Technical Contents

Engineering Guide: Plastic Parts Machining

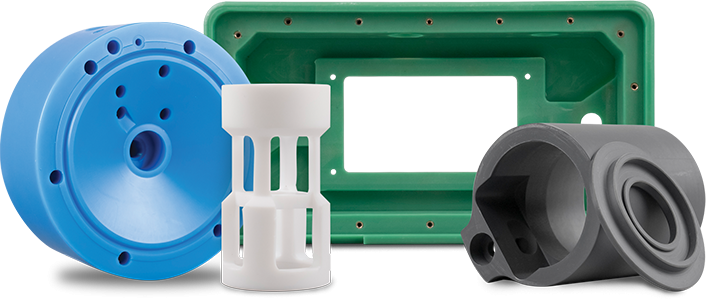

Engineering Insight Precision Plastic Machining Demands Absolute Control

Plastic parts machining presents unique challenges distinct from metal fabrication demanding specialized engineering rigor. Unlike metals plastics exhibit significant thermal expansion coefficients moisture absorption and variable chip formation characteristics. Neglecting these factors results in dimensional instability part warpage or compromised functional performance especially in critical applications like medical devices aerospace components or semiconductor equipment. At Wuxi Lead Precision Machinery we treat plastic machining not as a secondary capability but as a precision discipline requiring materials science expertise and uncompromising process control. Our decades of experience prove that achieving micron-level tolerances in plastics is not theoretical it is an operational necessity for high-reliability sectors.

The consequences of inadequate plastic machining are severe. A medical implant housing machined beyond tolerance could fail sterilization protocols. An aerospace sensor bracket with internal stress from improper cutting parameters might fracture under vibration. These risks underscore why leading OEMs demand partners who understand the interplay between polymer selection cutting tool geometry coolant strategy and thermal management. Our facility implements ISO 13485 and AS9100 compliant processes specifically calibrated for engineering plastics including PEEK Ultem PTFE and polycarbonate. Every operation undergoes rigorous first-article inspection and in-process verification to ensure geometric accuracy surface integrity and material property preservation.

Wuxi Lead Precision Machinery’s credibility in extreme precision environments is validated through mission-critical projects. We supplied dimensionally stable polymer components for Beijing Olympic infrastructure systems where thermal cycling and load tolerance were non-negotiable. Similarly our machining processes meet stringent military specifications for defense applications where component failure is not an option. This heritage informs our approach to every plastic machining project regardless of scale.

Our technical capabilities translate into measurable client advantages as demonstrated in the core specifications below:

| Specification Parameter | Capability Range | Industry Standard Comparison |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Exceeds typical ±0.025 mm |

| Surface Roughness (Ra) | 0.4 – 3.2 µm | Achieves optical-grade finishes |

| Material Compatibility | 50+ engineered polymers | Includes PEEK PEI PVDF PPS |

| Max Part Size | 1200 x 800 x 600 mm | Supports large structural components |

| Geometric Complexity | 5-axis simultaneous machining | Handles undercuts deep cavities |

Precision plastic machining is where material behavior meets engineering excellence. Wuxi Lead Precision Machinery combines deep polymer knowledge with military-grade process discipline ensuring your plastic components perform reliably under operational stress. Contact our engineering team to discuss how our Olympic-proven methodologies can secure your next critical plastic part application. We deliver not just parts but guaranteed performance.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the custom machining of high-precision plastic components, serving industries where material integrity, dimensional accuracy, and repeatability are paramount. Our expertise extends across engineering-grade thermoplastics such as PEEK, PTFE, Ultem, Acetal, and Polycarbonate, all of which are processed using state-of-the-art 5-axis CNC machining centers. These multi-axis systems enable us to execute complex geometries with tight tolerances, minimizing setup changes and ensuring superior part consistency. The integration of simultaneous 5-axis motion allows for undercuts, compound angles, and intricate contours that are unattainable with conventional 3-axis platforms.

Our machining process is supported by a rigorous quality control framework, anchored by Coordinate Measuring Machine (CMM) inspection. Every plastic component undergoes comprehensive dimensional verification to validate conformance with design specifications. The CMM system provides traceable, high-resolution data across critical features, ensuring compliance with ISO and customer-specific standards. This metrology-backed approach is essential in applications where fit, function, and regulatory compliance cannot be compromised—such as in medical devices, aerospace subsystems, and semiconductor manufacturing equipment.

Material behavior is a critical consideration in plastic machining. Unlike metals, thermoplastics exhibit higher thermal expansion and variable creep characteristics. Our engineering team applies material-specific compensation strategies during programming and toolpath optimization to account for these properties. We utilize precision carbide tooling with specialized geometries designed for non-ferrous and low-modulus materials, reducing the risk of burring, melting, or deformation during cutting. Additionally, our machining environment is climate-controlled to minimize thermal fluctuations that could affect dimensional stability during production.

