Technical Contents

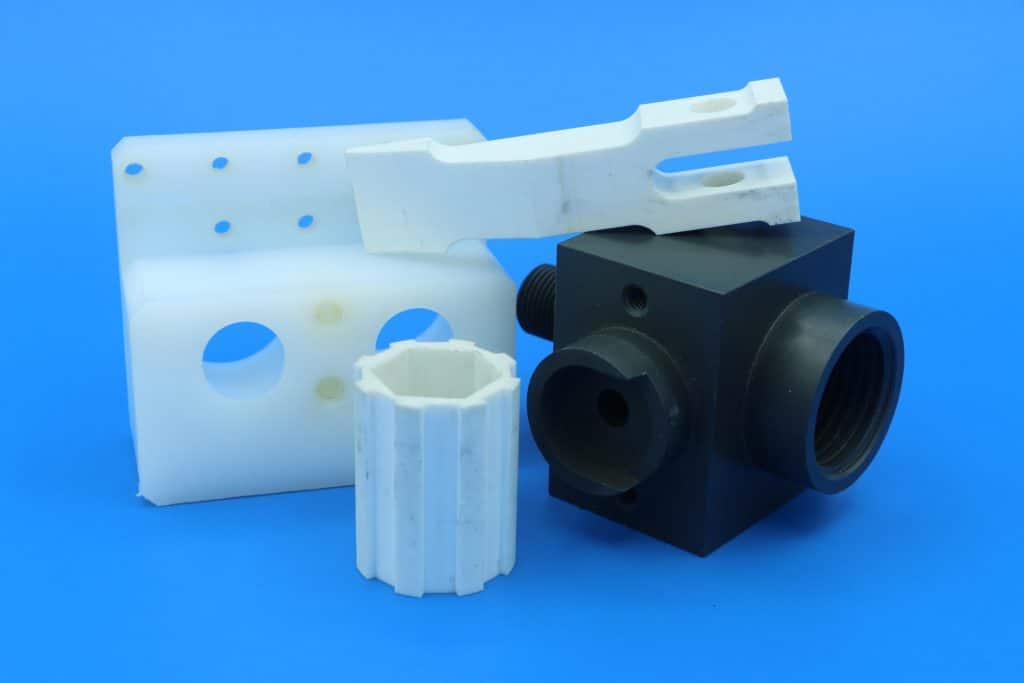

Engineering Guide: Plastic Moulding Parts

Engineering Insight: Precision as the Foundation of Plastic Moulding Parts Performance

In high-performance applications, the quality of plastic moulding parts is intrinsically tied to the precision of the metal tooling that forms them. While Wuxi Lead Precision Machinery operates within the custom metal manufacturing sector, our core expertise directly enables the success of critical plastic components. Plastic parts themselves may be the end product, but their dimensional accuracy, structural integrity, and functional reliability are dictated by the micron-level tolerances achieved in the steel or aluminum moulds we produce. Compromised mould precision inevitably translates to part warpage, flash, inconsistent wall thickness, or assembly failures—costly defects in aerospace, medical, or automotive systems where performance is non-negotiable. True precision engineering begins long before plastic injection, rooted in the metal fabrication stage.

