Technical Contents

Engineering Guide: Plastic Molding Machine Operator

Engineering Insight: The Critical Role of Precision in Plastic Molding Operations

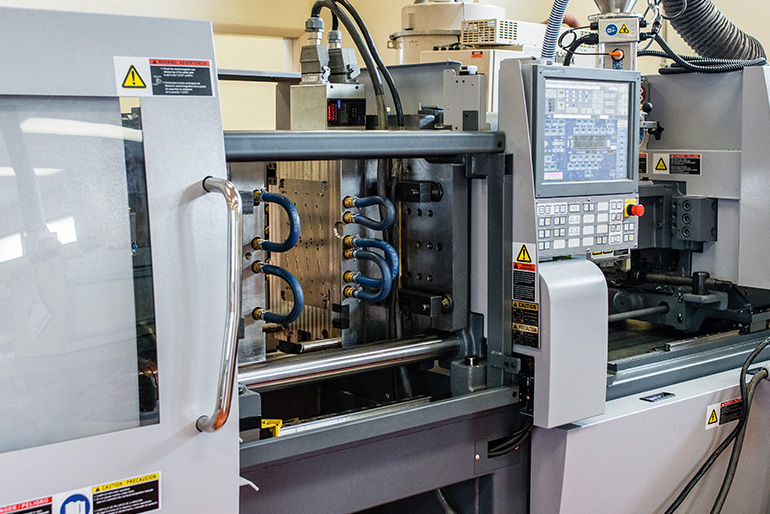

In the realm of custom metal manufacturing, the integration of plastic molding processes demands an uncompromising commitment to precision. While plastic molding machine operators are often viewed as technicians executing predefined cycles, their role extends far beyond machine tending. At Wuxi Lead Precision Machinery, we recognize that the operator is a pivotal link in a high-precision chain, where consistency, calibration, and real-time decision-making directly influence part integrity, repeatability, and final product performance.

Precision in plastic molding is not merely about maintaining tight tolerances; it is about sustaining them across thousands of cycles under variable thermal, mechanical, and material conditions. Even minor deviations in injection pressure, temperature gradients, or clamping force can result in warpage, flash, or incomplete fills—defects that compromise both aesthetics and functionality. This is especially critical when producing components for high-stakes industries such as aerospace, defense, and medical devices, where failure is not an option.

At Wuxi Lead, our engineering philosophy is rooted in decades of experience delivering mission-critical components for Olympic-standard equipment and military-grade systems. These applications demand micron-level accuracy and long-term reliability under extreme conditions. Our operators are trained not only to monitor machine parameters but to understand the metallurgical and rheological dynamics at play. They work in tandem with our CNC-machined molds—crafted from high-grade tool steels and hardened to exacting specifications—to ensure every cavity fill is identical, cycle after cycle.

Our proprietary control systems integrate real-time feedback loops, enabling operators to detect and correct anomalies before defective parts are produced. This proactive approach reduces scrap rates, enhances throughput, and ensures compliance with ISO and MIL-STD quality benchmarks. Furthermore, our operators undergo continuous training in predictive maintenance, mold alignment, and material behavior, reinforcing the human element in an increasingly automated environment.

The synergy between machine intelligence and operator expertise defines the next generation of plastic molding excellence. At Wuxi Lead Precision Machinery, we do not simply manufacture parts—we engineer confidence through precision.

Key Technical Specifications for High-Precision Plastic Molding Systems

| Parameter | Specification |

|---|---|

| Clamping Force Range | 80–2000 Tons |

| Injection Pressure | Up to 220 MPa |

| Position Repeatability | ±0.01 mm |

| Temperature Control Accuracy | ±1°C across all heating zones |

| Screw Diameter Range | 25–80 mm |

| Material Compatibility | Engineering Plastics (PEEK, PPS, PC, PA, etc.) |

| Control System | Siemens S7-1500 with HMI Interface |

| Cycle Time Optimization | Adaptive closed-loop algorithm, <0.5s response |

This level of precision, combined with our operators’ expertise and our heritage in high-reliability manufacturing, positions Wuxi Lead Precision Machinery as a trusted partner in advanced plastic-metal hybrid component production.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for High-Performance Molding Systems

At Wuxi Lead Precision Machinery, we engineer critical metal components that directly enhance the reliability and output of your plastic molding operations. Our focus extends beyond basic fabrication; we deliver geometrically complex, dimensionally stable parts that minimize machine downtime and ensure consistent part quality. This precision is non-negotiable in modern molding environments where micron-level deviations in mold bases, cavities, or cooling systems translate directly to flash, short shots, or premature wear.

