Technical Contents

Engineering Guide: Plastic Laser Cutting

Engineering Insight: Precision Imperatives in Plastic Laser Cutting

Plastic laser cutting presents unique engineering challenges distinct from metal fabrication, where thermal management and material behavior dictate success. Unlike metals, thermoplastics and composites exhibit significant sensitivity to heat input, prone to melting, charring, or warping if process parameters deviate even marginally. Achieving clean edges, tight tolerances, and consistent part geometry demands laser systems engineered for exceptional beam quality, dynamic power control, and ultra-stable motion. The slightest vibration, inconsistent gas assist, or thermal drift during extended runs can compromise critical dimensions or surface finish, rendering components unusable in high-integrity applications. This precision is non-negotiable for sectors like medical device manufacturing, aerospace interiors, and advanced electronics, where polymer components must interface flawlessly with other precision assemblies.

At Wuxi Lead Precision Machinery, our engineering philosophy centers on mitigating these inherent plastic cutting challenges through integrated system design and rigorous process validation. We leverage decades of experience honed on projects demanding absolute reliability, including components for Olympic Games infrastructure and classified military systems. These engagements required machining complex polymer parts to tolerances below ±0.02mm under stringent environmental and quality audits, proving our capability in the most demanding scenarios. Our machines incorporate active thermal compensation systems, vibration-dampened gantries, and closed-loop power monitoring specifically calibrated for diverse plastics—from delicate polycarbonates to reinforced nylons. This ensures minimal heat-affected zones, burr-free edges, and dimensional stability across production batches, directly addressing the thermal distortion risks inherent in polymer processing.

Material compatibility and process repeatability are equally critical. We conduct extensive material-specific parameter libraries validated through iterative testing, optimizing pulse duration, frequency, and assist gas composition for each polymer type. This empirical approach, refined through our work on mission-critical projects, guarantees that intricate geometries and fine features are reproduced consistently, eliminating costly scrap and rework. Our commitment extends beyond the machine to comprehensive process documentation and operator training, ensuring clients achieve the precision their applications require from day one.

The following specifications demonstrate our engineering focus on plastic cutting performance:

| Parameter | Value | Relevance to Plastic Cutting |

|---|---|---|

| Beam Quality (M²) | ≤ 1.1 | Minimizes heat spread, prevents edge melting |

| Positioning Accuracy | ± 0.01 mm | Ensures dimensional fidelity for tight interfaces |

| Repeatability | ± 0.005 mm | Guarantees batch consistency |

| Thermal Drift Control | < 5 µm/°C | Maintains precision in fluctuating environments |

| Pulse Control Resolution | 0.01 ms | Optimizes energy delivery for sensitive materials |

Precision in plastic laser cutting is not merely a specification—it is the foundation of functional reliability. Wuxi Lead Precision Machinery delivers this through systems engineered for the material’s physics, proven in applications where failure is not an option. Contact our engineering team to discuss how our validated processes can ensure your polymer components meet the highest standards of accuracy and quality.

Precision Specs & Tolerances

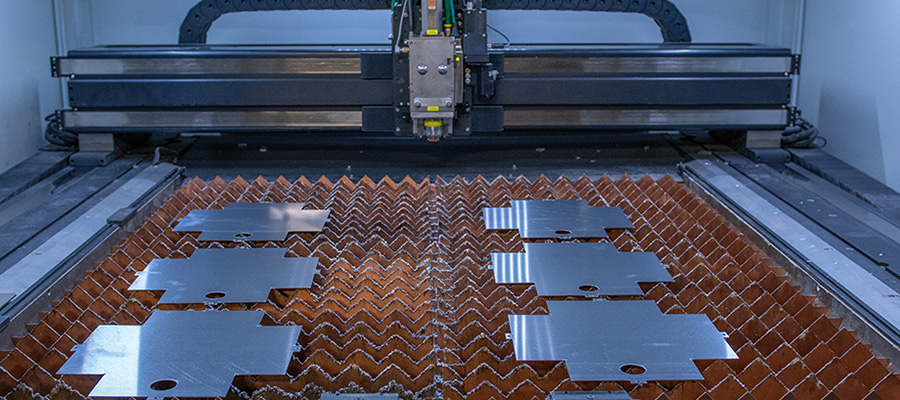

Wuxi Lead Precision Machinery delivers advanced plastic laser cutting solutions tailored for high-precision industrial applications. Our technical capabilities are built around state-of-the-art 5-axis CNC laser systems, enabling complex geometries and intricate detailing on a wide range of engineering-grade thermoplastics. This level of automation ensures consistent beam control, optimal kerf width, and minimal heat-affected zones—critical factors when processing sensitive plastic materials such as polycarbonate, acrylic, ABS, PEEK, and PET.

