Technical Contents

Engineering Guide: Plastic Mold Construction

Engineering Insight Precision in Plastic Mold Construction

Precision in plastic mold construction is non-negotiable for high-performance manufacturing. In sectors like aerospace, medical devices, and automotive, even micron-level deviations compromise part integrity, functionality, and lifecycle durability. A mold with inconsistent wall thickness or misaligned cavities induces stress points in the final product, accelerating wear or catastrophic failure under operational loads. At Wuxi Lead Precision Machinery, we treat mold accuracy as the foundation of production efficiency—reducing scrap rates, minimizing post-processing, and ensuring repeatability across millions of cycles. Our approach transcends standard tolerances; it integrates material science, thermal dynamics, and metrology to preempt real-world variables before the first shot.

Neglecting precision engineering incurs hidden costs. Poorly calibrated molds cause flash, sink marks, or dimensional drift, forcing costly downtime for adjustments. In high-volume production, a 0.01mm tolerance error can waste thousands in material and labor daily. For critical applications—such as hydraulic components in military vehicles or structural brackets for Olympic-grade sporting equipment—such errors risk safety compliance and brand reputation. This is why Lead Precision mandates multi-axis CNC machining with real-time thermal compensation, coupled with iterative CMM validation at every stage. Our proprietary stress-relief protocols for mold steel eliminate latent distortion, ensuring cavity geometries remain stable after 500,000+ cycles.

The following specifications reflect our baseline standards for mission-critical molds, validated through decades of aerospace and defense contracts:

| Parameter | Standard Tolerance | High-Precision Tolerance | Application Example |

|---|---|---|---|

| Linear Dimension | ±0.01 mm | ±0.002 mm | Aircraft sensor housings |

| Surface Roughness (Ra) | 0.8 µm | 0.05 µm | Medical implant cavities |

| Cavity Alignment | 0.02 mm | 0.003 mm | Satellite component molds |

| Steel Grade | P20, H13 | Maraging Steel (18Ni300) | Military-grade hydraulic molds |

| Cavity Count | 1–16 | 1–64 (synchronized) | Mass-production consumer parts |

Wuxi Lead’s expertise is forged in environments where failure is not an option. Our molds supported the hydraulic systems of Beijing 2022 Winter Olympic snowmaking infrastructure, operating flawlessly at -40°C. Similarly, we engineered corrosion-resistant molds for naval artillery components, meeting MIL-STD-810G vibration and salt-fog resistance requirements. These projects demanded zero-defect delivery under compressed timelines—a testament to our integrated design-to-manufacturing workflow. Every mold undergoes 120+ data-point verification, from initial CAD topology optimization to in-press validation under simulated production pressure.

For OEMs, precision mold construction is an investment in supply chain resilience. It eliminates the ripple effects of part rejection, accelerates time-to-market, and secures certification in regulated industries. At Lead Precision, we don’t just build molds; we engineer production certainty. Partner with us to transform your most demanding plastic part specifications into repeatable, cost-optimized reality.

