Technical Contents

Engineering Guide: Plastic Mould Maker

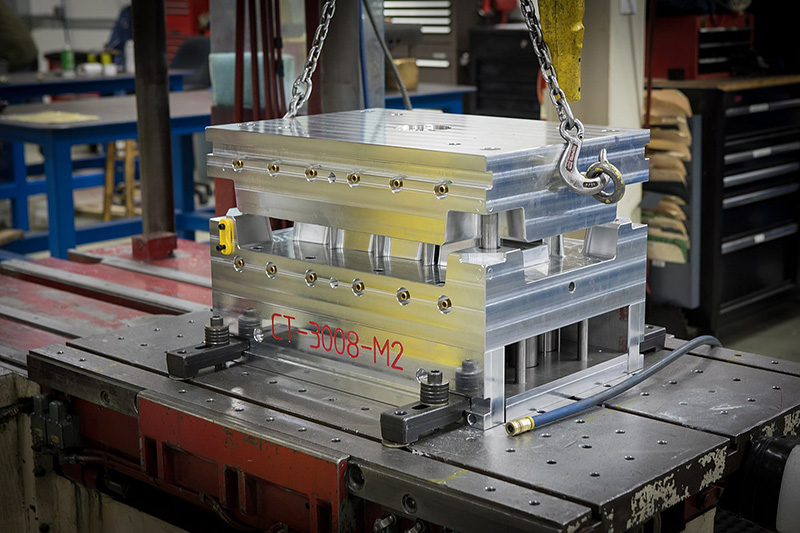

In the world of custom metal manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, repeatability, and product integrity are built. Nowhere is this more evident than in the domain of plastic mould making, where micron-level tolerances directly influence the functionality, aesthetics, and lifecycle of end components. At Wuxi Lead Precision Machinery, we approach plastic mould making as a convergence of advanced engineering, material science, and disciplined process control, ensuring that every mould we produce meets the most stringent industrial standards.

Plastic injection moulds are subjected to extreme thermal cycling, mechanical stress, and repetitive wear. A deviation of even a few microns can result in flash, warpage, or incomplete filling—defects that compromise part quality and increase production costs. This is why high-precision machining, combined with rigorous metrology and thermal stability analysis, is non-negotiable. Our engineering team leverages state-of-the-art CNC machining centres, wire EDM, and surface grinding technologies to achieve tolerances as tight as ±0.002 mm, ensuring dimensional consistency across thousands of production cycles.

Our expertise in precision extends beyond commercial applications. With proven experience in manufacturing critical components for Olympic-standard equipment and military-grade systems, Wuxi Lead has demonstrated the ability to deliver under the most demanding specifications. These projects required not only extreme accuracy but also full traceability, compliance with international standards, and zero-defect performance—benchmarks that now define our approach to every plastic mould project.

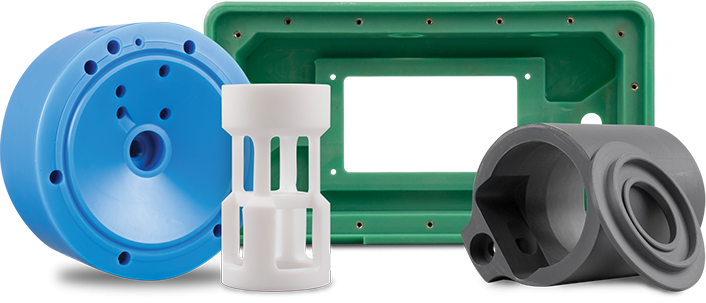

We understand that each mould is a custom solution, shaped by material selection, part geometry, production volume, and environmental conditions. Our design engineers work closely with clients during the prototyping phase, using 3D simulation and mold flow analysis to anticipate potential issues before machining begins. This proactive engineering insight reduces time-to-market and eliminates costly iterations.

