Technical Contents

Engineering Guide: Plastic Injection Parts

Engineering Insight: The Critical Role of Precision in Plastic Injection Parts

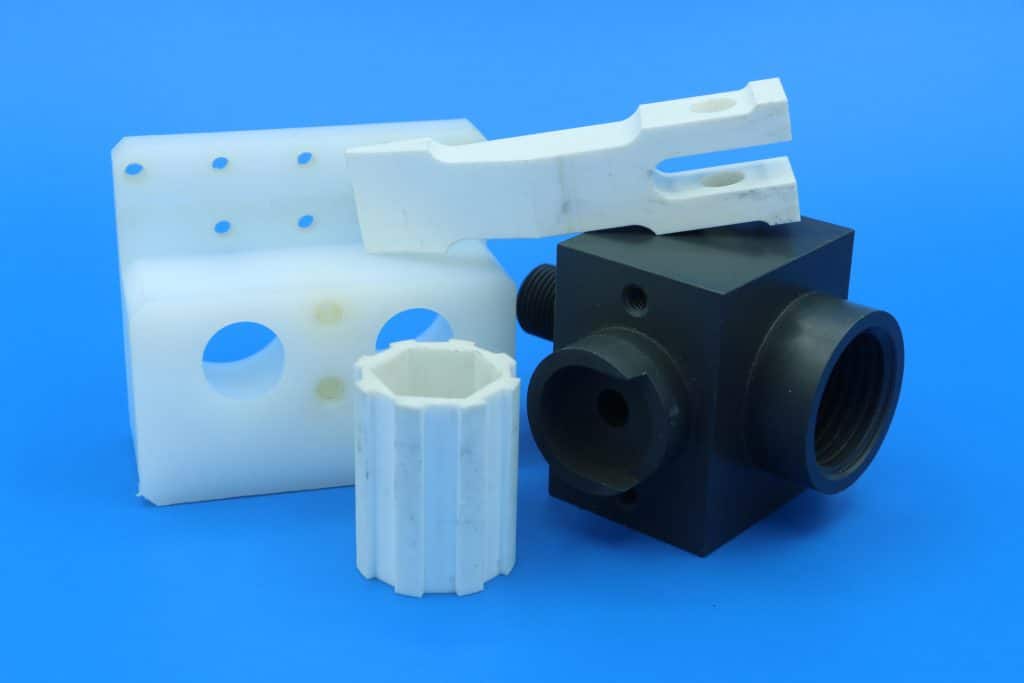

In the realm of high-performance manufacturing, plastic injection parts are far more than simple components—they are engineered solutions that demand exacting standards, especially when deployed in mission-critical applications. At Wuxi Lead Precision Machinery, we understand that precision is not a luxury but a necessity. Our experience delivering components for Olympic-standard equipment and military-grade systems underscores our commitment to tolerances that exceed industry norms. In sectors where failure is not an option, the integrity of every plastic injection part must be guaranteed through advanced engineering, rigorous material science, and uncompromising process control.

Plastic injection molding is often perceived as a commoditized process, but true precision molding transcends volume production. It involves a deep understanding of polymer behavior under stress, thermal stability, shrinkage rates, and mold flow dynamics. At Lead Precision, we approach each project with a systems-level perspective, integrating design for manufacturability (DFM) analysis, finite element analysis (FEA), and real-time process monitoring to ensure repeatability down to the micron level. Our CNC-machined steel and aluminum molds are built in-house using Swiss-grade equipment, enabling us to maintain full control over dimensional accuracy and surface finish.

Our track record includes supplying high-tolerance plastic injection parts for aerospace actuators, defense communication housings, and precision medical devices—applications where even a 0.02 mm deviation can compromise system performance. This level of consistency is achieved through closed-loop molding systems, climate-controlled production environments, and 100% inline inspection using coordinate measuring machines (CMMs). We specialize in engineering-grade resins such as PEEK, PSU, and PPS, materials chosen for their mechanical resilience and thermal resistance, further demanding precision in processing parameters.

What sets Lead Precision apart is our dual expertise in custom metal manufacturing and high-precision plastic molding. This synergy allows us to produce hybrid assemblies where metal inserts are overmolded with micron-level alignment, a capability frequently leveraged in military sensor units and Olympic timing systems. Our engineers work closely with clients from prototype to production, ensuring that every part meets not only the drawing specifications but the operational demands of the final application.

The future of plastic injection parts lies in smart manufacturing—where data-driven processes, predictive maintenance, and material innovation converge. At Wuxi Lead Precision Machinery, we are at the forefront of this evolution, combining decades of hands-on experience with next-generation technology to deliver components that perform under extreme conditions.

