Technical Contents

Engineering Guide: Plastic Molding Service

Engineering Insight: The Critical Role of Precision in Plastic Molding Services

In high-performance industries such as aerospace, defense, and advanced medical systems, the demand for flawless plastic components is non-negotiable. At Wuxi Lead Precision Machinery, we understand that plastic molding service is not merely about shaping polymer materials—it is a science-driven process where micron-level precision determines functional reliability, safety, and long-term performance. Our expertise in custom metal manufacturing directly informs our approach to precision plastic molding, ensuring that every mold, core, and cavity is engineered to exacting standards before a single shot of resin is injected.

Precision in plastic molding begins with mold design. Even minor deviations in cavity dimensions, venting, or cooling channel layout can result in warpage, sink marks, or inconsistent wall thickness—defects that are unacceptable in mission-critical applications. Our engineering team leverages advanced simulation software and finite element analysis (FEA) to predict material behavior, optimize flow dynamics, and eliminate potential failure points prior to tool fabrication. This proactive approach reduces trial-and-error cycles and accelerates time to production, a capability proven through our contributions to Olympic-grade equipment and military-certified systems.

Our experience in serving high-reliability sectors has reinforced a fundamental truth: repeatability is as important as accuracy. A mold must produce identical parts across thousands of cycles under varying environmental conditions. To achieve this, we utilize hardened tool steels, precision EDM machining, and automated polishing techniques that ensure surface finishes down to 0.02 µm Ra. Each mold undergoes rigorous inspection using coordinate measuring machines (CMM) and laser scanning to validate dimensional integrity against CAD models.

Material selection is another pillar of precision molding. We work with engineering-grade thermoplastics—including PEEK, PPS, and ULTEM—known for their thermal stability, chemical resistance, and mechanical strength. These materials demand precise control over melt temperature, injection pressure, and cooling rates. Our all-electric molding platforms offer closed-loop process control, enabling shot-to-shot consistency within ±0.005 mm tolerance.

The integration of metal and plastic components further underscores the need for precision. In hybrid assemblies—common in sensors, connectors, and actuation systems—tight tolerances between dissimilar materials prevent stress concentration and ensure long-term reliability. Our in-house capabilities in CNC machining, insert molding, and overmolding allow seamless integration of metal inserts with thermoplastic housings, all under one controlled manufacturing environment.

The table below outlines key performance specifications achievable through our precision plastic molding service.

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.02 mm |

| Mold Material | H13, S136, 420 Stainless, P20+Ni Plating |

| Surface Finish | SPI A1 to SPI B3, VDI 18–24, custom textures |

| Part Weight Range | 0.1 g – 1,500 g |

| Injection Pressure | Up to 2,000 bar |

| Process Control | Closed-loop, real-time monitoring |

| Materials Supported | PEEK, PC, PPS, PA6/66, PBT, ULTEM, LCP |

With a proven track record in supporting Olympic technology systems and defense-grade hardware, Wuxi Lead Precision Machinery delivers plastic molding services where precision is not an objective—it is the standard.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Advanced Plastic Molding

Wuxi Lead Precision Machinery delivers the critical metal foundation for high-performance plastic molding operations. Our core expertise lies in manufacturing the precision-engineered metal components – including hardened steel molds, cores, cavities, and intricate inserts – that directly determine the quality, consistency, and complexity achievable in your plastic parts. We bridge the gap between mold design intent and flawless production reality through advanced metal fabrication, specifically tailored to the demanding requirements of the plastic molding industry. Our integrated approach ensures the metal tooling we produce meets the exacting dimensional and surface finish standards necessary for optimal molding performance, minimizing defects like flash, sink marks, or dimensional drift in your final plastic components.

