Technical Contents

Engineering Guide: Plastic Insert Molding

Engineering Insight: The Critical Role of Precision in Plastic Insert Molding

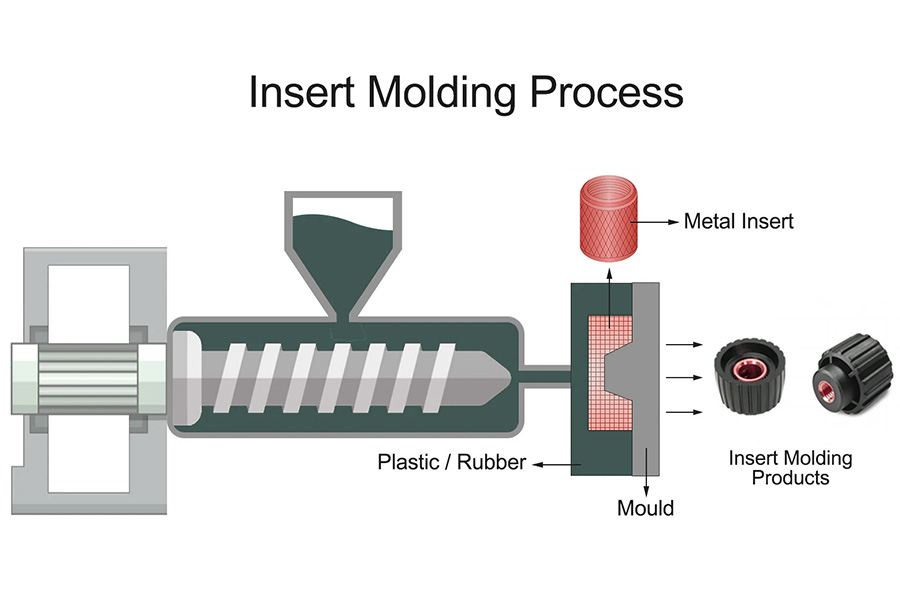

Plastic insert molding is a specialized manufacturing process that combines metal components with thermoplastic materials to produce robust, integrated parts. At Wuxi Lead Precision Machinery, we recognize that the success of this process hinges on one fundamental principle: precision. Whether producing components for high-performance aerospace systems or mission-critical defense equipment, the alignment, placement, and thermal compatibility between the metal insert and the molded plastic must be exact. Even micron-level deviations can compromise structural integrity, sealing performance, or electrical conductivity—factors that are non-negotiable in advanced industrial applications.

Insert molding begins with the precise placement of a pre-formed metal component—often machined to tight tolerances—into a mold cavity. Molten plastic is then injected around the insert, forming a permanent bond upon cooling. The integrity of this bond depends on multiple factors, including insert surface treatment, mold design accuracy, thermal expansion coefficients, and injection parameters. Any inconsistency in these variables can lead to defects such as warping, delamination, or incomplete encapsulation. This is where Wuxi Lead Precision Machinery’s engineering expertise becomes indispensable.

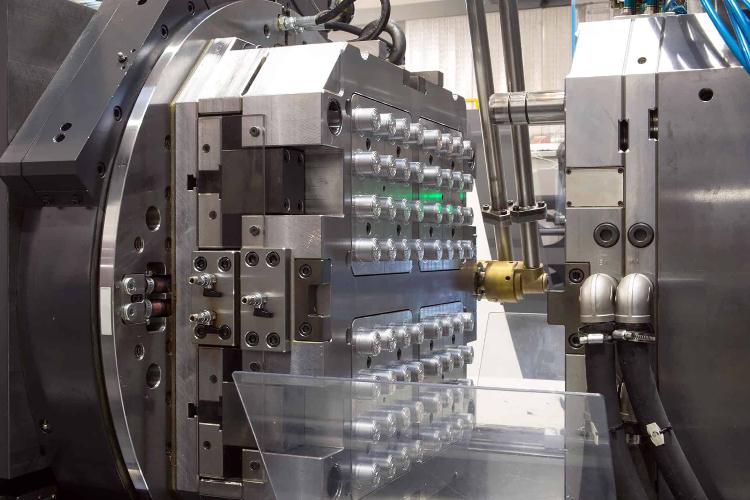

Our facility in Wuxi, China, leverages state-of-the-art CNC machining centers, real-time monitoring systems, and proprietary mold calibration techniques to ensure that every insert is positioned with micron-level accuracy. We maintain full control over both the metal fabrication and molding stages, enabling seamless integration and consistent quality. Our team of engineers applies decades of experience in materials science and process optimization to tailor each project to the client’s performance requirements.

