Technical Contents

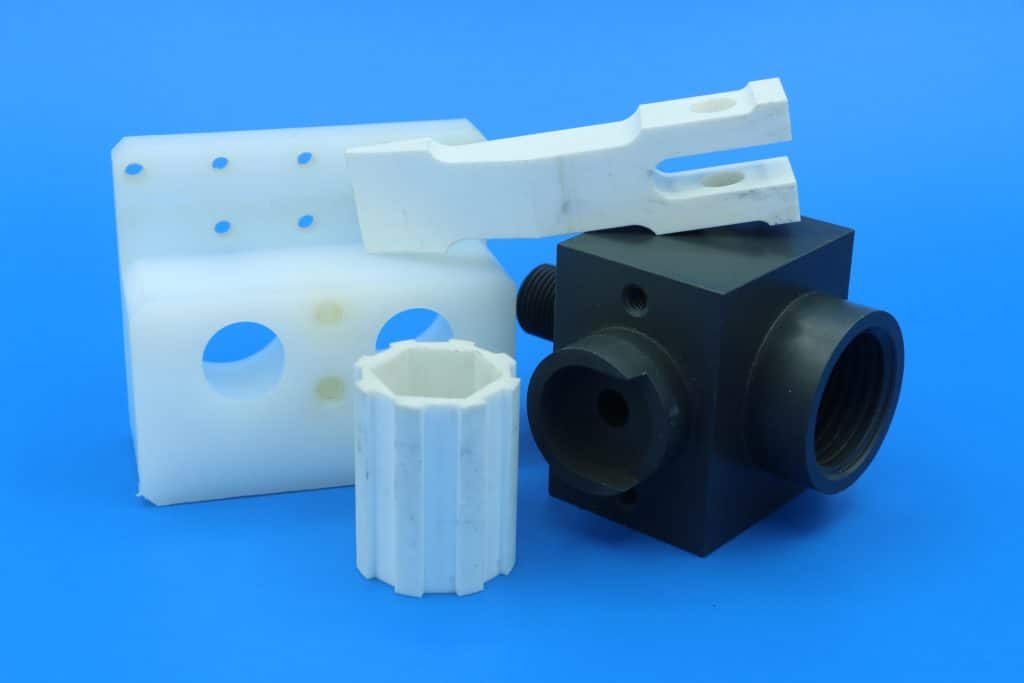

Engineering Guide: Plastic Mold Kit

Engineering Imperatives in Plastic Mold Kit Fabrication

Precision engineering is non-negotiable in plastic mold kit manufacturing. Minute deviations in cavity geometry, core alignment, or cooling channel placement directly translate to part defects, inconsistent cycle times, and accelerated tool wear. Surface finish irregularities cause ejection failures or secondary operations, while thermal management inaccuracies induce warpage and sink marks. These issues cascade into significant production downtime, scrap rates exceeding 15%, and compromised end-product integrity. For high-volume or safety-critical applications—medical devices, aerospace components, or automotive systems—even micron-level errors jeopardize regulatory compliance and brand reputation. Achieving dimensional stability across thousands of cycles demands not only advanced CNC capabilities but also profound material science expertise and rigorous process validation.

Wuxi Lead Precision Machinery operates at this exacting threshold. Our engineering team applies methodologies honed through mission-critical projects, including components for Beijing Winter Olympics timing systems and specialized tooling for Chinese military aerospace programs. These engagements demanded tolerances unattainable with standard manufacturing protocols, where failure was never an option. This experience directly informs our plastic mold kit production, embedding military-grade reliability into every cavity plate, ejector pin, and guide bushing we fabricate. We treat every client’s mold kit as a mission-critical system, applying the same zero-defect philosophy.

Our commitment manifests in quantifiable specifications, consistently achieved through 5-axis simultaneous machining, in-process metrology, and stress-relieved P20, H13, or S136 premium steels:

| Critical Parameter | Standard Industry Tolerance | Wuxi Lead Precision Tolerance | Impact on Mold Performance |

|---|---|---|---|

| Cavity/Core Match | ±0.02 mm | ±0.005 mm | Eliminates flash, ensures part consistency |

| Guide Pin/Bushing Fit | H7/g6 | H6/f5 | Prevents misalignment, extends mold life |

| Cooling Channel Position | ±0.1 mm | ±0.025 mm | Optimizes thermal transfer, reduces cycle time |

| Surface Finish (Cavity) | Ra 0.8 µm | Ra 0.2 µm (mirror polish) | Enhances part ejection, reduces defects |

| Hardness Uniformity | ±3 HRC | ±1 HRC | Ensures even wear resistance across mold |

