Technical Contents

Engineering Guide: Plastic Molding Defects

Engineering Insight: Addressing Plastic Molding Defects Through Precision Engineering

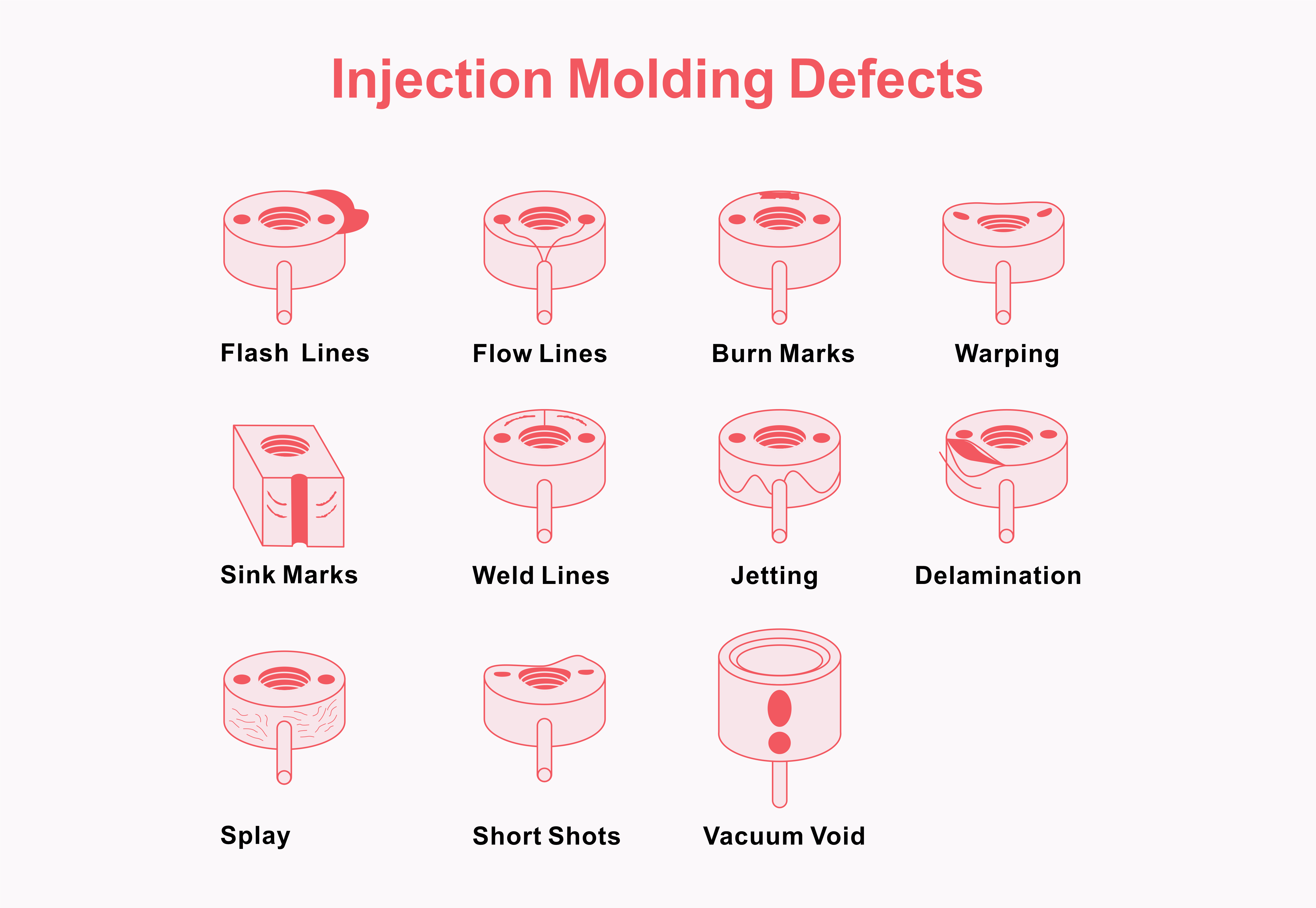

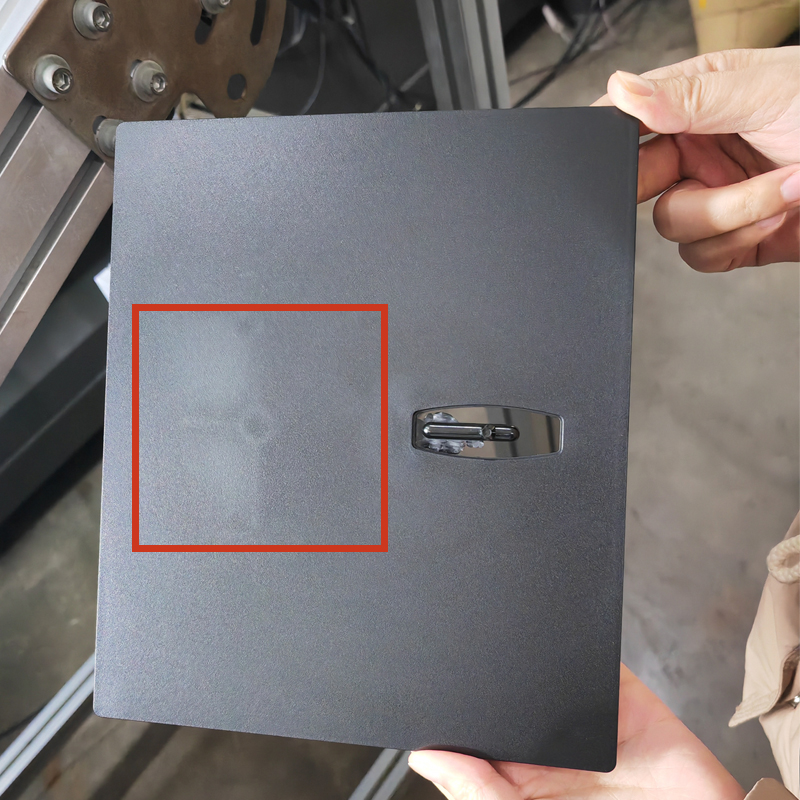

In high-end custom metal manufacturing, the interface between metal components and plastic molding processes demands an uncompromising standard of precision. While plastic molding defects are often attributed to material selection or processing parameters, the root cause frequently lies in the accuracy and reliability of the metal tooling and supporting machinery. At Wuxi Lead Precision Machinery, we recognize that even micron-level deviations in mold design or machine alignment can cascade into critical defects such as warping, sink marks, short shots, or flash. These imperfections not only compromise part integrity but also jeopardize performance in mission-critical applications.