Wuxi Lead Precision Machinery has delivered insert-molded components for applications where failure is not an option. Our work has supported systems used in Olympic-grade timing equipment, where split-second accuracy depends on flawless component performance, and in military-grade communication devices, where durability under extreme conditions is mandatory. These high-stakes applications underscore our commitment to engineering excellence and repeatable precision.

The following table outlines key specifications achievable through our insert molding process:

| Parameter | Typical Capability | High-Precision Capability |

|---|---|---|

| Insert Tolerance | ±0.05 mm | ±0.01 mm |

| Mold Temperature Control | ±2°C | ±0.5°C |

| Material Compatibility | ABS, PBT, Nylon, PPS, LCP | Engineered resins with fillers |

| Insert Bond Strength | 8–12 MPa | Up to 18 MPa (with surface prep) |

| Production Cycle Time | 30–90 seconds | Optimized for high-volume runs |

| Secondary Operations | Deburring, cleaning, inspection | Automated vision inspection |

By integrating precision metal manufacturing with advanced molding technology, Wuxi Lead Precision Machinery delivers insert-molded components that meet the most demanding technical and regulatory standards. Our proven track record in elite industrial sectors reflects our capability to transform complex engineering challenges into reliable, high-performance solutions.

Precision Specs & Tolerances

Precision Metal Components for Advanced Plastic Insert Molding

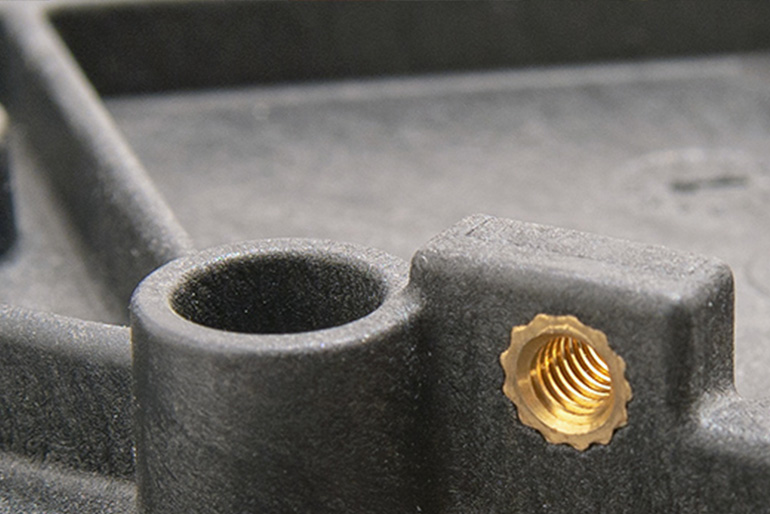

Wuxi Lead Precision Machinery delivers the critical metal foundation required for successful high-integrity plastic insert molding applications. Our core competency lies in manufacturing the precision metal inserts, sleeves, pins, and structural components that become permanently encapsulated within the plastic matrix. The dimensional accuracy, surface finish, and material integrity of these metal elements directly determine the final assembly’s performance, sealing capability, and longevity. We understand that even micron-level deviations in the metal component can propagate into significant functional failures post-molding, leading to costly scrap, assembly issues, or field failures. Our integrated manufacturing and quality systems are engineered specifically to eliminate this risk for demanding industrial clients.

Our technical capabilities are anchored by a modern fleet of multi-tasking 5-axis CNC machining centers. These advanced systems enable the complete machining of complex geometries—internal threads, undercuts, precise radii, and intricate profiles—in a single setup. This eliminates cumulative errors inherent in multi-setup processes, ensuring superior part-to-part consistency and geometric accuracy critical for the insert-to-plastic interface. We routinely machine challenging materials including stainless steels (303, 304, 316), aluminum alloys, brass, and specialty alloys to the tight tolerances demanded by insert molding. The simultaneous 5-axis motion capability is essential for producing the complex, often asymmetrical, shapes required in modern insert designs without manual intervention, significantly enhancing repeatability.

Rigorous quality control is non-negotiable. Every critical dimension on every insert undergoes verification using state-of-the-art Coordinate Measuring Machines (CMM). Our CMM inspection protocols are designed to validate not only linear dimensions but also complex geometric tolerances (GD&T) such as true position, profile, and runout, which are paramount for ensuring proper alignment and bonding within the mold cavity. All CMM equipment is calibrated to international standards with traceability to NIST, and inspection reports are provided as standard documentation. This comprehensive metrology ensures absolute confidence that every metal component shipped meets the exacting specifications required for seamless integration into the plastic molding process.

