Technical Contents

Engineering Guide: Plastic Pellets For Injection Molding

Engineering Insight: Plastic Pellet Precision in Injection Molding

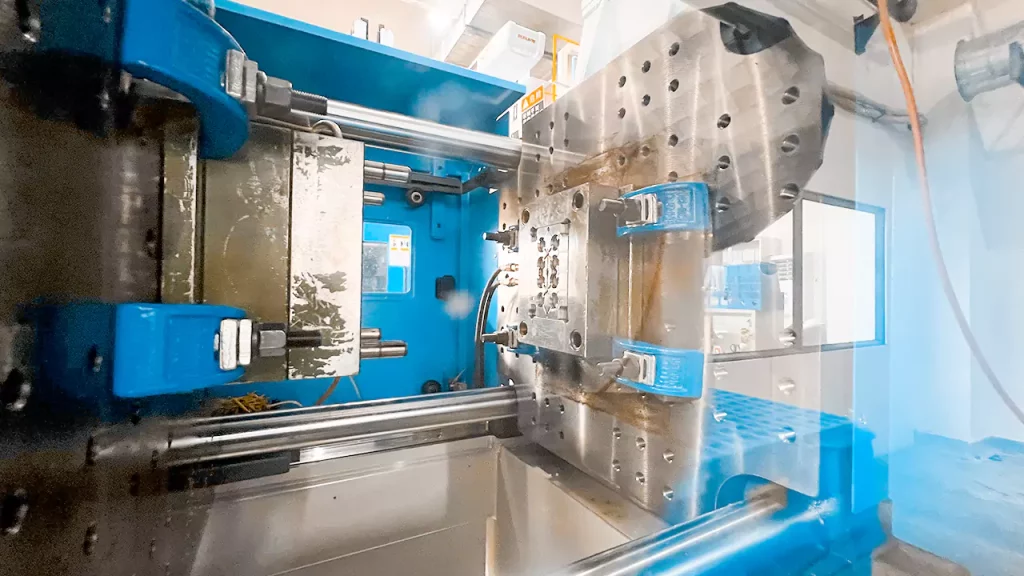

The consistent production of high-integrity molded components begins not with the machine, but with the fundamental raw material: the plastic pellet. For precision metal manufacturers supplying critical injection molding machinery, understanding pellet specifications is paramount. Variability in pellet characteristics directly impacts machine performance, component quality, and ultimately, the viability of high-tolerance production runs. At Wuxi Lead Precision Machinery, our decades of engineering custom metal components for global molding systems underscore that pellet precision is non-negotiable for achieving micron-level part accuracy and machine longevity.

Inconsistent pellet size, shape, or moisture content introduces significant process instability. Oversized pellets bridge hoppers, causing erratic feeding and machine starvation. Undersized fines generate excessive dust, contaminating screw barrels and hydraulic systems, accelerating wear on our precisely honed metal components. Moisture absorption, even at seemingly minor levels, vaporizes during melting, creating splay marks, voids, and internal stresses within the molded part – defects unacceptable in aerospace, medical, or high-end consumer goods. Variations in melt flow index (MFI) alter viscosity unpredictably, making precise control of fill, pack, and hold phases impossible. This instability forces operators into constant parameter adjustments, increasing scrap rates and reducing overall equipment effectiveness (OEE). For applications demanding absolute consistency, such as components for Olympic-standard equipment or military hardware, where Wuxi Lead has supplied mission-critical machine elements, pellet-induced fluctuations are a primary failure point we rigorously mitigate through system design.

The following key pellet specifications require stringent control to ensure optimal machine function and part quality:

| Specification | Critical Impact | Target Range (Typical High-Precision) | Relevant Standard |

|---|---|---|---|

| Moisture Content | Causes splay, voids, hydrolysis, degraded properties | < 0.02% (hygroscopic resins) | ISO 15512 |

| Melt Flow Index (MFI) | Determines melt viscosity, flow behavior, packing | Tight tolerance per resin grade (±5%) | ISO 1133 |

| Particle Size Distribution | Affects feeding consistency, melting uniformity | Narrow distribution; minimal fines/dust | Internal OEM Specs |

| Bulk Density | Influences volumetric feeding accuracy | Consistent batch-to-batch | Internal OEM Specs |

| Contaminants (Gel, Black Specks) | Causes surface defects, nozzle blockages | Strictly zero tolerance | ISO 1043-1 |

