Technical Contents

Engineering Guide: Plastic Mold Production

Engineering Insight: The Critical Role of Precision in Plastic Mold Production

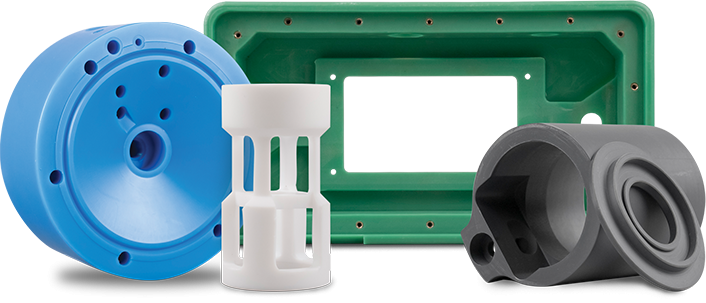

In the realm of custom metal manufacturing, plastic mold production stands as a discipline where micron-level accuracy directly determines the performance, longevity, and cost-efficiency of end components. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a metric—it is the foundation upon which successful mold design, tooling integrity, and mass production consistency are built. Every cavity, core, and ejector pin must conform to exacting dimensional tolerances to ensure flawless part replication, especially in high-cycle manufacturing environments.

Precision in plastic mold production influences multiple critical factors: part geometry stability, surface finish quality, material flow behavior, and overall cycle time efficiency. Even deviations within a few microns can lead to flash, warpage, or incomplete filling—defects that compromise part functionality and escalate rejection rates. This is particularly critical in sectors such as aerospace, medical devices, and defense systems, where component reliability is non-negotiable.

Wuxi Lead Precision Machinery brings decades of specialized expertise to this high-stakes domain. Our engineering team has supported mission-critical projects, including components for Olympic-standard equipment and military-grade systems, where failure is not an option. These applications demand molds capable of producing parts with zero variance across thousands of cycles under extreme conditions. Our success in these arenas underscores our mastery in integrating advanced CNC machining, real-time metrology, and thermal deformation compensation into every mold we manufacture.