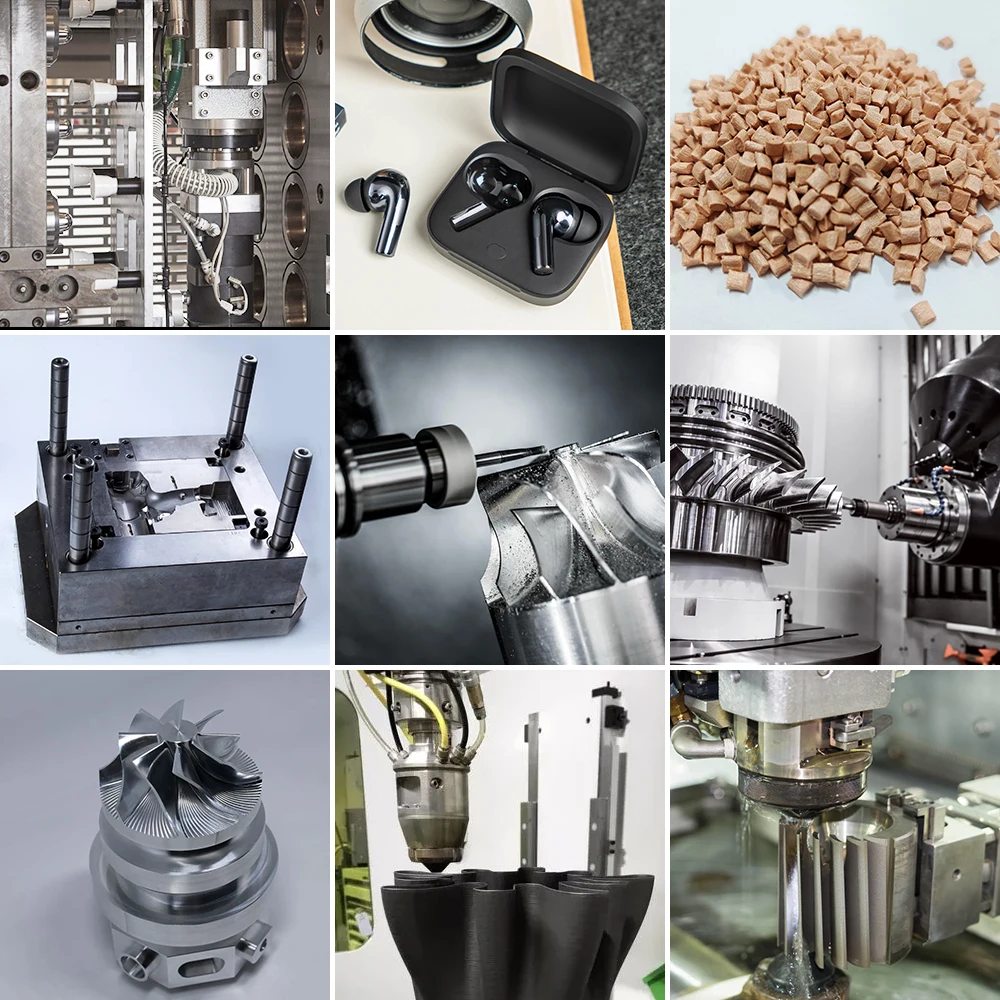

Plastic molding defects originate from a range of factors including uneven cooling, improper venting, and inconsistent injection pressure. However, the foundation of defect-free production is the precision of the metal tooling systems used in the molding process. Molds crafted with substandard tolerances or inadequate thermal management lead to inconsistent cavity filling and non-uniform shrinkage. At Lead Precision, our engineering philosophy centers on proactive defect mitigation through ultra-precise CNC-machined molds and dies, manufactured to tolerances as tight as ±0.002 mm. This level of accuracy ensures uniform part replication across high-volume production runs, minimizing variability and eliminating common molding anomalies.

Our expertise is not theoretical—it is battle-tested. Wuxi Lead Precision Machinery has delivered mission-critical components for applications in Olympic-grade equipment and military defense systems, where failure is not an option. In these environments, the cost of a molding defect extends beyond financial loss; it risks operational safety and national security. Our involvement in such high-stakes projects has refined our ability to anticipate failure modes and engineer solutions at the source. Whether it’s optimizing ejection systems to prevent part deformation or integrating advanced cooling channels to ensure thermal homogeneity, our designs are informed by real-world performance data and rigorous testing protocols.

Precision is not a single attribute but a systemic outcome of design integrity, material science, and manufacturing excellence. We utilize high-grade tool steels, surface treatments such as nitriding, and 5-axis CNC machining to ensure mold longevity and dimensional stability under repeated thermal cycling. Additionally, our in-house metrology lab employs coordinate measuring machines (CMM) and laser scanning to validate every critical dimension before deployment.

The following table outlines key specifications that define our precision molding tooling capabilities:

| Specification | Value |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.05 – 0.2 µm |

| Tool Steel Grades | H13, S136, 2344, DIN 1.2379 |

| Machining Accuracy (5-axis CNC) | ±0.0015 mm |