This precision foundation transforms mold kit performance. Clients achieve faster ramp-up to full production, sustained part quality over 500,000+ cycles, and elimination of costly post-molding corrections. For industries where component failure carries severe consequences, Wuxi Lead’s engineering rigor provides essential risk mitigation. Our process integrates finite element analysis for stress prediction and iterative validation against ISO 2768-mK standards, ensuring the mold kit performs exactly as simulated under real-world injection parameters. Partnering with us means your production stability begins not on the shop floor, but in the microscopic accuracy of the mold itself. Your critical components deserve nothing less than engineered certainty.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision plastic mold kits for demanding industrial applications. Our engineering-driven approach combines state-of-the-art equipment with rigorous quality assurance protocols to ensure every component meets exacting specifications. At the core of our production capability is a full suite of 5 Axis CNC machining centers, enabling us to produce complex geometries with superior surface finishes and tight tolerances. This multi-axis technology allows for simultaneous movement across five planes, reducing setup time and enhancing dimensional accuracy—critical for intricate mold components such as cavities, cores, and sliders.

Our 5 Axis CNC systems are operated by experienced machinists who utilize advanced CAM software to optimize toolpaths and maintain consistency across production runs. This integration of hardware and software ensures minimal human intervention, reduced error rates, and repeatable precision. Materials commonly processed include P20, 718H, S136, and other mold-grade steels, all machined to meet the thermal, wear, and corrosion resistance requirements of high-performance plastic molding.

Quality control is embedded at every stage of production. All critical dimensions are verified using a Coordinate Measuring Machine (CMM) with full 3D measurement capability. This allows for comprehensive inspection of form, position, and profile tolerances in alignment with ISO 1101 standards. Our CMM system is calibrated regularly to national standards, ensuring traceability and compliance with international quality requirements. In addition to final inspection, in-process checks are performed to detect deviations early and maintain process stability.

We support both prototype development and high-volume production, offering scalable solutions without compromising on precision. Our facility maintains strict environmental controls to minimize thermal variation during machining and inspection, further enhancing repeatability. All technical data, including inspection reports and process documentation, are archived for full traceability and customer access.

The following table outlines the standard tolerance capabilities achievable across our 5 Axis CNC and inspection platforms:

| Feature | Standard Capability | Notes |

|---|---|---|

| Linear Dimensional Tolerance | ±0.005 mm | Up to 300 mm |

| Positional Tolerance | ±0.01 mm | GD&T controlled |

| Surface Roughness (Ra) | 0.4 µm (typical) | Can achieve 0.2 µm with polishing |

| Form Tolerance (Flatness) | 0.01 mm per 100 mm | Measured via CMM |

| Angular Accuracy | ±0.05° | 5 Axis simultaneous machining |

| Repeatability (CpK ≥ 1.67) | Within ±0.008 mm | Statistical process control applied |

Wuxi Lead Precision Machinery is committed to technical excellence in every plastic mold kit we manufacture. Our combination of advanced 5 Axis CNC machining and metrology-grade CMM inspection ensures that customers receive components that perform reliably in high-cycle molding environments.

Material & Finish Options

Material Selection for High-Performance Plastic Mold Kits

Selecting the optimal material for plastic mold kits is a critical engineering decision directly impacting part quality, production efficiency, tool longevity, and overall project economics. At Wuxi Lead Precision Machinery, we emphasize that material choice must align precisely with production volume, part complexity, resin type, surface finish requirements, and thermal management needs. Understanding the distinct properties of aluminum, steel, and titanium is fundamental to achieving superior results in demanding injection molding applications.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer exceptional thermal conductivity and machinability. This enables rapid heat extraction during the molding cycle, significantly reducing cycle times for prototyping and low-to-medium volume production. Aluminum’s lighter weight also simplifies mold handling. However, its lower hardness compared to steel limits its use in high-volume runs with abrasive resins or stringent wear resistance requirements. Steel remains the dominant choice for high-volume production. Pre-hardened steels like P20 provide a balanced combination of machinability, moderate hardness (28-32 HRC), and good polishability. For extended tool life under high pressure or with glass-filled materials, hardened tool steels such as H13 (48-52 HRC) or S136 stainless steel (corrosion resistance) are essential, despite longer machining times and higher initial costs. Titanium alloys, while significantly more expensive and challenging to machine, offer unparalleled strength-to-weight ratio and exceptional corrosion resistance. Their niche application lies in highly specialized molds requiring extreme durability in corrosive environments or where weight reduction is paramount for large, complex molds, though thermal conductivity is lower than aluminum.