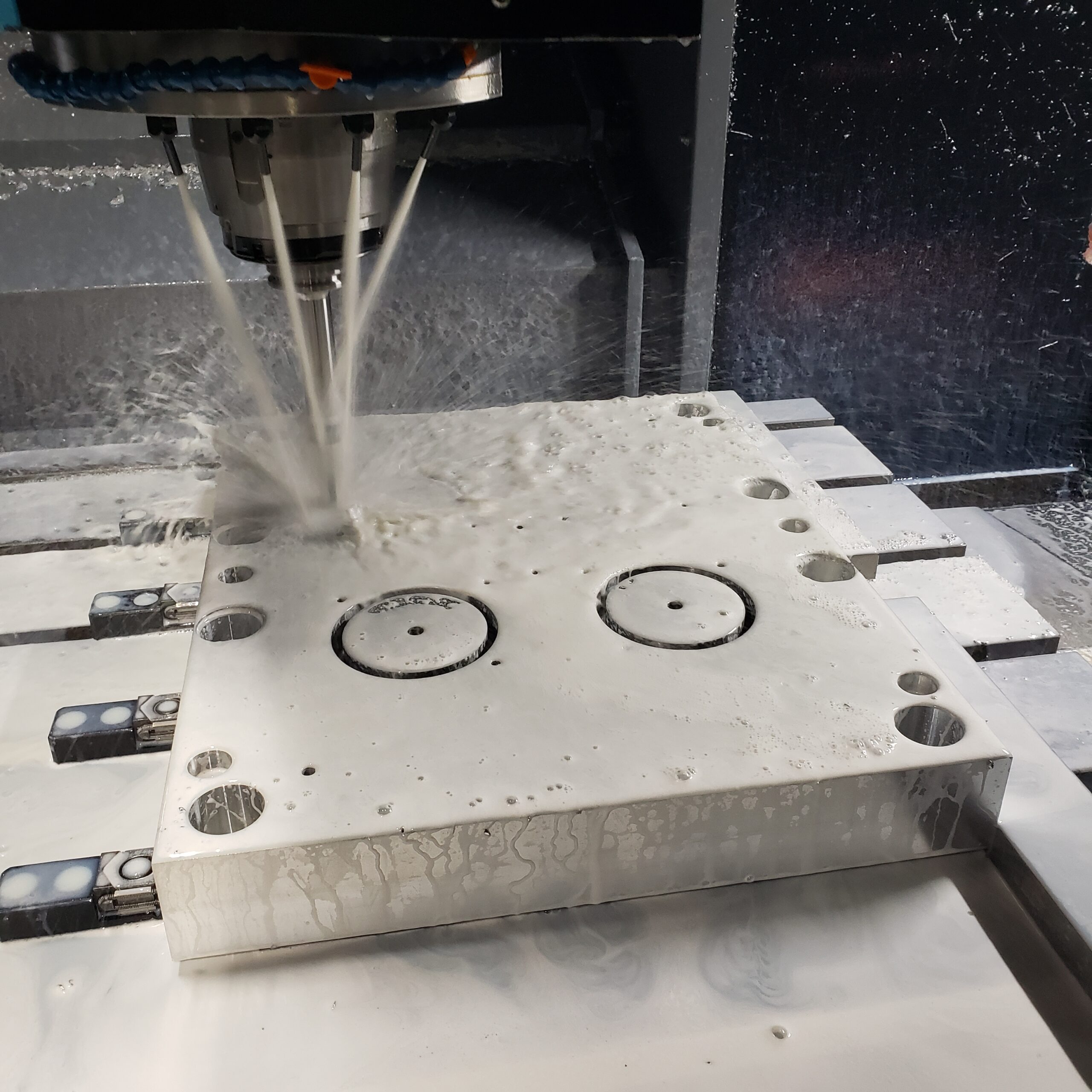

Achieving this requires advanced CNC machining capabilities applied to mould cores, cavities, ejector systems, and cooling channels. Sub-micron surface finishes on mould surfaces prevent cosmetic defects and ensure smooth part ejection. Tight geometric tolerances across multi-cavity moulds guarantee part-to-part consistency at production scale. Precise thermal management channel placement, machined directly into the mould steel, controls cooling rates to minimize internal stresses in the plastic. The interplay between metal mould accuracy and final plastic part quality is absolute; a 0.01mm deviation in the mould cavity can manifest as significant functional variance in safety-critical components. This demands not only cutting-edge machinery but deep process understanding honed through complex projects.

Our commitment to this precision standard is validated through demanding applications. Wuxi Lead has supplied mould tooling components for timing system housings in Olympic Games infrastructure, where environmental stability and zero-failure operation are paramount. Similarly, we manufacture precision inserts and electrodes for moulds producing military-grade connector housings, meeting stringent MIL-STD requirements for dimensional repeatability under extreme conditions. These projects exemplify our capability to deliver the metal foundation upon which mission-critical plastic parts depend.

