Technical Contents

Engineering Guide: Plastic Molde

Engineering Insight: The Non-Negotiable Role of Precision in Plastic Mold Manufacturing

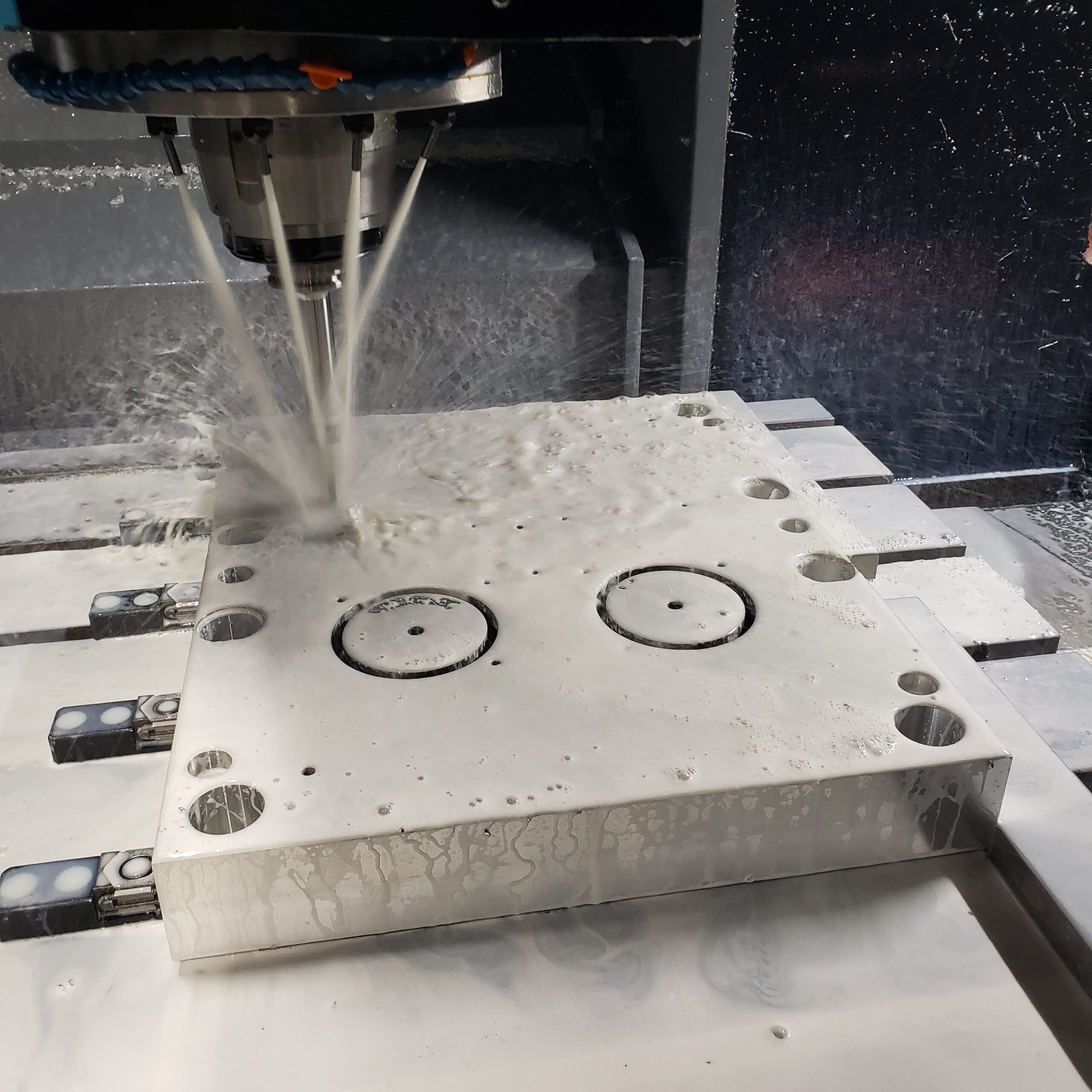

Achieving consistent, high-quality plastic injection molded parts begins long before the first pellet enters the hopper. It originates in the microscopic tolerances and flawless geometry of the mold itself. Precision in mold construction is not merely desirable; it is the absolute foundation for part functionality, dimensional stability, surface finish, and production efficiency. Even minor deviations in cavity dimensions, core alignment, or cooling channel placement propagate exponentially during the high-pressure, thermally dynamic molding process. This results in part warpage, sink marks, flash, inconsistent wall thickness, and premature mold wear – directly impacting scrap rates, cycle times, and ultimately, the bottom line for high-volume production.