The following table details the precision capabilities consistently achieved across our production for insert molding components:

| Parameter | Capability (Metric) | Capability (Imperial) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.0002 in | Up to 150 mm / 6 in |

| Angular Tolerances | ±0.05° | ±0.05° | Critical for mating surfaces |

| Positional Tolerance | ±0.01 mm | ±0.0004 in | True Position per GD&T |

| Surface Roughness (Ra) | 0.4 μm | 16 μin | Typical for sealing/bonding surfaces |

| Concentricity/Runout | 0.01 mm | 0.0004 in | Critical for rotating/shaft interfaces |

These capabilities are not theoretical maximums but represent the consistent production standards maintained across Wuxi Lead’s facility. We partner closely with your engineering and molding teams to understand the functional requirements of the final assembly, translating them into precise, achievable manufacturing specifications for the metal insert. This ensures optimal performance, minimizes molding cycle times by guaranteeing perfect fit in the tool, and ultimately delivers reliable, high-value components for your most demanding plastic insert molding applications. Trust in our precision metal manufacturing to be the unseen strength within your molded assemblies.

Material & Finish Options

Material Selection in Plastic Insert Molding: Precision Engineering from Wuxi Lead Precision Machinery

In high-performance plastic insert molding, the choice of metal insert material directly influences mechanical strength, thermal stability, and long-term reliability of the final component. At Wuxi Lead Precision Machinery, we specialize in precision metal manufacturing for insert molding applications, offering expert guidance on material and finish selection to meet the demanding requirements of industries such as automotive, medical devices, and industrial automation.

Aluminum is widely selected for insert molding due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suitable for applications requiring lightweight components with good heat dissipation. Grade 6061-T6 is commonly used for its balanced mechanical properties and weldability, while 7075-T6 offers higher strength for more demanding structural roles. Aluminum’s lower density reduces overall part weight, making it ideal for portable and performance-critical systems.

Steel inserts provide superior strength, wear resistance, and dimensional stability under high stress or elevated temperatures. Alloy steels such as 4140 and 4340 are frequently used when high tensile strength and fatigue resistance are required. Stainless steel grades like 304 and 316 offer additional corrosion resistance, making them suitable for medical and marine environments. While heavier than aluminum, steel ensures long service life in rugged applications where deformation must be minimized.

Titanium stands at the pinnacle of performance materials for insert molding. Known for its exceptional strength-to-density ratio and outstanding corrosion resistance, titanium (Grade 5, Ti-6Al-4V) is used in aerospace, defense, and high-end medical implants. Although more expensive and challenging to machine, titanium delivers unmatched durability in extreme environments, including high-temperature and chemically aggressive conditions.

Surface finishing plays a critical role in enhancing insert performance. Anodizing is the preferred finish for aluminum components, creating a durable, corrosion-resistant oxide layer that improves adhesion with molded plastic. Type II (sulfuric acid) anodizing offers good protection and dyeing capability, while Type III (hardcoat anodizing) delivers superior abrasion resistance for industrial applications. Properly anodized aluminum inserts ensure strong interfacial bonding and prevent galvanic corrosion in assembled systems.

Below is a comparative overview of key material properties and finishing options:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Recommended Finish | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 310–570 | 2.7 | 6061-T6, 7075-T6 | Type II or Type III Anodizing | Automotive sensors, consumer electronics |

| Steel | 655–1000 | 7.8 | 4140, 4340, 304/316 | Zinc plating, passivation | Industrial machinery, hydraulic systems |

| Titanium | 900–1100 | 4.5 | Ti-6Al-4V (Grade 5) | Passivation, grit blasting | Aerospace, medical implants |

Selecting the right material and finish requires a thorough understanding of operational demands. At Wuxi Lead Precision Machinery, we support clients with material testing, prototype validation, and precision CNC manufacturing to ensure optimal performance in every insert molding project.

Manufacturing Process & QC

Plastic Insert Molding: Precision Execution from Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, plastic insert molding transcends basic assembly; it is an engineered integration of metal and polymer demanding absolute precision from initial sketch to final shipment. Our proprietary process eliminates field failures by embedding rigorous quality control within every phase, ensuring inserts perform flawlessly under operational stress. We achieve Zero Defects not through aspiration, but through systematic execution.

The Design Phase begins with collaborative engineering. Our team works directly with your mechanical and materials specifications to optimize the metal insert geometry, polymer selection, and interface design. Critical factors like thermal expansion differentials, stress concentration points, and chemical compatibility are modeled using advanced FEA simulation. This prevents costly mismatches between metal and plastic during thermal cycling or load application. We validate draft angles, wall thickness transitions, and gate locations to ensure complete polymer encapsulation without voids or sink marks, directly addressing the root causes of insert pull-out or seal failure.