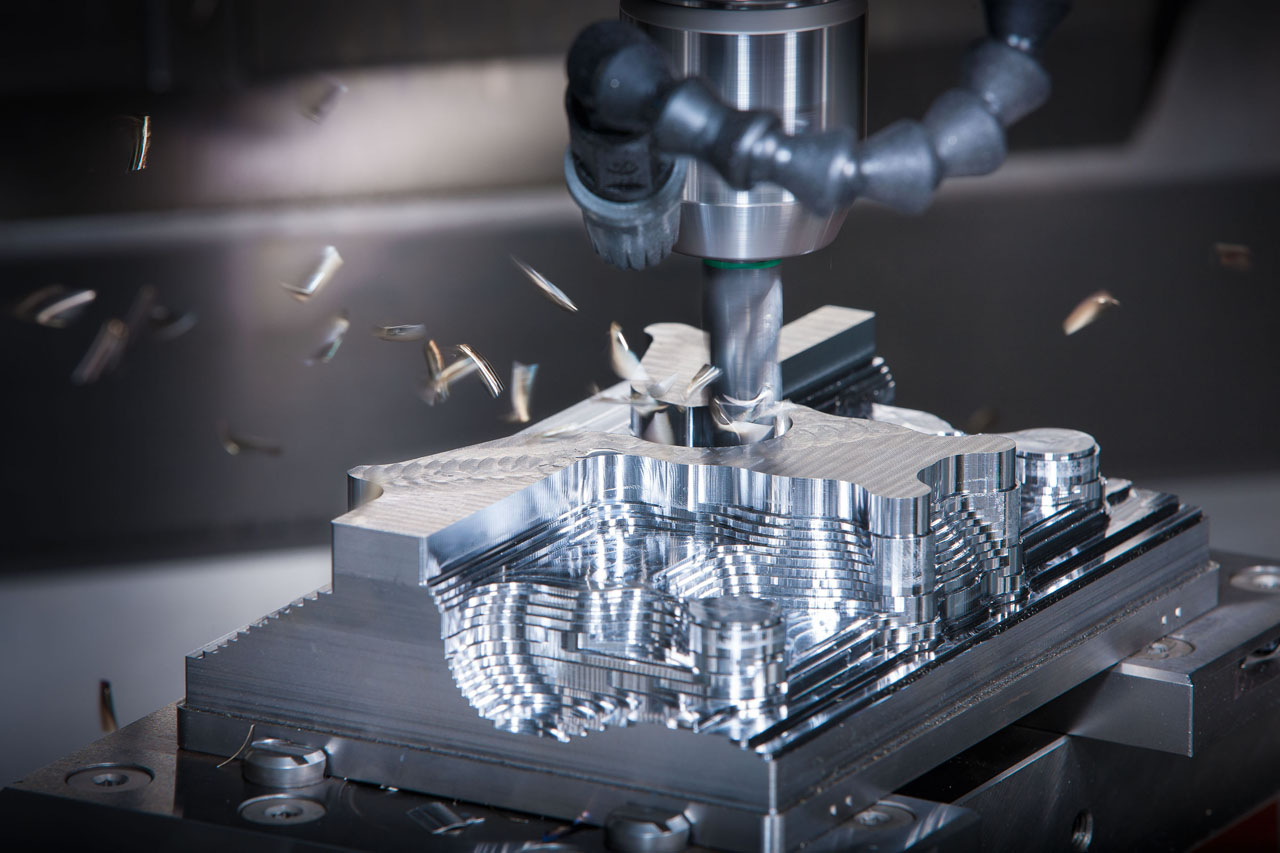

Central to our capability is a comprehensive fleet of state-of-the-art 5-axis CNC machining centers. These systems enable the simultaneous, multi-directional machining of complex geometries found in modern mold bases and cavities. This capability is essential for producing undercut-free parting lines, precise cooling channel contours, and intricate surface textures directly within hardened tool steels like P20, H13, and S136. The elimination of multiple setups inherent in 5-axis machining drastically reduces cumulative error, ensures superior positional accuracy between critical mold features, and significantly shortens lead times for complex tooling. We leverage this technology to machine molds with the internal precision required for consistent plastic flow, uniform cooling, and extended tool life under high-pressure injection cycles.

Rigorous quality control is non-negotiable. Every critical dimension on every mold component undergoes comprehensive verification using calibrated Coordinate Measuring Machines (CMM). Our CMM inspection process occurs in a temperature-controlled metrology lab, adhering strictly to ISO 10360 standards. We generate full inspection reports traceable to NIST standards, providing documented proof of conformance for all geometric features, including critical core/cavity matching, ejector pin bores, and alignment surfaces. This meticulous verification ensures the metal tooling arrives ready for immediate, trouble-free integration into your molding press, reducing setup time and preventing costly production delays caused by dimensional inaccuracies in the mold itself.