At Wuxi Lead Precision Machinery, we engineer molds where precision is measured in microns, not millimeters. Our CNC machining centers, operating under stringent environmental controls, consistently achieve tolerances critical for complex geometries and tight-clearance features demanded by aerospace, medical, and consumer electronics sectors. This capability stems from decades of specialized focus on the unique challenges of mold steel machining, thermal management design, and surface integrity. We understand that precision encompasses more than just dimensional accuracy; it includes thermal stability across the mold structure, perfect parallelism of parting lines, and the exacting finish required for optical or sealing surfaces. Compromises here lead to costly downtime and rework during production ramp-up.

Our commitment to uncompromising precision is validated through demanding applications. We have manufactured critical molds for components used in Olympic-standard sporting equipment, where material performance and dimensional repeatability under stress are paramount. Furthermore, our molds meet the rigorous traceability and performance specifications required for select military-grade applications, where failure is not an option. This experience translates directly to our commercial clients, ensuring molds built for longevity, consistency, and the ability to hold tight tolerances over millions of cycles.

The following specifications represent the baseline precision capabilities achievable with our standard processes for hardened mold steels (e.g., H13, S136):

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Linear Dimension Tolerance | ±0.005 mm | ±0.002 mm |

| Geometric Tolerance (Flatness/Parallelism) | 0.008 mm / 100 mm | 0.003 mm / 100 mm |

| Cavity/Core Surface Finish (Ra) | 0.2 µm | 0.05 µm (Mirror Polish) |

| Cooling Channel Position | ±0.01 mm | ±0.005 mm |

| Mold Base Parallelism | 0.01 mm | 0.005 mm |

Investing in precision mold manufacturing from the outset mitigates risk and optimizes total cost of ownership. It ensures first-article success, minimizes production interruptions, and guarantees the part quality your brand demands. Wuxi Lead Precision Machinery leverages its deep engineering expertise and proven track record in the most exacting environments to deliver molds that perform reliably from shot one to the end of life. Contact our engineering team to discuss how our precision-focused approach can secure your next critical molding project.

