Technical Contents

Engineering Guide: Plastic Molder

Engineering Insight: The Critical Role of Precision in Plastic Molding

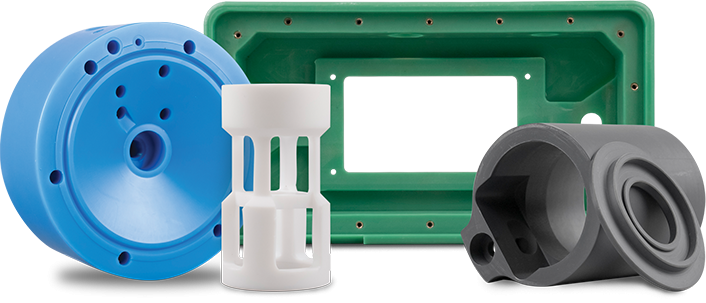

In high-performance manufacturing, plastic molding is far more than a shaping process—it is a precision engineering discipline. The integrity, functionality, and longevity of a molded component depend not only on material selection but on the exactness of tooling, tolerances, and process control. At Wuxi Lead Precision Machinery, we treat plastic molding as an extension of advanced metal manufacturing, where micron-level accuracy in mold design directly translates to consistency, repeatability, and performance in the final plastic part.

Precision in plastic molding begins with the mold itself—typically machined from hardened steel or aluminum using CNC processes that demand sub-micron repeatability. Even minor deviations in cavity geometry can lead to warpage, flash, or dimensional instability, especially in complex or thin-walled components. This is particularly critical in industries such as aerospace, defense, and medical devices, where molded parts must meet stringent regulatory and performance standards.

Our experience at Wuxi Lead Precision Machinery spans over a decade of delivering mission-critical components for Olympic-standard equipment and military-grade systems. These applications require not only flawless aesthetics but also mechanical reliability under extreme conditions. For example, in the production of sealed housings for tactical communication devices, we engineered molds capable of maintaining ±0.002 mm tolerances across multi-cavity configurations. Such precision ensures that plastic enclosures meet IP68 ratings and resist thermal cycling without compromising structural integrity.

The synergy between metal and plastic manufacturing is often underestimated. At Lead Precision, we leverage our expertise in custom metal fabrication—honed through high-stakes projects—to optimize mold design, cooling channel layout, and ejection systems. This holistic approach reduces cycle times, minimizes residual stress in molded parts, and enhances surface finish quality. Our in-house metrology lab, equipped with coordinate measuring machines (CMM) and laser scanning systems, validates every mold before deployment, guaranteeing conformance to ISO 1302 and AS9100 standards.

We understand that precision is not a one-time achievement but a continuous process. From initial prototyping to full-scale production, we apply statistical process control (SPC) to monitor key parameters such as melt temperature, injection pressure, and cooling rate. This data-driven methodology allows us to preempt defects and maintain consistency across batches of tens of thousands of parts.

For OEMs and Tier-1 suppliers, partnering with a manufacturer that integrates precision metalwork with advanced plastic molding offers a strategic advantage. At Wuxi Lead Precision Machinery, we bring the rigor of aerospace and defense engineering to every mold we build, ensuring that your plastic components perform as reliably as the systems they serve.

Typical Precision Specifications for Custom Plastic Molding at Wuxi Lead Precision Machinery

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.002 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.1 µm (mirror finish) |

| Mold Material | P20, H13, S136, 718H | 420SS, Maraging Steel |

| Cavity Accuracy (multi-cavity) | ±0.01 mm consistency | ±0.003 mm consistency |

| Cycle Time Optimization | Up to 30% reduction | Up to 50% reduction |

| Certification Standards | ISO 9001, ISO 13485 | AS9100, MIL-STD-810 |

Precision Specs & Tolerances

Technical Capabilities for Precision Plastic Mold Manufacturing

Wuxi Lead Precision Machinery delivers the advanced technical capabilities demanded by high-performance plastic injection molding. Our core strength lies in integrating cutting-edge equipment with rigorous quality assurance protocols specifically engineered for the complex demands of mold base and cavity/core production. This ensures dimensional integrity, superior surface finish, and extended mold life critical for consistent plastic part quality and production efficiency.

