Technical Contents

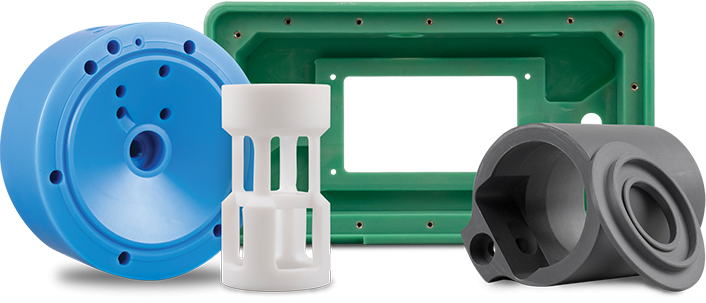

Engineering Guide: Plastic Moulding Company

Engineering Insight: Precision as the Foundation of Excellence in Plastic Moulding

In the realm of custom metal manufacturing for plastic moulding companies, precision is not merely a performance metric—it is the cornerstone of operational integrity, product consistency, and long-term reliability. As plastic injection moulding processes grow increasingly sophisticated, the demand for tooling components with micron-level accuracy has become non-negotiable. Even the slightest deviation in critical dimensions can result in part defects, reduced mould life, or costly production downtime. At Wuxi Lead Precision Machinery, we understand that precision engineering is the bridge between design intent and manufacturing reality.

With over 15 years of experience serving high-demand industries, including aerospace, defense, and Olympic-grade sports equipment manufacturing, our team has developed a rigorous approach to tolerances, material selection, and process control. These sectors impose some of the most stringent quality standards in the world, where failure is not an option. Our involvement in producing mission-critical components for military applications and precision tooling used in Olympic-level performance gear underscores our capability to deliver under extreme specifications. This same level of discipline is applied to every project we undertake for plastic moulding companies.

The performance of a plastic injection mould is directly influenced by the precision of its metal components—core pins, ejector plates, guide pillars, and cavity inserts. Thermal expansion, wear resistance, and alignment all depend on exacting machining tolerances and superior surface finishes. At Lead Precision, we utilize advanced CNC machining centers with in-process probing and laser calibration systems to maintain tolerances as tight as ±0.002 mm. Our quality assurance protocols include CMM (Coordinate Measuring Machine) inspection, 3D scanning, and first-article reporting, ensuring that every component conforms to the highest international standards.

Material integrity is equally critical. We specialize in high-grade tool steels such as H13, P20, and S136, selected for their durability, polishability, and resistance to corrosion and thermal fatigue. Each material is heat-treated using controlled processes to optimize hardness and dimensional stability. Our engineers work closely with clients during the design phase to recommend optimal geometries, draft angles, and cooling channel layouts that enhance both mould performance and part quality.

The table below outlines key precision specifications consistently achieved across our production line:

| Specification | Value | Standard / Equipment |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | ISO 2768-mK, CMM Inspection |

| Surface Roughness (Ra) | 0.05 – 0.2 µm | Superfinishing, Polishing |

| Parallelism | ≤ 0.003 mm | Laser Interferometer |

| Perpendicularity | ≤ 0.005 mm | Precision Granite Table |

| Material Hardness Range | 48 – 52 HRC | Heat-Treated Tool Steels |

| Repeatability (Batch) | CpK ≥ 1.67 | Statistical Process Control |

Precision is not an add-on—it is engineered into every stage of production. For plastic moulding companies aiming to achieve excellence in part quality and production efficiency, partnering with a manufacturer that upholds uncompromising standards is essential. At Wuxi Lead Precision Machinery, our heritage in high-stakes engineering drives our commitment to delivering precision that performs, every cycle, every time.