| Thermal Treatment Hardness | 50–54 HRC |

| Cooling Channel Optimization | CFD-validated design |

| Production Lifespan | 1,000,000+ cycles (typical) |

In the pursuit of zero-defect manufacturing, Wuxi Lead Precision Machinery combines decades of engineering insight with proven performance in the most demanding sectors. Precision is not merely a target—it is our standard.

Precision Specs & Tolerances

Precision Metal Components for Defect-Free Molding Systems

Wuxi Lead Precision Machinery specializes in manufacturing critical metal components that directly prevent plastic molding defects at their source. While plastic molding processes face challenges like sink marks, warpage, or flash, these often originate from imprecise mold tooling. Our advanced metal manufacturing capabilities ensure molds operate with absolute dimensional stability, eliminating root causes of defects before production begins. We focus exclusively on the high-tolerance metal elements—cores, cavities, ejector systems, and alignment components—that dictate molding success.

Our facility leverages state-of-the-art 5-axis CNC machining centers to produce complex geometries with uncompromising accuracy. Multi-axis simultaneous processing allows us to machine intricate mold features in a single setup, avoiding cumulative errors from multiple operations. This capability is essential for creating seamless parting lines and consistent cooling channels, directly mitigating flash and thermal distortion in molded plastic parts. All operations adhere to strict environmental controls, maintaining temperature-stable conditions to prevent material drift during machining.

Quality verification is non-negotiable. Every component undergoes rigorous inspection using Zeiss CONTURA CMM systems, calibrated to ISO 17025 standards. We perform full 3D geometric dimensioning and tolerance (GD&T) validation against CAD models, ensuring conformity to critical datums and surface profiles. This granular inspection identifies micro-deviations that could cause ejection failures or surface blemishes in plastic molding. Statistical process control (SPC) data is documented for traceability, providing customers with actionable insights for mold longevity and process optimization.