All processes are governed by documented work instructions and first-article inspection reports. We maintain full traceability from raw material certification through final inspection, supporting customers in regulated industries that require auditable manufacturing records. Our technicians are trained in lean manufacturing principles and precision machining best practices, ensuring efficient throughput without sacrificing quality.

The table below outlines our standard machining tolerances for plastic components, reflecting both machine capability and material response under controlled conditions.

| Feature | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.025 mm | Up to 300 mm |

| Hole Diameter | +0.03 / -0.00 mm | +0.015 / -0.00 mm | Reamed or precision bored |

| Flatness | 0.05 mm per 100 mm | 0.02 mm per 100 mm | Verified via CMM |

| Perpendicularity | 0.05 mm | 0.02 mm | Relative to primary datum |

| Surface Finish (Ra) | 3.2 µm | 0.8 µm | As machined or polished |

| Angular Features | ±0.1° | ±0.05° | 5-axis simultaneous control |

These capabilities are backed by continuous process validation and in-house engineering support. At Wuxi Lead Precision Machinery, we combine advanced equipment, disciplined quality systems, and deep material knowledge to deliver plastic machined parts that meet the most demanding technical requirements.

Material & Finish Options

Material Selection for Precision Metal Components: Engineering Performance into Every Part

Selecting the optimal material is the foundational engineering decision in high-precision metal component manufacturing. At Wuxi Lead Precision Machinery, we understand that material choice directly dictates part functionality, longevity, manufacturability, and total cost of ownership. For demanding applications across aerospace, medical, semiconductor, and industrial automation, Aluminum alloys, Stainless Steels, and Titanium alloys represent the pinnacle of performance. Each offers distinct advantages requiring careful alignment with your specific operational environment, mechanical loads, and regulatory constraints. Choosing incorrectly risks premature failure, excessive machining costs, or non-compliance – outcomes our clients rigorously avoid.

Aluminum 6061-T6 remains a dominant choice where an exceptional strength-to-weight ratio and excellent machinability are paramount. Its natural corrosion resistance and ease of anodizing make it ideal for structural aerospace components, fluid handling systems, and precision housings. Stainless Steel 304/316 delivers superior corrosion resistance in harsh chemical or saline environments and meets stringent hygiene standards, critical for medical devices, food processing equipment, and marine instrumentation. Titanium 6Al-4V provides the ultimate solution for extreme strength-to-weight requirements coupled with biocompatibility and exceptional resistance to fatigue and corrosion, essential for critical aerospace landing gear, surgical implants, and deep-sea components. Understanding the nuanced trade-offs between these materials is non-negotiable for mission-critical parts.

The following table details key mechanical and processing characteristics essential for informed selection:

| Material | Typical Yield Strength (MPa) | Key Advantages | Primary Machining Considerations | Common High-Value Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 240-275 | Excellent strength/weight, high machinability, good corrosion resistance, easily anodized | Very good chip control, high speeds possible | Aerospace brackets, optical mounts, fluid manifolds |

| Stainless Steel 304 | 205-310 | Superior corrosion resistance, high temperature strength, non-magnetic (annealed) | Work hardening requires sharp tools, lower speeds, adequate coolant | Medical instruments, valve bodies, chemical processing |

| Titanium 6Al-4V | 825-895 | Highest strength/weight, excellent fatigue/corrosion resistance, biocompatible | Low thermal conductivity demands rigid setup, sharp tools, controlled feeds/speeds | Aircraft structural fittings, surgical implants, marine hardware |

Surface finish selection is equally critical to component performance. Anodizing, particularly Type II (Sulfuric) and Type III (Hardcoat), is the definitive post-machining process for aluminum components. It significantly enhances surface hardness, wear resistance, and corrosion protection far beyond the base alloy’s capabilities. Hardcoat anodizing (Type III) achieves thicknesses of 50+ microns, creating an integral ceramic layer that withstands severe abrasion in hydraulic systems or semiconductor handling equipment. Crucially, anodizing preserves dimensional tolerances when specified correctly – a precision machining capability Wuxi Lead rigorously controls. While steel and titanium utilize alternative finishes like passivation or specialized coatings, anodizing remains the gold standard surface enhancement for performance-driven aluminum parts. Partner with our engineering team early; we translate your performance requirements into the optimal material and finish specification, ensuring your precision components perform flawlessly in service.

Manufacturing Process & QC

From Design to Zero-Defect Mass Production: Precision Machining of Plastic Parts at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, the production of high-performance plastic components follows a rigorously controlled, end-to-end process designed to ensure dimensional accuracy, material integrity, and zero-defect delivery. Our methodology integrates advanced engineering, precision CNC machining, and comprehensive quality assurance to meet the demanding requirements of industries such as medical devices, semiconductor equipment, and aerospace.

The process begins with Design Evaluation and Material Selection. Our engineering team collaborates closely with clients to analyze 3D CAD models, assess manufacturability, and recommend optimal thermoplastic materials—such as PEEK, PTFE, Ultem, or Acetal—based on thermal stability, chemical resistance, and mechanical load requirements. Finite element analysis (FEA) and tolerance stack-up simulations are performed to preempt potential deformation or assembly issues, ensuring the design is both functional and production-ready.