The following table outlines key precision specifications achievable at Wuxi Lead Precision Machinery for plastic mould manufacturing:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.05–0.2 µm |

| Parallelism | ≤ 0.003 mm |

| Flatness | ≤ 0.003 mm over 100 mm |

| Hole Position Accuracy | ±0.005 mm |

| Cavity Surface Finish | Mirror polish to SPI A1 standard |

| Tool Life | >1,000,000 cycles (material and application dependent) |

Backed by ISO 9001 certification and a fully integrated quality management system, Wuxi Lead Precision Machinery ensures that every plastic mould is not only built to specification but engineered for long-term performance. Our commitment to precision is not just technical—it is a philosophy that drives every decision, from material sourcing to final inspection. For industries where failure is not an option, we deliver moulds that perform with unwavering consistency, cycle after cycle.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Plastic Molds

Wuxi Lead Precision Machinery delivers the advanced manufacturing foundation essential for producing high-performance, long-life plastic injection molds. Our core strength lies in integrating cutting-edge multi-axis machining with rigorous metrology, ensuring every component meets the exacting demands of modern molding applications. We specialize in transforming complex 3D CAD data into physically precise mold bases, cavities, cores, and intricate inserts, directly addressing the geometric complexity and stringent surface finish requirements inherent in high-cavitation and micro-molding tooling.