Precision Specs & Tolerances

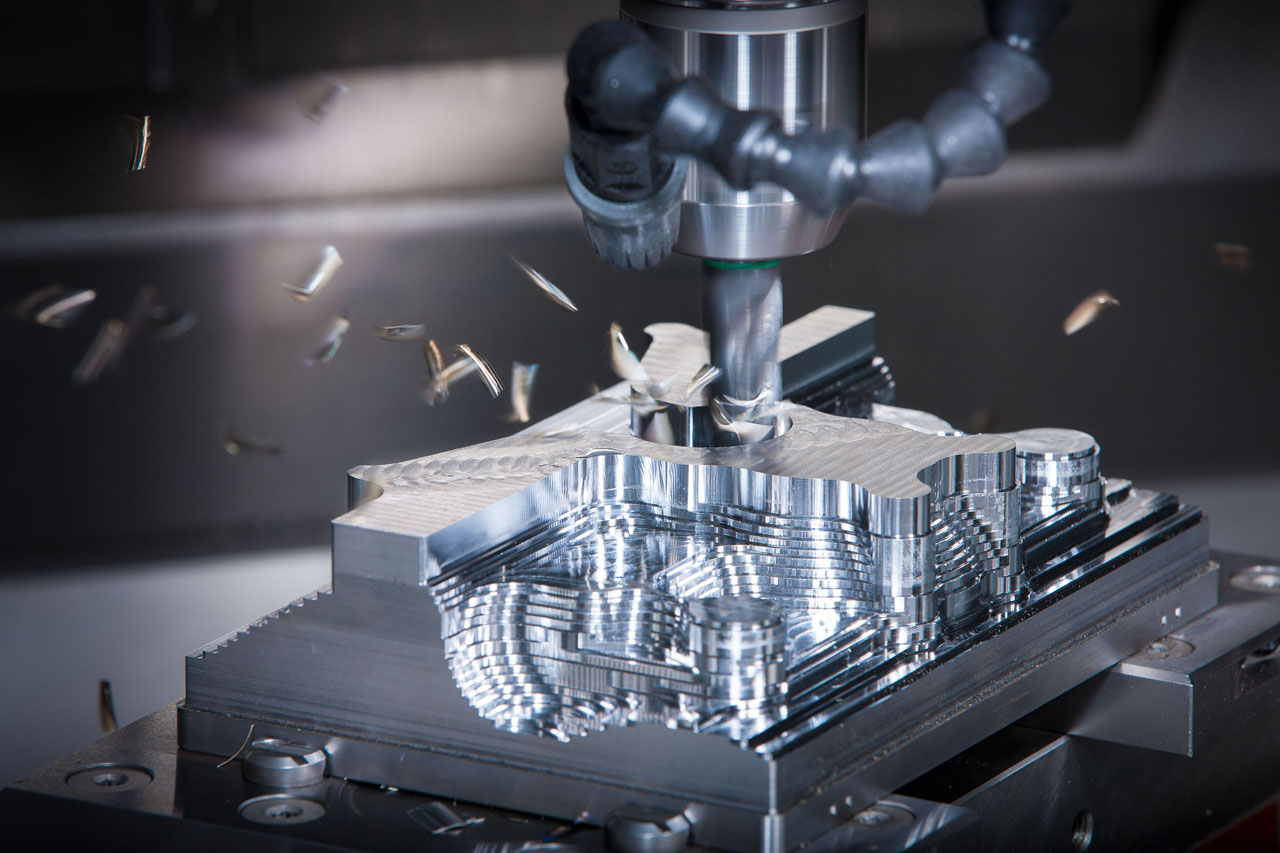

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for complex applications such as plastic mold tooling. Our production infrastructure is built around state-of-the-art 5-axis CNC machining centers, enabling us to produce intricate geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, ensuring optimal tool positioning and reduced setup times. This results in tighter tolerances, improved part consistency, and the ability to machine undercuts and deep cavities without re-fixturing—critical for mold cores, cavities, and conformal cooling channels.

Our 5-axis machining platforms are integrated with high-speed spindles and automated tool changers, supporting a wide range of materials including hardened steels, aluminum alloys, copper alloys, and specialty tool steels commonly used in plastic injection molds. Each machine is operated by certified CNC programmers and machinists who utilize advanced CAM software to develop optimized toolpaths, minimizing cycle time while maximizing precision and tool life. This digital workflow ensures seamless transition from CAD model to finished component, with full process traceability.

Quality control is embedded at every stage of production. All critical dimensions are verified using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), providing metrology-grade inspection with sub-micron repeatability. The CMM system performs automated 3D scanning and geometric dimensioning, validating form, position, flatness, and profile tolerances against customer specifications. First-article inspections (FAI) and in-process checks are standard practice, ensuring compliance with ISO 10360 accuracy standards. Inspection reports are fully documented and provided with each shipment, offering complete transparency and audit readiness.

We maintain a climate-controlled metrology lab to eliminate thermal drift during measurement, further enhancing data reliability. In addition to CMM inspection, we employ surface roughness testers, hardness testers, and optical comparators to validate material and finish requirements. Our quality management system is aligned with ISO 9001:2015 standards, reflecting our commitment to continuous improvement and zero-defect manufacturing.

The following table outlines our standard technical specifications and achievable tolerances for machined components:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Positional Tolerance | ±0.01 mm | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.012 mm | ±0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm (polish-ready) |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Hole Diameter Tolerance | H7 | H6 |

| Angular Accuracy | ±0.05° | ±0.02° |

| Maximum Work Envelope (mm) | 1200 x 800 x 600 | Custom upon request |

With integrated 5-axis CNC machining and precision CMM inspection, Wuxi Lead Precision Machinery ensures every plastic mold component meets the highest standards of dimensional integrity and functional performance.