The table below illustrates how specific metal mould precision parameters directly impact plastic part outcomes:

| Critical Mould Parameter | Target Tolerance Range | Direct Impact on Plastic Moulding Part |

|---|---|---|

| Cavity Dimensional Accuracy | ±0.005 mm to ±0.01 mm | Ensures final part meets GD&T specifications; prevents assembly interference or fit issues |

| Surface Roughness (Cavity) | Ra 0.05 µm to Ra 0.2 µm | Eliminates surface defects (striae, orange peel); critical for optical or seal surfaces |

| Inter-Cavity Consistency | ≤ 0.008 mm variation | Guarantees uniformity across multi-cavity production runs; essential for batch reliability |

| Cooling Channel Position | ±0.02 mm | Optimizes thermal homogeneity; reduces warpage and internal stresses in the plastic part |

| Ejector Pin Alignment | ≤ 0.01 mm runout | Prevents part damage during ejection; maintains edge integrity on thin-walled features |

At Wuxi Lead Precision Machinery, we treat every mould component as a precision instrument. Our CNC engineering rigor—forged through Olympic and military-grade projects—ensures the metal foundation of your plastic moulding parts delivers uncompromised performance. When specifications demand zero-defect output, the metal tooling must exceed expectations. We provide that certainty. Partner with us to transform plastic part requirements into engineered reality, backed by measurable precision.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the production of precision plastic moulding parts, serving high-demand industries such as automotive, medical, electronics, and industrial equipment. Our expertise lies in integrating custom metal manufacturing with high-precision machining processes to support complex mould development and long-term production reliability. At the core of our operations is a robust suite of 5-axis CNC machining centers, enabling us to produce highly intricate mould components with superior surface finishes and tight geometric control.

Our 5-axis CNC systems allow simultaneous multi-directional cutting, significantly enhancing accuracy and efficiency when machining complex contours and deep cavities typical in plastic injection moulds. This capability reduces the need for multiple setups, minimizing cumulative tolerances and ensuring part consistency. Utilizing high-rigidity machines equipped with automatic tool changers and real-time monitoring systems, we maintain stable production cycles even for the most demanding geometries. Materials such as P20, 718H, S136, and hardened tool steels are routinely processed with optimized toolpaths to extend tool life and maintain dimensional integrity.

Quality assurance is embedded throughout our manufacturing workflow. Every critical component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM), ensuring full compliance with design specifications. Our CMM systems provide 3D measurement accuracy down to ±0.002 mm, allowing verification of complex profiles, hole patterns, and form tolerances. Data from inspections are documented and traceable, supporting full quality reporting for audit and production validation purposes.

We specialize in producing mould bases, cavities, cores, sliders, and inserts with exceptional repeatability. Our engineering team collaborates closely with clients during the design-for-manufacturability phase to optimize part geometry, draft angles, and cooling channel layouts, ultimately reducing cycle times and improving part quality. With in-house heat treatment coordination and surface finishing options including polishing and texturing, we deliver fully integrated solutions tailored to high-volume plastic moulding applications.

The following table outlines our standard machining tolerances for plastic moulding components:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | Up to 500 mm |

| Hole Diameter | +0.01 / 0 mm | +0.005 / 0 mm | Reamed or bored |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | Verified on surface plate |

| Parallelism | 0.01 mm | 0.005 mm | Across mating surfaces |

| Perpendicularity | 0.01 mm | 0.008 mm | Critical for alignment |

| Profile Tolerance | ±0.02 mm | ±0.01 mm | Complex 3D surfaces |

| Surface Finish (Ra) | 0.8 μm | 0.4 μm | Machined; polish available |

Our technical capabilities are designed to meet the rigorous demands of modern plastic moulding, ensuring durability, precision, and seamless integration into automated production environments.

Material & Finish Options

Material Selection for Plastic Injection Molding Applications

Selecting the optimal mold material is critical for achieving precision, longevity, and cost-efficiency in plastic injection molding. At Wuxi Lead Precision Machinery, we engineer molds using Aluminum, Steel, and Titanium alloys, each offering distinct advantages tailored to specific production volumes, part complexity, and plastic resin characteristics. The correct choice directly impacts cycle times, surface finish quality, dimensional stability, and overall tooling investment.