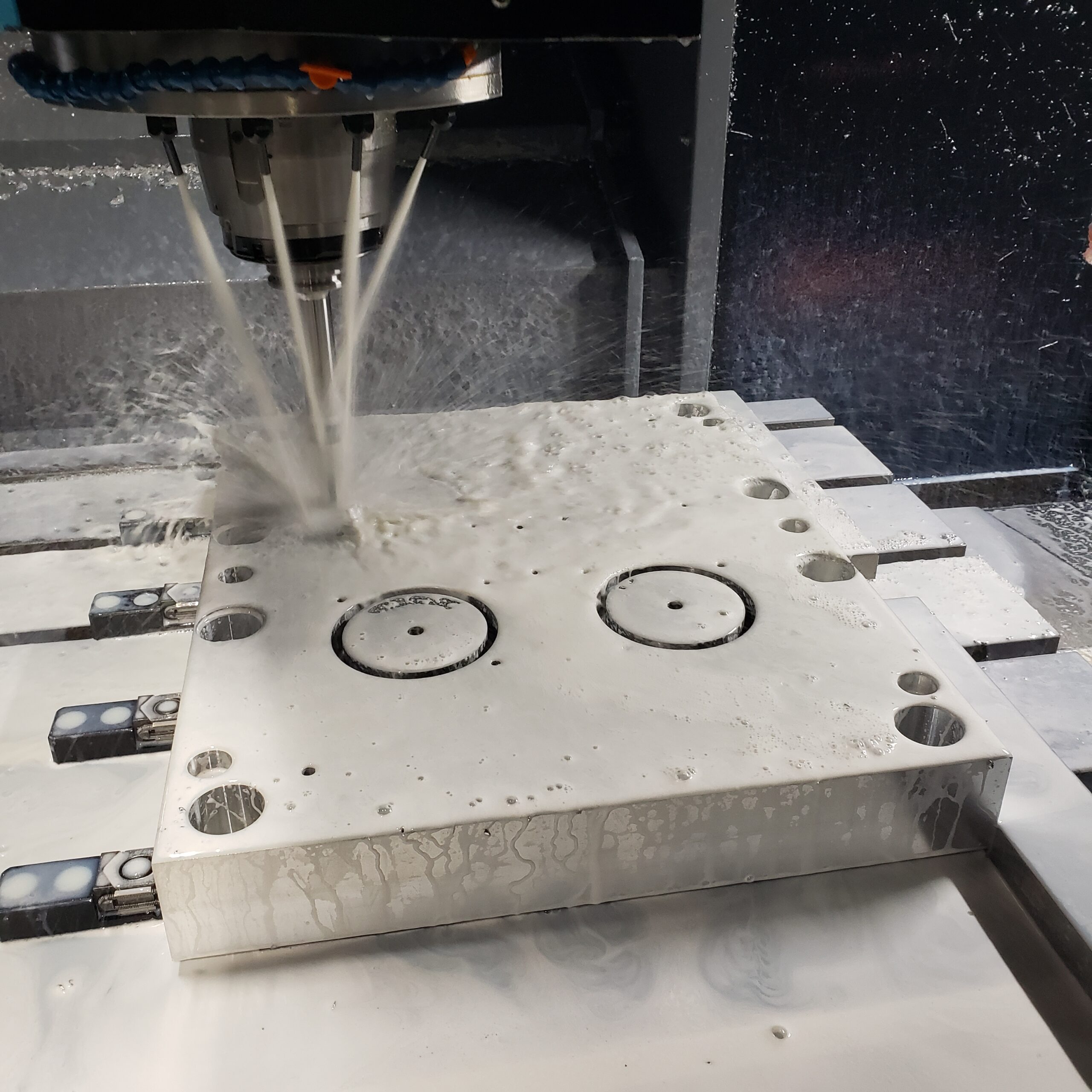

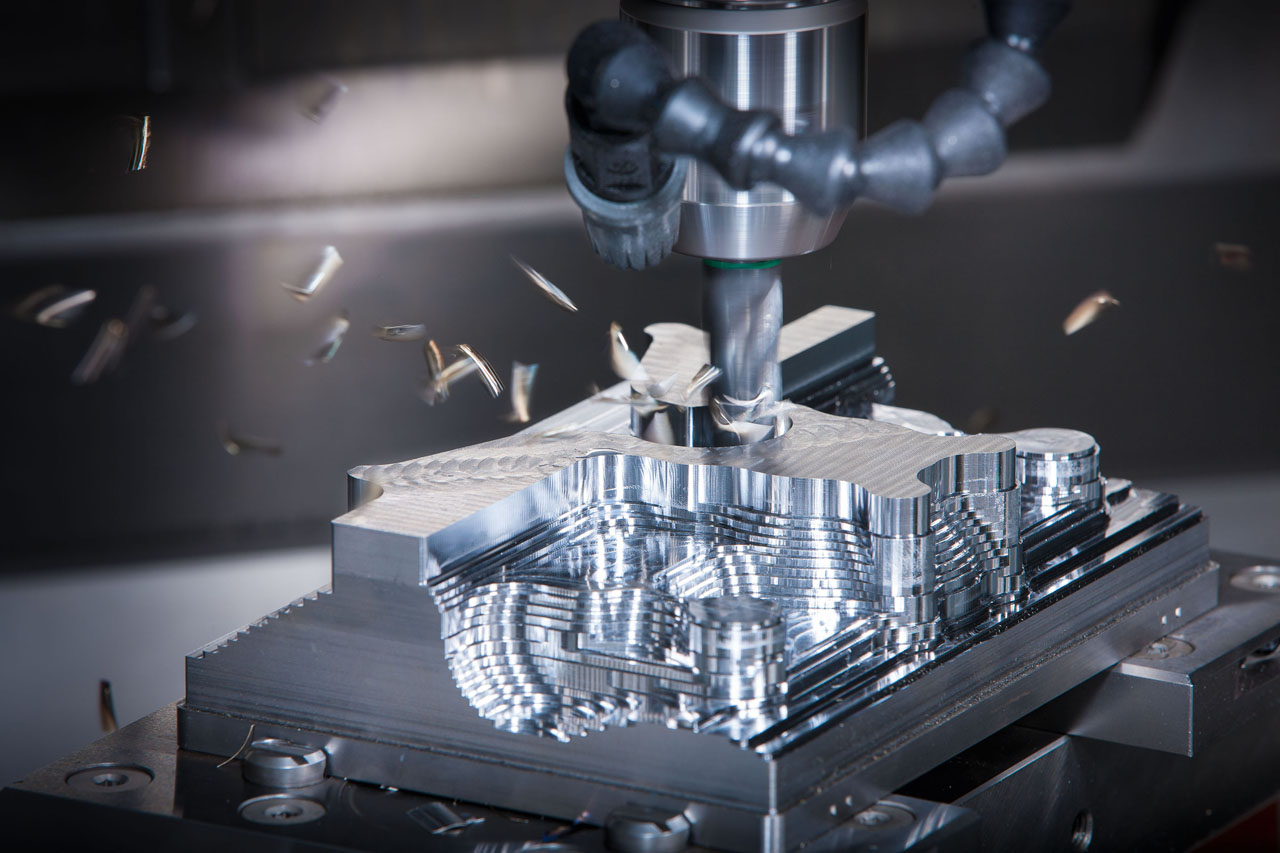

Central to our process is a dedicated fleet of high-precision 5-axis CNC machining centers. These machines, featuring thermal compensation systems and rigid construction, enable simultaneous 5-axis interpolation for single-setup machining of highly complex mold geometries. This capability eliminates cumulative errors from multiple fixtures, significantly reduces lead times, and achieves superior surface integrity critical for optical or textured mold finishes. We routinely machine hardened tool steels (up to 60 HRC) and specialized alloys like maraging steel, minimizing post-machining EDM requirements and enhancing overall mold durability. Our programming leverages advanced CAM strategies optimized specifically for mold steel characteristics and fine detail resolution.

Quality assurance is not a final step but an integrated process. Every critical mold component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMMs). Our Zeiss and Hexagon CMMs, operating within certified temperature-controlled environments, provide full 3D geometric dimensioning and tolerancing (GD&T) verification against the master CAD model. This includes precise measurement of cavity wall thicknesses, core pin locations, cooling channel positioning, and critical sealing surfaces. Real-time data analysis ensures immediate corrective action if deviations occur, guaranteeing dimensional conformity before mold assembly begins. This systematic approach provides documented evidence of quality, reducing trial-and-error during mold commissioning and accelerating time-to-production for our clients.

The following table details our standard and precision machining tolerance capabilities, reflecting achievable results under controlled production conditions for typical mold components:

| Feature Type | Standard Capability | Precision Capability | Key Notes |