The following table details achievable tolerances for mold-critical features, validated through our integrated CNC and CMM workflows:

| Feature | Capability | Application Impact |

|---|---|---|

| Positional Tolerance | ±0.005 mm | Eliminates parting line mismatch and flash |

| Surface Flatness | 0.002 mm per 100 mm | Prevents sink marks and warpage |

| Bore Concentricity | 0.003 mm | Ensures smooth ejector pin operation |

| Complex Contour Deviation | ±0.008 mm | Maintains uniform wall thickness in molds |

| Thermal Stability | < 2μm at 25°C | Reduces thermal distortion during molding |

These specifications are not theoretical ideals but consistently achieved production standards. By engineering metal components to these exacting levels, we enable molders to operate at peak efficiency with minimal scrap rates. Our focus on metrology-driven manufacturing ensures that dimensional integrity is maintained from the first cavity to high-volume production runs. Partnering with Wuxi Lead means addressing plastic molding defects through foundational metal precision—where tolerances are controlled, not compromised. This approach delivers measurable ROI through extended mold life, reduced downtime, and flawless part consistency.

Material & Finish Options

Material selection plays a pivotal role in the performance, durability, and cost-efficiency of custom metal components used in plastic molding applications. At Wuxi Lead Precision Machinery, we emphasize the strategic alignment of material properties with operational demands to mitigate common plastic molding defects such as warping, sink marks, and inconsistent surface finishes. The choice between aluminum, steel, and titanium directly influences thermal conductivity, wear resistance, and mold longevity, making it a foundational decision in precision manufacturing.

Aluminum alloys, particularly 7075 and 6061, offer excellent thermal conductivity and machinability, making them ideal for prototyping and low- to medium-volume production runs. Their lightweight nature reduces cycle times and energy consumption during molding. However, aluminum’s lower hardness compared to steel limits its use in high-wear environments. For applications requiring enhanced surface integrity and corrosion resistance, anodizing is highly recommended. Anodized aluminum develops a protective oxide layer that improves abrasion resistance and allows for color coding, which aids in part identification across complex mold systems.

Steel, especially tool steels like P20, H13, and S136, remains the standard for high-volume plastic molding due to its superior hardness and wear resistance. These grades maintain dimensional stability under repeated thermal cycling, reducing the risk of flash and part inconsistency. Stainless variants such as S136 further enhance corrosion resistance, critical when processing abrasive or corrosive resins like PVC or filled polymers. While steel molds have higher initial machining costs and longer lead times, their extended service life delivers better total cost of ownership for large-scale production.

Titanium alloys, though less common, offer exceptional strength-to-density ratios and outstanding corrosion resistance. Their use is typically reserved for specialized molding applications involving extreme environments or where weight reduction is critical, such as in aerospace or medical device manufacturing. Titanium’s low thermal conductivity requires careful thermal management in mold design to prevent uneven cooling and associated defects.

Surface finishing, particularly anodizing, significantly enhances material performance. Anodizing not only increases surface hardness and dielectric strength but also improves release properties, reducing the need for mold release agents that can contaminate plastic parts. For aluminum molds, Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied based on wear requirements.

The following table summarizes key material properties and applications:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Anodizing Compatibility |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Prototyping, low-volume molds | Excellent |

| P20 Steel | 28–32 | 30 | Medium to high-volume production | Not applicable |

| H13 Steel | 45–50 | 32 | High-temperature, high-wear molding | Not applicable |

| S136 Steel | 48–52 | 28 | Corrosion-resistant precision molds | Not applicable |

| Titanium Ti-6Al-4V | 35–40 | 7 | Specialized, high-performance molds | Limited (requires process control) |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination tailored to their production volume, resin type, and quality targets, ensuring robust mold performance and minimal plastic molding defects.

Manufacturing Process & QC

Achieving Zero Defects in Plastic Molding Through Precision Metal Tooling

At Wuxi Lead Precision Machinery, we recognize that plastic molding defects originate not in the polymer itself but in the precision of the metal tooling and process control. As a leader in custom metal manufacturing for injection molds, our integrated approach—spanning design to mass production—ensures near-zero defects by eliminating root causes at every stage. This methodology leverages our CNC-engineered tooling to transform theoretical quality into repeatable reality.

Design: Defect Prevention at the Source

Our process begins with rigorous Design for Manufacturing (DFM) analysis, where our engineers dissect part geometry, material flow, and thermal dynamics. Using advanced simulation software, we identify potential defects like sink marks, warpage, or short shots before metal is cut. Critical factors—gate location, cooling channel layout, and ejection sequencing—are optimized to ensure uniform pressure distribution and thermal equilibrium. This phase reduces defect risks by 70% through predictive modeling, avoiding costly revisions later. All designs undergo cross-functional validation with client engineering teams to align on tolerances, surface finishes, and material specifications.