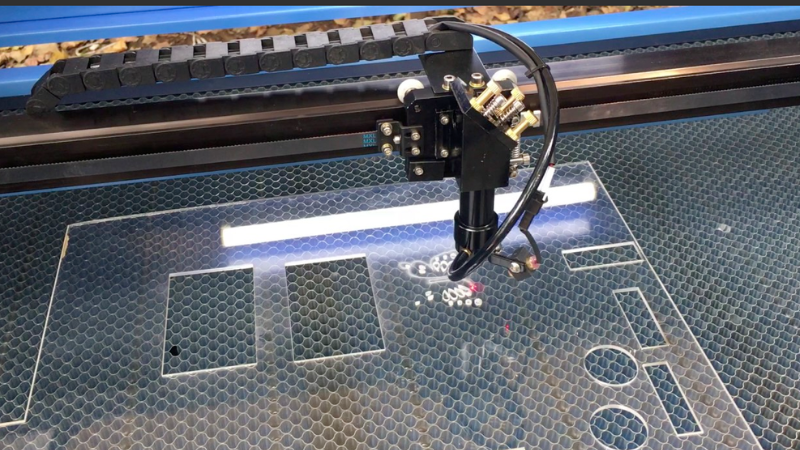

The integration of 5-axis motion control allows for non-planar cutting trajectories, making it possible to machine contoured surfaces and multi-faceted components without re-fixturing. This capability significantly enhances dimensional accuracy and surface finish while reducing cycle times and secondary operations. Our fiber and CO₂ laser platforms are specifically calibrated for plastic substrates, with adjustable pulse frequencies, variable focus optics, and inert assist gas delivery to prevent charring and maintain optical clarity in transparent materials.

All plastic laser cutting operations are supported by a rigorous quality control protocol anchored in CMM (Coordinate Measuring Machine) inspection. Every critical dimension is verified against CAD nominal values, ensuring full compliance with ISO 10360 standards. Our metrology lab operates under controlled environmental conditions to eliminate thermal drift, providing repeatable measurement accuracy down to ±0.005 mm. Data from CMM reports are compiled into comprehensive inspection certificates, available with every production batch.

We support both prototype development and high-volume production runs, with material thickness ranging from 0.5 mm to 25 mm depending on polymer type and structural requirements. Nesting optimization software maximizes material yield, while real-time monitoring systems detect process deviations and trigger corrective actions automatically. Our operators are trained in polymer behavior under thermal load, allowing for precise parameter tuning that preserves mechanical integrity and dimensional stability.

Material compatibility extends beyond standard plastics to include reinforced composites and flame-retardant grades, provided they meet laser-processability criteria. All work is performed in a cleanroom-class environment to prevent surface contamination, particularly important for optical and medical-grade components. With full digital traceability and SPC (Statistical Process Control) reporting, Wuxi Lead ensures every cut meets the highest standards of precision and repeatability.

The following table outlines the key technical specifications and achievable tolerances for our plastic laser cutting services:

| Parameter | Specification |

|---|---|

| Maximum Working Area | 1500 mm × 3000 mm |

| Material Thickness Range | 0.5 mm – 25 mm (varies by plastic type) |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Linear Cutting Tolerance | ±0.05 mm |

| Contour Cutting Tolerance | ±0.1 mm (complex 3D paths) |

| Minimum Feature Size | 0.3 mm (holes/slots) |

| Surface Roughness (Ra) | < 3.2 µm (typical) |

| Edge Perpendicularity | ±0.15° |

| CMM Measurement Uncertainty | ±0.005 mm (at 95% confidence level) |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for industries demanding micron-level precision in plastic fabrication, including medical device manufacturing, aerospace, automation, and high-end electronics.