Next, Prototyping is conducted using 5-axis CNC machining centers equipped with sub-micron positioning accuracy. This stage produces fully functional prototypes that undergo rigorous inspection for dimensional compliance, surface finish, and fitment. First Article Inspection (FAI) reports are generated, and clients receive physical and digital validation packages for approval. Iterations, if required, are executed swiftly using rapid tooling adjustments, minimizing time to production.

Upon prototype approval, the project transitions to High-Volume, Zero-Defect Mass Production. Our automated production lines utilize CNC machines with real-time tool wear monitoring, temperature-compensated encoders, and in-process probing systems to maintain ±0.005 mm tolerances consistently. Each batch is subject to Statistical Process Control (SPC), with critical dimensions measured at defined intervals using coordinate measuring machines (CMM) and optical comparators. Non-conforming parts are automatically quarantined, and root cause analysis is initiated immediately.

All finished components undergo 100% visual inspection under controlled lighting and are packaged in ESD-safe or cleanroom-compatible materials, depending on application requirements. Traceability is ensured through laser-etched lot codes and digital production logs accessible via our client portal.

The table below outlines key capabilities for plastic parts machining at Wuxi Lead:

| Parameter | Specification |

|---|---|

| Material Range | PEEK, PTFE, Ultem, PPS, Acetal, Nylon, PC |

| Tolerance Control | ±0.005 mm (standard), ±0.002 mm (tight) |

| Surface Finish | Ra 0.2–1.6 µm (adjustable) |

| Maximum Part Size | 800 × 600 × 400 mm |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centers |

| Quality Standards | ISO 9001:2015, IATF 16949 (automotive) |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days (scalable) |

Our integrated approach—combining expert design support, precision prototyping, and defect-free manufacturing—ensures that every plastic component meets the highest standards of performance and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Plastic Parts Machining

Wuxi Lead Precision Machinery delivers uncompromising precision in plastic parts machining, leveraging decades of expertise in high-tolerance metal manufacturing to solve your most demanding polymer challenges. While our core legacy lies in custom metal fabrication, we recognize that modern engineering increasingly demands hybrid solutions where plastics—such as PEEK, PTFE, Acetal, and Ultem—perform alongside metals in aerospace, medical, and semiconductor applications. Our approach transcends conventional plastic machining: we apply rigorous metal-grade process control to polymers, addressing thermal sensitivity, dimensional stability, and micron-level tolerances that generic shops cannot achieve. This cross-material proficiency ensures your plastic components integrate flawlessly within complex metal assemblies, eliminating field failures and accelerating time-to-market.

Our dedicated polymer machining division operates within the same ISO 9001-certified facility as our metal production lines, guaranteeing identical standards for metrology, environmental control, and traceability. Unlike specialized plastic vendors, we engineer solutions holistically—optimizing toolpaths to prevent burring in Delrin, managing crystallization in Nylon, or maintaining ±0.005mm tolerances in thin-walled PPS components. This is precision engineering rooted in material science, not just milling. When your application demands plastics that withstand extreme temperatures, chemical exposure, or ultra-high purity requirements, our process validation protocols—validated through in-house CMM, optical comparators, and material testing—deliver repeatable success where others compromise.

Critical Plastic Machining Capabilities at Wuxi Lead

| Parameter | Specification | Application Impact |

|---|---|---|

| Tolerance Range | ±0.005mm to ±0.025mm | Ensures sealing integrity in fluidic medical devices |

| Material Range | Engineering thermoplastics (PEEK, PSU, PVDF), Composites, Fluoropolymers | Supports chemically resistant semiconductor components |

| Machine Technology | 5-axis CNC mills, Swiss-type lathes with polymer-optimized spindles | Achieves complex geometries in single setups |

| Secondary Operations | Precision deburring, laser marking, cleanroom assembly (Class 10K) | Meets biocompatibility and particle control standards |

| Lead Time | Prototype: 7–10 days; Production: 15–25 days | Accelerates validation for time-sensitive projects |

Choosing Wuxi Lead means partnering with engineers who speak your technical language. We initiate every project with a free Design for Machinability (DFM) review, identifying cost-saving material substitutions or geometric refinements before cutting material. Our team collaborates directly with your R&D staff to resolve thermal expansion conflicts, stress-cracking risks, or surface finish requirements—transforming design intent into production reality. This proactive engineering partnership minimizes iterations, reduces scrap rates, and secures regulatory compliance from prototype through volume production.

Initiate your precision plastic machining project with a team that treats polymers with the same discipline as aerospace alloys. Contact our engineering desk at [email protected] to request a DFM analysis or discuss material-specific process validation data. Specify your application’s critical tolerances, environmental demands, and volume requirements—we will respond within 24 business hours with a tailored capability assessment. For mission-critical components where plastic performance is non-negotiable, trust Wuxi Lead Precision Machinery to deliver engineered certainty. Your next breakthrough assembly starts with an email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.