The precision we achieve in metal directly translates to the capability and yield of your plastic molding process. Our commitment to tight tolerances in the mold components is fundamental to producing plastic parts that meet your specifications consistently. The following table details the standard and achievable tolerance ranges for critical mold features we manufacture:

| Feature Type | Standard Tolerance (mm) | Tight Tolerance Option (mm) | Measurement Method | Typical Material |

|---|---|---|---|---|

| Core/Cavity Matching | ±0.01 | ±0.005 | CMM | P20, H13, S136 |

| Critical Dimensions | ±0.012 | ±0.008 | CMM | Hardened Steels |

| Ejector Pin Bores | H7 (0 / +0.015) | H6 (0 / +0.009) | CMM / Gauges | Pre-Hardened Steels |

| Surface Finish (Ra) | 0.4 µm | 0.2 µm | Profilometer | Polished Cavities |

| Alignment Surfaces | ±0.008 | ±0.005 | CMM | All Mold Bases |

This level of metal precision minimizes mold maintenance, reduces plastic part scrap rates, and ultimately lowers your total cost of ownership. Wuxi Lead Precision Machinery provides the engineered metal reliability that empowers your plastic molding success, ensuring your molds perform optimally from the first shot to the last.

Material & Finish Options

Material selection is a critical step in the design and production of high-performance molds for plastic molding services. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing, delivering precision-engineered solutions tailored to the specific demands of each application. The choice of mold material directly impacts tool life, part quality, production efficiency, and overall cost-effectiveness. Among the most widely used materials in our industry are aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum is often selected for low- to medium-volume production runs due to its excellent machinability and thermal conductivity. It allows for rapid prototyping and faster cycle times, making it ideal for development stages or short production cycles. However, aluminum’s lower hardness and wear resistance limit its use in high-volume applications. For molds requiring extended service life and durability, tool steel—particularly P20, H13, and S136 grades—is the preferred choice. Steel offers superior hardness, wear resistance, and the ability to maintain dimensional stability under repeated thermal cycling. It is especially suited for high-volume injection molding where surface finish and longevity are paramount.

Titanium, while less common in standard mold construction, is gaining traction in specialized applications where corrosion resistance, high strength-to-density ratio, and performance under extreme conditions are required. Its use is typically reserved for niche aerospace, medical, or high-performance automotive components, where the added cost is justified by performance demands.

Surface finishing processes further enhance mold performance and longevity. Anodizing is one of the most effective treatments for aluminum molds. By creating a thick, wear-resistant oxide layer on the surface, anodizing improves corrosion resistance, reduces friction, and increases surface hardness. Hard anodizing, in particular, can elevate aluminum’s surface hardness to levels approaching that of tool steel, significantly extending mold life in abrasive environments. For steel molds, alternative treatments such as nitriding or chrome plating are more commonly used, though anodizing remains a key solution for aluminum-based tooling.

The following table summarizes key mechanical and thermal properties of the three primary materials used in mold manufacturing:

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|---|

| Aluminum | 40–50 (anodized) | 300–500 | 160–220 | Moderate (improved with anodizing) | Prototyping, low-volume production |

| Steel | 48–54 | 900–1200 | 25–35 | High (especially stainless grades) | High-volume, precision molding |

| Titanium | 35–40 | 900–1100 | 7–10 | Excellent | Specialized, high-performance molds |

At Wuxi Lead Precision Machinery, we work closely with clients to select the optimal material and finish based on production requirements, environmental exposure, and cost targets. Our engineering team ensures every mold is built to deliver consistent performance, tight tolerances, and long service life.

Manufacturing Process & QC

Precision Metal Injection Molding: The Wuxi Lead Zero Defects Process

At Wuxi Lead Precision Machinery, we transform complex metal component requirements into flawless production realities through our rigorously controlled Metal Injection Molding (MIM) process. Unlike standard plastic molding, MIM leverages plastic-like processing for high-performance metal alloys, demanding exceptional precision at every stage. Our integrated workflow – from initial concept to high-volume delivery – is engineered for zero defects, ensuring your critical metal parts meet the most stringent aerospace, medical, and industrial specifications.

The foundation is meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with your designers using advanced simulation software to model material flow, predict shrinkage, and identify potential stress points before tooling begins. This proactive validation eliminates geometry-related failures early, optimizing part integrity and minimizing costly revisions. We focus on wall thickness transitions, gate placement, and ejection strategies specific to metal feedstocks, ensuring the design is inherently manufacturable to micron-level tolerances. This phase is non-negotiable for achieving zero defects in subsequent stages.