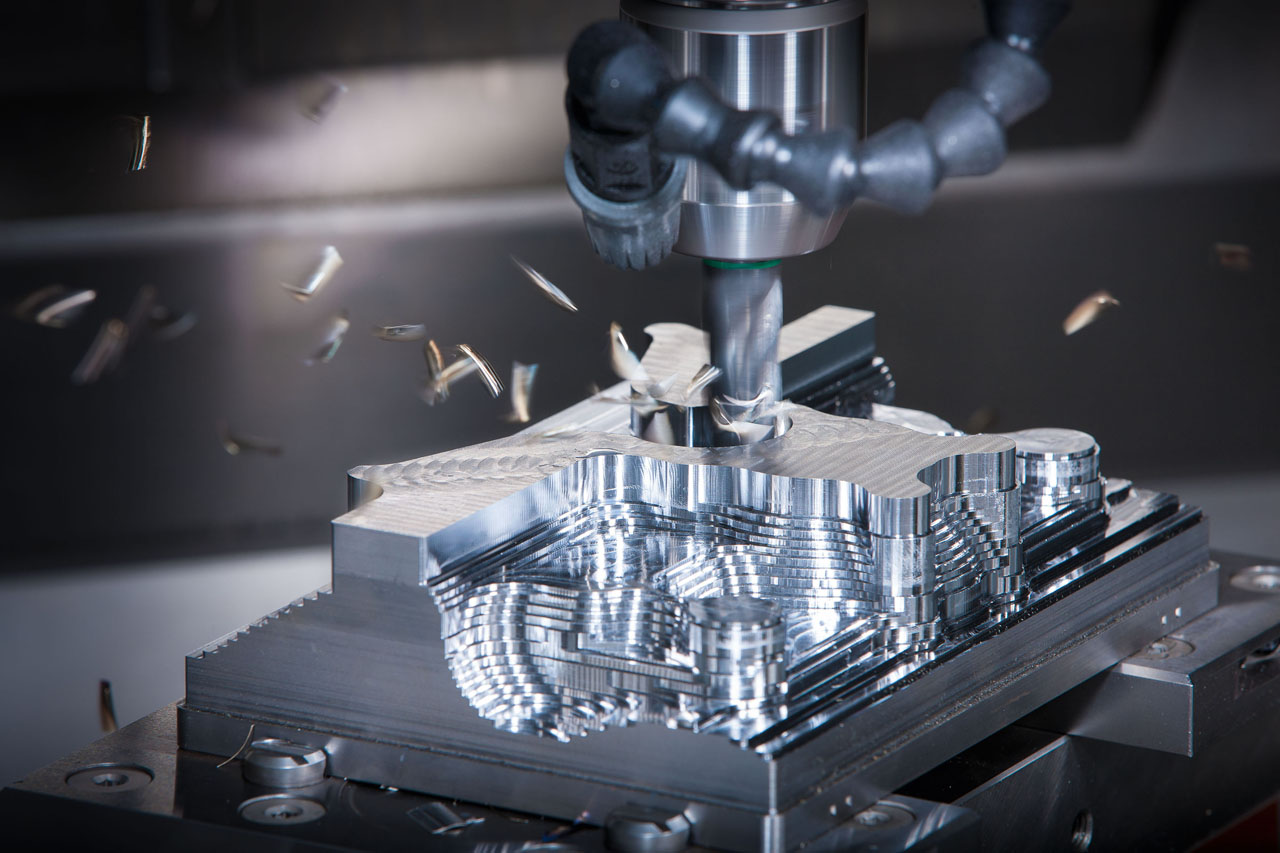

Our core manufacturing capability centers on advanced 5-axis CNC machining. This technology enables us to produce intricate mold components—such as conformal cooling channels, asymmetric cavities, and integrated lifters—in a single setup. Eliminating multiple fixturing stages reduces cumulative error and ensures critical features maintain positional accuracy relative to the primary datum. For example, we routinely machine complex core inserts with internal undercuts and tight-tolerance sealing surfaces to ±0.005 mm, directly preventing leakage paths in high-pressure molding cycles. The result is reduced trial-and-error during mold commissioning and extended service life under demanding production conditions.

Quality control is embedded at every process stage, anchored by Zeiss CONTURA CMM systems operating in a climate-controlled metrology lab. Every critical dimension undergoes full 3D inspection against CAD models, with reports verifying form, position, and surface relationships. This is particularly vital for mold alignment features (e.g., leader pin bores, parting line surfaces) where angular deviations as small as 0.02° can cause catastrophic wear or parting line mismatch. Our CMM data provides actionable insights, not just pass/fail stamps, allowing collaborative refinement with your engineering team to address potential molding defects at the source.