The following table summarizes key comparative properties for common mold base and cavity materials:

| Material | Typical Hardness (HRC) | Thermal Conductivity (W/m·K) | Key Advantages | Primary Applications | Relative Cost |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | 167-200 | Fast cycle times, easy machining, light | Prototypes, low/med volume, inserts | Low |

| P20 Pre-Hard Steel | 28-32 | 25-30 | Good balance, polishable, cost-effective | Medium/high volume production | Moderate |

| H13 Tool Steel | 48-52 | 25-30 | High wear resistance, toughness | High volume, abrasive materials, cores | High |

| Titanium Alloy | 30-36 (as machined) | 7-17 | Extreme corrosion resistance, high strength/weight | Specialized corrosive environments | Very High |

Surface finishing, particularly anodizing, is crucial for aluminum mold components. Type II (Sulfuric Acid) anodizing provides a standard decorative and moderately wear-resistant layer (5-25 µm), enhancing corrosion resistance. For demanding mold applications requiring superior hardness and abrasion resistance, Type III (Hardcoat) anodizing is essential. This process creates a much thicker (25-100+ µm), dense ceramic oxide layer with hardness approaching 60-70 HRC, significantly extending the life of aluminum cores, cavities, and inserts exposed to wear, especially with filled polymers. Proper sealing post-anodizing is critical for maximum corrosion protection in molding environments.

Ultimately, the optimal material and finish strategy requires careful analysis of your specific application. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise and deep material science knowledge to guide clients through this selection process. We ensure your plastic mold kit is engineered from the right material with the appropriate surface treatment, maximizing performance, longevity, and return on investment for your production goals. Consult our engineering team early in the design phase for the most effective solution.

Manufacturing Process & QC

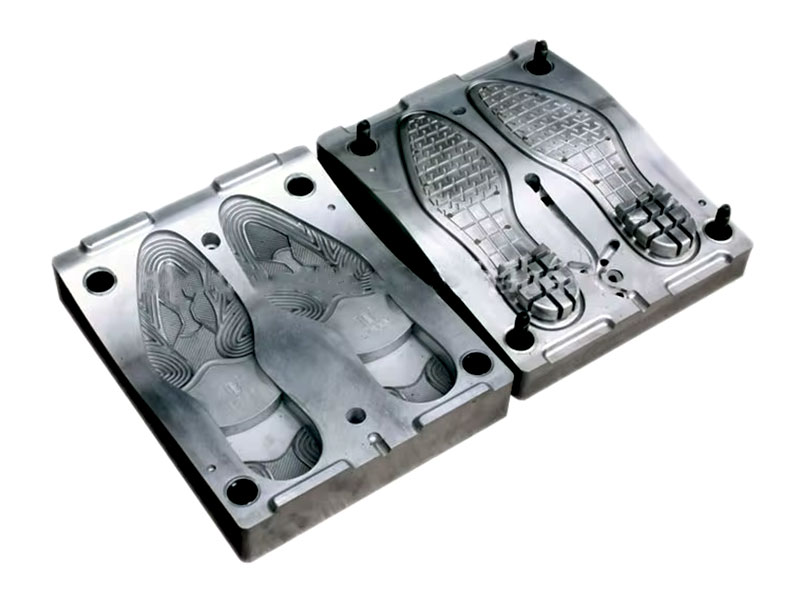

The production process for a high-precision plastic mold kit at Wuxi Lead Precision Machinery follows a rigorous, phase-gated methodology designed to ensure zero defects and full compliance with international quality standards. Our approach integrates advanced engineering, precision manufacturing, and systematic validation across three core stages: Design, Prototyping, and Mass Production.

Design is the foundation of a successful mold kit. Our engineering team begins with a detailed analysis of the client’s technical specifications, including part geometry, material properties, and production volume requirements. Utilizing 3D CAD software such as UG NX and SolidWorks, we develop mold flow analyses and structural simulations to optimize gate placement, cooling channels, and ejection systems. This virtual validation minimizes the risk of warpage, sink marks, or flow imbalances. All design outputs undergo internal peer review and are submitted for customer approval prior to progression, ensuring alignment with functional and dimensional expectations.