Prototyping utilizes production-intent tooling and actual MIM feedstock, not soft tooling or substitute materials. We produce functional prototypes under true process conditions, enabling rigorous mechanical and dimensional validation against your CAD model and performance criteria. Each iteration undergoes our full suite of metrology – including CMM, optical comparators, and metallurgical analysis – providing actionable data to refine the process window. This authentic prototyping phase is where theoretical designs prove their manufacturability, catching subtle issues that virtual models alone cannot reveal, directly preventing mass production defects.

Mass production operates within a closed-loop quality ecosystem. Our automated MIM presses are monitored in real-time for critical parameters like injection pressure, temperature profiles, and cycle time. Statistical Process Control (SPC) charts trigger immediate adjustments, maintaining the validated process window. Crucially, 100% automated vision inspection systems scan every part for surface defects, dimensional outliers, and critical features, rejecting non-conforming units before further processing. Full material traceability, from alloy batch to finished part, combined with rigorous final inspection against your first-article approval, guarantees statistically validated zero-defect output. Process capability (Cpk) is continuously measured and reported.

Wuxi Lead MIM Production Specifications

| Parameter | Capability | Typical Lead Time | Key Quality Control Method |

|---|---|---|---|

| Tolerance Range | ±0.005mm to ±0.1mm (geometry dependent) | 15-30 Days (Production) | CMM, Optical Comparator, Vision |

| Materials | 17-4PH, 316L, 304L, 420, 4605, Custom Alloys | Spectrographic Analysis, Density | |

| Part Weight Range | 0.1g to 200g | Precision Scale, Dimensional | |

| Surface Finish | As-molded Ra 1.6µm; Polished options | Surface Profilometer, Visual | |

| Production Volume | 10,000 to 1,000,000+ pcs | 100% Automated Vision Inspection |

This seamless integration of design foresight, production-realistic prototyping, and statistically controlled mass manufacturing is how Wuxi Lead delivers true zero-defect metal components. We don’t just meet specifications; we build quality into the process, ensuring your supply chain operates with absolute confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Plastic Molding Services in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision plastic molding services tailored to the rigorous demands of modern industrial applications. As a trusted name in custom metal manufacturing based in Wuxi, China, we integrate advanced molding technologies with decades of engineering expertise to deliver components that meet exacting specifications. Our clients across aerospace, automotive, medical devices, and industrial automation rely on us for consistent quality, rapid turnaround, and scalable production capabilities.

Our plastic molding services are designed to complement complex metal fabrication processes, enabling seamless integration of plastic and metal components in mission-critical assemblies. Whether you require overmolding, insert molding, or precision two-shot molding, our state-of-the-art facilities are equipped with high-tonnage presses, cleanroom environments, and real-time process monitoring systems. We work with a broad range of engineering-grade thermoplastics, including PEEK, PPS, PC, PBT, and nylon, ensuring material compatibility with thermal, chemical, and mechanical performance requirements.

What sets Wuxi Lead Precision Machinery apart is our end-to-end engineering support. From initial design consultation and DFM analysis to mold flow simulation and final inspection, our team collaborates closely with clients to optimize part geometry, reduce cycle times, and eliminate production risks. We maintain ISO 9001 and IATF 16949 certifications, underscoring our commitment to quality management and process control in every project.

Our global clients choose us not only for technical excellence but also for reliability and transparency. We provide full traceability, comprehensive reporting, and responsive communication throughout the production lifecycle. With in-house tooling design and rapid prototyping capabilities, we accelerate time-to-market without compromising precision or repeatability.

For high-mix, low-volume, or high-volume production runs, our facility supports annual outputs ranging from 10,000 to over 5 million units, with tight tolerances down to ±0.005 mm. Our strategic location in China’s industrial heartland ensures cost efficiency, while our export experience guarantees seamless logistics to North America, Europe, and Southeast Asia.

Below are key capabilities of our plastic molding service:

| Specification | Detail |

|---|---|

| Molding Press Capacity | 50 to 1,200 tons |

| Tolerance Range | ±0.005 mm to ±0.02 mm |

| Material Compatibility | PEEK, PPS, PC, PBT, Nylon, ABS, PP, PE, TPU |

| Maximum Part Weight | 800 grams |

| Production Volume | 10,000 to 5,000,000+ units/year |

| Secondary Operations | Insert molding, ultrasonic welding, CNC trimming, laser marking |

| Quality Standards | ISO 9001, IATF 16949, RoHS compliant |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally committed to innovation, precision, and long-term success. To discuss your next project or request a quote, contact us today at [email protected]. Let us bring your most demanding plastic molding challenges to life with engineering excellence and unwavering reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.