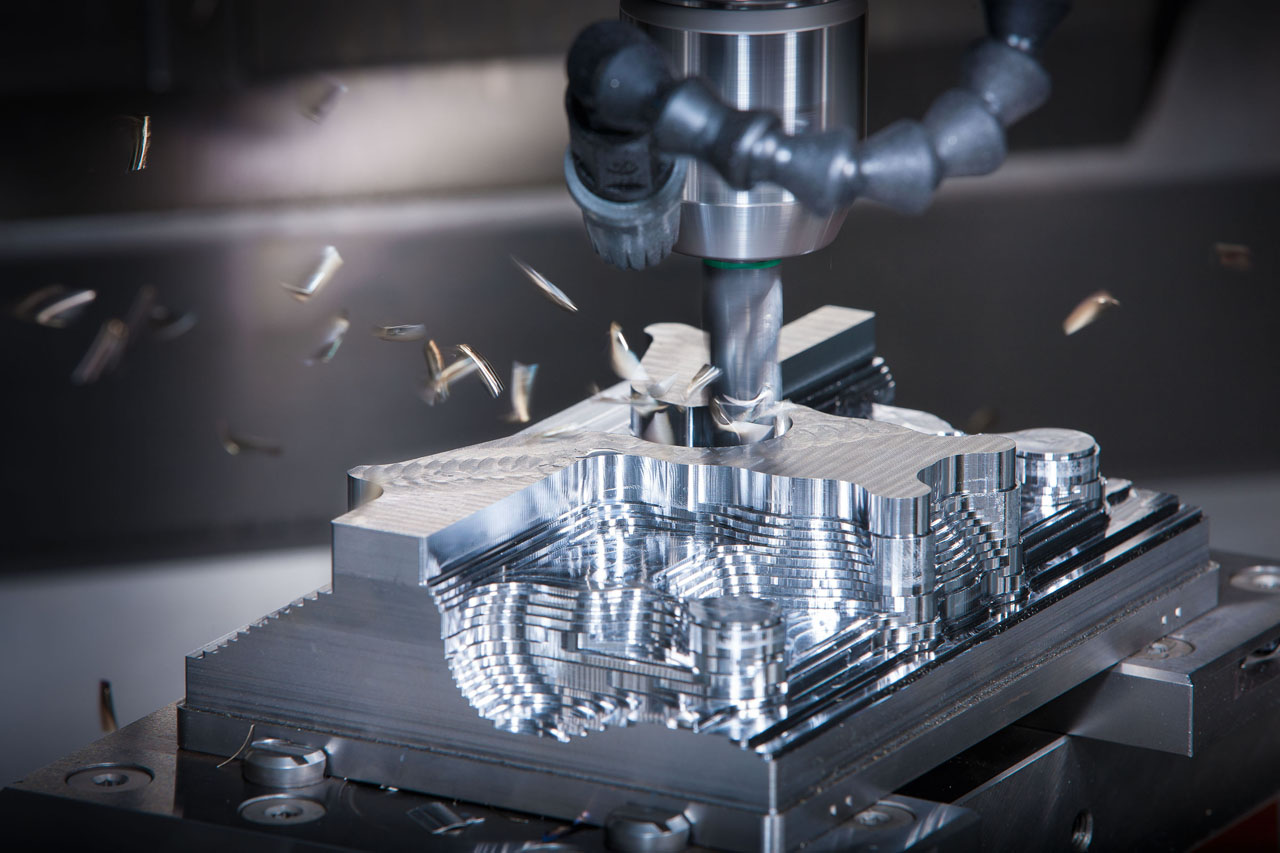

We utilize state-of-the-art 5-axis machining centers, high-speed milling technology, and electrode discharge machining (EDM) to achieve tolerances down to ±0.002 mm. Our design-phase simulations include mold flow analysis and structural stress modeling, allowing us to anticipate and correct potential defects before metal cutting begins. This proactive approach reduces prototyping iterations and accelerates time-to-market—key advantages in competitive industrial supply chains.

Below are key technical specifications that define our precision mold production capabilities:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.05 – 0.2 µm (polished cavities) |

| Maximum Mold Size | 2,000 x 1,500 x 1,200 mm |

| Tool Steel Options | P20, 718, S136, H13, 2738, 2344 |

| Machining Accuracy (CMM) | 1.5 + L/300 µm (per ISO 10360-2) |

| Mold Life Expectancy | 1,000,000+ cycles (optimized designs) |

| Lead Time (Average) | 4–8 weeks (varies by complexity) |

Our commitment to precision is reinforced by rigorous quality control protocols, including 100% first-article inspection and in-process CMM verification. Every mold leaving our facility in Wuxi is a testament to engineering excellence, built not just to meet specifications, but to exceed the operational demands of the most advanced manufacturing environments.

Precision Specs & Tolerances

Integrated Technical Capabilities for Precision Plastic Mold Production

Wuxi Lead Precision Machinery delivers uncompromising precision in custom plastic mold manufacturing through a tightly integrated ecosystem of advanced machining, metrology, and process control. Our core strength lies in the seamless execution from digital design to fully validated mold components, ensuring dimensional accuracy and surface integrity critical for high-volume, defect-free plastic part production. This capability directly translates to reduced cycle times, extended mold life, and minimized scrap rates for our clients’ end products.

Central to our process is a modern fleet of high-speed 5-axis CNC machining centers. These systems, featuring sub-micron repeatability and dynamic toolpath optimization, enable the efficient production of complex mold cores, cavities, slides, and intricate lifters in hardened tool steels and pre-hardened alloys. Multi-axis simultaneous machining eliminates multiple setups, drastically improving positional accuracy between critical features and reducing lead times by up to 40% compared to traditional 3-axis methods. Advanced coolant management and high-frequency spindles ensure superior surface finishes directly off the machine, minimizing subsequent hand polishing requirements and accelerating time-to-press.

Rigorous quality control is not a final step but an embedded process. Every critical mold component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMMs) calibrated to ISO 10360-2 standards. Our CMM protocols, utilizing Renishaw probes and PC-DMIS software, verify all geometric dimensions, complex contours, and positional relationships against the original CAD model. This systematic approach provides full traceability and generates detailed inspection reports, giving clients absolute confidence in part conformity before mold assembly begins. Surface roughness is independently verified using calibrated profilometers to ensure optimal release characteristics and part aesthetics.

The following table details our standard achievable tolerances for critical mold features, validated through our CMM inspection regime:

| Feature Category | Standard Capability | Verification Method |

|---|---|---|

| Linear Dimensions | ±0.005 mm | CMM (ISO 10360-2) |

| Geometric Tolerances | ±0.003 mm (GD&T) | CMM (ISO 10360-2) |

| Surface Roughness (Ra) | 0.2 – 0.8 µm | Profilometer |

| Hole Position Accuracy | ±0.002 mm | CMM (Multi-point probe) |

| Flatness | 0.003 mm per 100 mm | CMM / Optical Flat |

This precision foundation directly addresses the root causes of common plastic molding defects such as flash, short shots, warpage, and ejection marks. By guaranteeing mold cavity and core geometry within stringent tolerances, Wuxi Lead ensures consistent plastic flow, optimal packing, and uniform cooling – the fundamental requirements for producing high-integrity plastic components at scale. Our technical capabilities provide the dimensional stability necessary for molds to perform reliably over millions of cycles, protecting our clients’ production uptime and part quality objectives. Partnering with us means your mold investment is built to exacting standards from the first machining pass to final validation.