Precision Specs & Tolerances

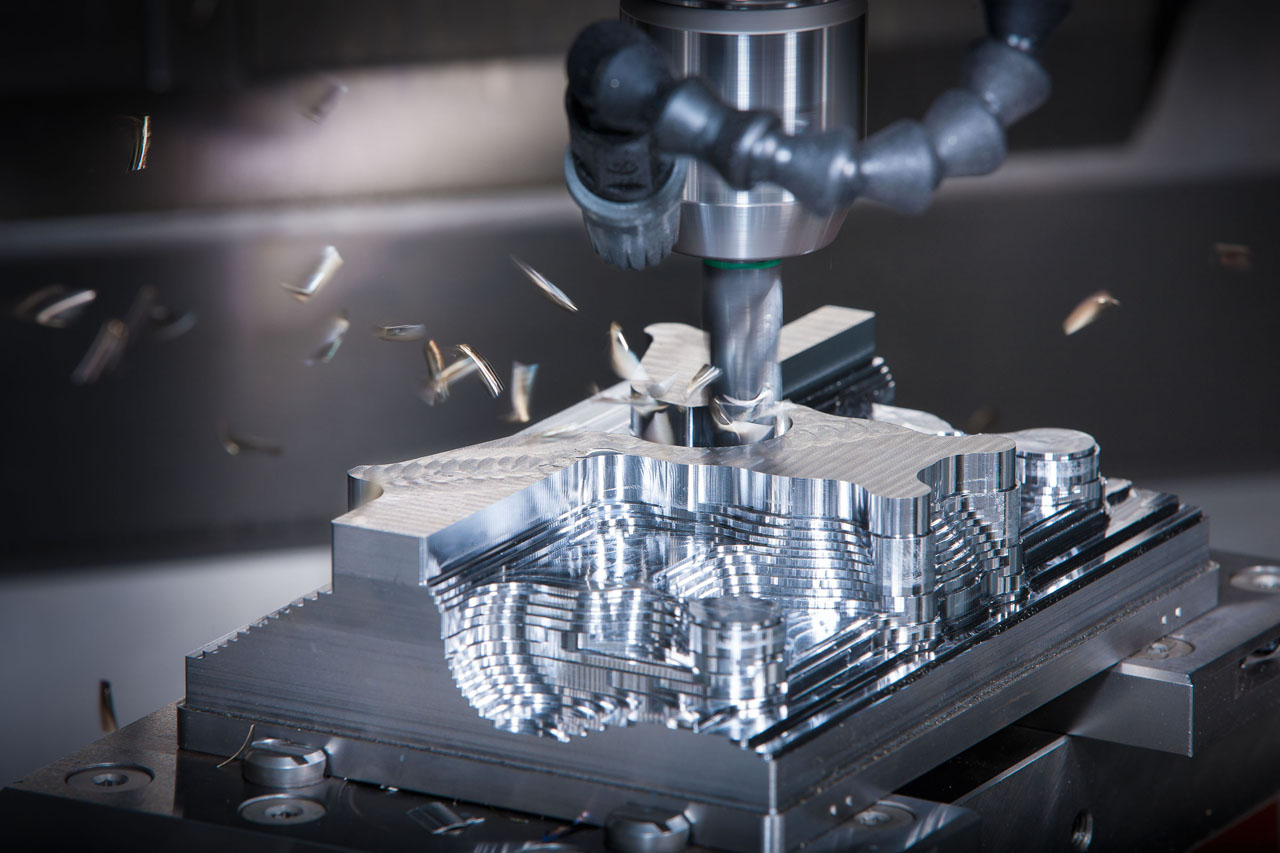

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision plastic mold construction for global industrial clients. Our facility integrates state-of-the-art 5 Axis CNC machining systems to achieve complex geometries with superior surface finishes and dimensional accuracy. These multi-axis platforms enable simultaneous cutting from five different directions, allowing for intricate core and cavity details common in injection molds for automotive, medical, and consumer electronics applications. By eliminating the need for multiple setups, 5 Axis CNC machining reduces human error, improves part consistency, and shortens lead times without compromising on quality.

All machining operations are supported by a rigorous quality control framework anchored in CMM (Coordinate Measuring Machine) inspection. Our Zeiss and Hexagon CMM systems provide metrology-grade verification of critical mold features, ensuring compliance with international standards such as ISO 2768 and ASME Y14.5. Every mold undergoes full dimensional validation, including profile, position, flatness, and surface contour analysis. Data from CMM reports is documented and traceable, providing clients with full transparency and audit-ready documentation for regulated industries.

Our technical team combines decades of mold-making expertise with advanced simulation software to optimize toolpaths, minimize thermal deformation, and extend tool life. This digital-first approach ensures that each mold is manufactured to exacting specifications while maintaining structural integrity and long-term durability under high-cycle production conditions. We work with a wide range of tool steels and specialty alloys, including P20, 718H, S136, and H13, tailored to the client’s production volume, material, and environmental requirements.

Material selection, heat treatment, and surface finishing are all managed in-house, enabling tight process control across every phase of mold construction. From electrode fabrication for EDM operations to fine polishing and texturing, our capabilities support molds that meet SPI-SPE standards up to Class 101. This comprehensive process integration ensures repeatable precision and superior part replication over millions of cycles.

The following table outlines our standard technical specifications and achievable tolerances in plastic mold construction:

| Feature | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimension Tolerance | ±0.01 mm (up to 300 mm) |

| Surface Flatness | 0.003 mm per 100 mm |

| Surface Finish (milled) | Ra 0.8 µm (typical), down to Ra 0.2 µm |

| Profile Tolerance | ±0.01 mm (complex contours) |

| Hole Concentricity | ≤ 0.01 mm TIR |

| CMM Measurement Accuracy | ±0.0025 mm |

| Maximum Work Envelope | 1200 x 800 x 700 mm (5 Axis CNC) |

| Minimum Internal Radius | 0.2 mm (with micro tooling) |

At Wuxi Lead Precision Machinery, precision is not just a target—it is a measurable outcome built into every stage of production. Our technical capabilities ensure that each custom mold meets the highest standards of performance, longevity, and repeatability.

