment within 24 business hours. Let us prove why global leaders in medical, semiconductor, and aerospace manufacturing rely on Lead Precision as their strategic plastic machining partner. Your standard for excellence starts here.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.