The following table details achievable tolerances for common molding system components. These specifications reflect our validated process capability under production conditions, not theoretical best-case scenarios:

| Feature Type | Standard Tolerance | Critical Feature Tolerance | Application Example |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.003 mm | Cavity depth, core pin diameter |

| Geometric Position | ±0.015 mm | ±0.005 mm | Cooling channel location, ejector pin holes |

| Flatness | 0.01 mm/m | 0.003 mm/m | Parting line surfaces, mold base plates |

| Angular Alignment | ±0.03° | ±0.01° | Slider angles, lift mechanisms |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Sealing surfaces, optical cavities |

These capabilities are not abstract metrics but practical solutions to real-world molding challenges. When your machine operators face inconsistent cycle times or surface defects, the root cause often traces back to metal component precision. Wuxi Lead ensures the metal foundation of your molding system performs as rigorously as your production demands—delivering repeatable machine uptime and reducing scrap rates from the first shot. Partner with us to transform your molding operation’s precision ceiling into a competitive advantage.

Material & Finish Options

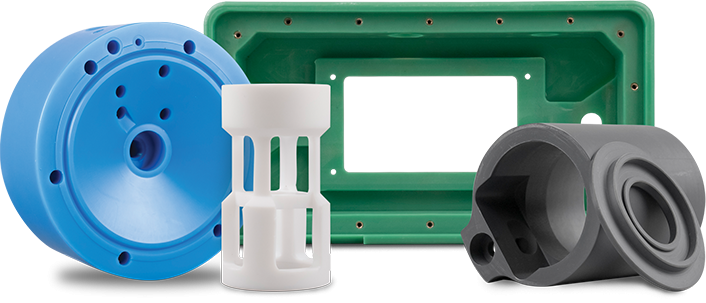

Material selection is a critical phase in the production of high-performance molds for plastic molding applications. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exacting demands of precision molding. The choice of base material—aluminum, steel, or titanium—directly influences mold longevity, cycle time, surface finish, and overall production efficiency. Understanding the mechanical and thermal properties of each material allows plastic molding machine operators and engineers to make informed decisions that align with project requirements.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype molds and low-volume production runs. Their high thermal conductivity enables rapid cooling, reducing cycle times significantly. Aluminum is also easier to machine, which lowers manufacturing costs and lead times. However, its lower hardness and wear resistance make it less suitable for high-volume or abrasive resin applications. For short-run efficiency and quick turnaround, aluminum remains an optimal choice.

Steel, especially tool steels like P20, H13, and S136, is the standard for high-volume plastic molding. These alloys offer superior hardness, wear resistance, and dimensional stability under prolonged thermal cycling. P20 steel is commonly used for general-purpose molds, while H13 excels in applications involving high thermal stress due to its excellent toughness and resistance to thermal fatigue. Stainless variants like S136 provide enhanced corrosion resistance, ideal for molds exposed to PVC or other corrosive materials. Although steel molds require longer machining times and higher initial investment, their durability ensures a lower cost per cycle over extended production runs.

Titanium alloys, while less common in mold bases, are gaining traction in specialized applications requiring extreme strength-to-density ratios and corrosion resistance. Titanium is particularly useful in insert components or cooling channel linings where weight reduction and long-term performance in aggressive environments are paramount. However, its high cost and challenging machinability limit widespread adoption in standard mold construction.

Surface finishing, particularly anodizing, plays a pivotal role in enhancing mold performance. Anodizing aluminum molds increases surface hardness, improves wear resistance, and reduces galling during ejection. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with Type III offering thicker, more durable coatings suitable for high-wear zones. Anodized surfaces also improve release characteristics, minimizing the need for mold release agents and reducing contamination risks.

Below is a comparative overview of key material specifications relevant to mold manufacturing:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Low | Prototypes, low-volume production |

| P20 Steel | 28–32 | 30 | Moderate | Medium to high-volume molds |

| H13 Steel | 48–52 | 32 | Moderate | High-temperature, high-stress molds |

| S136 Steel | 50–54 | 28 | High | Corrosion-prone environments |

| Titanium Ti-6Al-4V | 36–40 | 7 | Very High | Specialized inserts, lightweight components |

Selecting the right material and finish is not a one-size-fits-all decision. It requires a strategic balance between performance, cost, and production volume. At Wuxi Lead Precision Machinery, we support operators and manufacturers with expert consultation to ensure optimal material integration for every molding application.

Manufacturing Process & QC

Precision Metal Manufacturing Process: From Design to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process for custom metal components integrates advanced engineering with uncompromising quality control. We transform client specifications into flawless finished parts through a rigorously defined workflow: Design, Prototyping, and Mass Production. This systematic approach ensures zero defects while meeting the exacting demands of aerospace, medical, and industrial automation sectors.