Material & Finish Options

Material selection is a critical phase in plastic mold production, directly influencing mold performance, service life, and production efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-precision molds, leveraging advanced CNC machining and material science to deliver optimal solutions. The choice between aluminum, steel, and titanium depends on production volume, part complexity, thermal requirements, and cost objectives.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype and low-to-medium volume molds due to their excellent machinability and thermal conductivity. Aluminum allows faster cycle times and reduces wear on cutting tools, making it ideal for rapid development and testing phases. While softer than steel, aluminum’s lightweight nature and responsiveness to anodizing enhance its durability and surface performance. Anodized aluminum molds exhibit improved wear resistance and release properties, critical in complex plastic molding applications.

Steel remains the standard for high-volume production molds. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and dimensional stability under prolonged thermal cycling. These properties make steel molds suitable for injection molding of engineering plastics and long production runs exceeding hundreds of thousands of cycles. While steel is slower to machine and heavier than aluminum, its longevity and ability to maintain tight tolerances justify its use in industrial-scale manufacturing. Surface treatments such as nitriding or polishing further extend mold life and improve part finish.

Titanium, though less common in mold construction, is gaining attention for specialized applications requiring extreme strength-to-weight ratios and corrosion resistance. While its high cost and challenging machinability limit broad adoption, titanium is occasionally used in core components exposed to aggressive environments or where weight reduction is critical. At Wuxi Lead, we evaluate titanium on a case-by-case basis, ensuring its deployment aligns with functional necessity and return on investment.

Anodizing is a key surface finishing process, particularly for aluminum molds. This electrochemical treatment creates a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. Hard anodizing, in particular, significantly enhances surface hardness—up to 60 HRC—making it suitable for molds subjected to abrasive materials or high friction. The porous nature of the anodized layer also allows for effective release agent retention, improving demolding efficiency.

The following table summarizes key material properties and applications in plastic mold production:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Common Finishes |

|---|---|---|---|---|

| Aluminum 7075 | 40–45 | 130 | Prototypes, low-volume production | Anodizing, hard anodizing |

| Steel P20 | 28–32 | 30 | Medium to high-volume molds | Polishing, nitriding |

| Steel H13 | 48–52 | 36 | High-temperature injection molding | PVD coating, mirror polishing |

| Steel S136 | 50–54 | 22 | Corrosion-resistant, optical molds | Electro-polishing, coating |

| Titanium Gr5 | 35–40 (base) | 7 | Specialized, high-strength components | Anodizing, plasma coating |

Selecting the right material and finish ensures mold reliability, part quality, and production efficiency. At Wuxi Lead Precision Machinery, we collaborate closely with clients to match material characteristics with application demands, delivering precision-engineered molds that meet the highest industrial standards.

Manufacturing Process & QC

Plastic Mold Production: Engineering Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, Zero Defects is not an aspiration—it is the engineered outcome of our rigorously controlled plastic mold production process. We integrate precision metal manufacturing expertise with systematic quality gates across three non-negotiable phases: Design, Prototyping, and Mass Production. This approach eliminates latent risks before they reach your production floor.

The Design phase begins with collaborative engineering to translate your part geometry into a mold architecture that guarantees manufacturability. Our specialists perform Moldflow analysis to predict material behavior, optimize gate locations, and eliminate weld lines or sink marks. Critical steel selection—such as H13 for thermal stability or S136 for corrosion resistance—is validated against your resin’s chemical properties and cycle time requirements. Every draft angle, ejection path, and cooling channel is simulated to achieve ±0.005mm tolerances, ensuring the mold blueprint inherently prevents defects before metal cutting begins.