Prototyping transitions virtual models into physical validation under production-intent conditions. Utilizing our high-precision CNC machining centers, we produce functional metal inserts meeting tight tolerances before molding. These inserts undergo rigorous first-article inspection against your CAD data. Subsequent molding trials on our dedicated, climate-controlled presses generate test units for comprehensive analysis. We perform destructive bond strength testing, dimensional verification of the overmolded assembly, and accelerated environmental exposure trials. This phase identifies microscopic weaknesses—such as inadequate adhesion or subtle warpage—long before mass production commences, providing actionable data for final process lock-down.

Mass Production leverages the validated parameters within our ISO 13485-certified facility. Every insert is machined on Swiss-type lathes or multi-axis milling centers with real-time SPC monitoring, ensuring dimensional conformity. Molding occurs on servo-electric presses with closed-loop control of melt temperature, injection speed, and pack pressure—critical for consistent polymer flow around intricate inserts. In-line vision systems and automated dimensional checks at defined intervals verify each component against the approved prototype. Statistical process control charts track critical metrics like insert position and overmold thickness, triggering immediate process adjustment if trends approach tolerance limits. This closed-loop manufacturing system guarantees every unit meets the exact specifications validated during prototyping, delivering true Zero Defects performance.

Critical Process Specifications for Zero-Defect Insert Molding

| Parameter | Capability Range | Control Method | Industry Standard Reference |

|---|---|---|---|

| Insert Dimensional Tolerance | ±0.005 mm to ±0.025 mm | CMM + In-Process Gauging | ISO 2768-mK |

| Overmold Bond Strength | 15 MPa to 40 MPa (min) | Destructive Pull Testing | ASTM D638 / ISO 527 |

| Insert Position Accuracy | ±0.05 mm max deviation | In-Line Vision System | Customer Specific Drawings |

| Material Compatibility | Engineering Thermoplastics (PPS, PEEK, Nylon) + Metals (Stainless, Brass, Aluminum) | Material Certificates + Adhesion Testing | UL 746C / ISO 10993-10 |

| Production Cycle Time | 15 sec to 120 sec (typical) | Press Monitoring + SPC Analysis | Customer Agreed Target |

This integrated approach—where design rigor, prototype validation, and controlled mass production converge—ensures your plastic insert molded components deliver guaranteed performance and longevity, eliminating costly field failures and warranty claims. Wuxi Lead Precision Machinery transforms complex integration challenges into reliable, high-value manufacturing solutions.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Plastic Insert Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal manufacturing solutions engineered to meet the evolving demands of modern industrial applications. Our expertise extends into the specialized field of plastic insert molding—a critical process that combines metal components with engineered thermoplastics to create robust, high-performance parts for automotive, medical, electronics, and industrial equipment sectors. When you partner with us, you’re not just sourcing a component manufacturer—you’re aligning with a precision engineering team committed to innovation, quality, and long-term value.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, multi-axis grinders, and advanced injection molding systems, enabling seamless integration of metal inserts into plastic housings with micron-level accuracy. We control every stage of production—from raw material selection and insert fabrication to molding, post-processing, and 100% quality inspection. This vertical integration ensures consistent tolerances, superior bond integrity, and repeatable performance across high-volume production runs.

We understand that insert molding is not a one-size-fits-all process. Each application presents unique challenges in thermal expansion, mechanical load, chemical resistance, and electrical insulation. That’s why our engineering team works closely with clients during the design phase to optimize insert geometry, material compatibility, and mold flow dynamics. Our goal is to eliminate stress points, prevent delamination, and ensure long-term reliability under real-world operating conditions.

Below are key technical capabilities that define our insert molding service:

| Specification | Performance Detail |

|---|---|

| Insert Material Options | Stainless steel, brass, aluminum, tool steel, specialty alloys |

| Plastic Materials | PPS, PEEK, PA6, PA66, PBT, PC, LCP (glass-filled and high-temp grades) |

| Insert Tolerance | Up to ±0.002 mm |

| Molding Tolerance | ±0.05 mm (depending on part size and material) |

| Insert Bond Strength | Up to 3,500 N/cm² (validated via pull-out testing) |

| Production Capacity | 50,000 to 2 million units per month |

| Quality Standards | ISO 9001:2015 certified, full FAI and SPC reporting |

We serve global OEMs and Tier-1 suppliers who demand more than just manufacturing—we deliver engineering collaboration. Whether you’re prototyping a new sensor housing or scaling production for a medical device, our team ensures your insert molded components meet the highest standards of precision and durability.

Contact us today to discuss your next project. Send your design files or inquiries to [email protected] and receive a detailed technical evaluation within 24 hours. Let Wuxi Lead Precision Machinery be your trusted partner in high-end insert molding and custom metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.