Technical Contents

Engineering Guide: Plastic Mold Design

Engineering Insight: Precision as the Non-Negotiable Core of Plastic Mold Design

In high-stakes plastic injection molding, the mold is not merely a tool; it is the definitive determinant of part quality, production efficiency, and ultimately, product success. Achieving true precision in mold design transcends basic dimensional accuracy. It demands an intricate understanding of material behavior under extreme pressure and temperature, microscopic control over cavity geometry, and flawless execution of complex cooling and ejection systems. Minute deviations—measured in microns—directly translate to part warpage, flash, sink marks, inconsistent mechanical properties, or premature mold failure. For industries where component integrity is critical—medical devices, aerospace components, or advanced consumer electronics—such deviations are unacceptable. Precision mold design is the engineered solution to these challenges, ensuring consistent replication of geometry, optimal material flow, balanced thermal management, and extended tool life under relentless production cycles.

Wuxi Lead Precision Machinery operates at this pinnacle of expectation. Our engineering team possesses over 15 years of specialized expertise in designing and manufacturing molds where tolerances are non-negotiable. This rigor is forged through direct experience delivering for the most demanding sectors. We engineered precision molds for components used in Olympic-grade athletic equipment, where performance consistency under peak stress is paramount. Similarly, our adherence to stringent military specifications (MIL-STD) for defense-related plastic assemblies underscores our capability to meet exacting standards for durability, environmental resistance, and absolute dimensional fidelity. These projects demanded not only exceptional design insight but also mastery of advanced materials, sophisticated simulation (Moldflow analysis), and ultra-precise CNC machining capabilities—all core competencies honed at our Wuxi facility.

The tangible output of this precision philosophy is embedded in measurable specifications. Our standard capabilities consistently achieve levels essential for mission-critical applications:

| Critical Parameter | Standard Capability (Wuxi Lead) | Significance for Performance |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | Ensures perfect part fit and assembly integrity |

| Surface Roughness (Cavity) | Ra 0.025 µm (Mirror Polish) | Critical for optical clarity and low-friction surfaces |

| Core/Cavity Alignment | < 0.003 mm | Eliminates flash and ensures uniform wall thickness |

| Thermal Stability (ΔT) | ±1.5°C across cavity | Prevents warpage and internal stresses in part |

| Tool Life (Cyclic Testing) | > 1,000,000 cycles (Verified) | Guarantees production uptime and cost efficiency |

This level of precision is not accidental. It is the result of integrated engineering disciplines: advanced CAD/CAM for flawless digital modeling, rigorous mold flow simulation predicting material behavior, strategic use of premium mold steels (e.g., S136HH, NAK80), and meticulous attention to detail in cooling channel design and venting. At Wuxi Lead, we recognize that your plastic part’s success is born in the mold cavity. Our commitment is to transform your design intent into a robust, high-precision manufacturing reality, proven by the components trusted in Olympic competition and military deployment. Partner with engineering certainty.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for complex plastic mold design applications. Our integrated manufacturing ecosystem combines state-of-the-art 5-axis CNC machining with rigorous quality control protocols to ensure every mold component meets the exacting standards required in aerospace, medical, automotive, and consumer electronics industries.