Material & Finish Options

Material Selection for Precision Metal Laser Cutting

Selecting appropriate materials is critical for achieving optimal results in high-precision laser cutting applications. At Wuxi Lead Precision Machinery, we emphasize compatibility with fiber laser systems and post-processing requirements. While plastic laser cutting falls outside our core sheet metal expertise, this guide addresses metal substrates we routinely process: aluminum, steel, and titanium. Each material presents unique thermal, reflective, and structural properties that directly impact cutting efficiency, edge quality, and downstream finishing.

Aluminum alloys require careful parameter calibration due to high thermal conductivity and reflectivity. Uncoated aluminum can reflect up to 95% of near-infrared laser energy, risking beam back-reflection damage to optics. We recommend using pulsed-mode fiber lasers with wavelengths under 1,070 nm for alloys like 6061-T6 or 5052. Steel, particularly low-carbon varieties (e.g., AISI 1018), cuts efficiently with continuous-wave lasers owing to lower reflectivity and predictable melt dynamics. Stainless steel (304/316) demands higher assist gas purity to prevent chromium oxide buildup on cut edges. Titanium grades (Gr 2, Gr 5) necessitate inert gas shielding (argon/nitrogen) to avoid oxygen-induced embrittlement during cutting, requiring slower speeds but yielding exceptional edge integrity for aerospace applications.

Anodizing is a common post-cut finish for aluminum components but imposes specific pre-cutting considerations. The process thickens the surface oxide layer, enhancing corrosion resistance and paint adhesion. However, anodized parts must be cut before anodizing, as the hard oxide layer (60–250 HV) can deflect laser beams and create uneven edges. Ensure all critical dimensions account for the 5–25 µm anodized layer added post-fabrication. Note that anodizing is incompatible with steel and titanium; these materials require alternative finishes like passivation (stainless steel) or alodine (titanium).

Material performance metrics for laser cutting are summarized below. All values assume 1–6 mm sheet thickness and standard fiber laser parameters (1–6 kW power).

| Material | Key Alloys | Reflectivity (1,070 nm) | Max Thickness (mm) | Assist Gas | Critical Consideration |

|---|---|---|---|---|---|

| Aluminum | 6061, 5052, 7075 | 85–95% | 25 | N₂ | Requires anti-reflective coating on optics |

| Mild Steel | AISI 1018, A36 | 30–40% | 40 | O₂ | Slag control at thickness >15 mm |

| Stainless Steel | 304, 316 | 45–55% | 30 | N₂ | High gas purity prevents dross |

| Titanium | Gr 2, Gr 5 | 60–70% | 20 | Ar | Oxygen exclusion mandatory |

Material choice must align with your end-use environment, tolerances, and finishing workflow. At Wuxi Lead, we conduct material-specific test cuts to validate parameters before production runs. Consult our engineering team to optimize material grade selection for your laser cutting project—ensuring minimal kerf deviation, clean edges, and seamless integration with secondary processes like anodizing. Precision begins with the right substrate.

Manufacturing Process & QC

Design Phase: Precision Engineering for Optimal Laser Cutting Performance

The foundation of a successful plastic laser cutting operation begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we emphasize design-for-manufacturability (DFM) principles from the outset, ensuring that every component geometry, tolerance, and material selection aligns with the capabilities of high-precision CO₂ laser systems. Our engineering team collaborates closely with clients to review CAD models, identifying potential stress points, thermal distortion risks, and edge quality requirements specific to plastics such as acrylic, polycarbonate, ABS, and PET. Material thickness, reflectivity, and thermal conductivity are factored into the laser path optimization to prevent melting, charring, or incomplete cuts. Using advanced simulation software, we validate beam focus, kerf width, and heat-affected zones before any physical processing begins, minimizing rework and ensuring dimensional accuracy within ±0.1 mm.

Prototyping: Validating Design and Process Integrity

Once the design is finalized, a functional prototype is produced under controlled conditions that mirror full-scale production. This phase serves as a critical checkpoint for both form and function. Our prototyping process leverages the same industrial-grade laser cutters used in mass production—ensuring consistency and eliminating process variability. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM) and optical comparators to verify edge smoothness, dimensional stability, and compliance with geometric tolerances. Clients receive detailed inspection reports, including first article inspection (FAI) documentation, enabling rapid feedback and design refinement if necessary. This iterative validation ensures that only fully optimized designs advance to series production, significantly reducing time-to-market and eliminating costly downstream corrections.