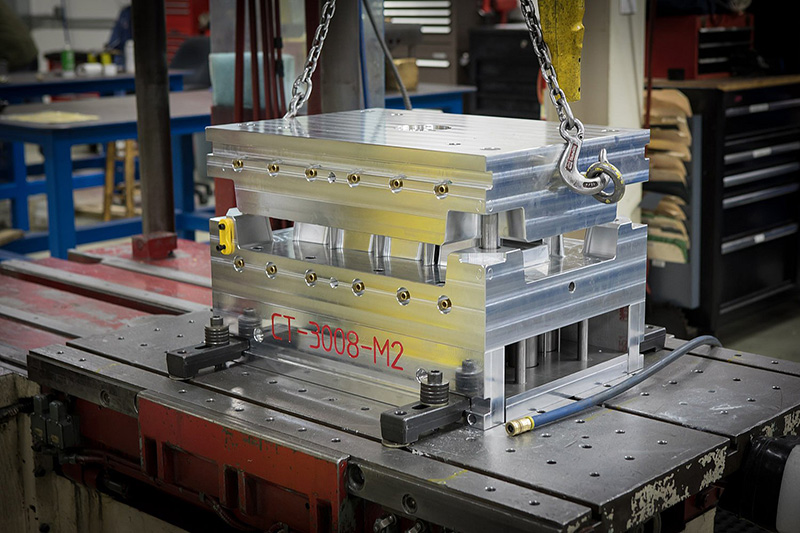

Prototyping transforms the validated design into physical reality through rapid steel tooling. Unlike conventional soft tooling, we machine prototype molds from production-grade P20 or 718H steel using 5-axis CNC milling, achieving 90% of final cavity accuracy. This allows functional testing under near-production conditions. Rigorous first-article inspection validates flow dynamics, part dimensions, and surface finish against your CAD model. Only when all parameters meet our zero-deviation threshold does the mold advance. Key specifications for this phase are detailed below:

| Parameter | Prototyping Phase | Mass Production Phase |

|---|---|---|

| Steel Grade | P20 / 718H | H13 / S136 ESR |

| Tolerance (mm) | ±0.01 | ±0.005 |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm |

| Validation Cycles | 500 shots | 100,000+ shots |

| Metrology | CMM + Optical Scanning | In-Mold Sensors + AI SPC |

Mass Production leverages our automated high-cavitation molding cells, where defect prevention is hardwired into every cycle. Real-time cavity pressure transducers monitor fill behavior, while integrated vision systems inspect each part for flash, short shots, or dimensional drift. Statistical Process Control (SPC) algorithms adjust clamp force and injection speed within milliseconds—preempting deviations before they occur. Our closed-loop cooling channels, machined via high-speed contouring, maintain thermal uniformity to ±1°C, eliminating warpage. Every mold undergoes 72-hour continuous run validation at rated capacity, with zero concessions to tolerance stack-up.

Zero Defects is achieved through this seamless integration of predictive design, steel-validated prototyping, and self-correcting production. At Wuxi Lead, we don’t just manufacture molds—we engineer confidence into every cavity, core, and cycle. Your yield targets are our non-negotiable starting point.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Plastic Mold Production

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency define success in high-end plastic mold manufacturing. As a leading provider of custom metal manufacturing solutions based in China, we specialize in delivering fully engineered plastic molds that meet the exacting standards of global industries—from automotive and medical devices to consumer electronics and industrial equipment. When you partner with us, you are not just sourcing a component—you are gaining a strategic manufacturing ally with deep technical expertise and a relentless commitment to quality.

Our advanced production capabilities are built on decades of engineering excellence. We utilize state-of-the-art CNC machining centers, high-speed milling systems, and EDM technology to produce molds with micron-level accuracy. Every stage of our process—from initial design consultation and material selection to mold testing and final delivery—is managed with rigorous quality control protocols, including ISO 9001-certified practices and comprehensive inspection reports. This ensures that each mold performs reliably over extended production cycles, reducing downtime and maximizing return on investment.

We pride ourselves on our ability to handle complex, custom projects with tight tolerances and demanding timelines. Whether you require single-cavity precision molds or high-cavity production systems, our team of experienced toolmakers and process engineers works closely with your design team to optimize mold flow, cooling efficiency, and ejection mechanisms. Our use of premium-grade tool steels such as P20, 718H, and S136 ensures superior wear resistance and longevity, even under continuous operation.

Our clients choose Wuxi Lead Precision Machinery not only for our technical capabilities but also for our responsive communication, transparent pricing, and on-time delivery performance. We support international clients across North America, Europe, and Southeast Asia with seamless logistics, real-time project updates, and post-delivery technical support. From prototype development to full-scale production, we are equipped to scale with your needs.

Below are key technical specifications that define our plastic mold production capabilities.

| Specification | Detail |

|---|---|

| Maximum Mold Size | 1200 mm × 800 mm × 800 mm |

| Tolerance | ±0.005 mm |

| Surface Finish | As polished to SPI standards (A1 to D3) |

| Tool Steels | P20, 718H, NAK80, S136, H13 |

| Machining Equipment | 3-axis, 4-axis, and 5-axis CNC; EDM; High-Speed Milling |

| Lead Time (Average) | 25–35 days, depending on complexity |

| Quality Standards | ISO 9001:2015, First Article Inspection, CMM Reports |

When precision matters, trust a partner who delivers engineering integrity and manufacturing excellence. Contact us today at [email protected] to discuss your next plastic mold project. Let Wuxi Lead Precision Machinery be the foundation of your production success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.