Technical Contents

Engineering Guide: Plastic Part Fabrication

Engineering Insight: Precision in Plastic Part Fabrication

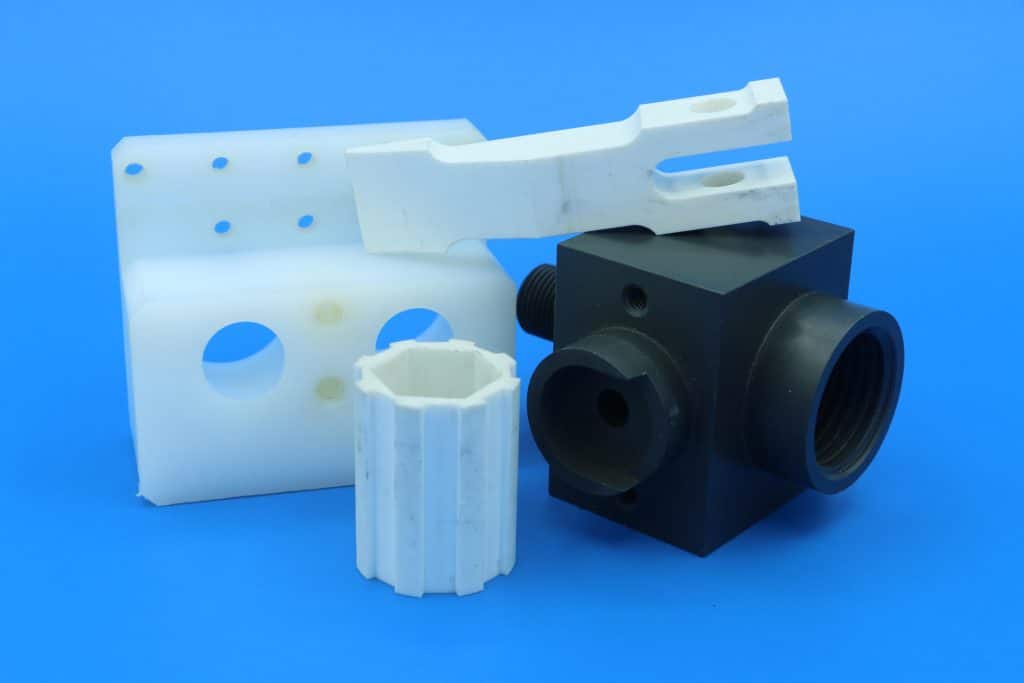

In the realm of advanced manufacturing, plastic part fabrication demands a level of precision that rivals, and in many cases exceeds, that of traditional metalworking. At Wuxi Lead Precision Machinery, we apply the same rigorous engineering standards to plastic fabrication as we do in our sheet metal operations—standards forged through decades of delivering mission-critical components for high-stakes industries. Whether supporting infrastructure for Olympic venues or supplying precision-machined polymer components for military-grade equipment, our commitment to dimensional accuracy, material integrity, and repeatability remains unwavering.

Plastics, by nature, present unique challenges compared to metals. Their thermal expansion coefficients are higher, they are more susceptible to warping under stress, and their machining behavior varies significantly between thermoplastics and thermosets. Without precise control over cutting speed, tool geometry, and clamping force, even minor deviations can result in part failure. This is why precision is not just a performance metric—it is a foundational requirement. At Lead Precision, we leverage CNC machining centers with sub-micron positioning accuracy, in-process probing systems, and climate-controlled environments to ensure every plastic component meets exacting tolerances.

Our engineering team treats each plastic fabrication project as a systems challenge. Material selection, toolpath optimization, fixturing design, and post-machining stress relief are all integrated into a unified process. For instance, when machining PEEK for aerospace connectors or UHMW-PE for medical guide rails, we adjust feed rates and spindle loads in real time to prevent melting or delamination. These protocols, refined through projects requiring ISO 13485 and MIL-STD compliance, enable us to deliver parts with tolerances as tight as ±0.005 mm—a benchmark rarely achieved in conventional plastic machining.