Precision Specs & Tolerances

Technical Capabilities for Precision Mold Manufacturing

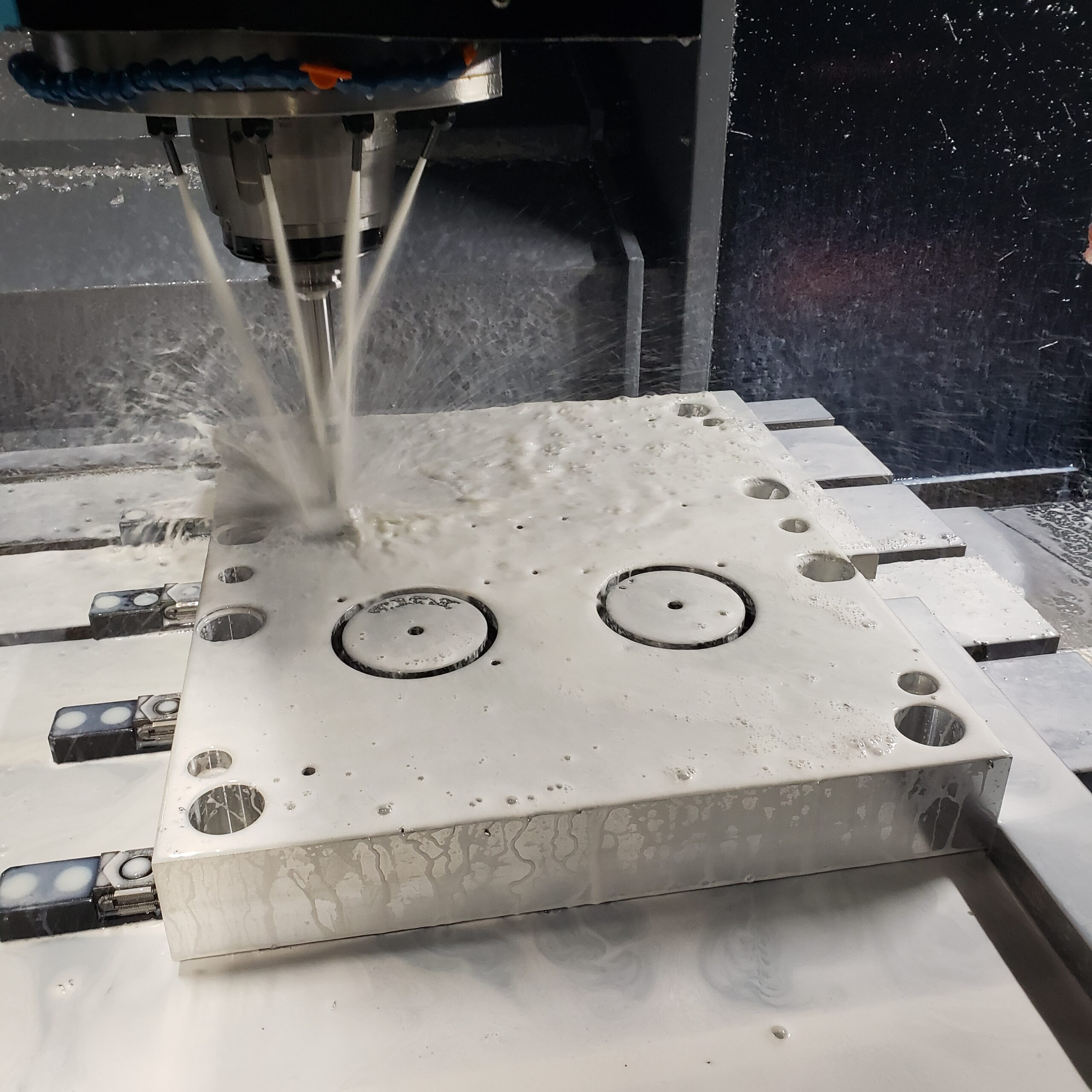

Wuxi Lead Precision Machinery delivers engineered metal solutions critical to high-performance plastic injection molds. Our custom manufacturing process integrates advanced 5-axis CNC machining with rigorous metrology to ensure dimensional stability and longevity under demanding production cycles. This capability directly addresses core challenges in mold performance: thermal distortion, part ejection consistency, and surface finish integrity.

Our DMG MORI and Hermle 5-axis CNC centers enable single-setup machining of complex mold bases, cavities, and cores. Simultaneous 5-axis interpolation eliminates repositioning errors inherent in 3+2 axis methods, achieving geometric accuracy within 0.003mm. This is essential for undercuts, cooling channels, and conformal geometries where traditional machining introduces cumulative tolerances. High-speed spindles (up to 30,000 RPM) paired with Renishaw probing systems ensure micron-level precision on hardened tool steels (H13, S136) and pre-hardened alloys, maintaining surface finishes to Ra 0.2µm without secondary polishing. The result is reduced cycle times, minimized weld lines, and elimination of knit lines in finished plastic parts.

Quality validation is non-negotiable in mold manufacturing. Every component undergoes full CMM inspection using Zeiss CONTURA systems with 0.5µm volumetric accuracy. Our inspection protocols follow ISO 10360-2 standards, verifying critical features against 3D CAD models. This includes comprehensive analysis of draft angles, parting line alignment, ejector pin bores, and cooling channel positioning. Real-time SPC data tracking identifies process drift before defects occur, ensuring 100% conformity to mold flow analysis requirements. For large mold bases exceeding 2,000mm, our portable CMM arms (FARO Quantum) provide on-machine verification, preventing costly rework after assembly.