Wuxi Lead Precision Machinery integrates this deep understanding of material science into our custom metal manufacturing process. Our experience engineering components for systems producing Olympic-certified sporting goods and demanding military specifications has ingrained a zero-defect mentality. We recognize that the precision of our hardened steel barrels, reciprocating screws, and nozzles is only fully realized when fed consistent, high-quality pellets. We collaborate closely with molding partners to specify material handling and drying protocols that protect pellet integrity, ensuring our metal components operate within their designed parameters for maximum uptime and part fidelity. Precision manufacturing demands precision inputs; controlling the pellet variable is the essential first step in achieving true process stability and component excellence.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the demanding requirements of high-precision industries, including automotive, medical, aerospace, and industrial equipment. At the core of our technical capabilities is our state-of-the-art 5-axis CNC machining platform, which enables the production of complex, high-integrity metal components with exceptional accuracy and surface finish. This advanced machining technology allows for simultaneous multi-directional cutting, reducing setup time and part handling while maintaining tight geometric tolerances across intricate geometries. Our investment in 5-axis systems ensures that even the most sophisticated component designs—such as those required for precision molds, manifold blocks, and high-performance housings—can be executed with consistency and repeatability.

Complementing our machining expertise is a rigorous quality control process anchored by Coordinate Measuring Machine (CMM) inspection. Every critical dimension is verified using calibrated CMM systems, ensuring full compliance with engineering drawings and international standards. Our quality technicians are trained to interpret GD&T (Geometric Dimensioning and Tolerancing) specifications and perform comprehensive first-article inspections, in-process checks, and final audits. This systematic approach to quality assurance guarantees that all machined components meet the exact performance and fitment requirements of our clients’ injection molding systems and related equipment.

Our facility supports full-process manufacturing, from raw material sourcing to final inspection and packaging. We specialize in producing mold bases, ejector systems, runner components, and other precision-machined parts used in plastic injection molding applications. Materials commonly processed include P20, H13, 718 steel, stainless steels, aluminum alloys, and specialty tool steels, all selected based on thermal stability, wear resistance, and longevity under molding cycle stress.

To ensure dimensional integrity across production runs, we maintain strict environmental controls within the machining and inspection zones, minimizing thermal drift and measurement uncertainty. All equipment is regularly calibrated, and our operators follow standardized work instructions aligned with ISO 9001 quality management practices.

The table below outlines the standard tolerance capabilities achievable across our 5-axis CNC and inspection systems under controlled conditions.

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Hole Diameter | +0.015 / -0.005 mm | +0.008 / -0.002 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Angular Tolerance | ±0.05° | ±0.02° |

These capabilities reflect our commitment to delivering components that perform reliably in high-cycle injection molding environments. By integrating 5-axis precision machining with certified metrology, Wuxi Lead Precision Machinery provides a technically robust foundation for clients seeking dependable, high-performance metal parts in support of their plastic pellet processing and molding operations.

Material & Finish Options

Material Selection for Precision Injection Molding Components

Selecting the optimal substrate material is paramount for achieving durability, precision, and cost-efficiency in custom injection molding tooling and components. At Wuxi Lead Precision Machinery, our expertise centers on high-performance metals engineered to withstand the demanding thermal cycles, mechanical stresses, and corrosive environments inherent in plastic processing. The choice directly impacts tool life, part quality, production speed, and total cost of ownership. Aluminum, tool steel, and titanium represent the primary material families, each serving distinct application requirements based on production volume, plastic resin type, and geometric complexity.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer exceptional thermal conductivity and machinability. This enables rapid cooling cycles, significantly reducing part cycle times during prototyping or low-to-medium volume production runs. While less hard than steel, modern aluminum grades provide sufficient wear resistance for many engineering plastics when properly treated. Their primary limitation lies in longevity for high-cavitation or abrasive-filled resin applications. Tool steels, including P20, H13, and hardened stainless variants like S136, deliver superior hardness, wear resistance, and dimensional stability. These are the standard for high-volume production molds processing abrasive nylons, glass-filled polymers, or demanding engineering resins. The higher initial cost is offset by vastly extended service life measured in millions of cycles. Titanium alloys, though less common due to cost and machining complexity, provide an unparalleled strength-to-weight ratio and exceptional corrosion resistance against highly aggressive plastics like PVC or specific fluoropolymers, making them suitable for niche, high-value applications.

Surface finishing, particularly anodizing, is critical for aluminum components. Hard anodizing (Type III) creates a dense, wear-resistant ceramic layer that dramatically improves surface hardness, corrosion resistance, and release properties for plastic resins. This minimizes part sticking and facilitates ejection, reducing cycle times and preventing surface defects on molded parts. For steel components, nitriding or specialized PVD coatings often serve similar functional purposes.