|---|---|---|---|

| Linear Dimension | ±0.010 mm | ±0.005 mm | Up to 300 mm; ±0.008 mm typical for molds |

| Geometric (Flatness) | 0.015 mm | 0.005 mm | Per 100 mm²; critical for parting lines |

| Geometric (Roundness) | 0.010 mm | 0.003 mm | For core pins, guide posts, bushings |

| Positional (Holes) | ±0.012 mm | ±0.005 mm | Critical for ejector pin alignment |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Machined finish; polishable to <0.05 µm Ra |

| Hardened Steel (60 HRC) | ±0.015 mm | ±0.008 mm | Post-heat treat machining capability |

These tolerances represent our standard production benchmarks for mold components. Tighter specifications are achievable for critical features through dedicated process validation and are commonly applied to optical lens molds or micro-feature applications. Our engineering team collaborates closely with clients during the design phase to identify tolerance-critical zones, ensuring manufacturability and optimizing the balance between precision requirements and project timelines. This commitment to measurable accuracy and process control forms the bedrock of reliable, high-yield plastic molding operations.

Material & Finish Options

Material Selection for High-Precision Plastic Mould Making

Selecting the appropriate material for plastic moulds is critical to achieving optimal performance, longevity, and cost-efficiency in high-volume or precision manufacturing environments. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing with a focus on advanced material integration tailored to the demands of modern injection moulding. The three primary materials used in plastic mould fabrication—aluminum, steel, and titanium—each offer distinct mechanical properties, thermal behaviors, and economic trade-offs that must be evaluated based on production volume, part complexity, and environmental exposure.