Material & Finish Options

Strategic Material Selection for High-Performance Plastic Molds

Material selection is a critical determinant of mold performance, longevity, and overall project economics in precision plastic injection molding. At Wuxi Lead Precision Machinery, we guide clients through the optimal choice between Aluminum, Steel, and Titanium based on production volume, part complexity, resin type, and total cost of ownership. Each material offers distinct advantages and limitations demanding careful evaluation against specific application requirements.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production. Their superior thermal conductivity accelerates cycle times significantly compared to steel, improving throughput during initial runs. Aluminum machines faster, reducing lead times and initial tooling costs. However, its lower hardness and wear resistance limit suitability for abrasive resins, high-cavity-count molds, or extended high-volume production exceeding 100,000 shots. Surface treatments like hard anodizing are often essential to enhance wear resistance for these applications.

Tool steels, including P20, H13, S7, and stainless grades like 420, form the backbone of high-volume production molds. Offering exceptional hardness, wear resistance, and dimensional stability under thermal cycling, they withstand millions of shots even with glass-filled or mineral-loaded engineering plastics. P20 provides a cost-effective balance for moderate volumes, while H13 excels in demanding thermal environments requiring superior toughness. Stainless steels are mandatory for medical or optical applications demanding absolute corrosion resistance and ultra-smooth surfaces. The higher initial machining cost and longer lead times are justified by vastly extended service life in high-production scenarios.

Titanium alloys, while possessing extraordinary strength-to-weight ratio and corrosion resistance, see extremely limited use in standard plastic molds due to high cost, challenging machinability, and lower thermal conductivity compared to aluminum. Their application is typically restricted to highly specialized, niche scenarios like corrosive environments where steel fails and weight is critical, often proving cost-prohibitive for mainstream molding.

Anodizing is a vital surface enhancement primarily for aluminum molds. Standard sulfuric acid anodizing (Type II) provides moderate corrosion resistance and a base for dyeing. For mold applications, hard anodizing (Type III) is essential, creating a thick, dense, abrasion-resistant ceramic oxide layer that significantly extends the life of aluminum molds in production, particularly against wear from part ejection and resin flow. Proper sealing post-anodizing is crucial to prevent moisture ingress and maintain performance. Note that anodizing is not applicable to steel or titanium molds; these require alternative surface treatments like nitriding, PVD, or HVOF coatings.

The table below summarizes key material properties for mold construction:

| Material | Common Grades | Hardness (HRC) | Thermal Conductivity (W/m·K) | Primary Application Range |

|---|---|---|---|---|

| Aluminum | 7075-T6, 6061-T6 | 15-35 | 130-180 | Prototypes, Low/Med Volume |

| Tool Steel | P20, H13, 420 SS | 28-54 | 25-40 | Medium/High Volume Production |

| Titanium Alloy | Ti-6Al-4V | 30-40 | 6-7 | Highly Specialized Applications |

Selecting the correct base material and appropriate surface treatment is fundamental to achieving optimal mold performance and part quality. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise and deep material science knowledge to recommend and fabricate molds using the precise material solution for your unique production demands, ensuring maximum return on your tooling investment. Consult our engineering team early in the design phase for the most effective material strategy.

Manufacturing Process & QC

Plastic Mold Construction: From Precision Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our approach to plastic mold construction is engineered for uncompromising quality, repeatability, and performance. As a leader in custom metal manufacturing, we integrate advanced engineering with rigorous process control to deliver molds that meet the highest global standards. Our production workflow follows a disciplined sequence: Design, Prototyping, and Mass Production—each phase meticulously optimized to achieve zero defects.

The process begins with Design, where our engineering team leverages industry-leading CAD/CAM software to create fully detailed 3D models of the mold. This phase includes comprehensive analysis of part geometry, material flow, cooling efficiency, and ejection dynamics. Finite Element Analysis (FEA) and Mold Flow Simulation ensure that potential defects such as warpage, sink marks, or air traps are identified and corrected before any metal is cut. All designs adhere to ISO 13000 mold standards and are reviewed collaboratively with the client to ensure alignment with functional and production requirements.