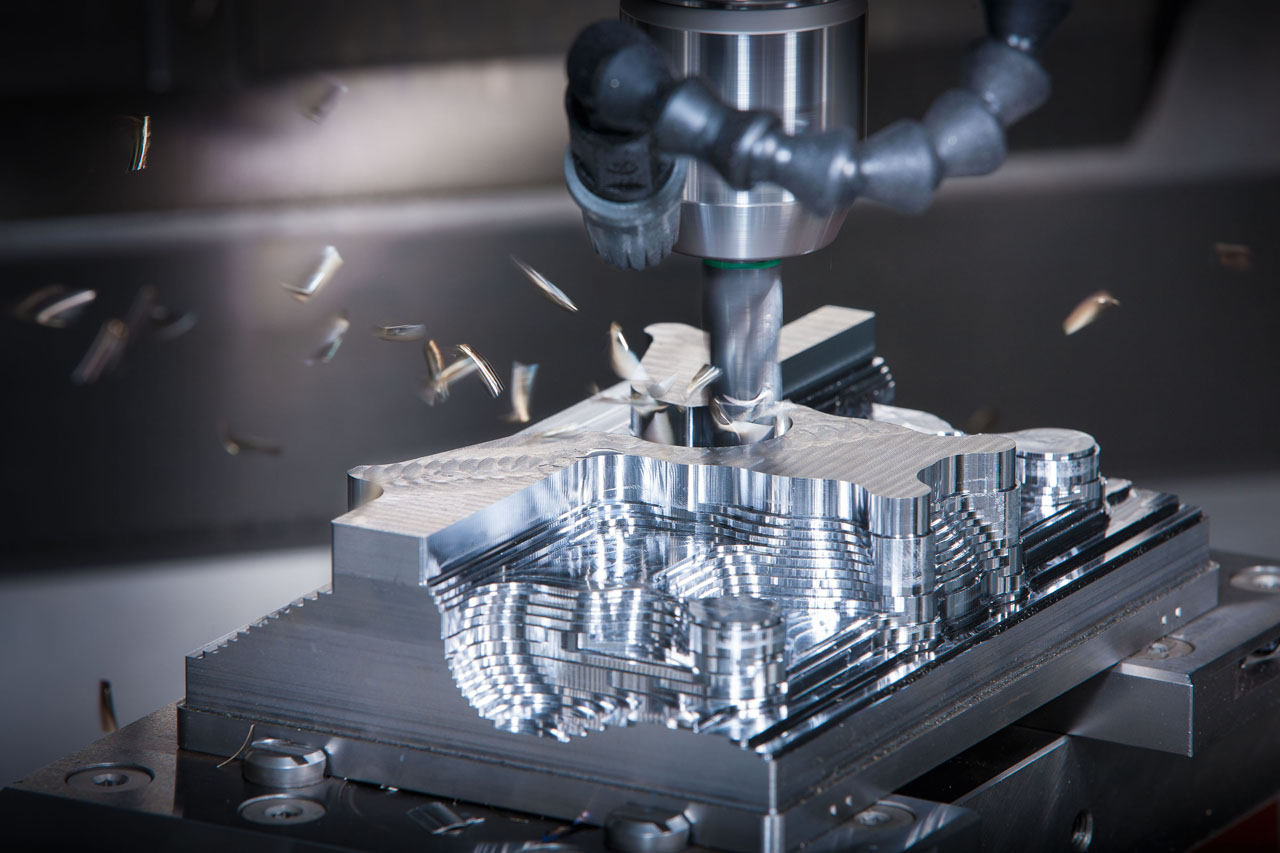

Our foundation is a modern fleet of multi-tasking 5-axis CNC machining centers. These systems are essential for producing the intricate geometries inherent in today’s plastic molds, including deep ribs, undercuts, and organic cooling channels. Simultaneous 5-axis motion eliminates the need for multiple setups, significantly reducing cumulative error and machining time while improving part accuracy. This capability directly translates to molds that achieve tighter draft angles, complex venting patterns, and precise conformal cooling circuits – features impossible to manufacture cost-effectively with 3-axis technology alone. The result is enhanced plastic flow, minimized warpage, and accelerated cycle times for our clients’ end products.

Complementing our machining prowess is a comprehensive Coordinate Measuring Machine (CMM) inspection regime. Every critical mold component undergoes meticulous dimensional verification against the original CAD model using state-of-the-art metrology equipment. Our CMM processes provide full 3D data capture, generating detailed inspection reports that validate geometric dimensioning and tolerancing (GD&T), surface profiles, and positional accuracy. This data-driven approach is non-negotiable for ensuring mold halves align perfectly, ejector systems function flawlessly, and cavity surfaces meet stringent finish requirements, preventing costly production delays and part defects downstream.