Beyond machinery, our precision is rooted in experience. Having supported Olympic construction projects with custom polymer bushings and seals that operate under extreme loads and temperatures, and having supplied non-conductive, EMI-shielded enclosures for defense applications, we understand how environmental and functional demands shape design. These high-profile, high-reliability applications have honed our ability to anticipate failure modes and engineer them out before the first cut is made.

The result is a fabrication process where consistency, traceability, and performance are engineered into every component. For global OEMs and system integrators, this level of precision translates into reduced assembly time, longer service life, and compliance with the most stringent industry certifications.

Typical Plastic Fabrication Specifications at Wuxi Lead Precision Machinery

| Parameter | Capability |

|---|---|

| Material Types | PEEK, PTFE, UHMW-PE, Acetal, Polycarbonate, PVC, ABS |

| Tolerance Range | ±0.005 mm to ±0.05 mm (depending on geometry) |

| Surface Finish | Ra 0.4 µm to 3.2 µm (custom finishes available) |

| Maximum Part Size | 1200 mm × 800 mm × 500 mm |

| Machining Processes | CNC Milling, CNC Turning, Laser Cutting, Drilling |

| Quality Standards | ISO 9001, ISO 13485, MIL-STD-810 compliant |

| Lead Time (Average) | 7–15 days (varies by complexity and volume) |

Precision Specs & Tolerances

Technical Capabilities: Precision Plastic Part Fabrication

Wuxi Lead Precision Machinery extends its core sheet metal fabrication expertise into the demanding realm of high-performance plastic part manufacturing. We specialize in machining complex, tight-tolerance components from advanced engineering thermoplastics, including PEEK, Ultem, PPS, Acetal, and Polycarbonate. Our capability is built upon the same rigorous precision engineering principles applied to metal, recognizing the unique thermal and mechanical properties inherent to plastics. This ensures dimensional stability, critical surface finishes, and functional integrity for mission-critical applications in aerospace, medical devices, semiconductor, and fluid handling systems.

Central to our plastic fabrication capability is a dedicated fleet of state-of-the-art 5-axis CNC machining centers. These machines, featuring high-precision spindles, rigid structures, and sophisticated thermal compensation systems, are essential for producing intricate geometries, deep cavities, and complex contours in plastic materials without inducing stress or distortion. Programming leverages advanced CAM software specifically configured for optimal plastic machining parameters, including controlled feed rates, specialized toolpath strategies to minimize heat generation, and the use of sharp, polished carbide tooling designed for non-ferrous and plastic materials. Strict environmental controls within our machining cells mitigate thermal fluctuations, a critical factor for maintaining dimensional accuracy during and after processing.

Quality assurance for plastic components demands protocols exceeding standard metal inspection. All critical features undergo comprehensive verification using calibrated Coordinate Measuring Machines (CMM) within our temperature-stabilized metrology laboratory. Our CMM inspection routines are meticulously developed to account for plastic-specific behaviors, such as potential part relaxation after machining and the influence of ambient temperature on final dimensions. Inspections strictly adhere to ASME Y14.5 GD&T standards, providing detailed reports that validate conformity to customer drawings and functional requirements. Material certification and traceability are maintained throughout the process, supporting compliance with stringent industry regulations.

The following table outlines our standard and achievable tolerance capabilities for machined plastic parts, reflecting our commitment to precision. Note that final achievable tolerances are inherently material-dependent and influenced by part geometry, wall thickness, and feature complexity. Tighter tolerances are attainable through specific process optimization and material selection consultation.

| Feature | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.025 mm |

| Linear Dimensions (in) | ±0.002 in | ±0.001 in |

| Hole Diameter (mm) | +0.025 / -0.000 mm | +0.010 / -0.000 mm |

| Hole Diameter (in) | +0.001 / -0.000 in | +0.0004 / -0.000 in |

| Flatness (per 100 mm) | 0.05 mm | 0.025 mm |

| Flatness (per 4 in) | 0.002 in | 0.001 in |

| Positional Tolerance | ±0.05 mm | ±0.025 mm |

| Positional Tolerance | ±0.002 in | ±0.001 in |

| Surface Roughness (Ra) | 1.6 µm (63 µin) | 0.8 µm (32 µin) |

Wuxi Lead Precision Machinery delivers plastic components where precision is non-negotiable. Our integrated approach—combining advanced 5-axis CNC technology, material-specific process expertise, and rigorous CMM-based quality control—ensures parts meet the most demanding functional and assembly requirements. Partner with us for plastic fabrication solutions underpinned by industrial-grade precision and unwavering commitment to quality.