Aluminum alloys, particularly 7075 and 6061, are widely favored for prototype moulds and low-to-medium production runs. Their high thermal conductivity enables faster cooling cycles, reducing overall cycle times and increasing throughput during initial product validation. Aluminum is also easier to machine, allowing for complex geometries with tight tolerances and reduced lead times. However, its lower hardness and wear resistance make it less suitable for long-term, high-volume production involving abrasive resins.

Steel, especially tool steels like P20, H13, and S136, remains the standard for high-volume plastic moulding. These alloys provide superior hardness, wear resistance, and dimensional stability under prolonged thermal cycling. Stainless tool steels such as S136 offer additional corrosion resistance, making them ideal for moulds exposed to halogenated or acidic polymers. While steel moulds require longer machining and heat treatment processes, their extended service life and ability to maintain surface finish over millions of cycles justify the initial investment for large-scale manufacturing.

Titanium alloys, though less common due to cost and machining complexity, are emerging in specialized applications requiring extreme strength-to-density ratios and exceptional corrosion resistance. Their use in plastic mould making is currently limited to niche aerospace or medical components where weight reduction and biocompatibility are paramount. Titanium’s low thermal conductivity can be a limitation, but its performance in aggressive chemical environments makes it a candidate for specific high-performance resins.

Surface finishing, particularly anodizing, plays a vital role in enhancing mould performance. Anodizing aluminum increases surface hardness, improves wear resistance, and provides electrical insulation. Hard anodizing (Type III) can achieve coating thicknesses up to 50–80 µm with hardness values exceeding 60 HRC, significantly extending mould life. For steel and titanium, alternative surface treatments such as nitriding, PVD coating, or electro-polishing are typically preferred.

Below is a comparative summary of key material properties relevant to plastic mould making:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 40–45 | 130 | Moderate | Prototypes, low-volume runs |

| P20 Steel | 28–32 | 30 | Low | Medium-to-high volume moulds |

| H13 Steel | 48–52 | 35 | Moderate | High-temperature applications |

| S136 Steel | 50–54 | 25 | High | Corrosive resin processing |

| Titanium Ti-6Al-4V | 35–40 | 7 | Very High | Aerospace, medical components |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production requirements, resin type, and lifecycle cost analysis to ensure optimal mould performance and return on investment.

Manufacturing Process & QC

Precision Plastic Mold Manufacturing: The Zero-Defect Production Process

At Wuxi Lead Precision Machinery, our plastic mold manufacturing process is engineered for uncompromising quality from inception to volume delivery. We integrate advanced engineering with rigorous validation to eliminate defects before they occur, ensuring every mold meets the exacting standards of automotive, medical, and electronics industries.

The journey begins with collaborative Design Engineering. Our team partners with clients to transform concepts into manufacturable realities using Siemens NX and Moldflow simulation. Finite Element Analysis (FEA) predicts stress points, cooling efficiency, and material flow, preempting warpage or sink marks. Critical tolerances are defined to ±0.002mm, with mold steel selection (e.g., NAK80, S136H) optimized for longevity and surface finish. This phase concludes with a Design Failure Mode and Effects Analysis (DFMEA), ensuring all potential risks are mitigated before tooling begins.

Prototyping is where theory meets precision. We fabricate first-article molds using 5-axis CNC machining and wire EDM, achieving micron-level accuracy. Each prototype undergoes comprehensive metrology: Coordinate Measuring Machine (CMM) scans validate dimensional conformity against CAD models, while trial runs in our in-house injection molding cells verify part ejection, gate sealing, and cycle stability. Material compatibility and surface texture (e.g., SPI-A1, VDI 3400) are certified. Only after 30+ consecutive defect-free parts are produced does the mold advance to mass production.