The following table details our standard achievable tolerance capabilities for key manufacturing processes, reflecting the precision standard applied to critical plastic mold features:

| Process | Typical Tolerance Range | Critical Feature Application for Plastic Molds |

|---|---|---|

| 5-Axis CNC Milling | ±0.005 mm to ±0.012 mm | Cavity/core contours, slide paths, precision pockets |

| CNC Turning | ±0.003 mm to ±0.008 mm | Ejector pins, leader pins, bushings, precision sleeves |

| Precision Grinding | ±0.002 mm to ±0.005 mm | Parting line surfaces, sealing surfaces, critical bores |

Achieving these tolerances consistently requires more than just advanced machinery; it demands skilled programming, optimized toolpaths, thermal stability management, and stringent environmental controls within our facility. Our engineering team collaborates closely with clients during the design-for-manufacturability phase to identify critical-to-quality dimensions and ensure our processes are calibrated to exceed expectations. This integrated approach to precision manufacturing minimizes mold tryout iterations, reduces scrap rates in plastic production, and delivers molds capable of sustaining high-volume, high-quality output over their operational lifespan. Wuxi Lead Precision Machinery provides the technical foundation for your most demanding plastic molding applications.

Material & Finish Options

Material selection is a critical factor in the success of custom metal manufacturing, particularly for plastic molders requiring precision, durability, and thermal efficiency. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance mold components tailored to your production demands. The choice between aluminum, steel, and titanium directly impacts mold life, cycle time, surface finish, and overall cost-effectiveness. Understanding the mechanical properties and compatibility with finishing processes such as anodizing ensures optimal performance in injection molding applications.

Aluminum is widely favored for prototypes and low- to medium-volume production due to its excellent machinability and superior thermal conductivity. It enables faster cooling cycles, reducing overall production time. While not as wear-resistant as steel, modern high-strength aluminum alloys offer sufficient durability for thousands of cycles, especially when protected with anodized finishes. Anodizing enhances surface hardness, corrosion resistance, and wear performance, making aluminum a cost-efficient solution for time-sensitive projects.

Steel remains the standard for high-volume molding applications where extended tool life and resistance to wear and deformation are paramount. Hardened tool steels such as P20, H13, and S136 provide exceptional dimensional stability under repeated thermal cycling. These grades are commonly used in cavity and core inserts, ejector components, and mold bases. While steel does not anodize like aluminum, it benefits from alternative surface treatments such as nitriding, chrome plating, or PVD coatings to improve release properties and resistance to corrosion.

Titanium is less common but offers a unique value proposition in specialized molding environments. With an outstanding strength-to-density ratio and exceptional corrosion resistance, titanium is ideal for applications involving aggressive materials or where weight reduction is critical. Its biocompatibility also makes it suitable for medical-grade molding tools. However, titanium’s high reactivity during machining and elevated cost limit its use to niche applications. It cannot be anodized in the conventional sense, though specialized oxide layering techniques can enhance surface properties.

The following table summarizes key mechanical and thermal properties of these materials relevant to plastic mold manufacturing:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Hardness (HB) | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | 167 | 95 | Yes |

| Steel P20 | 7.8 | 950 | 28 | 290 | No |

| Steel H13 | 7.8 | 1,700 | 32 | 230 | No |

| Titanium Gr5 | 4.5 | 900 | 7 | 330 | Special Process Only |

Selecting the right material requires balancing performance requirements with production volume and budget. At Wuxi Lead Precision Machinery, we support our clients in making informed decisions by combining material science expertise with precision manufacturing capabilities. Whether you require rapid prototyping in anodized aluminum or long-run stability in hardened steel, our engineering team ensures your mold materials align with your operational goals.

Manufacturing Process & QC

Precision Manufacturing Process for Plastic Molding Applications

At Wuxi Lead Precision Machinery, our production process for custom metal components serving the plastic molding industry is engineered for absolute reliability. We eliminate defects at origin through a rigorously controlled sequence spanning design validation to high-volume output. This integrated approach ensures your mold bases, inserts, and precision tooling meet the exacting demands of modern injection molding, directly reducing your scrap rates and downtime.

The process commences with collaborative design engineering. Our team conducts comprehensive Design for Manufacturability (DFM) and Design for Assembly (DFA) reviews, focusing on thermal management, material selection, and tolerance stack-up analysis specific to plastic flow dynamics. We utilize advanced simulation software to predict mold behavior under production conditions, identifying potential stress points or cooling inefficiencies before metal is cut. This phase establishes the foundational blueprint where zero defects originate, ensuring geometry and material properties align with your polymer and cycle time requirements.