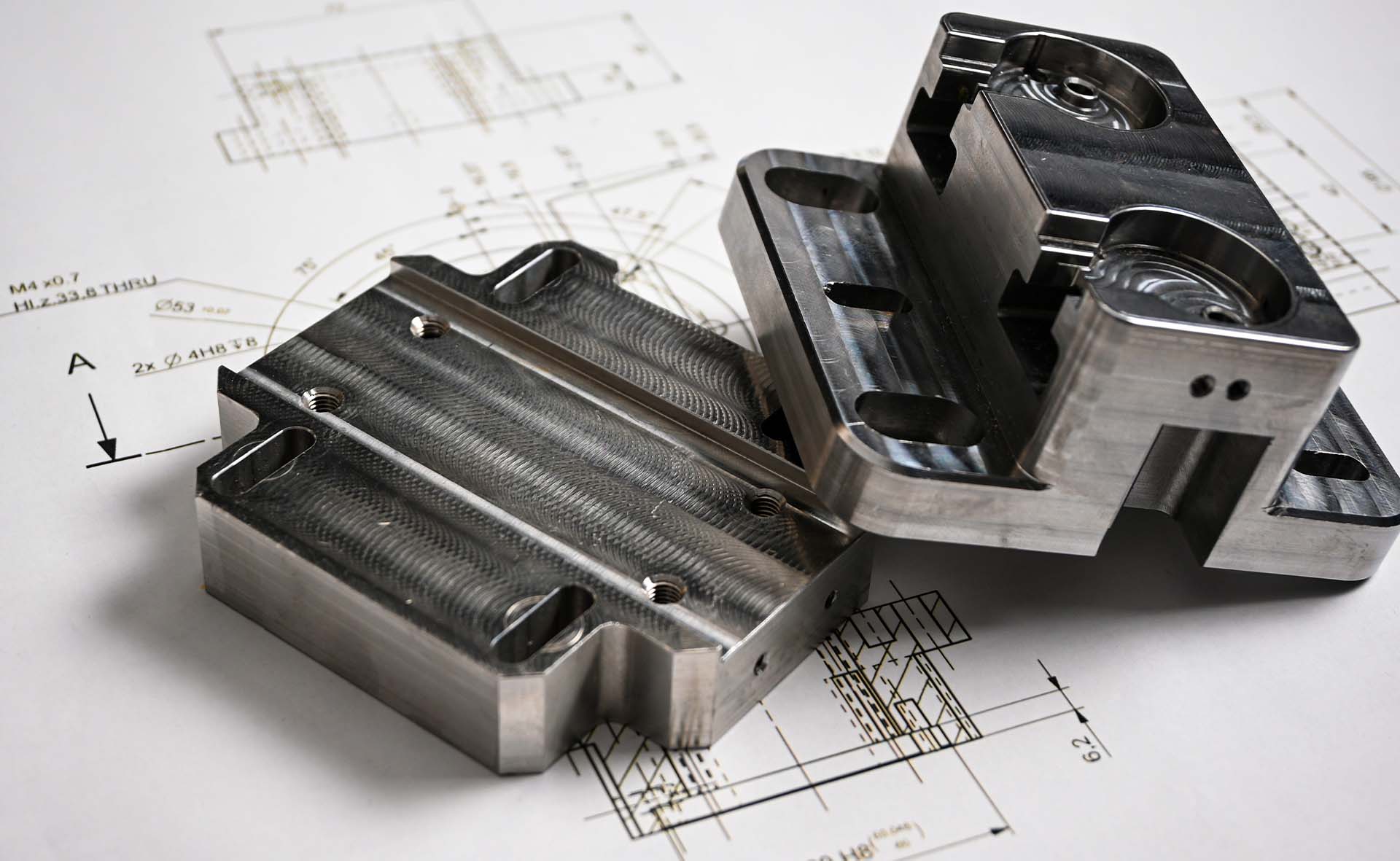

At the core of our production capability is our 5-axis CNC machining platform. This technology enables simultaneous multi-directional cutting, allowing us to produce highly intricate geometries with superior surface finishes and dimensional accuracy. The dynamic motion control of our 5-axis systems reduces the need for multiple setups, minimizing human error and significantly improving repeatability. We work with a broad range of tool steels, stainless alloys, and hardened materials commonly used in injection mold cores, cavities, ejector pins, and sliders. Our CNC systems are equipped with high-speed spindles and automated tool changers, ensuring efficient material removal rates while maintaining micron-level precision.

Complementing our machining excellence is a comprehensive quality assurance process anchored by Coordinate Measuring Machine (CMM) inspection. Every critical component undergoes full dimensional verification using Zeiss and Hexagon CMM systems, which provide non-contact and tactile probing for accurate 3D data capture. Our inspection protocols are aligned with ISO 10360 standards, ensuring traceability and compliance. In addition to CMM, we employ optical comparators, surface roughness testers, and hardness gauges to validate both macro and micro characteristics of finished parts.