Aluminum alloys, particularly 7075-T6 and 6061-T6, provide exceptional thermal conductivity and rapid machinability. This makes them ideal for prototype molds, low-to-medium volume production runs, and applications requiring quick heat dissipation to minimize cycle times. While offering lower hardness than steel, modern aluminum grades deliver sufficient wear resistance for many engineering plastics. Their lighter weight also simplifies mold handling and installation. Aluminum molds represent a lower initial cost solution where extended high-volume production is not required.

Tool steels remain the industry standard for high-volume, high-precision plastic molding. Grades like P20 offer excellent machinability and good polishability for standard applications. For demanding resins requiring superior wear resistance, thermal fatigue resistance, and extended service life under high cavity pressures, H13 (hot work steel) and S136 (stainless) are preferred. H13 excels with abrasive or high-temperature plastics like PC or PPS, while S136 provides critical corrosion resistance for PVC or flame-retardant materials. Steel molds command a higher initial investment but deliver unparalleled durability and consistency over millions of cycles.

Titanium alloys, though less common due to cost and machining complexity, offer unique benefits for highly corrosive environments or specialized applications requiring extreme strength-to-weight ratio and non-magnetic properties. Their exceptional corrosion resistance surpasses even stainless steels, making them suitable for specific medical or chemical processing molds where part purity is paramount.

Surface finishing, particularly hard anodizing, significantly enhances aluminum mold performance. This electrolytic process creates a dense, hard aluminum oxide layer on the mold surface, dramatically improving abrasion resistance, release properties, and corrosion protection. Anodized aluminum molds can effectively bridge the gap between standard aluminum and steel for medium-volume production with abrasive fills, reducing galling and extending tool life while maintaining faster cycle times than steel. Standard hard anodizing achieves thicknesses of 25-50μm with hardness exceeding 60 HRC.

The following table summarizes key material properties relevant to plastic injection mold performance:

| Material | Typical Hardness (HRC) | Thermal Conductivity (W/m·K) | Primary Use Case | Key Advantage for Plastic Molding |

|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 HB (≈40 HRC anodized) | 130-150 | Prototypes, Low/Med Volume | Fast cycle times, Low cost, Easy repair |

| P20 Tool Steel | 28-32 | 28-36 | Medium Volume, General Purpose | Good balance of cost, polish, toughness |

| H13 Tool Steel | 48-52 | 24-30 | High Volume, High Temp/Abrasive Resins | Superior thermal fatigue & wear resistance |

| S136 Stainless | 48-52 | 20-25 | Corrosive Resins (PVC, FR) | Excellent corrosion resistance |

| Hard Anodized Al | 60+ (surface) | 130-150 (core) | Med Volume, Abrasive Fills | Enhanced wear resistance on Al base |

Wuxi Lead Precision Machinery leverages decades of experience to match your specific plastic part requirements, resin type, and production goals with the optimal mold material and surface treatment strategy, ensuring peak performance and value.

Manufacturing Process & QC

The production process for high-precision plastic moulding parts at Wuxi Lead Precision Machinery follows a disciplined, end-to-end workflow designed to ensure zero defects and full compliance with industrial standards. Rooted in custom metal manufacturing expertise, our approach integrates engineering precision with advanced quality control to deliver consistent, high-performance components for demanding sectors such as automotive, medical, and industrial automation.

The process begins with Design Engineering, where our technical team collaborates closely with clients to analyze part geometry, material selection, and functional requirements. Utilizing 3D CAD modeling and mold flow simulation software, we optimize gate locations, cooling channels, and ejection systems to prevent warping, sink marks, or other molding defects. This stage includes Design for Manufacturability (DFM) reviews to ensure that the proposed design can be efficiently and reliably produced at scale.

Once the design is finalized and approved, we proceed to Prototyping. Using CNC-machined aluminum or pre-hardened steel molds, we produce functional prototypes in the actual engineering-grade thermoplastics specified by the client. These prototypes undergo rigorous dimensional inspection, material testing, and fit-function validation. This phase allows for early detection of design flaws, mold performance issues, or assembly challenges—enabling corrections before full-scale production begins. Our rapid prototyping capabilities reduce time-to-market while maintaining precision within ±0.02 mm tolerances.