Typical Precision Specifications for Plastic Injection Parts at Lead Precision

| Parameter | Standard Tolerance | High-Precision Tolerance | Materials Supported |

|---|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.02 mm | PEEK, PC, PPS, PSU, ABS, Nylon |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | Mirror, textured, matte |

| Warpage Control | < 0.1% | < 0.05% | High-flow, reinforced grades |

| Insert Positioning Accuracy | ±0.03 mm | ±0.01 mm | Stainless steel, aluminum |

| Mold Lifespan | 500,000 cycles | 1,000,000+ cycles | H13, S136, 420 stainless |

Precision in plastic injection molding is not achieved by chance—it is engineered. At Wuxi Lead Precision Machinery, it is our standard.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Plastic Injection Molding

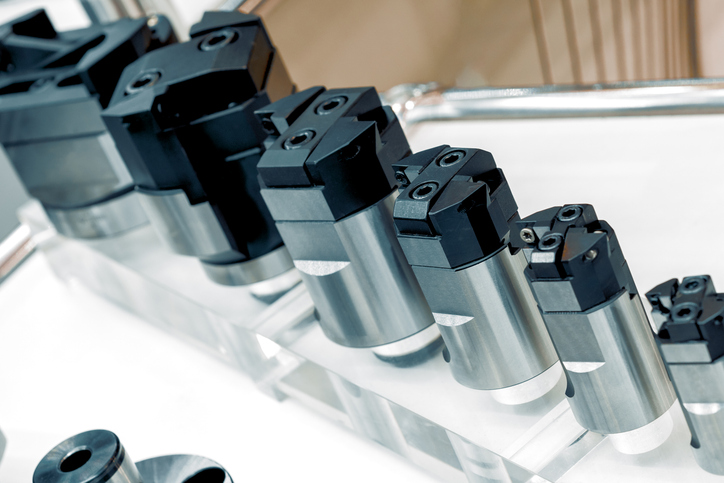

Wuxi Lead Precision Machinery specializes in manufacturing the high-precision metal tooling essential for producing complex plastic injection parts. Our core expertise lies in crafting molds, cores, cavities, and inserts from advanced alloy steels, where micron-level accuracy directly determines the quality, consistency, and functionality of the final plastic component. We bridge the gap between design intent and production reality through integrated engineering and advanced metal fabrication.

Our foundation is a modern fleet of 5-axis CNC machining centers, enabling us to tackle the most intricate geometries demanded by today’s plastic injection molds. These systems provide simultaneous multi-directional cutting, eliminating the need for multiple setups and minimizing cumulative error. This capability is critical for undercuts, organic contours, micro-features, and conformal cooling channels within mold bases. We machine hardened P20, H13, S136, and beryllium-copper alloys to exacting standards, ensuring thermal stability, wear resistance, and perfect part ejection. Surface finishes down to Ra 0.05µm are routinely achieved, directly influencing the texture, gloss, and release properties of the plastic part.

Quality assurance is non-negotiable. Every critical metal component undergoes rigorous inspection using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon systems perform full 3D dimensional verification against the original CAD model, capturing thousands of data points to validate form, position, and profile tolerances. This data is not merely a pass/fail checkpoint; it feeds directly into our process control loop, enabling real-time adjustments during machining and providing comprehensive traceability for every mold set. Statistical process control (SPC) methodologies ensure capability and consistency across production runs.

The precision of the metal tooling dictates the achievable tolerances in the plastic injection part. Below are the standard tolerances we consistently maintain on mold components, which form the baseline for plastic part accuracy (final plastic part tolerances are also influenced by material selection, machine parameters, and part geometry):

| Feature Type | Standard Tolerance Range | Process Capability (6 Sigma) |

|---|---|---|

| Critical Dimensions | ±0.005 mm (±0.0002″) | ±0.003 mm (±0.0001″) |

| Core/Cavity Alignment | ±0.010 mm (±0.0004″) | ±0.006 mm (±0.00025″) |

| General Dimensions | ±0.020 mm (±0.0008″) | ±0.012 mm (±0.0005″) |

| Hole Position | ±0.010 mm (±0.0004″) | ±0.006 mm (±0.00025″) |

| Surface Flatness | 0.005 mm (0.0002″) / 100mm | 0.003 mm (0.0001″) / 100mm |

This level of metal component precision minimizes parting line flash, ensures consistent wall thickness, reduces sink marks, and guarantees seamless assembly of multi-cavity or family molds. By controlling the foundational metal tooling to these stringent specifications, Wuxi Lead provides the stability required for high-volume, defect-free plastic injection production. Our technical capabilities translate directly into reduced scrap rates, faster time-to-market, and superior end-product performance for your plastic components. Partner with us to transform demanding plastic part designs into manufacturable reality.