All inspection data is documented and archived for full production traceability, supporting APQP and PPAP requirements for our OEM partners. Our quality engineers work in parallel with design and manufacturing teams to implement GD&T best practices from the initial design phase, reducing rework and accelerating time-to-market.

The following table outlines the standard tolerances we consistently achieve across typical mold-making projects:

| Feature | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, Micrometer |

| Angular Accuracy | ±0.05° | ±0.02° | CMM, Optical Comparator |

| Positional Tolerance (GD&T) | ±0.015 mm | ±0.008 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Surface Tester |

| Flatness | 0.01 mm / 100 mm | 0.005 mm / 100 mm | CMM, Surface Plate |

| Core & Cavity Matching | ±0.01 mm | ±0.005 mm | CMM, Fit Testing |

Our technical capabilities are reinforced by a culture of precision engineering and continuous improvement. At Wuxi Lead Precision Machinery, we do not merely manufacture mold components—we engineer reliability into every micron.

Material & Finish Options

Strategic Material Selection for High-Performance Plastic Injection Molds

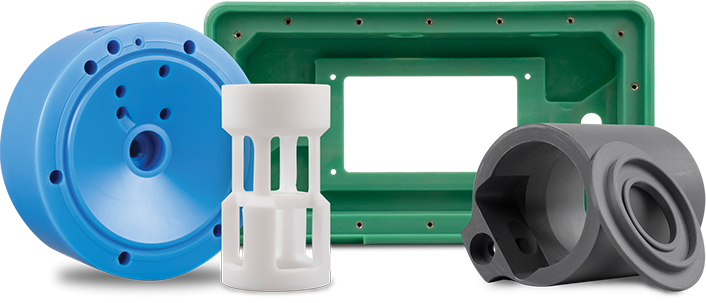

Material selection is a foundational strategic decision in plastic mold design, directly impacting production economics, part quality, and tool longevity. At Wuxi Lead Precision Machinery, we guide clients through this critical phase by aligning material properties with specific application demands, production volume, and resin characteristics. Choosing incorrectly risks premature wear, dimensional instability, and unsustainable operational costs. The optimal choice balances upfront investment against total lifecycle value.

Aluminum alloys, particularly 7075-T6, offer exceptional machinability and thermal conductivity. This enables significantly faster cooling cycles and reduced lead times for mold fabrication, making aluminum ideal for rapid prototyping, low-to-medium volume production runs under 100,000 shots, and applications requiring frequent design iterations. Its lower hardness compared to steel necessitates protective surface treatments like anodizing for most production scenarios to resist abrasion from filled resins. Aluminum provides the lowest initial tooling cost but is unsuitable for high-volume, abrasive, or high-temperature polymer applications.

Tool steels, such as P20, H13, and S136, represent the industry standard for medium-to-high volume production exceeding 100,000 shots. Their superior hardness, wear resistance, and thermal stability withstand the rigors of demanding polymers, including glass-filled or mineral-filled compounds, and extended production cycles. While machining and heat treatment increase lead times and initial costs compared to aluminum, the extended service life and consistent part quality deliver superior long-term value for high-output manufacturing. Steel molds require precise heat treatment and may utilize specialized coatings for enhanced performance in corrosive environments.

Titanium alloys (e.g., Ti-6Al-4V) serve highly specialized niche applications where extreme corrosion resistance is paramount, such as molding aggressive PVC or specific medical-grade polymers in cleanroom environments. Its exceptional strength-to-weight ratio and biocompatibility are advantageous in specific medical device tooling. However, titanium’s high cost, challenging machinability, and lower thermal conductivity compared to aluminum generally limit its use to situations where its unique corrosion properties are non-negotiable, often offsetting its disadvantages only in very specific, high-value applications.

Surface finishing, particularly for aluminum molds, is non-optional for production viability. Anodizing creates a hard, wear-resistant ceramic layer. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and a base for dyeing, suitable for many standard applications. For demanding production involving abrasive materials or requiring maximum surface hardness and wear life, Type III (Hardcoat) anodizing is essential, producing a significantly thicker, harder, and more durable oxide layer capable of withstanding hundreds of thousands of cycles when properly specified and applied.