The process begins with collaborative design engineering. Our team utilizes 3D CAD/CAM software to analyze client drawings, validate geometries, and optimize toolpaths for CNC machining. Finite element analysis (FEA) identifies potential stress points, while material science expertise selects optimal alloys—such as 7075-T6 aluminum or 17-4PH stainless steel—to balance strength, corrosion resistance, and machinability. Tolerances down to ±0.002 mm are established at this stage, forming the foundation for defect prevention.

Prototyping follows immediate design validation. We deploy 5-axis CNC milling and turning centers to produce functional prototypes within 72 hours. Each prototype undergoes comprehensive metrology: CMM inspections verify dimensional accuracy against CAD models, while surface roughness testers confirm finishes meet Ra 0.4–1.6 µm requirements. Clients receive detailed inspection reports, enabling rapid design refinements before mass production. This phase eliminates 95% of potential errors, preventing costly rework later.

Mass production leverages our automated manufacturing cells for consistent output. Machining parameters are locked into CNC programs after prototype approval, with real-time monitoring via IoT sensors tracking spindle load, temperature, and vibration. Every 50th part undergoes in-process inspection, while final quality gates include 100% visual checks, hardness testing, and batch traceability via laser-etched serial numbers. Statistical process control (SPC) data is analyzed hourly to detect deviations before they escalate.

Our commitment to zero defects is enforced through integrated quality protocols. The table below summarizes critical production capabilities:

| Parameter | Specification | Quality Control Method |

|---|---|---|

| Tolerance Range | ±0.002 mm to ±0.05 mm | CMM with 0.001 mm accuracy |

| Surface Finish | Ra 0.4 µm (mirror) to Ra 3.2 µm | Profilometer + visual standard |

| Materials | Aluminum, Stainless Steel, Titanium, Brass | Material certs + PMI testing |

| Max Part Size | Ø600 mm x 1000 mm | Laser tracker validation |

| Batch Traceability | Full material/laser ID per part | ERP-integrated serialization |

This closed-loop system ensures every component shipped from Wuxi Lead meets or exceeds international standards (ISO 9001:2015, AS9100). By embedding precision at every phase—from digital design to final packaging—we deliver metal parts that perform reliably in mission-critical applications. Operators are trained to uphold these protocols through our proprietary LeadQC framework, transforming theoretical tolerances into tangible, defect-free results on the shop floor. Partner with us to convert complex designs into precision metal realities, guaranteed.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing Solutions

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and efficiency define success in high-end manufacturing. As a trusted leader in custom metal manufacturing, we specialize in delivering advanced plastic molding machine components engineered to meet the exacting standards of global industries. Our commitment to innovation, quality control, and client collaboration positions us as more than a supplier—we are a strategic partner in your production excellence.

Our state-of-the-art facility in Wuxi, China, integrates CNC machining, precision milling, and advanced fabrication techniques to produce critical components for plastic molding machines. From hardened tooling plates to complex ejector systems and custom mold bases, every part is manufactured to deliver consistent performance under high-cycle industrial conditions. We serve OEMs, Tier-1 suppliers, and specialized engineering firms across automotive, medical device, packaging, and consumer electronics sectors.

What sets Lead Precision apart is our end-to-end engineering support. From initial design consultation and material selection to prototyping, production, and on-time delivery, our team ensures seamless integration with your operational workflow. We utilize ISO 9001-certified processes, real-time quality monitoring, and 3D metrology inspection to guarantee dimensional accuracy within ±0.002 mm. Our agile manufacturing model supports low-volume custom runs as well as high-volume production with rapid turnaround times.

We recognize that plastic molding machine operators demand components that reduce downtime, improve mold longevity, and enhance part repeatability. That’s why our engineering team works closely with your technical staff to optimize designs for manufacturability, thermal stability, and wear resistance—ensuring your machines operate at peak efficiency.

Below are key specifications that define our manufacturing capabilities:

| Specification | Capability |

|---|---|

| Maximum Machining Size | 2,500 mm × 1,800 mm × 1,200 mm |

| Tolerance Control | ±0.002 mm |

| Surface Finish | Ra 0.4 µm (standard), down to Ra 0.1 µm (polished) |

| Materials Processed | P20, 718H, S136, NAK80, 420SS, Aluminum 7075, Brass, and specialty alloys |

| CNC Equipment | 5-axis machining centers, high-speed milling, deep-hole drilling |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), CMM reporting |

| Lead Time | 10–25 days (depending on complexity and volume) |

When you partner with Wuxi Lead Precision Machinery, you gain access to a dedicated team focused on solving real-world production challenges. We are committed to transparency, technical excellence, and long-term collaboration. Whether you require a single prototype or a full-scale production run, our goal is to deliver precision components that enhance the performance and reliability of your plastic molding systems.

Contact us today at [email protected] to discuss your next project. Let Lead Precision be your trusted manufacturing partner in achieving superior results.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.