The following table details achievable tolerances for common mold components under controlled production conditions:

| Feature Type | Material Condition | Standard Tolerance | Tight Tolerance Option | Measurement Method |

|---|---|---|---|---|

| Cavity/Cores | Hardened Steel (52 HRC) | ±0.010 mm | ±0.005 mm | CMM |

| Mold Base Plates | Pre-hardened P20 | ±0.020 mm | ±0.010 mm | CMM |

| Ejector Pin Bores | Through Hardened | +0.005/-0.000 mm | +0.002/-0.000 mm | Air Gage + CMM |

| Cooling Channels | All Materials | ±0.050 mm (positional) | ±0.020 mm | CMM |

| Surface Finish (milled) | Hardened Steel | Ra 0.8 µm | Ra 0.2 µm | Profilometer |

These specifications are validated across our production floor’s 22°C ±1°C thermal-controlled environment. We prioritize dimensional repeatability over single-point accuracy—critical for mold inserts requiring interchangeability across multiple production runs. By aligning machining parameters with your specific polymer viscosity and clamping requirements, we eliminate guesswork in mold trials. Partner with Wuxi Lead to transform precision metal fabrication into measurable gains: 30% faster mold commissioning, 15% longer tool life, and zero scrap during initial production runs. Your mold’s performance begins with our metal.

Material & Finish Options

Material selection is a critical phase in custom metal manufacturing, particularly for plastic moulding companies that require precision, durability, and thermal efficiency in their tooling and components. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance metal solutions tailored to the exacting demands of modern injection moulding and related industrial applications. The choice between aluminum, steel, and titanium directly impacts tool life, cycle time, surface finish quality, and overall production cost-efficiency.

Aluminum is widely used for prototyping and low- to medium-volume production due to its excellent machinability and superior thermal conductivity. It allows for faster cooling cycles, reducing overall production time during mould trials. While not as hard as steel or titanium, modern high-strength aluminum alloys such as 7075 and 6061-T6 offer sufficient durability for thousands of cycles when properly treated. Aluminum is also significantly lighter, facilitating easier handling and integration into automated systems.

Steel remains the standard for high-volume production moulds. Tool steels like P20, H13, and S136 provide exceptional hardness, wear resistance, and dimensional stability under repeated thermal cycling. These properties make steel ideal for complex moulds subjected to high pressure and prolonged operation. While steel has lower thermal conductivity than aluminum, its longevity and resistance to deformation ensure consistent part quality over extended runs.

Titanium, though less common due to cost and machining complexity, offers a unique combination of high strength-to-density ratio, excellent corrosion resistance, and performance at elevated temperatures. It is typically reserved for specialized applications where weight reduction and environmental resistance are paramount, such as in aerospace or medical moulding components.

Surface finishing, particularly anodizing, plays a vital role in enhancing the functional and aesthetic properties of metal parts. Anodizing aluminum creates a durable, corrosion-resistant oxide layer that can be dyed for identification or branding. It also improves surface hardness and wear resistance, extending the life of mould components exposed to friction or corrosive resins. While steel and titanium are not anodized in the traditional sense, they benefit from alternative surface treatments such as nitriding, chrome plating, or PVD coatings—options we also support based on application needs.

Below is a comparative overview of key material properties relevant to plastic moulding applications.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 15–20 | 167 | Prototype moulds, low-volume production |

| Steel P20 | 950–1100 | 28–32 | 28–36 | High-volume mould bases and cavities |

| Steel H13 | 1550 | 45–50 | 30–35 | Hot-runner systems, high-heat moulds |

| Titanium Gr5 | 900–1000 | 35–40 | 7–8 | Aerospace, medical, corrosive environments |

Selecting the right material and finish requires a deep understanding of operational parameters and lifecycle requirements. At Wuxi Lead Precision Machinery, we partner with clients to analyze these factors and deliver optimized solutions that balance performance, cost, and reliability.

Manufacturing Process & QC

Precision-Driven Production Process for Zero-Defect Plastic Moulding Components

At Wuxi Lead Precision Machinery, we understand that flawless plastic moulding hinges on the absolute precision of the metal components within your moulds and tooling. Our integrated production process, rigorously applied to every custom metal manufacturing project, is engineered to eliminate defects at the source, ensuring your plastic production runs with maximum efficiency and minimal scrap. We partner with leading plastic moulding companies to transform complex designs into reality through a seamless, quality-embedded workflow.

This phase initiates with intensive collaborative design analysis. Our engineering team conducts thorough Design for Manufacturability (DFM) and Design for Assembly (DFA) reviews, focusing specifically on the demands of high-pressure plastic injection or blow moulding. We scrutinize thermal management requirements, ejection dynamics, parting line integrity, and wear resistance. Utilizing advanced simulation software, we predict potential stress points, cooling inefficiencies, or deflection risks within the metal structure under operational loads. This proactive analysis identifies and resolves potential failure modes before metal is cut, preventing costly mould revisions and production delays downstream. Client feedback is integrated iteratively to finalize the optimal design blueprint.