Material & Finish Options

Material selection is a critical phase in the fabrication of high-performance plastic and metal components, particularly when integrating structural supports or housings in advanced industrial systems. At Wuxi Lead Precision Machinery, we specialize in precision sheet metal fabrication for hybrid assemblies where plastic components interface with metal frameworks. Selecting the appropriate metal—aluminum, steel, or titanium—depends on mechanical requirements, environmental exposure, weight constraints, and compatibility with finishing processes such as anodizing.

Aluminum is widely favored in plastic part fabrication due to its lightweight nature, excellent strength-to-weight ratio, and inherent corrosion resistance. It is especially suitable for applications requiring thermal management or electromagnetic shielding, such as enclosures for medical devices or automation equipment. Its high machinability and weldability allow for complex geometries that align precisely with molded plastic elements. When paired with anodizing, aluminum gains enhanced surface hardness, wear resistance, and aesthetic control, making it ideal for consumer-facing or high-durability applications.

Steel, particularly stainless and cold-rolled variants, offers superior strength and rigidity. It is the preferred choice for structural frames, jigs, and fixtures that support plastic components in high-load or high-temperature environments. While heavier than aluminum, steel provides exceptional impact resistance and dimensional stability. However, unlike aluminum, steel cannot be anodized. Instead, it relies on passivation, powder coating, or plating for surface protection. Its magnetic properties also make it suitable for electromagnetic applications where aluminum may not suffice.

Titanium stands at the premium end of material options, delivering an unmatched strength-to-density ratio and extraordinary resistance to corrosion, even in harsh chemical or marine environments. Though more costly and challenging to machine, titanium is indispensable in aerospace, defense, and high-end medical systems where weight savings and longevity are paramount. Titanium can undergo anodizing, not only for protective purposes but also for color coding and aesthetic customization, leveraging its natural oxide layer for stable interference coloring.

The decision among these materials must account for the entire product lifecycle, including assembly methods, thermal expansion differentials with plastic components, and long-term maintenance. Surface finishing, especially anodizing, plays a pivotal role in extending service life and ensuring compatibility with adjacent materials.

Below is a comparative overview of key mechanical and finishing properties:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Anodizing Compatibility | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | Yes | Enclosures, brackets, consumer electronics |

| Stainless Steel 304 | 8.0 | 505 | Very High | No (passivation used) | Industrial frames, medical tools |

| Titanium Grade 5 | 4.5 | 900 | Exceptional | Yes | Aerospace, defense, surgical devices |

At Wuxi Lead Precision Machinery, we support clients in matching material and finish choices to functional demands, ensuring optimal performance in integrated plastic-metal systems.

Manufacturing Process & QC

Plastic Part Fabrication: Precision Process from Design to Zero-Defect Production

At Wuxi Lead Precision Machinery, our plastic part fabrication process integrates rigorous engineering discipline with advanced manufacturing to achieve zero-defect outcomes. We begin with collaborative design engineering, where our team conducts comprehensive Design for Manufacturability (DFM) analysis. This phase identifies potential flaws early, optimizing geometry, material selection, and tooling requirements. We validate part functionality through CAD simulations, including mold flow analysis to predict fill patterns, weld lines, and cooling behavior. Critical parameters such as wall thickness uniformity, draft angles, and gate locations are refined to eliminate sinks, warpage, or stress points before tooling commences. This proactive approach reduces rework by up to 70% and ensures alignment with ISO 13485 and automotive IATF 16949 standards.

Prototyping transitions validated designs into tangible validation. We utilize rapid tooling with aluminum or soft steel molds for functional testing under real-world conditions. Parts undergo rigorous dimensional verification via CMM and optical scanning, alongside material property checks for impact resistance, thermal stability, and chemical compatibility. Client feedback is incorporated within 72 hours, enabling swift iterations. Unlike generic prototyping services, our process replicates mass-production parameters, ensuring prototype-to-production consistency and de-risking scale-up.