With prototype approval, we transition to Mass Production using high-clamp-force, all-electric injection molding machines equipped with real-time monitoring systems. Each mold is built from hardened steel or stainless alloys, precision-machined on multi-axis CNC centers and EDM systems, ensuring longevity and repeatability over millions of cycles. Production runs are managed under strict process controls, including cavity pressure monitoring, automated part ejection, and in-line vision inspection systems that detect surface defects or dimensional deviations instantly.

Quality assurance is embedded at every stage. Raw materials are certified and batch-tracked. In-process statistical process control (SPC) ensures consistency, while first-article and final inspections are conducted using CMMs, optical comparators, and 2.5D measuring instruments. All components are 100% visually inspected and packaged in cleanroom conditions where required.

Our zero-defect philosophy is enforced through ISO 9001-certified procedures, corrective action loops, and continuous feedback from production data analytics. This structured approach ensures that every plastic moulding part meets the highest standards of precision, reliability, and performance.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.02 mm to ±0.05 mm |

| Material Compatibility | ABS, PC, POM, PBT, PA6/66, PPS, PEEK, LCP |

| Mold Life | 500,000 to 1,000,000+ cycles |

| Injection Press Capacity | 50 to 1,200 tons |

| Surface Finishes | SPI, VDI, texture, polish, coating |

| Quality Standards | ISO 9001, IATF 16949, RoHS compliant |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Plastic Molding Excellence

Precision plastic molding demands more than advanced machinery—it requires a strategic partner with deep engineering insight and unwavering commitment to quality. At Wuxi Lead Precision Machinery, we bridge the gap between complex design requirements and flawless production execution. With over 15 years of specialized expertise in custom metal manufacturing for high-precision plastic molding components, we transform your most challenging specifications into reality. Our integrated approach combines German-engineered CNC systems, rigorous material science protocols, and proactive engineering collaboration to eliminate costly iterations and accelerate time-to-market.

Unlike commodity suppliers, we prioritize co-development from the initial design phase. Our engineers conduct thorough Design for Manufacturability (DFM) analysis to optimize part geometry, material selection, and tooling strategies—reducing waste while enhancing structural integrity. Every component undergoes multi-stage in-process validation, including CMM inspection, surface roughness testing, and thermal stability checks, ensuring compliance with ISO 9001 and IATF 16949 standards. This meticulous process delivers consistent repeatability down to ±0.002mm tolerances, critical for medical, aerospace, and automotive applications where failure is not an option.

Our technical capabilities are engineered to solve your toughest production hurdles. The table below outlines core competencies driving measurable value for global OEMs:

| Capability | Specification | Application Impact |

|---|---|---|

| Tolerance Control | ±0.002mm to ±0.005mm | Ensures perfect assembly in multi-part systems |

| Material Expertise | PEEK, Ultem, PPS, LCP, PTFE | Supports extreme chemical/thermal environments |

| Secondary Operations | Micro-milling, threading, laser marking | Eliminates third-party dependencies |

| Lead Time | 15-25 days for complex tooling | Reduces project delays by 30% vs. industry average |

| Quality Assurance | 100% inline CMM + SPC monitoring | Achieves 99.98% first-pass yield |

We understand that reliability in plastic molding hinges on metallurgical precision. Our hardened stainless steel and pre-hardened tool steels undergo proprietary heat treatment and surface finishing processes, extending mold life by 40% while maintaining dimensional stability across 500,000+ cycles. This technical mastery translates to lower total cost of ownership and zero-defect supply chain continuity for your operations.

Partnering with Lead Precision means gaining an extension of your engineering team. We provide dedicated project managers fluent in English and German, real-time production dashboards, and rapid prototyping support to de-risk your innovation pipeline. When your application demands micron-level accuracy in demanding polymers, trust a partner certified by Siemens and Bosch for mission-critical components.

Initiate your next high-stakes project with confidence. Contact our engineering team at [email protected] to schedule a technical consultation. Share your CAD files and requirements—we will deliver a comprehensive DFM report and production timeline within 48 hours. Let us prove why global leaders choose Wuxi Lead Precision Machinery for plastic molding parts where precision defines performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.