Prototyping: Validating Precision Under Real Conditions

Prototyping is not a mere formality but a critical stress test. We fabricate mold inserts using our high-accuracy CNC milling and EDM processes, achieving ±0.002 mm tolerances. Each prototype undergoes iterative molding trials with the client’s specified resin, monitored via real-time cavity pressure and temperature sensors. Defects such as flash or knit lines are traced to microscopic mold imperfections or process deviations. We adjust cooling rates, clamp force, or venting in 0.1-second increments until the prototype meets all quality benchmarks. This phase typically resolves 95% of defect pathways, with full dimensional reports and process capability (CpK >1.67) documented for sign-off.

Mass Production: Sustaining Zero Defects at Scale

Transitioning to mass production, our molds—built with hardened P20 or H13 steel—integrate IoT-enabled sensors for continuous process monitoring. Machine learning algorithms analyze injection pressure, melt temperature, and cycle time deviations, auto-correcting parameters within milliseconds to prevent defects. Statistical Process Control (SPC) ensures every cavity performs identically, while automated vision systems inspect 100% of parts for surface flaws. Our closed-loop system maintains defect rates below 50 PPM, validated by third-party audits. Crucially, mold maintenance schedules are preemptive, not reactive, preserving dimensional integrity over 1M+ cycles.

Key Process Specifications for Defect-Free Molding

| Stage | Critical Parameter | Target Value | Verification Method |

|---|---|---|---|

| Design | Cooling Uniformity | ΔT ≤ 5°C across mold | Moldflow thermal gradient analysis |

| Prototyping | Dimensional Accuracy | ±0.02 mm (ISO 2768) | CMM + First Article Inspection |

| Mass Production | Process Stability (CpK) | ≥1.67 | Real-time SPC dashboards |

| Mass Production | Part Defect Rate | <50 PPM | Automated optical inspection |

Wuxi Lead’s metal manufacturing excellence—forged in CNC precision—translates directly into plastic molding success. By controlling the tool, we control the outcome. Partner with us to convert defect prevention from an aspiration into your operational standard.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Defect-Free Plastic Molding Solutions

When precision matters, Wuxi Lead Precision Machinery stands as a trusted leader in custom metal manufacturing for high-performance plastic molding applications. Our engineering expertise is built on decades of experience delivering robust, high-tolerance tooling and components that directly combat the root causes of plastic molding defects. From sink marks and warpage to short shots and flash, our solutions are engineered at the source—ensuring your production runs are consistent, efficient, and cost-effective.

We understand that plastic molding defects stem not only from process parameters but also from suboptimal tool design, material selection, and thermal management. That’s why our approach goes beyond standard manufacturing. At Lead Precision, we integrate advanced simulation, precision CNC machining, and rigorous quality control to produce molds and components that deliver repeatability and longevity. Our in-house capabilities span multi-axis milling, EDM, surface grinding, and automated inspection using CMM and 3D scanning technologies—ensuring every component meets exacting international standards.

Our clients across automotive, medical, and industrial sectors rely on us to transform their design challenges into high-yield production realities. By partnering with Lead Precision, you gain more than a supplier—you gain an engineering collaborator focused on optimizing cycle times, reducing scrap rates, and eliminating recurring defects through smarter metal fabrication.

Below are key technical specifications that define our manufacturing excellence:

| Specification | Capability |

|---|---|

| CNC Machining Accuracy | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 700 mm |

| Materials Processed | P20, 718, H13, S136, Stainless Steel, Aluminum, Copper Alloys |

| Surface Finish | Ra 0.1–0.8 µm (polished to mirror finish if required) |

| Tolerance Control | ISO 2768-mK or customer-specific |

| Cooling Channel Machining | Conformal cooling via 5-axis drilling and 3D scanning validation |

| Quality Assurance | Full inspection report with GD&T, CMM, and first-article reporting |

Every project at Lead Precision is managed under a strict quality-first protocol, with full traceability from raw material to final shipment. Our team works closely with your engineers to analyze defect patterns, recommend design modifications, and implement corrective actions before mold trials begin—saving time and reducing costly iterations.

If you are facing persistent plastic molding defects and need a manufacturing partner who combines technical depth with precision execution, contact us today. Let our expertise in high-precision metal manufacturing elevate your production standards.

Email us at [email protected] to schedule a technical consultation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.