The following table summarizes key comparative properties for common mold materials:

| Material | Hardness (HB) | Thermal Conductivity (W/mK) | Cost Factor | Best For Applications |

|---|---|---|---|---|

| Aluminum 7075 | 150 | 130 | Low | Prototypes, low-volume, rapid iterations |

| P20 Steel | 280-320 | 28-36 | Medium | Medium/high volume, general production |

| H13 Steel | 200-240 | 24-30 | Medium-High | Hot runner systems, high-temp resins |

| S136 Stainless | 250-300 | 20-25 | High | Corrosive resins, optical, medical parts |

| Ti-6Al-4V | 330 | 7-8 | Very High | Extreme corrosion resistance requirements |

Selecting the precise material and finish requires deep understanding of your polymer, part geometry, volume targets, and quality expectations. Wuxi Lead Precision Machinery leverages decades of custom mold manufacturing expertise to ensure your material choice delivers optimal performance and cost efficiency throughout the mold’s operational life. Contact our engineering team for a tailored assessment.

Manufacturing Process & QC

From Concept to Perfection: The Plastic Mold Design and Manufacturing Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal manufacturing solutions, with a core focus on advanced plastic mold design and production. Our integrated process ensures zero defects, on-time delivery, and consistent part quality across every production run. The journey from initial concept to mass production is meticulously controlled through three key phases: Design, Prototyping, and Mass Production.

The process begins with Design, where our engineering team collaborates closely with clients to translate product requirements into optimized mold architecture. Utilizing industry-leading CAD/CAM software such as UG (NX), SolidWorks, and AutoCAD, we conduct detailed 3D modeling, mold flow analysis, and structural validation. This phase includes precise cavity layout planning, gate positioning, cooling system design, and ejection mechanism engineering. Every design is reviewed for manufacturability, material compatibility, cycle time efficiency, and long-term durability under production conditions.

Once the design is finalized and approved, we move to the Prototyping stage. Rapid prototyping allows us to produce a functional mold for initial trial runs using the same materials and precision machining techniques as full-scale production. This prototype is used to manufacture sample parts, which undergo rigorous inspection for dimensional accuracy, surface finish, and structural integrity. Any deviations are analyzed using CMM (Coordinate Measuring Machine) reports and 3D scanning data, enabling immediate design or process adjustments. This iterative validation ensures that the mold performs flawlessly before entering high-volume manufacturing.

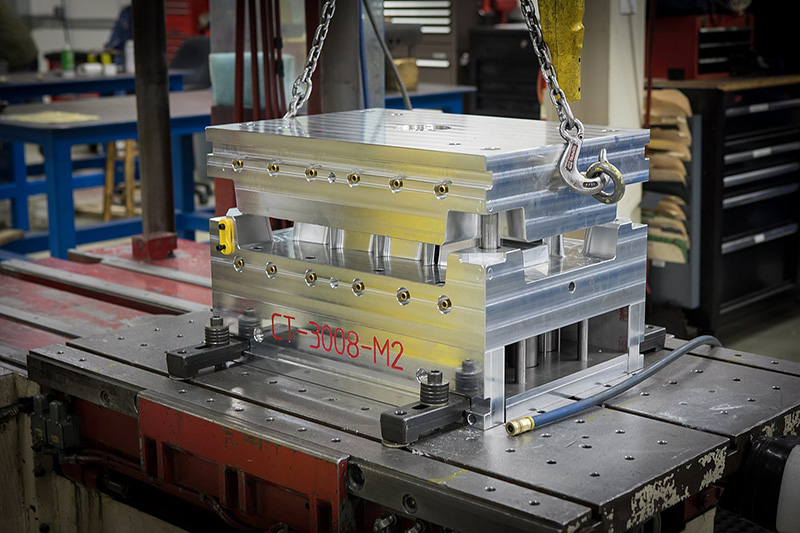

The final phase, Mass Production, leverages our fully automated CNC machining centers, EDM systems, and robotic mold handling to maintain consistency and precision. Our production floor operates under strict ISO 9001-certified quality management protocols, with real-time monitoring of key parameters such as injection pressure, temperature, and cycle time. Every mold is built to withstand over 1 million cycles with zero degradation in part quality. We implement preventive maintenance schedules and in-process inspections to guarantee zero-defect output across all production batches.