Prototyping transitions validated designs into physical reality under full production intent conditions. We manufacture initial components using the same hardened tool steels and CNC processes planned for mass production, not soft metals or rapid prototyping shortcuts. Each prototype undergoes dimensional verification against CAD models using CMMs and surface finish analysis critical for part ejection and cosmetic quality. Mold flow trials are conducted with your specified resin to validate cooling efficiency, clamp force distribution, and venting. Defect root causes are identified and resolved here; no design proceeds to mass production without statistically validated Cpk values exceeding 1.67 for all critical features.

Mass production leverages our closed-loop manufacturing ecosystem. Multi-axis CNC machining centers operate under strict environmental controls, with real-time tool wear monitoring and in-process gauging. Every component batch includes first-article inspection reports and ongoing statistical process control (SPC) tracking key dimensions. Our integrated quality management system mandates 100% critical feature inspection via automated optical comparators for high-risk geometries, alongside random destructive testing for material integrity. Traceability is absolute, with laser-etched part numbers linking to machine parameters, inspection data, and raw material certificates. This systematic execution guarantees consistent output where dimensional stability and surface perfection are non-negotiable.

The table below summarizes our process specifications ensuring zero-defect outcomes for plastic molding tooling:

| Process Stage | Key Activities | Quality Control Metrics | Output Specification |

|---|---|---|---|

| Design Validation | DFM/DFA, Mold Flow Simulation, Material Selection | Tolerance Stack-up Analysis, Thermal Simulation Accuracy | Approved CAD Model with Geometric Tolerancing |

| Prototyping | Hard Tool Steel Machining, Mold Flow Trials | Cpk ≥ 1.67, Surface Roughness Ra ≤ 0.4 μm | Fully Validated Prototype with Test Report |

| Mass Production | Closed-Loop CNC Machining, SPC Monitoring | 100% Critical Feature Inspection, Cpk ≥ 1.33 | Dimensional Certificate, Material Traceability Report |

This disciplined progression from design insight through prototype validation to controlled mass production forms the core of Wuxi Lead’s zero-defect commitment. We deliver not just components, but assured process stability for your molding operations.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand the critical role precision components play in the success of advanced plastic molding operations. As a trusted partner to global leaders in injection molding, automation, and industrial equipment manufacturing, we deliver custom metal solutions engineered for performance, durability, and seamless integration. Our commitment to excellence is reflected in every component we produce—tailored to meet the exacting demands of high-cycle, high-pressure molding environments.

We specialize in manufacturing precision-machined parts, mold bases, ejector systems, and custom structural components using premium-grade tool steels, stainless alloys, and hardened materials. Our CNC machining centers, operated by skilled technicians and supported by stringent quality control protocols, ensure tolerances as tight as ±0.002 mm. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing ecosystem adapts to your timeline without compromising accuracy or consistency.

Our engineering team collaborates directly with your design and R&D departments to optimize part geometry, material selection, and manufacturability. We support full digital integration with 3D CAD/CAM file compatibility (STEP, IGES, SolidWorks) and provide detailed inspection reports, including CMM validation and material certifications. Every project is managed under ISO 9001:2015 standards, ensuring traceability, repeatability, and compliance with international quality benchmarks.

Choosing the right manufacturing partner is not just about capability—it’s about reliability, responsiveness, and long-term value. At Lead Precision, we pride ourselves on transparent communication, on-time delivery, and solutions that reduce total cost of ownership. Our facility in Wuxi, Jiangsu Province, is equipped with over 120 CNC machines, including 5-axis machining centers, wire EDM, and surface grinders, enabling us to handle complex components up to 2,500 kg.

We invite plastic molders seeking a strategic manufacturing partner to contact us today. Let our team help you achieve higher precision, faster turnaround, and greater operational efficiency.

For project inquiries, technical consultations, or to request a quote, email us at [email protected]. Our engineering support team responds within 12 business hours and can provide DFM analysis, prototyping timelines, and production scheduling tailored to your needs.

Key Technical Specifications

| Parameter | Capability |

|---|---|

| Maximum Workpiece Size | 2500 mm × 1800 mm × 1200 mm |

| Weight Capacity | Up to 2,500 kg |

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (custom finishes available) |

| Materials Supported | P20, 718, H13, S136, 420SS, Aluminum 7075, Brass, Titanium |

| Machining Processes | CNC Milling, 5-Axis Machining, Wire EDM, Surface Grinding, Drilling, Threading |

| Quality Standards | ISO 9001:2015, Full CMM Inspection, First Article Inspection (FAI) |

| Lead Time (Typical) | 15–25 days (varies by complexity and volume) |

Elevate your molding performance with components built to last. Contact [email protected] and partner with precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.