Material & Finish Options

Material Selection for High-Performance Plastic Injection Molds

Selecting the optimal material for plastic injection molds is a critical engineering decision directly impacting part quality, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your specific production volume, part geometry, resin type, and surface finish requirements. Aluminum, steel, and titanium represent the primary contenders, each offering distinct advantages for precision mold manufacturing.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production. Their high thermal conductivity significantly reduces cycle times compared to steel, accelerating time-to-market. Aluminum is also substantially easier and faster to machine, lowering initial tooling costs. While less wear-resistant than steel, modern hard anodizing processes dramatically enhance surface hardness and corrosion resistance, making aluminum viable for thousands of cycles with many standard resins. It is the pragmatic choice for startups, complex geometries requiring fast iteration, or applications where thermal management is paramount.

Tool steels, including P20, H13, and stainless variants like S136, are the industry standard for high-volume production. Their superior hardness, wear resistance, and compressive strength withstand the abrasive nature of glass-filled resins and demanding production schedules exceeding hundreds of thousands of cycles. Properly heat-treated and polished steel molds deliver exceptional dimensional stability and surface finish replication. While initial machining costs and lead times are higher than aluminum, the extended service life and reduced maintenance downtime provide a compelling return on investment for long production runs. Steel is essential for optical components, medical devices, and any application demanding micron-level precision over extended periods.

Titanium alloys, while possessing extraordinary strength-to-weight ratio and corrosion resistance, see limited application in mainstream plastic molding due to high cost, challenging machinability, and lower thermal conductivity compared to aluminum. Its niche use is typically restricted to highly corrosive resin environments or specialized aerospace components where its unique properties justify the premium investment. For the vast majority of industrial applications, aluminum or steel provides superior cost-performance balance.

Surface finishing, particularly hard anodizing for aluminum molds, is non-negotiable for durability. This electrolytic process creates a hard, wear-resistant aluminum oxide layer (typically 50-100 µm thick) with enhanced lubricity and corrosion resistance. Hard anodizing transforms aluminum from a prototype material into a viable production solution for many applications, significantly extending mold life.

Material performance characteristics are summarized below for key comparison:

| Property | Aluminum 7075-T6 (Hard Anodized) | P20 Pre-Hard Steel | H13 Tool Steel |

|---|---|---|---|

| Hardness (HRC) | 60-70 (Anodized Surface) | 28-32 | 48-52 (After HT) |

| Thermal Conductivity (W/m·K) | 130-180 | 28-36 | 24-30 |

| Typical Mold Life (Cycles) | 10,000 – 100,000+ | 100,000 – 500,000+ | 500,000 – 1M+ |

| Machinability | Excellent | Good | Fair (After HT) |

| Corrosion Resistance | Very Good (Anodized) | Moderate | Good (Stainless) |

| Best Suited For | Prototypes, Med. Volume, Fast Cycle | High Volume Standard | High Volume, Harsh Resins, Precision |

Wuxi Lead Precision Machinery leverages advanced CNC machining and deep materials expertise to optimize your mold construction. We rigorously evaluate your production parameters to recommend the precise material and finish combination maximizing your operational efficiency and part quality. Partner with us to transform material selection from a cost center into a strategic advantage.

Manufacturing Process & QC

The production process for high-precision plastic molds at Wuxi Lead Precision Machinery follows a disciplined, phase-gated approach designed to ensure zero defects and maximum repeatability in mass production. Our methodology integrates advanced engineering, precision machining, and rigorous quality validation across three core stages: Design, Prototyping, and Mass Production.

The Design phase begins with a comprehensive analysis of customer specifications, including part geometry, material requirements, cycle time targets, and expected production volume. Our engineering team employs industry-leading CAD/CAM software—Siemens NX, SolidWorks, and Autodesk Moldflow—to develop 3D models and perform mold flow simulations. These simulations predict how molten plastic will fill the mold cavity, allowing us to optimize gate locations, cooling channels, and venting to prevent warpage, sink marks, or short shots. Design for manufacturability (DFM) reviews are conducted internally and shared with the client to ensure alignment before any physical work begins.