Mass production leverages our CNC-machined steel molds and automated injection molding cells. Each run is governed by Statistical Process Control (SPC) with real-time monitoring of 15+ parameters including melt temperature, injection pressure, and cooling time. Every 30 minutes, automated vision systems inspect critical dimensions, while destructive testing validates mechanical properties per ASTM standards. Our closed-loop system adjusts process variables instantly to maintain tolerances, ensuring batch-to-batch repeatability. Final parts undergo 100% first-article inspection and AQL 0.65 sampling, with full traceability from raw material lot to finished component.

Key production specifications guaranteeing zero defects:

| Parameter | Standard Tolerance | Capability Target | Measurement Method |

|---|---|---|---|

| Dimensional Accuracy | ±0.05 mm | Cpk ≥ 1.67 | CMM / Optical Comparator |

| Surface Finish | Ra 0.8 µm | Ra ≤ 1.2 µm | Profilometer |

| Flatness | 0.1 mm per 100 mm | 0.05 mm | Laser Scanner |

| Material Consistency | ±0.5% density | ±0.2% | ASTM D792 |

| Defect Rate | Zero | PPM < 50 | Automated Vision + SPC |

This end-to-end workflow—anchored in predictive design, validated prototyping, and closed-loop production—ensures every plastic component meets the uncompromising quality demands of aerospace, medical, and automotive sectors. At Wuxi Lead, zero defects is not a goal; it is the engineered outcome of our precision ecosystem.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Excellence in Plastic Part Fabrication

When precision, reliability, and scalability define your manufacturing needs, partnering with Wuxi Lead Precision Machinery ensures you gain a competitive edge in plastic part fabrication. As a leading innovator in advanced sheet metal and plastic component manufacturing based in Wuxi, China, we specialize in delivering high-performance solutions tailored to the exacting standards of global industries including automotive, medical devices, telecommunications, and industrial automation.

Our expertise extends beyond conventional fabrication. We integrate precision CNC machining, laser cutting, thermal forming, and multi-axis milling to produce complex plastic components with tight tolerances and superior surface finishes. Whether your project demands low-volume prototypes or high-volume production runs, our agile manufacturing ecosystem adapts to your timeline, quality benchmarks, and material specifications.

At Wuxi Lead Precision Machinery, we understand that consistency is paramount. Our ISO 9001-certified production floor employs real-time quality monitoring, in-process inspections, and first-article testing to ensure every plastic part meets your engineering requirements. From engineering thermoplastics like PEEK, PTFE, and polycarbonate to commodity resins such as ABS and nylon, our material expertise ensures optimal performance under demanding operational conditions.

We also offer comprehensive design for manufacturability (DFM) support, enabling you to refine part geometry, reduce assembly complexity, and lower production costs—before tooling begins. Our engineering team collaborates directly with your R&D department to optimize wall thickness, draft angles, and structural integrity, minimizing cycle times and material waste.

Our global clients rely on us not only for technical precision but also for seamless integration into their supply chains. With dedicated project management, real-time production tracking, and on-time delivery rates exceeding 98%, we become an extension of your manufacturing operations.

To accelerate your next project with confidence, contact us today. Our engineering team is ready to review your specifications, provide rapid quotations, and support your transition from concept to certified production.

| Specification | Capability |

|---|---|

| Material Range | PEEK, PTFE, Polycarbonate, ABS, Nylon, Acrylic, PVC, HDPE |

| Tolerance | ±0.05 mm (standard), down to ±0.02 mm (precision) |

| Maximum Part Size | 1200 mm × 800 mm × 500 mm |

| Machining Centers | 3-axis, 4-axis, and 5-axis CNC |

| Secondary Operations | Threading, tapping, polishing, engraving, assembly |

| Quality Standards | ISO 9001:2015, RoHS compliant, full inspection reporting |

| Lead Time | 7–15 days for prototypes, 15–30 days for production batches |

Contact us at [email protected] to initiate a technical consultation. Let Wuxi Lead Precision Machinery be your trusted partner in high-precision plastic part fabrication.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.