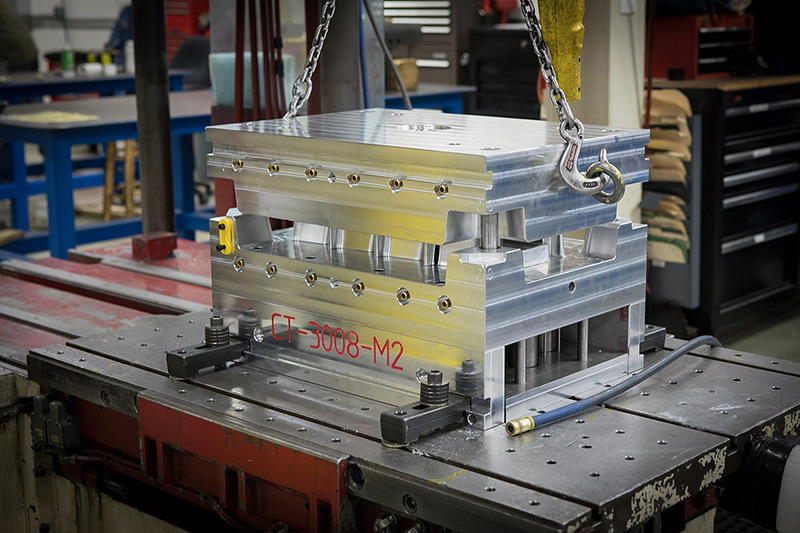

Following design approval, we move into Prototyping. A functional prototype mold is fabricated using high-precision CNC machining, wire EDM, and surface grinding to achieve tolerances within ±0.002 mm. This prototype is used to produce initial sample parts under near-production conditions. These samples undergo full dimensional inspection, material validation, and fit/function testing. Any deviations are traced to root causes using Six Sigma methodologies, and corrective actions are implemented before progression. This phase not only validates the design but also confirms process stability and repeatability.

Once prototyping is successfully completed, the project transitions to Mass Production. Our automated production cells, equipped with multi-axis CNC machines and real-time monitoring systems, ensure consistent output. Each mold component is tracked through our Manufacturing Execution System (MES), enabling full traceability of materials, tooling, and process parameters. In-process inspections occur at critical stages, supported by CMMs, optical comparators, and laser scanning. Final molds are subjected to a 100% functional test, including dry cycles, pressure checks, and surface finish verification.

Our zero-defect philosophy is enforced through continuous process validation and preventive maintenance. Every mold is delivered with a comprehensive quality dossier, including inspection reports, material certifications, and process capability (Cp/Cpk) data.

The table below outlines key specifications achieved in our plastic mold construction process:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (cavity) | Ra ≤ 0.05 µm (polished) |

| Mold Life Expectancy | 1,000,000+ cycles (standard) |

| Material Standards | P20, 718, S136, H13, or customer-specified |

| Lead Time (Design to Delivery) | 4–8 weeks (varies by complexity) |

| Quality Compliance | ISO 9001, IATF 16949, PPAP Level 3 |

Wuxi Lead Precision Machinery ensures that every plastic mold is not only a precision-engineered tool but a cornerstone of reliable, high-efficiency production for our clients worldwide.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Plastic Mold Excellence

At Wuxi Lead Precision Machinery, we engineer plastic molds that redefine industry standards for durability, accuracy, and production efficiency. Our dedicated facility in Wuxi, China, operates under rigorous ISO 9001:2015 protocols, merging German-inspired precision engineering with agile Chinese manufacturing execution. We specialize in complex, high-cavitation molds for medical, automotive, and consumer electronics applications—where tolerances below 5μm and flawless surface replication are non-negotiable. Unlike generalist suppliers, our team comprises mold designers and CNC specialists with 15+ years of hands-on experience in P20, 718H, S136, and maraging steel optimization. We eliminate costly iterations through integrated mold-flow analysis and real-time in-process metrology, ensuring your design transitions seamlessly from CAD to high-volume production.

Our technical capabilities are built for mission-critical mold construction:

| Specification | Capability | Industry Benchmark |

|---|---|---|

| Positional Accuracy | ±0.002 mm | ±0.005 mm |

| Surface Finish (Cavity/Core) | Ra 0.025 μm (Mirror Polish) | Ra 0.1 μm |

| Max Mold Size | 1200 x 800 x 700 mm | 1000 x 600 x 500 mm |

| Steel Grades | S136, NAK80, 2344, Maraging Steel (250/300) | Limited to P20/718H |

| Cooling Channel Precision | ±0.01 mm positional tolerance | ±0.05 mm |

| Lead Time Reduction | 25–30% faster vs. conventional suppliers | Standard industry cycle |

Choosing Lead Precision means partnering with a team that treats your project as a technical collaboration—not a transaction. We deploy proprietary electrode wear compensation algorithms in our EDM processes and enforce zero-defect culture through 100% CMM validation of critical features. Our clients consistently achieve 30% longer mold lifespans and 40% faster cycle times due to precision-engineered venting, ejection, and thermal management systems. When material warpage or sink marks threaten your production schedule, our engineers deliver root-cause solutions within 72 hours—not weeks.

Initiate your mold project with confidence. Contact our technical sales team at [email protected] to schedule a confidential consultation. Include your CAD files or technical specifications, and we will provide a detailed manufacturability analysis within 4 business hours—no obligation. Our engineers stand ready to optimize your design for cost, cycle time, and longevity, backed by a 24-month structural warranty on all mold bases. For global OEMs and tier-1 suppliers demanding zero-compromise tooling, Wuxi Lead Precision Machinery is the strategic partner that delivers precision on deadline, every time. Trust your next high-stakes mold project to the standard-bearers of Chinese precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.