Our commitment to excellence is reflected in the technical capabilities we bring to every project. Below are the core specifications of our plastic mold manufacturing process.

| Specification | Details |

|---|---|

| Mold Material | P20, 718H, S136, H13, 420 Stainless Steel |

| Tolerance | ±0.005 mm |

| Surface Finish | SPI A1, B1, VDI 10–25 (polished, textured, matte) |

| Maximum Mold Size | 1200 × 1000 × 800 mm |

| Machining Equipment | 3-Axis, 4-Axis, 5-Axis CNC, EDM, Wire Cut |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 30–50 days |

| Quality Standards | ISO 9001:2015, Full CMM Inspection, Mold Flow Analysis |

At Wuxi Lead Precision Machinery, we don’t just build molds—we engineer reliability, precision, and long-term value for global manufacturing partners.

Why Choose Wuxi Lead Precision

Elevate Your Plastic Mold Design with Precision Engineering

In the demanding landscape of custom metal manufacturing for plastic injection molds, precision is non-negotiable. Complex geometries, stringent tolerances, and extended production cycles demand a partner with uncompromising technical mastery. Wuxi Lead Precision Machinery delivers engineered excellence where others compromise, transforming your most challenging mold designs into high-yield, long-life production assets. Our ISO 9001-certified facility in China integrates German-engineered CNC systems with decades of mold-making expertise, ensuring every component meets aerospace and medical-grade standards. We eliminate costly iterations through finite element analysis (FEA) and mold flow simulation, directly translating your specifications into molds that perform flawlessly from first shot to millionth cycle.

Our commitment extends beyond machining to holistic design optimization. Our engineers collaborate early in your development phase, identifying potential stress points, ejection risks, and cooling inefficiencies before metal is cut. This proactive approach reduces time-to-market by up to 30% while extending mold service life through strategic material selection and surface hardening techniques. We specialize in multi-cavity molds for high-volume production, micro-molding for sub-gram components, and corrosion-resistant solutions for aggressive polymer formulations. Every mold undergoes rigorous metrology validation using Zeiss CMM systems, guaranteeing dimensional accuracy that sustains part consistency across 500,000+ cycles.

Technical Capabilities at a Glance

| Specification | Capability Range | Industry Benchmark |

|---|---|---|

| Max Mold Size | 1,200 x 800 x 700 mm | 1,000 x 600 x 500 mm |

| Tolerance Precision | ±0.002 mm (sub-micron critical zones) | ±0.005 mm |

| Cavity Complexity | Up to 32 cavities with hot runners | 16 cavities |

| Tool Steel Grades | S136, NAK80, AISI H13, Maraging Steel | Standard P20 |

| Surface Finish Options | SPI A1 (Mirror) to EDM textures | SPI B2 |

| Lead Time Reduction | 25-40% via concurrent engineering | Industry standard |

Partnering with Lead Precision means accessing a strategic advantage in reliability and innovation. We reject the notion that cost efficiency requires sacrificing precision—our lean manufacturing protocols and automated workflows deliver superior value without margin erosion. Our clients in automotive, medical device, and consumer electronics sectors rely on us for zero-defect performance in mission-critical applications. When your project demands molds that withstand 200+ ton clamping forces while maintaining micron-level registration, our technical team becomes your extension.

Initiate a technical consultation today to validate your mold design against real-world production physics. Email [email protected] with your CAD files and performance requirements. Our engineering lead will respond within 4 business hours with a feasibility assessment and actionable optimization roadmap—no generic quotes, only engineered solutions. Trust Wuxi Lead Precision Machinery to transform plastic mold complexity into your competitive certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.