Prototyping follows design approval and serves as a critical validation step. We fabricate a functional prototype mold using CNC machining, wire EDM, and surface grinding to achieve tight tolerances. The prototype mold is then tested on our in-house injection molding machines using the client’s specified resin. This allows us to produce initial sample parts for dimensional inspection, surface finish evaluation, and functional testing. Any deviations are traced back to the mold design or process parameters and corrected before advancing. This iterative process ensures that the final mold design is robust and production-ready.

Once the prototype is validated, we transition to Mass Production. Our automated manufacturing cells, equipped with multi-axis CNC machines and robotic part handling, ensure consistent cycle times and precision. Each mold component is machined from premium-grade tool steel—typically P20, 718H, or H13—and undergoes heat treatment and fine polishing to achieve mirror finishes or texture as required. Throughout production, we apply real-time quality monitoring using coordinate measuring machines (CMM), optical comparators, and in-process gauging to maintain tolerances within ±0.002 mm.

Our zero-defect philosophy is enforced through full traceability, documented process validation, and adherence to ISO 9001 standards. Every mold is delivered with a complete quality dossier, including inspection reports, material certifications, and process parameters.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Finish | Ra 0.05 µm to 3.2 µm (polished, textured, or as-machined) |

| Tool Steel Grades | P20, 718H, H13, S136, NAK80 |

| Mold Life | 100,000 to 1,000,000+ cycles |

| Cooling Optimization | Conformal cooling channels via 3D printing or precision drilling |

| Quality Standards | ISO 9001, First Article Inspection (FAI), PPAP Level 3 |

| Lead Time (Prototype) | 4–6 weeks |

| Lead Time (Production Mold) | 8–12 weeks |

This structured process ensures that every plastic mold we deliver meets the highest standards of precision, durability, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Plastic Mold Excellence

At Wuxi Lead Precision Machinery, we engineer plastic injection molds that redefine precision and reliability for global manufacturers. Our Shenzhen facility operates under stringent ISO 9001 and ISO 13485 standards, merging advanced CNC capabilities with decades of mold-making expertise. We specialize in complex, high-cavitation molds for medical, automotive, and consumer electronics applications where micron-level accuracy directly impacts your product’s performance and market success. Partnering with us means transitioning from generic suppliers to a strategic engineering ally focused solely on resolving your most demanding molding challenges.

Our technical foundation lies in proprietary processes for hardened steel and pre-hardened tool steels, supported by 5-axis milling, wire EDM, and micro-milling technologies. This enables us to achieve sub-micron tolerances consistently while optimizing mold flow dynamics for reduced cycle times and zero-defect production. Unlike conventional vendors, we integrate mold validation directly into our workflow using scientific molding principles, ensuring your tool performs flawlessly from the first shot. Below are core specifications defining our capability envelope:

| Parameter | Specification | Industry Impact |

|---|---|---|

| Tolerance Range | ±0.001 mm to ±0.005 mm | Eliminates post-mold machining |

| Materials | NAK80, S136, H13, Stainless Steels | Corrosion resistance & 1M+ cycles |

| Lead Time | 25-45 days (complex molds) | 30% faster than regional averages |

| Surface Finish | SPI A1 (Mirror) to VDI 3400 #24 | Critical for optical/medical parts |

| Certifications | ISO 9001, ISO 13485, FDA compliant | Global market access assurance |

We recognize that mold performance hinges on collaborative engineering. Our project managers and tooling engineers engage during your design phase to identify potential manufacturability risks, propose gate optimization, and validate cooling channel layouts—preventing costly revisions downstream. This proactive approach has reduced client time-to-market by 22% across 300+ projects. Your success is measured not just in delivered molds, but in sustained production uptime and yield rates exceeding 99.2%.

When selecting a partner for mission-critical plastic molds, prioritize technical rigor over transactional convenience. Wuxi Lead Precision Machinery delivers engineering accountability from concept to量产, with full traceability on every component. We invest in your long-term competitiveness through continuous improvement cycles and lifetime mold support.

Resolve your most complex molding challenges with a team that treats your specifications as non-negotiable commitments. Contact our engineering division directly at [email protected] to initiate a capability review. Include your part drawings and production requirements for a targeted assessment within 24 business hours. Let us demonstrate how precision engineering becomes your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.