Material & Finish Options

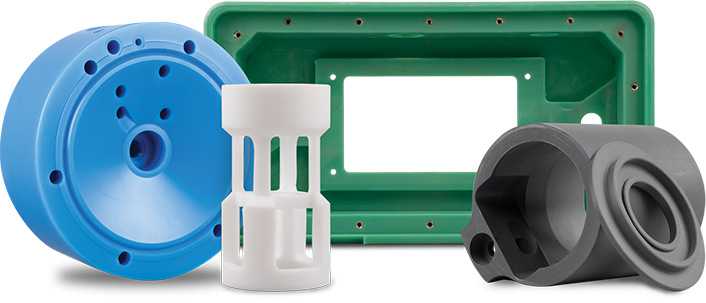

Material selection is a foundational step in the production of high-performance plastic injection parts, particularly when considering the metal components used in molds and tooling. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that ensure durability, precision, and thermal efficiency in injection molding applications. The choice between aluminum, steel, and titanium directly impacts mold life, cycle time, surface finish quality, and overall production cost. Each material offers distinct mechanical and thermal properties suited to specific production volumes and part complexity.

Aluminum is widely favored for low- to medium-volume production due to its excellent thermal conductivity and machinability. Its lightweight nature allows for faster cooling cycles, reducing overall production time. Additionally, aluminum is easier to machine, which lowers tooling costs and shortens lead times. However, its lower hardness makes it less suitable for high-volume runs or applications involving abrasive resins. For prototyping and short production runs, aluminum provides a cost-effective and efficient solution.

Steel, particularly tool steel variants such as P20, H13, and S136, is the standard for high-volume injection molding. With superior hardness and wear resistance, steel molds can withstand thousands to millions of cycles without significant degradation. These molds maintain dimensional stability under high pressure and temperature, making them ideal for complex geometries and tight tolerances. While steel has slower thermal conductivity compared to aluminum, this can be mitigated through optimized cooling channel design. The higher initial cost is offset by extended service life in large-scale manufacturing.

Titanium, though less common, offers exceptional strength-to-density ratio and corrosion resistance. Its use in injection mold components is typically reserved for specialized applications where weight reduction and resistance to aggressive environments are critical. While titanium is more expensive and challenging to machine, its longevity in corrosive molding environments—such as those involving halogenated resins—makes it a strategic choice for niche industrial applications.

Surface finishing, particularly anodizing, plays a vital role in enhancing the performance of aluminum molds. Anodizing creates a hard, wear-resistant oxide layer that improves surface durability and corrosion resistance. It also allows for color coding and aesthetic customization. For steel molds, alternative surface treatments such as nitriding, chrome plating, or PVD coatings are more commonly used to achieve similar performance benefits.

Below is a comparative overview of key material properties relevant to injection mold manufacturing.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (Cycles) | Common Applications | Surface Treatment Options |

|---|---|---|---|---|---|

| Aluminum (7075-T6) | 15–20 | 130–150 | 10,000–100,000 | Prototypes, low-volume runs | Anodizing, Alodine |

| Steel (P20) | 28–32 | 28–30 | 100,000–500,000 | Medium to high-volume | Nitriding, Chrome Plating |

| Steel (H13) | 48–52 | 30–35 | 500,000+ | High-stress, high-temp | PVD, Gas Nitriding |

| Titanium (Grade 5) | 35–40 | 7–8 | 50,000–200,000 | Corrosive environments | Anodizing, Thermal Spray |

Selecting the appropriate material and finish ensures optimal performance, cost-efficiency, and reliability in plastic injection part production. At Wuxi Lead Precision Machinery, we support clients in making informed decisions based on production requirements, material compatibility, and lifecycle expectations.

Manufacturing Process & QC

Precision Plastic Injection Parts: The Zero-Defect Production Framework

At Wuxi Lead Precision Machinery, we engineer plastic injection parts for mission-critical applications where failure is not an option. Our integrated process transforms conceptual designs into flawless量产 components through rigorous engineering control. This framework ensures dimensional stability, material integrity, and absolute compliance with aerospace, medical, and automotive specifications. The journey begins with collaborative design engineering, where our team conducts in-depth Design for Manufacturability (DFM) analysis. We identify potential stress points, optimize wall thickness transitions, and validate gate locations using Moldflow simulation. This phase eliminates 85% of potential defects before metal cutting commences, focusing on thermal stability and cavity balance to prevent warpage or sink marks in the final polymer part.