Prototyping follows design validation and serves as a physical proof of concept. We fabricate a single-cavity prototype mold using CNC machining, wire EDM, and surface grinding processes, achieving tolerances as tight as ±0.002 mm. The prototype mold is then tested on our in-house injection molding machines using the client-specified resin. First-article inspection reports (FAIR) and dimensional certifications are generated using CMM and optical measurement systems. Any deviations are addressed through iterative design adjustments, and the process is repeated until all parts meet the required specifications. This phase not only verifies mold performance but also validates cycle time, part quality, and process stability.

Upon successful prototyping, the project transitions to Mass Production. Full-scale molds—multi-cavity or family configurations—are manufactured using hardened tool steels such as P20, 718H, or H13, depending on lifespan and application. Each component undergoes strict in-process inspections, including hardness testing and surface roughness measurement. Assembly is performed in a climate-controlled environment by certified mold technicians, followed by mold trials under production conditions. We implement Statistical Process Control (SPC) and First Article Inspection (FAI) protocols to maintain consistency. Every mold kit is delivered with comprehensive documentation, including 2D/3D drawings, material certificates, and maintenance guidelines.

Our zero-defect commitment is enforced through ISO 9001-certified quality management systems, real-time traceability, and 100% final inspection. This disciplined process ensures that every plastic mold kit meets the highest standards of performance, durability, and repeatability.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Roughness | Ra 0.05 µm to Ra 0.4 µm |

| Tool Steel Options | P20, 718H, H13, S136 |

| Mold Life | 100,000 to 1,000,000+ cycles |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 30–50 days |

| Quality Standards | ISO 9001, SPC, FAIR, CMM Inspection |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Plastic Mold Kit Excellence

In high-volume plastic injection molding, the performance of your mold kit directly dictates production yield, part consistency, and operational cost. Substandard components lead to premature wear, flash defects, and costly downtime—risks no competitive manufacturer can afford. Wuxi Lead Precision Machinery delivers engineered metal solutions where tolerances matter most. We specialize in custom-manufactured mold bases, cavities, cores, and precision inserts that withstand 500,000+ cycles without degradation. Our CNC-machined components eliminate alignment drift and thermal distortion, ensuring your plastic parts meet aerospace, medical, and automotive specifications on every shot.

What sets Lead Precision apart is our integrated engineering-to-manufacturing workflow. Unlike commodity suppliers, we begin with your CAD data and material requirements, then apply 18 years of mold-steel metallurgy expertise to optimize geometry, cooling channels, and surface finishes. Our facility operates under ISO 9001:2015 and IATF 16949 protocols, with in-house heat treatment and hard milling capabilities that achieve ±0.002mm tolerances consistently. We don’t just machine parts—we solve for your total cost of ownership through extended tool life and reduced scrap rates.

Key technical capabilities for plastic mold kits include:

| Specification | Capability | Industry Standard |

|---|---|---|

| Tolerance Range | ±0.002mm to ±0.005mm | ±0.01mm–±0.02mm |

| Surface Finish (Ra) | 0.05µm–0.2µm (mirror grade) | 0.8µm–1.6µm |

| Hardness Range | HRC 52–54 (pre-hardened tool steels) | HRC 28–32 |

| Material Options | P20, 718H, S136, NAK80, H13 | P20 only |

| Lead Time (Complex) | 15–25 days | 30–45 days |

Your success hinges on partners who anticipate failure points before they occur. We conduct rigorous mold-flow analysis validation and coordinate pressure testing to 150% of operational loads. Our engineering team collaborates with you from concept to trial runs, adjusting cooling circuits or venting in real-time using 5-axis simultaneous machining. This proactive approach reduces your time-to-market by 30% while eliminating costly redesigns.

When you submit your project to Lead Precision, you gain a technical ally—not a vendor. We assign a dedicated manufacturing engineer to manage your kit’s lifecycle, providing material certifications, first-article inspection reports, and continuous process feedback. For urgent requirements, our priority scheduling guarantees drawing review within 24 hours of receipt.

Do not compromise on the foundation of your plastic molding operation. Email [email protected] today with your technical specifications and volume requirements. Include your target cycle count and material grade for a tailored feasibility assessment. Our engineering team will respond within 48 hours with a precision manufacturing plan, dimensional inspection protocol, and firm timeline. Partner with the precision leader trusted by Tier-1 automotive and medical device manufacturers worldwide—where every micron of accuracy translates to your bottom line.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.