The following table summarizes key comparative specifications for common mold materials:

| Material | Typical Hardness (HRC) | Max Production Cycles | Thermal Conductivity (W/m·K) | Key Advantages | Primary Applications |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 (Base) | 10,000 – 100,000 | 130 | Fast machining, rapid cooling, low cost | Prototypes, low-volume production |

| 50-60 (Hard Anodized) | |||||

| P20 Tool Steel | 28-32 | 100,000 – 1,000,000+ | 28-36 | Good toughness, polishability, weldable | Medium to high-volume production |

| H13 Tool Steel | 44-52 | 500,000 – 2,000,000+ | 25-30 | Excellent hot hardness, thermal fatigue | High-temp resins, high-volume runs |

| Titanium Grade 5 | 32-36 | 500,000+ | 7-8 | Extreme corrosion resistance, light | Aggressive resins, medical, aerospace |

Material selection is not a one-size-fits-all decision. It requires careful analysis of your specific resin, part geometry, volume targets, and quality requirements. Wuxi Lead Precision Machinery leverages decades of CNC machining and metallurgical expertise to guide clients toward the optimal material and finish combination. We ensure your tooling investment delivers maximum precision, longevity, and return, directly supporting your production efficiency and part quality goals in the competitive global manufacturing landscape. Partner with us to transform your material selection from a cost factor into a strategic production advantage.

Manufacturing Process & QC

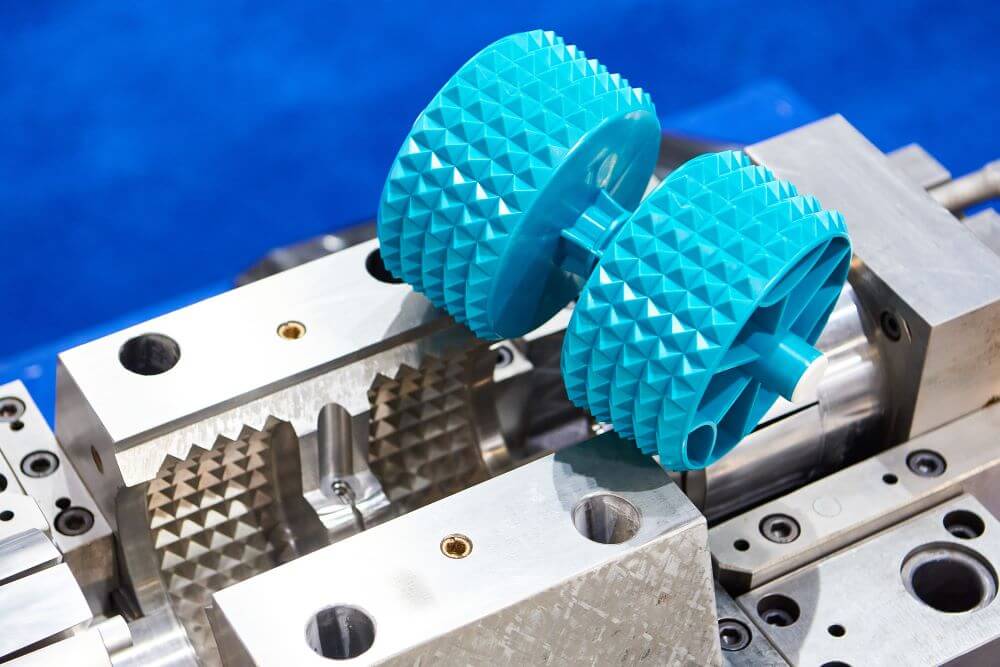

Design, prototyping, and mass production form the core of a precision-driven manufacturing process for plastic pellets used in injection molding. At Wuxi Lead Precision Machinery, this workflow is engineered to ensure zero defects, consistent material performance, and full alignment with client specifications. Every stage integrates advanced metrology, real-time monitoring, and stringent quality validation to deliver pellets optimized for high-performance molding applications.

The process begins with design, where material science and engineering converge. Engineers analyze the end-use requirements—thermal stability, mechanical strength, flow characteristics, and environmental resistance—to select the appropriate polymer resin and additive package. This phase includes rheological modeling and melt flow simulation to predict pellet behavior during injection. Custom formulations are developed in-house, ensuring compatibility with the client’s molding equipment and cycle times. Design documentation is finalized with traceable material data sheets and processing parameters.

Prototyping follows, serving as a validation bridge between concept and scale. Small-batch extrusion lines produce trial pellets under controlled conditions, allowing for immediate testing of density, moisture content, melt index, and dimensional uniformity. These samples undergo accelerated aging and injection trials in simulated production environments. Any deviation triggers a root-cause analysis, with adjustments made to screw speed, cooling rates, or feed ratios. This iterative phase ensures that only fully verified pellet profiles advance to mass production.