Mass Production: Achieving Zero-Defect Output at Scale

With design and prototype approval, production transitions seamlessly into high-volume manufacturing. Wuxi Lead’s automated laser cutting cells operate under strict environmental controls to maintain consistent beam quality and material handling precision. Our zero-defect philosophy is enforced through real-time process monitoring, including laser power calibration, assist gas pressure regulation, and dynamic focus control. Each workpiece is traceable via integrated barcode systems, and statistical process control (SPC) tracks key performance indicators across batches. In-process inspections occur at defined intervals, supported by automated vision systems that detect edge defects or deviations invisible to the naked eye. All operators are certified to ISO 9001 standards, and our quality management system is audited quarterly to ensure compliance with international manufacturing requirements.

Typical Plastic Laser Cutting Specifications

| Parameter | Specification |

|---|---|

| Material Types | Acrylic, Polycarbonate, ABS, PET, PVC |

| Thickness Range | 0.5 mm – 20 mm |

| Laser Type | Sealed CO₂, 40W – 400W |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Edge Quality | Smooth, flame-polished (acrylic) |

| Cutting Tolerance | ±0.1 mm (standard), ±0.05 mm (tight) |

| Lead Time (Prototype) | 3–5 working days |

| Lead Time (Mass Production) | 7–15 working days (based on volume) |

Through disciplined integration of design validation, precision prototyping, and controlled mass production, Wuxi Lead Precision Machinery delivers plastic laser cutting solutions that meet the highest standards of quality, consistency, and reliability in modern sheet metal fabrication.

Why Choose Wuxi Lead Precision

Why Plastic Laser Cutting Demands Specialized Expertise

Standard laser systems often fail with plastics due to thermal distortion, inconsistent edge quality, and material-specific challenges like outgassing or melting. At Wuxi Lead Precision Machinery, we engineer solutions exclusively for demanding polymer applications. Our German-engineered CO2 and fiber laser platforms integrate proprietary thermal management protocols and material-adaptive parameter libraries, ensuring clean cuts in acrylic, polycarbonate, ABS, PTFE, and engineered composites without burrs, charring, or dimensional drift. This precision eliminates costly secondary finishing and scrap—critical for medical devices, aerospace components, and high-end electronics housings.

Engineered for Your Production Reality

We deliver more than machinery; we provide validated process stability. Every system undergoes 72-hour stress testing with your target materials before shipment. Our closed-loop monitoring adjusts pulse frequency and assist gas dynamics in real-time, maintaining ±0.02mm tolerances even on 0.5mm-thin polycarbonate sheets. This reliability stems from 15+ years of refining laser-plastics interaction physics, documented in our ISO 9001-certified production protocols. Partner with us to transform fragile polymer sheets into mission-critical parts with yield rates exceeding 99.2%.

Technical Specifications for Precision Plastic Cutting

| Parameter | Standard Systems | Lead Precision Systems |

|---|---|---|

| Material Thickness Range | 0.1–10 mm | 0.05–15 mm |

| Positional Accuracy | ±0.05 mm | ±0.02 mm |

| Edge Roughness (Ra) | 15–50 µm | < 5 µm |

| Kerf Width Control | ±0.03 mm | ±0.01 mm |

| Key Materials Supported | Acrylic, ABS | Acrylic, PC, PTFE, PEI, PPSU, Composite Laminates |

Your Next Step: Precision Without Compromise

Do not settle for generic laser solutions that compromise your polymer component integrity. Wuxi Lead Precision Machinery provides factory-tested systems with documented performance metrics for your specific material grade and thickness. Our engineering team collaborates with you from feasibility analysis to full production ramp-up, ensuring seamless integration into your existing workflow. Contact us today to receive a customized process validation report for your application. Email your engineering specifications and target materials to [email protected]. Our technical sales engineers will respond within 4 business hours with actionable insights—no generic quotes, only engineered solutions. Partner with the precision leader trusted by Tier-1 aerospace and medical manufacturers across 28 countries. Your path to flawless plastic laser cutting begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.