Prototyping transitions the validated design into a tangible, fully functional metal component. Employing our high-accuracy CNC machining centres and wire EDM capabilities, we produce a single, representative unit mirroring mass production methods. This prototype undergoes exhaustive metrology, including CMM inspection against the original CAD model and critical functional testing under simulated moulding conditions. We measure dimensional stability, surface finish critical for part release, and alignment tolerances. Any deviation, however minute, triggers immediate root cause analysis and design or process refinement. This stage is non-negotiable for verifying performance and locking in the process parameters for zero-defect replication.

Mass production leverages the perfected parameters from prototyping within a tightly controlled Statistical Process Control (SPC) environment. Every machining operation, heat treatment cycle, and surface finishing step is monitored in real-time. Automated in-process gauging verifies critical dimensions after each major operation, feeding data directly into our SPC system. Full first-article inspection (FAI) is mandatory, followed by defined sampling plans based on part criticality. Our commitment to zero defects is quantified through stringent process capability indices maintained throughout the production run. This systematic control ensures every component shipped meets the exacting specifications required for uninterrupted, high-yield plastic moulding operations.

The following table details our core production specifications guaranteeing component integrity for demanding moulding applications:

| Specification Parameter | Performance Standard | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (Standard) | CMM, Optical Comparator |

| Surface Roughness (Ra) | 0.05 µm (Critical Surfaces) | Profilometer |

| Geometric Tolerance (GD&T) | ISO 2768-mK / Specific Callouts | CMM, Functional Gauges |

| Process Capability (Cpk) | ≥ 1.67 (Minimum) | SPC Chart Analysis |

| First Article Inspection | 100% Critical Dimensions | AS9102 Form B Documentation |

| In-Process Inspection Rate | Per Control Plan (Min 100%) | Automated Gauging / Manual Checks |

This disciplined approach, from initial concept validation through to certified mass production, delivers the foundational metal precision your plastic moulding processes require. Partner with Wuxi Lead to eliminate the root causes of mould-related defects and achieve true operational excellence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Metal Manufacturing Excellence

When your plastic molding operations demand seamless integration with high-performance metal components, the foundation of success lies in precision, reliability, and technical mastery. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing engineered to support the most demanding requirements of the plastic molding industry. Our advanced CNC machining, sheet metal fabrication, and precision assembly services are designed to deliver components that enhance mold performance, extend tool life, and ensure consistent production output.

As a trusted partner to global plastic molding companies, we understand that every micron matters. From mold bases and inserts to ejection systems and cooling manifolds, our manufacturing processes are built around tight tolerances, superior material selection, and rigorous quality control. We combine state-of-the-art equipment with decades of engineering experience to produce metal components that meet the exact specifications of your molding applications—whether for automotive, medical, packaging, or consumer electronics.

Our facility in Wuxi, China, operates under ISO 9001-certified quality systems, ensuring every part is traceable, repeatable, and manufactured to international standards. We utilize advanced 5-axis CNC machining centers, wire EDM, surface grinding, and laser cutting technologies to achieve complex geometries and superior surface finishes. Our engineering team works closely with your design and production staff to optimize manufacturability, reduce lead times, and lower total cost of ownership.

What sets us apart is our commitment to partnership. We don’t just manufacture parts—we solve production challenges. Whether you require rapid prototyping, low-volume custom runs, or high-volume production support, we scale our capabilities to match your needs. Our responsive project management, real-time communication, and on-time delivery record make us a reliable extension of your supply chain.

Below are key specifications that define our manufacturing capabilities:

| Capability | Specification |

|---|---|

| CNC Machining | 3-axis to 5-axis, ±0.005 mm tolerance |

| Wire EDM | ±0.002 mm accuracy, fine finish options |

| Laser Cutting | Up to 25 mm thickness, carbon & stainless steel |

| Sheet Metal Fabrication | Bending, stamping, welding, assembly |

| Surface Finish | Polishing, anodizing, plating, coating |

| Materials | P20, 718, H13, S136, aluminum, titanium, brass |

| Quality Standards | ISO 9001:2015, full inspection reports |

| Lead Time | Prototype: 7–10 days; Production: 15–25 days |

Partnering with Wuxi Lead Precision Machinery means aligning with a team that values precision as much as you do. We are committed to delivering metal components that elevate the performance and efficiency of your plastic molding systems.

Contact us today at [email protected] to discuss your next project. Let our engineering expertise become your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.