Mass production is executed on fully automated twin-screw extrusion systems equipped with inline sensors and closed-loop feedback controls. Raw materials are pre-dried and fed through precision dosing units to maintain blend consistency. The extruder melts and homogenizes the polymer, which is then pelletized using underwater or strand-cut systems depending on the resin type. Each pellet batch is monitored for color consistency, particle size distribution, and surface integrity. Automated vision inspection systems detect anomalies in real time, triggering rejection of non-conforming material before packaging.

Throughout all stages, quality assurance is non-negotiable. Every lot is tested against internal and international standards, including ISO 1133 for melt flow rate and ASTM D1921 for particle size. Full traceability is maintained via batch coding and digital process logs, enabling rapid recall if necessary. The zero-defect objective is supported by Six Sigma methodologies, preventive maintenance schedules, and operator training programs.

The following table outlines key specifications monitored during production:

| Parameter | Standard Test Method | Acceptable Range | Measurement Frequency |

|---|---|---|---|

| Melt Flow Rate (MFR) | ISO 1133 | ±0.2 g/10 min (at 230°C/2.16 kg) | Per batch |

| Moisture Content | ASTM D7258 | <0.02% by weight | Every 2 hours |

| Pellet Diameter | Internal Standard | 3.0 ± 0.2 mm | Continuous (vision) |

| Bulk Density | ASTM D1895 | 0.85–0.95 g/cm³ | Per 500 kg |

| Color Consistency (ΔE) | ASTM E308 | ΔE < 0.5 | Per shift |

This end-to-end process ensures that plastic pellets meet the exacting demands of modern injection molding, minimizing downtime, reducing waste, and enhancing final part quality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Elevate Your Injection Molding Performance Through Precision Metal Components

While plastic pellets serve as the essential feedstock for injection molding, the relentless pursuit of part quality, machine uptime, and production efficiency hinges critically on the performance of the metal components within your molding systems. At Wuxi Lead Precision Machinery, we specialize not in polymer formulation, but in the high-precision custom metal manufacturing that forms the backbone of reliable, high-output injection molding operations. We understand that substandard mold bases, wear plates, ejector systems, or spindle components directly translate to costly downtime, defective parts, and compromised pellet-to-product conversion. Our engineering-driven approach delivers the dimensional stability, surface integrity, and material resilience your machinery demands to maximize the value derived from your chosen plastic pellets.

We partner with global injection molding leaders and mold builders to transform complex metal component requirements into reality. Leveraging advanced CNC milling, turning, grinding, and EDM capabilities within our ISO 9001:2015 certified facility, we consistently achieve micron-level tolerances and superior surface finishes on demanding alloys like P20, H13, S136, and hardened tool steels. Our process integrates rigorous material traceability, in-process inspection using Zeiss CMMs, and final validation against your exact specifications. This ensures every component we deliver – from intricate core pins to massive platen plates – contributes directly to smoother pellet flow, consistent cavity filling, reduced cycle times, and extended mold life. We optimize for the stresses inherent in high-pressure molding environments, preventing deflection, galling, or premature wear that disrupts production.

The precision of your metal tooling directly dictates the fidelity of the molded part produced from your plastic pellets. Below are representative specifications achievable for critical injection molding components:

| Component Type | Typical Material | Dimensional Tolerance | Surface Hardness | Surface Finish (Ra) |

|---|---|---|---|---|

| Mold Bases | P20, 718H | ±0.005 mm | HRC 28-32 | 0.8 μm |

| Core/Cavity Inserts | H13, S136, Stainless | ±0.002 mm | HRC 48-52 | 0.4 μm |

| Ejector Pins/Sleeves | SKD61, Pre-hardened | ±0.001 mm | HRC 58-62 | 0.2 μm |

| Spindle Components | 42CrMo4, Tool Steel | ±0.003 mm | HRC 50-55 | 0.1 μm |

| Wear Plates | D2, Tungsten Carbide | ±0.002 mm | HRC 60+ | 0.2 μm |

Partnering with Wuxi Lead Precision Machinery means securing a supplier committed to being an extension of your engineering team. We proactively engage during the design phase to optimize manufacturability, reduce lead times, and enhance component longevity. Our dedicated project managers provide transparent communication and rigorous quality documentation, ensuring seamless integration of our precision metal parts into your molding systems. The result is a tangible reduction in total cost of ownership through minimized scrap rates, extended maintenance intervals, and maximized machine utilization – allowing you to focus on optimizing pellet selection and processing parameters for your end products.

Do not let metal component limitations constrain the potential of your injection molding process. Contact our engineering sales team today to discuss how Wuxi Lead Precision Machinery can deliver the custom metal solutions that transform your production reliability and output quality. Send detailed specifications or inquiries to [email protected]. Our experts will respond within 24 business hours to initiate a technical consultation and provide a precise quotation tailored to your operational demands. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.