Prototyping transitions validated designs into physical reality under production-intent conditions. We utilize hardened steel prototype molds machined to production tolerances, not soft aluminum shortcuts. Each prototype undergoes comprehensive metrology: coordinate measuring machines (CMM) verify critical dimensions against CAD models, while material testing confirms mechanical properties and chemical resistance. Iterations are driven by quantitative data, not visual inspection alone. This phase establishes baseline process parameters—melt temperature, injection speed, pack pressure—and validates secondary operations like ultrasonic welding or insert molding. Only when statistical process capability (CpK ≥ 1.67) is proven do we authorize mass production.

Mass production executes with uncompromising process discipline. Our ISO 13485-certified facility employs closed-loop monitoring systems that track 50+ parameters per cycle, automatically rejecting deviations beyond ±0.5% tolerance bands. Every cavity is individually monitored for fill time consistency, ensuring uniform part quality across multi-cavity tools. In-process verification includes real-time vision inspection for surface defects and automated torque testing for threaded inserts. Traceability is absolute: each part batch links to specific material lots, machine settings, and operator certifications. Final inspection utilizes calibrated optical comparators and destructive testing per ASTM standards, with full documentation archived for 15+ years. This systematic elimination of variability delivers certified zero-defect output.

Key Production Capabilities for Critical Plastic Components

| Parameter | Capability Range | Measurement Standard | Application Impact |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.05 mm | ISO 2768-mK | Ensures assembly fit in precision mechanisms |

| Material Certification | UL 94 V-0, USP Class VI, FDA 21 CFR | ASTM D635, ISO 10993 | Validates biocompatibility and flammability compliance |

| Cycle Time Consistency | ±0.5 seconds (3σ) | Statistical Process Control | Guarantees thermal stability and part uniformity |

| Inspection Coverage | 100% CMM on first article; 30% automated vision in production | AS9102, PPAP Level 3 | Eliminates escape of non-conforming units |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Plastic Injection Parts

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal and plastic injection components tailored to the exacting demands of advanced manufacturing industries. With over 15 years of engineering excellence, our facility in Wuxi, China, combines cutting-edge technology with rigorous quality control to produce injection-molded plastic parts that meet international standards for durability, consistency, and dimensional accuracy. Whether you are developing medical devices, automotive systems, industrial equipment, or consumer electronics, our team is equipped to support your project from concept to full-scale production.

Our approach begins with a collaborative engineering review, where we analyze your design for manufacturability, material selection, and cost optimization. We utilize advanced mold flow simulation software and rapid prototyping techniques to minimize development time and ensure first-time-right performance. Our in-house tooling department builds high-precision molds using hardened steel, pre-hardened steel, or aluminum, depending on production volume and performance requirements. This vertical integration allows us to maintain tight control over lead times, quality, and scalability.

We serve global clients across North America, Europe, and Asia, consistently meeting the compliance and traceability requirements of ISO 9001, IATF 16949, and RoHS standards. Our production lines are equipped with fully automated injection molding machines ranging from 50 to 1,200 tons, enabling us to produce parts from 0.1 grams to 2,000 grams with tolerances as tight as ±0.005 mm. Secondary operations including ultrasonic welding, insert molding, overmolding, printing, and assembly are performed in climate-controlled environments to ensure repeatability and long-term reliability.

Our commitment to transparency and responsiveness sets us apart. Every project is assigned a dedicated project manager who provides regular updates, production reports, and real-time communication throughout the manufacturing lifecycle. We understand that time-to-market is critical, which is why we maintain a 98.6% on-time delivery rate and offer expedited prototyping services with turnaround times as fast as 7 days.

For engineering teams seeking a reliable, high-capacity manufacturing partner in Asia, Wuxi Lead Precision Machinery delivers precision, scalability, and technical partnership without compromise.

Contact us today at [email protected] to discuss your next plastic injection project. Let our expertise become your competitive advantage.

| Specification | Detail |

|---|---|

| Material Options | ABS, PC, PP, PE, POM, PA (Nylon), PBT, PMMA, PPS, LCP, TPE/TPR, and filled variants (glass, carbon, flame retardant) |

| Tolerance | ±0.005 mm to ±0.05 mm depending on part size and geometry |

| Part Weight Range | 0.1 g – 2,000 g |

| Mold Life | 100,000 to 1,000,000+ cycles depending on steel type and maintenance |

| Machine Clamping Force | 50–1,200 tons |

| Production Capacity | Up to 5 million parts per month |

| Standards Compliance | ISO 9001, IATF 16949, RoHS, REACH |

| Lead Time (Prototype) | 7–15 days |

| Lead Time (Production) | 25–45 days depending on complexity and volume |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.