Mass Production leverages our zero-defect philosophy through closed-loop control. All molds are monitored via IoT-enabled sensors tracking temperature, pressure, and clamp force in real time. Statistical Process Control (SPC) charts flag deviations before they escalate, while automated vision systems inspect every component for micro-burrs or flash. Our facility maintains ISO 9001 and IATF 16949 certifications, with full traceability from raw material heat numbers to final shipment. This systematic rigor ensures <50 PPM defect rates and on-time delivery for runs exceeding 500,000 cycles.

Wuxi Lead’s end-to-end ownership—design, prototyping, and production under one roof—eliminates supply chain vulnerabilities. By embedding quality at every phase, we deliver molds that consistently produce flawless components, reducing client scrap costs and accelerating time-to-market.

Wuxi Lead Precision Capabilities

| Parameter | Specification | Validation Method |

|---|---|---|

| Tolerance Range | ±0.002mm to ±0.01mm | CMM, Optical Comparator |

| Lead Time (Prototype) | 15-25 days | Real-time Production Dashboard |

| Material Range | P20, 718H, NAK80, S136H, M300 | Material Certificates (EN/ASTM) |

| Surface Finish | SPI-A1 to VDI 3400 (Ra 0.025μm) | Profilometer, Visual Standard |

| Validation | 30+ defect-free trial parts | SPC, First Article Inspection |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Plastic Mould Making

At Wuxi Lead Precision Machinery, we understand that in high-performance manufacturing, precision, reliability, and consistency are non-negotiable. As a global leader in custom metal manufacturing, we specialize in delivering advanced plastic mould solutions that meet the exacting standards of industries ranging from automotive and medical devices to consumer electronics and industrial automation. When you partner with us, you’re not just sourcing a component—you’re gaining a strategic manufacturing ally committed to engineering excellence and long-term success.

Our expertise in plastic mould making is built on decades of technical refinement, cutting-edge CNC machining capabilities, and a deep understanding of material science. Every mould we produce is engineered to tight tolerances, optimized for cycle efficiency, and built to withstand the rigors of high-volume production. We integrate advanced simulation software and quality assurance protocols at every stage—from design and prototyping to final inspection—ensuring that your mould performs flawlessly from the first shot to the millionth.

What sets Lead Precision apart is our end-to-end service model. We don’t outsource critical processes. From raw material selection and heat treatment to surface finishing and assembly, every step is controlled in-house at our ISO-certified facility in Wuxi, China. This vertical integration allows us to maintain consistent quality, reduce lead times, and respond quickly to design changes or urgent revisions. Whether you require a single prototype or a full production run of complex multi-cavity moulds, we deliver with speed, accuracy, and scalability.

Our clients trust us not only for our technical capabilities but also for our collaborative approach. We work closely with your engineering team to optimize part design for manufacturability, suggest cost-saving modifications, and ensure seamless integration with your existing production lines. This proactive partnership model minimizes risk, accelerates time-to-market, and reduces total production costs.

Below are the key technical specifications that define our manufacturing capabilities:

| Specification | Detail |

|---|---|

| Maximum Mould Size | 1200 mm × 800 mm × 1000 mm |

| Tolerance | ±0.005 mm |

| Materials Supported | P20, 718H, S136, NAK80, 420 Stainless Steel, Aluminum 7075 |

| Surface Finishes | Mirror polish (up to SPI A1), texture (VDI 3400), EDM finish |

| CNC Machines | 5-Axis, High-Speed Milling, Wire EDM, Sinker EDM |

| Quality Control | CMM, 3D Scanning, Optical Measuring Systems |

| Lead Time (Typical) | 25–45 days, depending on complexity |

Choosing the right plastic mould maker is a critical decision that impacts product quality, production efficiency, and long-term profitability. At Wuxi Lead Precision Machinery, we combine precision engineering, advanced technology, and a commitment to partnership to deliver moulds that exceed expectations.

Contact us today at [email protected] to discuss your next project. Let Lead Precision be your trusted partner in manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.